Research Article

Research Article

An Evaluation of the Quality of Men’s 100% Cotton Jersey Knit T-Shirts

Jeanne Badgett, Department of Retailing and Tourism Management, Textile Testing Lab, University of Kentucky, USA.

Received Date: July 02, 2019; Published Date: July 09, 2019

Introduction

According to a survey conducted by Cotton Incorporated, consumers have seen a “decline in the quality of apparel, including fading, pilling, losing shape, and shrinking” [1]. Increasing consumer disappointment in apparel quality has coincided with the proliferation and success of fast fashion apparel. Fast fashion is described as “trendy, inexpensive versions of runway styles that shoppers wear for one season, or one occasion and often toss” [2]. Top fast fashion retailers have grown 9.7% since 2010, while traditional apparel retailers have grown only 6.8% in the same time period [3]. These traditional and middle market brands are now being considered plodding and dowdy and must scramble to try to either up their fashionability or lower their prices to try to compete [4]. Hence, in order to stay in business, some apparel companies are adopting the fast fashion business model.

Increased production costs, including the rise of cotton prices, joined with higher transportation costs and wages have resulted in clothing that is more expensive to manufacture [5]. Retailers and brands are faced with finding methods to minimize costs and save margins [6]. Markups can help neutralize the increase in productions costs, however, retailers selling low-cost basic apparel are not able to offset this hike in order to compete at a lower price point [5]. Basic apparel is considered as any item with continued demand, which can be produced in large quantities, season after season, with minimal design changes [7,8]. A significant price increase on a basic item, such as a t-shirt, will cause consumers to complain about the price tag. Therefore, with regard to rising manufacturing costs, shoppers of basic apparel should be prepared for a decline in quality [9].

Apparel price is inherently defined by how a brand needs to position its product relative to where the competition is, but pricing is also heavily dependent on consumer expectations [10]. Consumers are value driven and expect more for what they are prepared to pay [11]. Because the relationship between product pricing, positioning, branding, and perceived quality is complex, it is crucial that an apparel retailer finds the right balance between these criteria in order to remain profitable and satisfy the consumers’ desire for value [12].

It is important to understand the different features in products because consumers are bombarded with a plethora of brands of the same merchandise in varying degrees of quality [13]. Under the vast umbrella of fast fashion retailers and traditional retailers, apparel quality and pricing can be so indiscriminate in nature, it is difficult for consumers to distinguish differences in order to ascertain its value. Therefore, manufacturers, brands, and marketers use quality as a concept to differentiate their product from their competitors [14]. Chowdhary U [13] states, “quality products tend to meet or exceed the consumer expectation”. Consumers want price tags that are commensurate with the quality, yet apparel retailers are not consistently delivering on that desire because product pricing and positioning is not a reliable indicator of quality [15,16,17]. Some apparel companies have resorted to altering production methods to remain profitable [20]. And as a result of rapidly changing productions methods and quality being in the eye of the beholder, gone are the days when the retailer and cost of apparel indicate quality [3,18].

Purpose

The purpose of this research was to evaluate the quality of design, materials, construction, appearance, and performance of men’s 100% cotton jersey knit t-shirts from three retail categories: mass merchant, fast fashion, and better

Research objectives of this study were to:

1. Identify and compare the product specifications of men’s 100% cotton jersey knit t-shirts at three retail categories.

2. Measure and compare the appearance and performance characteristics of men’s 100% cotton jersey knit t-shirts at three retail categories before and after home laundering.

3. Compare the appearance and performance characteristics of men’s 100% cotton jersey knit t-shirts at three retail categories to the ASTM D4154 Standard Specification requirements.

Review of Literature

Fast Fashion is a business model originally developed to make better, more fashionable clothes at affordable prices [19]. It has become the most well-recognized business model in the fashion industry due to its impressive performance in the global market during recent years [20,21].

Increased competition between traditional retailers and fastfashion retailers has contributed to a decrease in the average price of apparel over the past decade [22]. And, consequently, some traditional retailers have adopted production methods similar to fast fashion in order to remain competitive and profitable [23].

Quality is a concept promoted by textile and apparel brands to distinguish their product from the competition and to justify a higher price for similar items [24]. Quality includes understanding how product development and production are integrated so that products satisfy consumer expectations. Differences in product quality can be attributed to differences in components or characteristics of a finished product [25].

Quality products are designed to consistently conform to specifications and standards. Brands consider a quality product to be suitable for their target market in terms of fashion [26], fit, price, performance, materials, etc. [27]. They strive to convey that quality is not just about the price because apparel construction, and materials used, are important factors in determining how well clothing lasts. And although a brand name can sometimes be a telling sign of apparel quality, designers rely on the consumer to be a bit of a “clothing detective”, too, by examining the construction and fabric of a garment [28].

Consumers define quality from many different perspectives: excellence in construction, good performance at a reasonable price, exquisite materials with a good hand, high fashion, good fit and function, attractive or unique detailing, unusual trims, and a recognized brand. But brands realize that when the consumer examines sewn products at the retail level, only a few of the factors which ultimately influence quality can be easily discerned by careful inspection of the garment and its accompanying labels and tags. Consumers’ perception of quality has been shown to be affected by factors that may have no relationship to the actual quality of the item under consideration [29,30]. When consumers cannot see a difference in two similar garments, they often rely on price in deciding which garment is of higher quality. However, price does not necessarily reflect quality, including aesthetic or durability benefits [31,32]. Although quality is a multidimensional construct that cannot be measured by a single attribute, the consumer is the final judge of quality [33].

T-shirts have been a popular fashion staple since the 1950s, with a classic style that is available year-round from almost every apparel manufacturer, sold at all price points and quality levels [34,14]. The adaptability of the t-shirt has made it the “everyday garment for so-called underclasses, but in other social contexts, it can be a high fashion product with a chic designer logo for which an affluent consumer will pay an exorbitant price” [35]. The characteristics of a perfect t-shirt depend on the desires of the consumer. Quality perceptions and preferences “guide the choices for t-shirts that are either fitted or relaxed, thick or thin, long or short, and crisp or worn” [36]. The physical and chemical properties of the materials in a t-shirt fabric will affect how it performs, and ultimately determine if it is suitable for the desired use.

Product positioning describes how a garment relates to others similar in style, the complexity of design, fabric, quality, and price [37]. The classic t-shirt is a good example of how a garment can be designed, constructed, and positioned with various levels of quality. To help the consumer ascertain the value of a t-shirt purchased at a particular price point within a retail category, it is important to identify and understand how quality is specified and measured. And as the t-shirt is a commodity product, its success can be driven and defined in terms of value by lowest price, but ultimately, the consumer may assign value based on the t-shirt’s construction, appearance, and performance [38,39]. When product specifications for a garment are developed, designers must take into account how the design, materials, and construction methods relate in order to produce a garment that will satisfy the consumer [40]. The t-shirts in this research varied in design, materials, construction and these aspects have been compared.

Methodology

The purpose of this research was to evaluate the quality of design, materials, construction, appearance, and performance of men’s 100% cotton jersey knit t-shirts from three retail categories: mass merchant, fast fashion, and better. Retail categories were represented by brand “MM”, brand “FF”, and brand “B” respectively. The ‘mass merchant’ brand (MM) is made by an American company and is sold at a variety of national big-box retailers as well as department stores. The ‘fast fashion’ brand (FF) is made by a publically traded international company with stores in over 60 countries. The ‘better’ brand (B) is a privately-owned company established over 200 years ago with stores in over 70 countries.

A quantitative, quasi-experimental design was utilized to evaluate the t-shirts according to industry standards and procedures. The t-shirt sample set was chosen based on the assumption of a positive relationship between price and quality and the extended connection between price and retail category [41,42]. Although one impetus for this research is derived from the view that the retail category is no longer indicative of quality, Fasanella K [43] states that [based on retail category], “quality levels typically increase or decrease accordingly”.

All of the t-shirts were 100% cotton jersey knit with short sleeves and a crewneck style without pockets or other adornments. White t-shirts and navy t-shirts from each retail category were selected to provide diversified data. The white t-shirts were sold in a pack of multiples, while the navy t-shirts of each brand were sold individually. The t-shirts were marketed to be worn alone or as an underlayer. In all, there were 78 t-shirts: 13 white MM, 13 navy MM, 13 white FF, 13 navy FF, 13 white B, and 13 navy B. The 13 t-shirts within each grouping were identical. This quantity provided enough fabric and enabled observations and measurements to be collected from the t-shirts before laundering, and after the t-shirts were washed and dried one, five, ten, and twenty times. However, due to the large amount of data collected, only the data and results from the navy t-shirts are presented here.

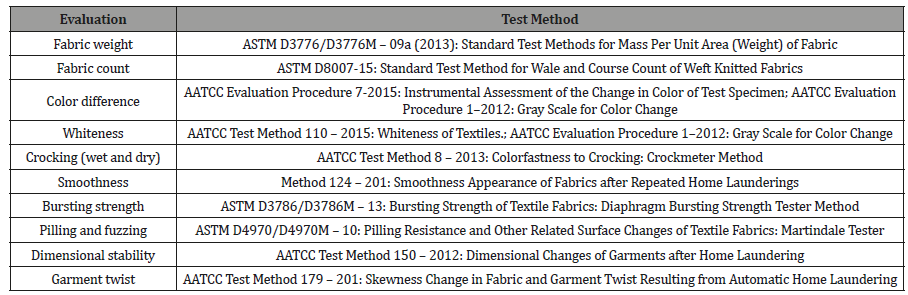

Key variables of the experimental segment included the recommended test methods designated in the ASTM D6321/ D6321M-14: Standard Practice for the Evaluation of Machine Washable T-Shirts. Test methods are listed in Table I and a detailed experimental design is noted in the original thesis. Instruments used for direct testing of the apparel were the specified textile testing equipment located in the University of Kentucky Textile Testing Laboratory. When required, samples and specimens were conditioned for a minimum of four hours in an atmospheric chamber, registering 70° ± 2° Fahrenheit and with a relative humidity of 65% ± 5%, prior to testing and evaluation, as set forth by the ASTM D1776 Standard Practice for Conditioning and Testing Textiles (ASTM, 2016).

Table 1:Test Methods.

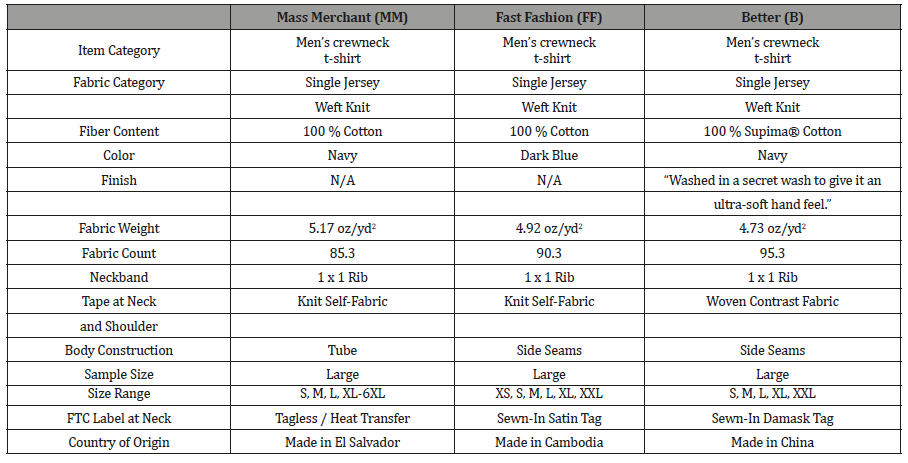

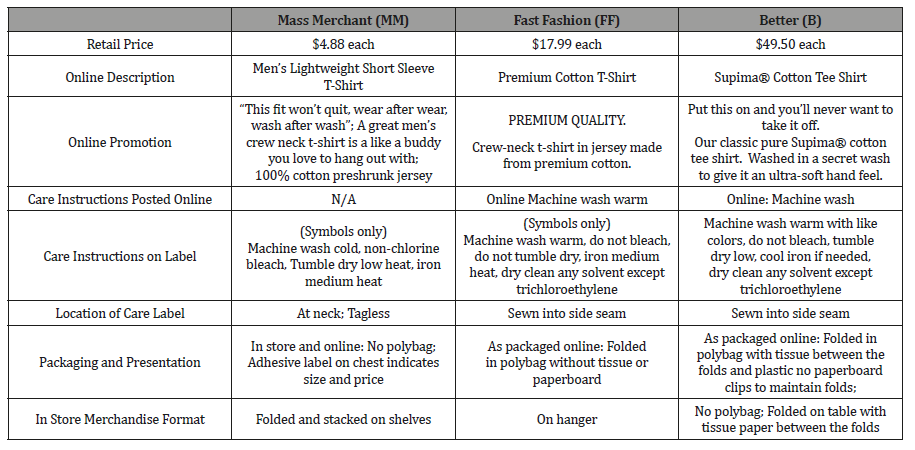

The t-shirt care labels were reviewed to establish washer and dryer cycles that would closely mimic a consumer’s laundry habits. T-shirts were laundered, face-side out, in residential washers and dryers for 20 cycles, with testing before the first cycle, and after the first, fifth, tenth, and twentieth cycles. Two identical top-load, center-agitator washers, and two identical electric tumble dryers were used. The white t-shirts were laundered separately from the navy t-shirts. Both loads were washed in a ‘large level’ of ‘warm’ water (40° C / 104 °F), on a 35-minute ‘Colors/Regular’ cycle, using 40 grams of a national brand of liquid detergent. The t-shirts were dried on a medium, ‘timed dry’ cycle for 60 minutes (Tables 2&3).

Table 2:Style and materials summary, navy T-Shirts.

Table 3:Price, promotion, and packaging details, navy T-Shirts.

The t-shirt design specifications were evaluated by comparing the sizing and fit of the new t-shirts to the technical measurement specifications and tolerances for men’s size large t-shirts, sourced from The Apparel Design and Production Handbook [44]. Materials were evaluated through fabric weight at all five testing intervals and fabric count was collected initially and after the final laundering cycle. The construction specifications were evaluated on the t-shirts before laundering. Differences in stitch types, seam and hem types, and the order of garment assembly were compared.

Changes in appearance were evaluated instrumentally and subjectively. The degree of color change was measured with a spectrophotometer. The color difference (Delta E) of the navy t-shirts before and after washing was calculated using Easy Match QC™ software. Ratings for crocking, subjective color change and smoothness retention were assigned by the researcher, according to the AATCC [45] reference standards. A visual inspection of all stitches, seams, hems, and necklines was conducted initially, and after laundry cycles one, five, ten, and twenty, to assess each shirt’s ability to maintain its original appearance. Durability and performance were assessed by measuring bursting strength, pilling propensity, dimensional stability, and skewness.

Data Analysis

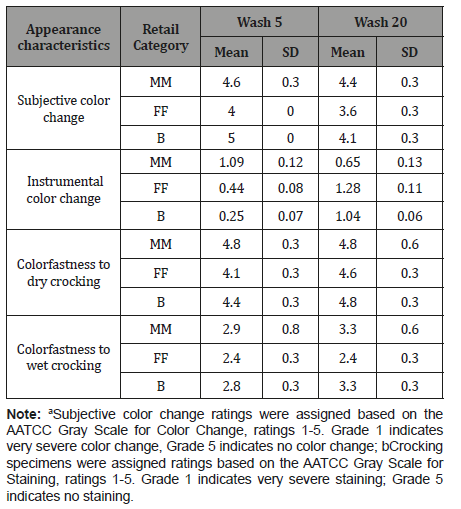

Numerical data was entered into Excel software to calculate descriptive statistics. For data analysis, Excel data was imported to Minitab statistical software to complete a one-way analysis of variance (ANOVA). A 95% confidence interval with a significance level (α) of 0.05 was used to determine the statistical significance. To interpret results, data were grouped by testing interval and retail category. The data was statistically analyzed after washes FIVE and TWENTY to ascertain differences and similarities and to provide rankings according to the garment specifications. Results from select tests were compared to the ASTM D4154–14: Standard Performance Specification for Men’s and Boy’s Knitted and Woven Beachwear and Sports Shirt Fabrics to determine if the t-shirts met voluntary minimum ratings. Numerical data and statistical significance are presented in Tables 4 to 7.

Table 4:Descriptive data for appearance characteristics.

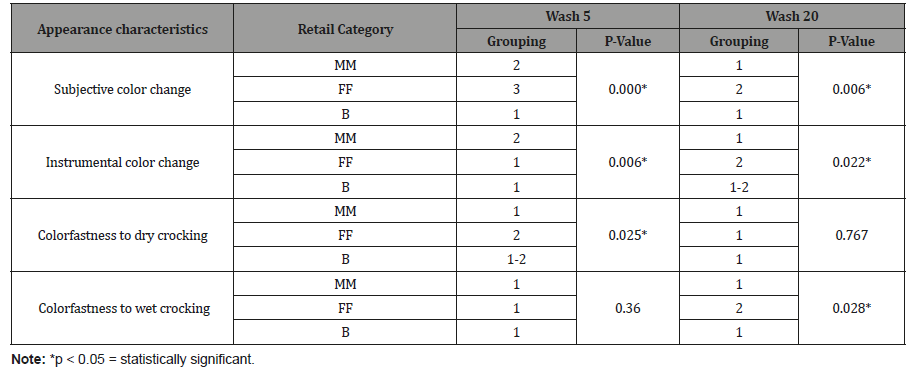

Table 5:Statistical significance of appearance characteristics data.

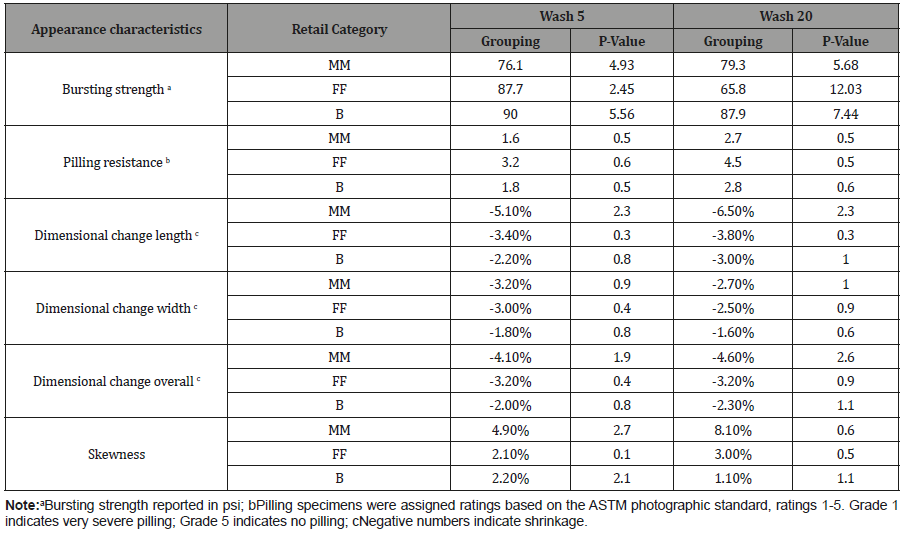

Table 6:Descriptive data for performance characteristics.

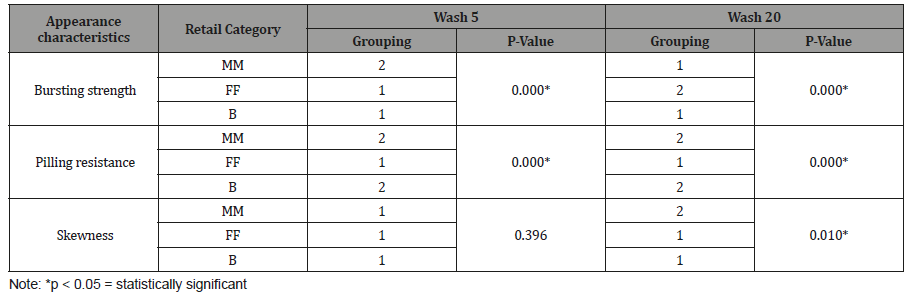

Table 7:Statistical significance of performance characteristics data.

Results and Discussion

The purpose of this research was to evaluate the quality of design, materials, construction, appearance, and performance of men’s 100% cotton jersey knit t-shirts from three retail categories: mass merchant, fast fashion, and better. Observations and measurements were collected from new t-shirts, and after the t-shirts were washed and dried one, five, ten, and twenty times. The t-shirts evaluated in this study were easily differentiated by brand and price; but as a result of this research, the t-shirts were also differentiated by design, materials, construction, appearance, and performance.

Due to the large sample size and data set, the focus of this discussion and statistical analysis is the data collected from the navy t-shirts after washes five and twenty. A product tested after five washes should reflect how it will function after residual and/or temporary finishes are removed. Results after twenty washes are an indication of the expected serviceability of a garment throughout its wear [4,18]. When applicable, results are discussed in comparison to the ASTM D4154–14: Standard Performance Specification for Men’s and Boy’s Knitted and Woven Beachwear and Sports Shirt Fabrics.

Design and materials specifications

A summary of style and materials, as well as price and promotion details, are outlined in Tables II and III. The B t-shirts had three design elements not included on the other t-shirts. They included a self-colored embroidered logo, side vents at the bottom hem, and a contrasting woven fabric used to tape the neck and shoulder seams. Photographs of these additions are included in Appendix B of the original thesis.

Size and fit: All t-shirts exhibited a wide range of size and fit measurements, with many of them outside the tolerances specified in The Apparel Design and Production Handbook: [15]. Three essential measurements that impact fit are body length, chest width, and neckline circumference. For a men’s size large t-shirt, the technical specification of the body length is 30” with a tolerance of ± 3/4”. The MM t-shirts were within that tolerance. The FF and B t-shirts were both shorter than the 29 1/4” tolerance. The technical specification of the chest width is 48” with a tolerance of ± 1/2”. All three categories of t-shirts had chest widths smaller than 48 ±1/2” tolerance. The technical specification of neckline circumference is 20 1/2” with a tolerance of ± 3/8”. The B t-shirts were within the tolerance range. The MM t-shirts were greater than the 20 1/2 ± 3/8” tolerance. The FF t-shirts were smaller than 20 1/2 ± 3/8”.

Fiber content and finish: All of the t-shirts were labeled as having a “100% cotton” fiber content. This was verified with a chemical fiber analysis. However, the B t-shirts identified the variety of cotton used as Supima®, which is considered to be of higher quality because its long, staple fibers produce softer, smoother, and stronger fabrics [27]. The B t-shirts were also described as being finished with a “secret wash to give them an ultra-soft hand feel.”

Fabric weight: Fabric weight is a factor that determines cost and quality, as well as its suitability for the intended use and comfort of the wearer [4,26,42]. However, “there isn’t necessarily a correlation between the thickness of a t-shirt’s fabric and its quality” [34]. All of the fabric weight specimens were within a typical “light top weight t-shirt” range of 4 to 6 oz/yd² (Bubonia, 2014, p. 257). The t-shirts with the lightest fabric weight after five and twenty washes were the B at 4.89 oz/yd² and 4.84 oz/yd² respectively. The t-shirts with the heaviest fabric weight after five and twenty washes were the MM at 5.63 oz/yd² and 5.66 oz/yd² respectively. The final fabric weights of all t-shirts increased after washing and drying as a result of shrinkage.

Fabric count: For all t-shirts, the initial fabric counts ranged from 85.3 to 95.3. After twenty washes, the fabric counts ranged from 89.5 to 98.8. Similar to fabric weight, the increase in fabric count was due to shrinkage. MM t-shirts had the lowest fabric counts and B t-shirts had the highest fabric counts.

Construction specifications

Stitch types: A jersey knit fabric, such as that used in the sample, would have a stitch length of 10 to 12 SPI (Lee & Steen, 2014). The MM t-shirts included stitching that ranged from 9 to 13 SPI. In contrast, the FF t-shirts included stitching that ranged from 12 to 15 SPI and the SPI of the B t-shirts ranged from 12 to 14.

There were four classifications of stitches used in the construction of the t-shirts: 101 (chainstitch), 406 (coverstitch), 504 (3 thread overedge), and 514 (4 thread overedge). The MM t-shirts used a class 504 stitch to close the underarm seam and insert the sleeves. However, both the FF and B t-shirts used a morecostly class 514 stitch for these operations. A class 504 stitch was used to close the shoulder seams on the MM and B t-shirts, and the FF t-shirt shoulder seam was closed with a class 514 stitch. The tapes inside the neck and shoulder seams were attached using a class 101 stitch, and all neckbands were attached using a class 504 stitch. The neckband topstitching, which was visible across the neckband front, utilized a class 406 stitch on the MM and B t-shirts. The FF t-shirts used a class 101 stitch for neckband topstitching. Side seams of the FF and the B t-shirts were closed with a class 514 stitch. The bottom hem on all t-shirts was finished with a class 406 stitch. The B t-shirts included a side vent finished with contrasting tape using a class 301 stitch. A bartack class 101 stitch was used to reinforce the mitered tape. The B t-shirts were the only t-shirts that included an embroidered logo at the left chest (constructed using a class 304 stitch).

Seam and hem types: All three retail categories featured the same seam classifications. The FF and B t-shirts (constructed with side seams) utilized a superimposed seam for the closure. The placket creating the side vent on the B t-shirts included an edge finish and a lapped seam. All t-shirts were constructed with the same edge finish on the sleeve and bottom hems, however, the width of the hems varied between 11/16” (MM category) to 1” (B category). In general, wider hems tend to hang more smoothly and are less prone to roll when the fabric is stretched. Therefore, higher quality garments tend to have wider hems than those on lower quality garments. Because wider hems require more fabric, they can cost more [28].

Assembly: There was a difference in the order in which the underarm seams and sleeve hems were constructed. The sleeve hem of the MM t-shirts was constructed first, followed by the closure of the underarm seam. This can result in a visible underarm seam that extends to the edge of the sleeve, possibly causing discomfort to the wearer. Contrarily, the t-shirts from FF and B closed the underarm seam first, then finished the sleeve hem. This is a desirable, yet more expensive, process to construct a sleeve hem [32].

Appearance specifications

Subjective color change: After five washes, there was a statistically significant difference (p=0.000) between the color change ratings of all retail categories (MM 4.6, FF 4.0, B 5.0). After twenty washes, the FF t-shirts were perceived to have the most color change (3.6) and this was significantly different (p=0.006) than the color change for the MM t-shirts (4.4) and the B t-shirts (4.1). All of the t-shirts met the minimum grade 4 shade change specified by the ASTM D4154 Standard at all intervals, except for the FF t-shirts after wash twenty.

Instrumental color change: After five washes, the navy MM t-shirts (1.09) had a significantly higher (p=0.006) degree of color change (deltaE) compared to the FF (0.44) and B (0.25) t-shirts. However, the degree to which the color of the MM t-shirts changed decreased after wash twenty (0.65). This can be an indication that the color is actually getting darker. This also correlates with the subjective color change data. After wash twenty, the degree of color change of the B t-shirts increased to 1.04 and there was a significant difference (p=0.022) in the degree of color change among the FF (1.28) and MM (0.65) t-shirts.

Colorfastness to crocking: Initial crocking ratings can help predict how a garment will perform during use and care. When dry crocking was performed on the t-shirts before laundering, the ratings were: MM, 4.8; FF, 3.5; and B, 3.5. Initial wet crocking ratings for the MM, FF, and B t-shirts were 1.9, 2.0, and 2.0 respectively. These ratings were not significantly different, yet they did indicate that all of the navy t-shirts have a high propensity for color transfer when wet.

After five washes, the dry crocking ratings for the FF t-shirts (4.1) were significantly different (p=0.025) than the MM t-shirts (4.8), but not the B t-shirts (4.4). After twenty washes, there was less color transfer from all t-shirts, and there was no significant difference (p=0.767) among all three retail categories (MM 4.8, FF 4.6, B 4.8). After washes five and twenty, all t-shirts exceeded the minimum ASTM D4154 dry crocking rating of 4.0.

After five washes there was no significant difference (p=0.360) in the wet crocking ratings of all three retail categories of t-shirts. After twenty washes, the wet crocking ratings improved for MM and B t-shirts (both 3.3) and were significantly different (p=0.028) than the wet crocking rating for the FF t-shirts (2.4). Crocking became less severe by wash twenty because residual dyes have been removed. The ASTM D4154 minimum wet crocking rating of 3.0 was met by the MM t-shirts after washes ten and twenty, and the B t-shirts after wash twenty.

Appearance of stitches/seams/hems/neckline after laundering: After washing, there was puckering and roping in the armscye seams on all of the t-shirts. The narrow hem depths on the MM t-shirts contributed to hem rolling after laundering, detracting from the appearance.

Smoothness appearance: After five washes, the MM t-shirts had the lowest rating (3.3) and the B t-shirts had the highest rating (3.8). After twenty washes, the MM t-shirts continued to have the lowest rating (3.4) and the B t-shirts continued to have the highest rating (4.0). Smoothness appearance improved for all t-shirts and this can be attributed to the relaxation of the fabric yarns and the removal of any sizing finishes during laundering. A minimum smoothness rating of 3.5 is specified by the ASTM D4154 standard. The FF and B t-shirts met this rating after five, ten, and twenty washes. Data for smoothness appearance was not statistically analyzed because of the low number of replications.

Performance specifications

Fabric bursting strength: The initial bursting strengths for the t-shirts, from lowest psi to highest psi, were as follows: MM 79.5, FF 79.6, and B 87.2. After five washes, the bursting strength for MM (76.1 psi) was significantly lower (p=0.000) than both the FF (87.7 psi) and B t-shirts (90.0 psi). After twenty washes, the FF t-shirts exhibited the lowest bursting strength (65.8 psi), which was significantly different (p=0.000) than the MM (79.3 psi) and B t-shirts (87.9 psi). All t-shirts, at all intervals, met the ASTM D4154 minimum bursting strength of 50 psi.

Pilling and fuzzing: After five washes, the difference in the pilling rating of the FF t-shirts (3.2) was statistically significant (p=0.000) compared to the MM (1.6) and B t-shirts (1.8). And after wash twenty, the ratings for the t-shirts improved proportionately due to the removal of short fiber ends on the fabric surface, resulting in a statistically significant difference (p=0.000) between the FF t-shirts (4.5) and the MM (2.7) and B t-shirts (2.8). Although the ASTM D4154 standard does not specify a minimum pilling rating, guidelines published in 2010 set forth by Brand FF Quality Standards & Requirements for knit tops require minimum pilling ratings of 3.0. Using these ratings as a model, only the FF would pass these requirements at all intervals with a range of 3.2 to 4.5.

Dimensional stability: After five and twenty washes, the MM t-shirts exhibited the highest change (shrinkage) in length (5.1% and 6.5%), while the B shirts exhibited the least percent shrinkage (2.2% and 3.0%). Change in t-shirt width was the highest for the MM t-shirts after five and twenty washes (3.2% and 2.7%), while the B shirts continued to exhibit the least percent change in width (1.8% and 1.6%). The results for overall dimensional change, show that, after five and twenty washes, the MM t-shirts exhibited the highest overall shrinkage (4.1% and 4.6%), while the B shirts exhibited the least percent overall shrinkage (2.0% and 2.3%).

A 3% change in either shrinkage or growth is the ASTM D4154 maximum for dimensional change. Only the B t-shirts were within that range for both length and width.

Garment twist: After five washes, there was no statistically significant difference (p=0.245) in the skewness change between the MM (4.9%), FF (2.1%), and B t-shirts (2.2%). However, after twenty washes, there was a statistically significant difference (p=0.010) in the skewness changes between the MM t-shirts (8.1%) compared to the FF (3.0%) and B t-shirts (1.1%). Maximum skewness change is not specified by the ASTM D4154 standard, however, guidelines published by Brand FF recommend skewness to be less than 5%. Using these suggestions as a guide, the MM t-shirts exceeded the maximum rating after wash twenty (8.1%).

Conclusion

The purpose of this research was to evaluate the quality of design, materials, construction, appearance, and performance of men’s 100% cotton jersey knit t-shirts from three retail categories: mass merchant (brand MM), fast fashion (brand FF), and better (brand B), in the colors of white and navy. Due to the large data set, remarks for only the navy t-shirts are concluded below (the complete narrative for both colors of t-shirts is in the original thesis).

Research objectives of this study were to:

Identify and compare the product specifications of men’s 100% cotton jersey knit t-shirts at three retail categories

All of the t-shirts featured the same basic T design. The body of the MM t-shirt was a tube construction. The bodies of the FF and B t-shirts were assembled with side seams. The B t-shirts had other additional design details that added to the production costs, but this communicates the brand image and may lead to the consumer to associate the t-shirts with a higher quality garment [27,29]. All of the t-shirts were 100% cotton. However, the B t-shirts were advertised as made with Supima® variety cotton and treated with a “secret wash” to yield a softer fabric. With the differences in cotton variety and fabric finishes, the B fabric could be perceived by the consumer to be of higher quality. Both the FF and B t-shirts featured labels attached at the neck seam that could add to the production costs. There was no difference in the fabric weights of the t-shirts because they all increased from the initial weight, over the course of washing and drying, and ultimately measured heavier after wash twenty. Overall, the additional design details and materials used in the ‘better’ retail category (brand B) would be associated with a higher production cost and a perceived higher quality.

The ‘fast fashion’ category t-shirt (brand FF) was constructed with the same, more durable, types of stitches as the ‘better’ t-shirt category (brand B). However, the stitches per inch (SPI) were the highest in the FF t-shirt. Stitch length directly relates to the amount of labor required to sew a garment. Garments with a lower SPI can be sewn in a shorter period of time, impacting the cost of manufacturing. A higher SPI is associated with higher quality apparel [4]. Topstitching was used on all three retail categories (MM, FF, and B) of t-shirts. This is also an indicator of better-quality garments [18]. Although the t-shirt in the ‘mass merchant’ category (MM) had topstitching on the neckband, a lower SPI was used in this location. The t-shirt order of assembly was the same in all, except for the order in which the sleeve hems were finished on the MM t-shirt. By finishing the hem before closing the underarm seam, MM used a lower cost production method [32]. The construction of the ‘fast fashion’ t-shirt (FF) was similar to the t-shirt in the ‘better’ category (B).

Measure and compare the appearance and performance characteristics of men’s 100% cotton jersey knit t-shirts at three retail categories before and after home laundering

Before laundering, the appearance of the three categories of t-shirts was similar. From a colorfastness standpoint, however, some transfer of color from the FF t-shirt and B t-shirt onto another dry surface may occur if rubbed against the t-shirt fabric. This could also occur with all three retail categories of t-shirts if rubbed against a fabric that was wet. With regard to performance, a consumer is unlikely to perceive much difference if the t-shirts were worn before laundering. This research tested bursting strength on the t-shirts initially, and all three retail categories had bursting strength psi measurements (avg. 82.1 psi) that were well above the ASTM D4154 minimum requirement of 50 psi. Pilling would be least noticeable on the FF t-shirt if worn before laundering.

After washing, there was puckering and roping of the armscye seams on all of the t-shirts. The narrow hem depths of the MM t-shirt contributed to hem rolling after laundering, detracting from the appearance. A consumer would be most satisfied with the stitching, seaming and hemming of the t-shirts in the fast fashion (FF) and better (B) retail categories.

All t-shirts exhibited color loss after laundering, but the highest degree of color change (Delta E) was in the FF t-shirts. However, the appearance of the MM t-shirts could be viewed as having the least satisfactory appearance. This is because the MM t-shirts had the lowest pilling rating, negatively impacting its appearance as fuzz and pilling contribute to a perceived loss of color. After twenty washes, the FF t-shirts exhibited the least degree of pilling, therefore, the consumer may perceive that the color is brighter. And although this retail category experienced the most color loss, a consumer may be more satisfied with the appearance of the ‘fast fashion’ (FF) t-shirts because of the low amount of fuzz and pilling.

Bursting Strength after laundering changed less than 1% for the MM and B t-shirts. The FF bursting strength decreased by 17%. Regardless, all three retail categories met the minimum requirements for bursting strength. And although the B t-shirts had the highest bursting strength, it was not significantly better than the MM category. A consumer is unlikely to be disappointed with the bursting strength of any of the t-shirts.

The dimensional change was the highest in the MM t-shirts, whereby the percent decrease in length and width would impact the size or fit of the t-shirt. The least percent change in the overall size was exhibited in the B t-shirts. The B t-shirts also exhibited the least percent skewness, followed by the FF t-shirts. This can be attributed to the fact that the B and FF t-shirts were constructed with seamed pieces in the body. The circular knitting process used to achieve the tubular construction of the MM fabric has a propensity to experience distortion [27]. Therefore, with regard to skew, a consumer would be most satisfied with the fit and appearance of the t-shirts in the fast fashion (FF) and better (B) retail categories.

Compare the appearance and performance characteristics of men’s 100% cotton jersey knit t-shirts at three retail categories to the ASTM D4154 Standard Specification requirements

The MM t-shirts met the ASTM D4154 requirements for subjective color change, colorfastness to dry crocking, and bursting strength. The FF t-shirts met the requirements for subjective color change, colorfastness to dry crocking, smoothness appearance, and bursting strength. The B t-shirts met the requirements for subjective color change, colorfastness to dry crocking, smoothness appearance, bursting strength, and dimensional change. None of the t-shirts retail categories met the minimum requirement for wet crocking. The B t-shirts met the most (five out of the six) applicable requirements specified by ASTM D4154 [2]. From a production standpoint, the t-shirts in the ‘better’ retail category (brand B) would be considered a higher quality 100% cotton men’s jersey knit t-shirt [11].

Implications

This assessment of men’s 100% cotton jersey knit t-shirts in three retail categories provided an objective comparison of similar merchandise. The selection of a homogenous sample of a basic apparel item, that was not as dependent on fashions and trends [4], supports this objectivity. Furthermore, the sample set was not limited by end use; a “dilapidated t-shirt can be as much a leisure choice for the wealthy, as a necessity for the poor” [33].

In appearance and performance testing, the B t-shirts had the most results with ratings and measurements that would be considered the ‘best’ or more desirable. But from a statistical standpoint, none of the results for the ‘better’ retail category were significantly (p<0.05) better than the ‘mass merchant’ or the ‘fast fashion’ categories. In conclusion, the decision to purchase a particular t-shirt from these three retail categories depends on consumer

Limitations and Recommendations

This research was restricted by the use of a non-randomized, convenience sample, without control over the manufacturers’ lots from which the materials originated. Additionally, the evaluations and data provide a comparison among only t-shirts in three retail categories, as opposed to other styles of garments or other retail categories [23]. To simplify the experimental design and to replicate the laundry habits of a typical consumer, all of the t-shirts were laundered using the same wash and dry parameters. A 40°C, “warm water” wash was used, followed by a drying cycle on medium heat. However, the care label of the MM t-shirts recommended washing in cold water and the FF t-shirts recommended avoiding the dryer. Had the MM and FF t-shirts been laundered according to the specified care instructions, results may have differed. And although the suitability of the t-shirt’s designs, materials, construction, appearance, and performance was evaluated before and after laundering, the t-shirts were never worn. Speculation about consumer satisfaction was inferred based on results collected in a laboratory setting. The t-shirts may perform differently if exposed to other environmental stressors, including wearer usage, soiling, and individual home laundering methods. In the realm of apparel testing, it is not always known how a textile fabric will be used by consumers, and because of the variability of consumer behavior, even when the end use is known, the actual performance expectations may not be well understood [10].

Recommendations for future research are to include a wear study in order to supplement data acquired through test methods that are limited by a laboratory setting. Also, because exposure to body oils and environmental soils during wear may impact the appearance of the t-shirt fabrics, the addition of a soil ballast to the wash cycle would help simulate this. The ability to obtain samples from different production lots would aid in the randomization of the experimental design. And the degree of accuracy could be improved if more samples were included at each testing interval. Other recommendations are to introduce variables in the laundering conditions. Finally, with the increasing popularity of the slow fashion movement, which focuses on quality-based instead of time-based fashions [45], a study comparing t-shirts from this quality-based production method to the MM, FF, B sample would be informative.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Salfino C (2012a) The quality conundrum Quality conundrum (2012) Cotton Incorporated Supply Chain: Insights.

- Holmes E (2014) Fashion brands’ message for fall shoppers: Buy less, spend more. The Wall Street Journal.

- (2015) Fast fashion garners fast growth.

- Siegle L (2011) To die for: Is fashion wearing out the world? London: Fourth Estate.

- Smith R (2014) Finding the perfect t-shirt: Why is something so simple so hard to get right? The Wall Street Journal.

- ASTM (2016) Annual book of ASTM standards (Vols. 7.01-7.02). West Conshohocken, PA: American Society for Testing and Materials.

- Johnson MJ, Moore EC (2001) Apparel product development (2nd edn) New Jersey: Prentice Hall, USA.

- Keiser SJ, Garner MB (2012) Beyond design: The synergy of apparel product development (3rd edn), New York: Fairchild Books, USA.

- Kiplinger K (2010) Fashionistas take a hit in the wallet. Kiplinger’s Personal Finance 64(10): 1-15.

- Carroll M (2012) How fashion brands set prices.

- Swinker ME, Hines JD (2006) Understanding consumers’ perception of clothing quality: a multidimensional approach. International Journal of Consumer Studies 30(2): 218-223.

- Joung HM (2014) Fast-fashion consumers’ post-purchase behaviours. International Journal of Retail & Distribution Management 42(8): 688- 697.

- Chowdhary U (2002) Does price reflect emotional, structural or performance quality? International Journal of Consumer Sciences 26(2): 128-133.

- Glock RE, Kunz GI (2005) Apparel manufacturing: Sewn product analysis (4th edn). New Jersey: Pearson, USA.

- ASTM (2016) Annual book of ASTM standards (Vols. 7.01-7.02). West Conshohocken, PA: American Society for Testing and Materials.

- Halzack S (2016) Why are sales suffering at so many women’s stores? They made bad clothes. The Washington Post.

- Walters G (2014) Why men’s shirts today fall apart after 30 washes.

- (2015) Fast fashion garners fast growth.

- Brown P, Rice J (2001) Ready-to-wear apparel analysis (3rd edn). Upper Saddle River, NJ: Prentice Hall, USA.

- Bain M (2016). Bigger Faster Cheaper: One chart shows how fast fashion is reshaping the global apparel industry.

- Halzack S (2016) Why are sales suffering at so many women’s stores? They made bad clothes. The Washington Post.

- Cline EL (2012) Overdressed: The shockingly high cost of cheap fashion. New York, NY: Penguin, USA.

- (2014) Decline of quality clothes: This is frugal finery.

- Romeo L (2009) Consumer evaluation of apparel quality (master’s thesis).

- Joung HM (2014) Fast-fashion consumers’ post-purchase behaviours. International Journal of Retail & Distribution Management 42(8): 688- 697.

- Kendall GT (2009) Fashion brand merchandising. New York: Fairchild Books, USA.

- Collier B, Epps H (1999) Textile testing and analysis. Upper Saddle River, NJ: Prentice Hall, USA.

- O’Donnell J, Kutz E (2008) Cheap clothes make for a bad long-term investment. USA Today.

- DeKlerk HM, LuBe S (2008) Female consumers’ evaluation of apparel quality: Exploring the importance of aesthetics. Journal of Fashion Marketing and Management 12(1): 36-50.

- Salfino C (2012a) The quality conundrum Quality conundrum (2012) Cotton Incorporated Supply Chain: Insights.

- Keiser SJ, Garner MB (2012) Beyond design: The synergy of apparel product development (3rd edn), New York: Fairchild Books, USA.

- Stamper AA, Sharp SH, Donnell LB (1991) Evaluating apparel quality (2nd edn) New York: Fairchild, USA.

- Mehta PV (1992) An introduction to quality control for the apparel industry. New York: ASQC Quality Press.

- Centeno A (2013) A man’s guide to undershirts: History, styles, and which to wear.

- Maynard M (2004) Dress and globalization. New York, NY: Manchester United Press, UK.

- Smith R (2014) Finding the perfect t-shirt: Why is something so simple so hard to get right? The Wall Street Journal.

- Bubonia J (2014) Apparel quality: A guide to evaluating sewn products. New York, NY: Bloomsbury Inc, USA.

- D’Arienzo B (2016) Reshoring success stories: What’s branding got to do with it?

- Gross M (1987) Consumer Saturday: Confusing clothing categories. The New York Times.

- Lee J, Steen C (2014) Technical sourcebook for designers (2nd edn) New York: Fairchild Books, USA.

- Glock RE, Kunz GI (2005) Apparel manufacturing: Sewn product analysis (4th edn). New Jersey: Pearson, USA.

- Norum PS (2003) A comparison of apparel garment prices by national, retail, and private labels. Clothing and Textiles Research Journal 21(3): 142-148.

- Fasanella K (2009) Apparel price point categories.

- Fashiondex (2001) The apparel design and production handbook [Technical Reference]. New York, NY: The Fashiondex, Inc, USA.

- AATCC (2016) AATCC technical manual (Vol. 91) Research Triangle Park, NC: American Association of Textile Chemists and Colorists.

-

Elizabeth Easter, Jeanne Badgett. An Evaluation of the Quality of Men’s 100% Cotton Jersey Knit T-Shirts. J Textile Sci & Fashion Tech. 3(2): 2019. JTSFT.MS.ID.000557.

-

Cotton Jersey, Knit T- shirts, Apparel, Fading, Pilling, Shrinking, Fashion retailers, Clothing, Consumers, Branding

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.