Research Article

Research Article

Chemical and Microbiological Evaluation of Dried Tomato slices for Nigerian System

Adegbola Dauda*, Olufunmilola Abiodun, Tari Salami and Olaide Akintayo

Department of Home Economics and Food Science, University of Ilorin, Nigeria

Adegbola Dauda, Department of Home Economics and Food Science, University of Ilorin, Nigeria.

Received Date: April 24, 2019; Published Date: May 16, 2019

Abstract

Effect of two simple drying methods (sun drying and oven drying at 40 °C, 50 °C and 60 °C) on the quality of tomato slices were evaluated. Fresh tomato sample served as the control. Firm and fresh ripe tomatoes were washed and sliced to a uniform thickness of 7mm. 200g each of the sample was dried for12 hours and the moisture loss was monitored at 2-hour interval. The fresh and dried tomato slices were evaluated for changes in moisture content, lycopene, beta-carotene, ascorbic acid, as well as total bacterial and fungi counts.

The moisture content was significantly (at p<0.05) reduced after drying from 88.09% (for fresh samples) to 16.87%. The contents of ascorbic acid in the control sample significantly (at p<0.05) reduced from 17.78mg/100mg (for fresh) to 10.23mg/100mg in the sun-dried samples (lowest value). There was considerable increase in the beta-carotene content from 1.16±0.22% in the control sample to 1.91±0.11%, 1.96±0.22%, 1.78±0.11% and 1.45±0.19% in samples dried at 40 °C, 50 °C, 60 °C and sun-dried samples respectively. Lycopene content also increased with drying. Beta-carotene and lycopene were best retained in samples dried at 50 °C. Tomato slices dried in the oven had lower microbial load compared with sun-dried samples. Microbial load reduced with increase in oven temperature with sun-dried samples having the highest microbial load.

Keywords: Drying; Tomatoes; Shelf life; Chemical components; Microbial load

Introduction

Tomato (Lycopersicon esculentum) is regarded as one of the most important vegetable crops grown all over the world and Nigeria in particular, after onions and pepper [1]. In Nigeria, tomato accounts for about 18% of the average daily consumption of vegetables [2]. Tomatoes are a good source of vitamin C and vitamin A equivalents (in the form of β-carotene) and provide some vitamin E, folic acid, potassium and other trace elements. One of the most well-known tomatoes eating benefits is its lycopene content. Lycopene is a vital anti-oxidant that helps in the fight against cancerous cell formation as well as other kinds of health complications and diseases. Diets that include tomato have been linked with reduced risk of obesity and some neurological diseases including Alzheimer’s disease.

Nigeria is ranked the second largest producer of tomato in Africa and 13th in the world [3]. Due to lack of post-harvest enterprise and poor post-harvest storage plans, Nigeria is unable to meet its domestic demands for tomatoes even though it ranks 13th on the world tomato production hierarchy. The high moisture content of tomato makes their handling, transportation and marketing a problem especially in the tropics [4]. Tomatoes deteriorate rapidly after harvest, requiring preservation and/or processing in other to extend its shelf life.

Drying tomatoes is one of the easiest known preservation methods. The amount of time it takes to dry tomatoes depends on the tomato variety, the air’s humidity during the drying process, the thickness of the tomato slices or pieces, and the efficiency of the dehydrator or oven. Traditionally, drying has been used as a method of preserving foodstuffs in Nigeria and other developing countries [5]. Drying basically removes moisture from food and this inhibits the growth of bacteria and fungi. Moreover, it slows down the enzyme action without deactivating them. These factors ensure that food does not spoil easily and hence, makes drying an effective food preservation technique.

Since tomato is seasonal, preservation is important to minimize wastage and spoilage during the tomato producing season and to ensure that maximum nutritional contents of the fruits are retained. The success of such effort would lead to the development of a suitable and usable technology profile that would ensure the optimization of the production of good quality dried tomato fruits at small and medium scale levels. This study, therefore, intends to determine the effect of sun drying and oven drying (at some selected temperatures) on the chemical and microbiological properties of fresh tomatoes, with a view to reducing wastages and increasing the income generation of rural farmers.

Raw beetroot is 89% water, 11% carbohydrates, 3% protein, and less than 2% fat. In every 200-gram amount providing 86 calories, raw beetroot is a rich source of folate and a moderate source of manganese, with other nutrients having insignificant content. Beetroot based ORS can be prepared by cooking it with added salt combined with ORS.

Materials and Methods

Procurement of tomatoes

Matured fresh tomato fruits devoid of any form of known injury were obtained from “Ipata” market in Ilorin, Kwara State and were transported in a clean polythene bag to the microbiological laboratory of the Department of Home Economics and Food Science, University of Ilorin, Ilorin, Kwara State, Nigeria.

Samples preparation

The tomatoes were washed with clean and portable tap water. Prior to drying, the individual tomatoes were cut into slices of 7mm thickness. The tomato slices were placed on the drying tray and dried in an oven operated at temperatures of 40, 50 and 60 °C. Reduction in weight and moisture content were monitored at 2-hour intervals until the equilibrium moisture content was achieved. Some tomato slices were also sun dried. Sun drying was done between 10.00 hours and 16.00 hours for two days. Sun drying was operated with the sliced samples placed on a clean drying tray and placed on a raised platform to eliminate or drastically reduced the rate of contamination.

Chemical analysis

Dried tomato slices were analyzed for moisture, ascorbic acid, beta-carotene and lycopene. Moisture and ascorbic acid were determined according to [6].

Beta-Carotene and lycopene analyses

Beta-carotene and lycopene were determined from the dried methanolic extract according to [7]. 100mg of extract was mixed with 10ml of acetone-hexane mixture (4:6) for 1 minute and filtered. The absorbance was read in a spectrophotometer at three different wavelengths (453,505&663nm). The β-carotene and lycopene content were calculated by:

β-Carotene (mg/100 ml) = 0.216×A663 - 0.304xA505 + 0.452xA453.

Lycopene (mg/100 ml) = -0.0458xA663 + 0.372xA505 - 0.0806xA453.

Microbiological analysis

The samples were macerated and 1g each of the sample was mixed with 9 ml of sterilized peptone water to release bacterial and fungi cells. Two different types of agar culture media were used to culture the released bacteria and fungi cells. They were nutrient agar (NA) and potato dextrose agar (PDA). The former was used to culture bacteria, while the later was used to culture fungi infections. The culture media, for each thickness, was serially diluted to three population densities (10-1, 10-2 and 10-3CFU/g) in sterilized peptone water. Thereafter, 0.1ml of each of the dilution was surface plated in duplicate. For bacteria and fungi count, 10-3was plated. The inoculated plates for bacteria were incubated for 48 hours, while that for fungi were incubated for 72 hours [8]. At the end of the incubation period, the colonies were counted for both samples using laser colony counter.

Statistical analysis

Data obtained were analyzed statistically using [9] and where significant differences exist, the Duncan Multiple range test was employed to separate the means.

Results and Discussion

Moisture content

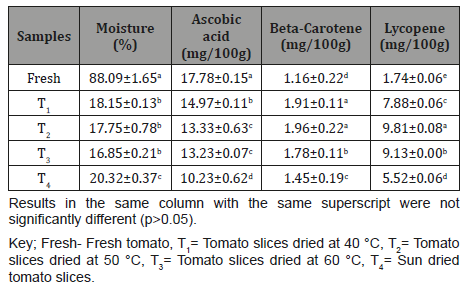

(Table 1) shows the moisture content of the fresh and dried tomato slices. The result of the proximate analysis showed that, there was significant differences (at p< 0.05) in the moisture content of the samples (fresh and dried). However, there was no significant difference between samples T1, T2 and T3 (T1= Tomato slices dried at 40 °C, T2= Tomato slices dried at 50 °C, T3= Tomato slices dried at 60 °C, and T4= Sun dried tomato slices). The moisture content of fresh tomato fruit was 88.09±1.65%, while the moisture content of dried tomato slices ranged from 16.85±0.37 to 20.32±0.13% as expected. Sample T3 dried faster and had a lower moisture content (16.85±0.21%) compared to samples T1 (18.15±0.13%), T2 (17.75±0.78%) and T4 (20.32±0.37%). This may likely be due to the increased temperature. These results show that the moisture content of dried tomato slices is below the maximum limit of 25%.

Table 1: Chemical Composition of Fresh and Dried Tomato Slices.

Drying involves the application of heat/or other means to remove water vapour [10], and drying in this case, sun drying, slightly reduces the quality of the colour and vitamin content [11]. Drying method was adopted putting into consideration the financial capability of majority of people in this country (third world and developing) and to design for the farmers, a very simple method of preserving their tomato glut and increasing their income generation. Their low per capital income made them adopt little/ no or poor preservative methods [12-14]. The need to drastically reduce the huge losses being recorded in tomato production in the country in order to make all round availability of the tomatoes and more income to the producers was of great importance to us. Some researchers, [15] had looked at sundried tomatoes samples that were kept in olive oil.

For the records, drying method is one of the numerous methods used in curbing losses and [16] reported that about 20% losses are being recorded in tomato harvested annually in Nigeria due to poor storage and transportation or through poor handling and packaging. Drying would help reduce the weight of the produce, make handling easier and help increase the shelf life of the produce even more in this part of the world, where the ambient temperature is very high and per capital income, very low.

According to [17], ascorbic acid content of tomatoes is about 16.9mg/100g, and for the ascorbic acid content of the fresh tomato used for the research, it was 17.78±0.15, while that of the dried tomato samples ranged from 10.23±0.62 to 14.97±0.11. The values recorded were like that reported by [18] (9.11 to 14.76 mg/100g). The two drying methods (sun and oven) reduced the ascorbic acid content of the tomatoes, which was in line with the report of [19]. Also, [20] reported a decrease in ascorbic acid content at different drying conditions. From (Table 1), it could be observed that the oven dried samples had higher ascorbic acid values when compared with sun dried samples. It could be observed that there was a continuous decrease in the value of ascorbic acid as the drying time and the temperature increased (for oven and sun drying). Hence, the higher drying time and temperature result in the lower value of ascorbic acid in tomato. This may be since ascorbic acid content of food is destroyed by exposure to heat [5]. The ascorbic acid content of fresh and dried tomato slices was significantly different at p<0.05.

The beta-carotene content of fresh and dried tomato slices is also reported in (Table 1). The beta-carotene of fresh sample was 1.16±0.22 and those of samples T2 to T4 ranged between 1.45±0.19 and 1.96±0.22. Beta-carotene was better retained in sample T2. The increase in carotene could be due to concentration of pigment in dried samples after a considerable amount of moisture has been removed [21]. Bioavailability of carotenes can also be enhanced by thermal treatment [22]. The β-carotene content of fresh tomatoes significantly increased (at p< 0.05) from 1.16±0.22 to 1.91±0.11 (T1), 1.96±0.22 (T2), 1.78±0.11 (T3) and 1.45±0.19 (T4) when dried in the oven at 40°C, 50°C and 60°C and when sun dried. The value of beta-carotene obtained after sun drying was lower than the value (5.2mg/100g) reported by [26].

Lycopene is a phytonutrient and an antioxidant, and this pigment is responsible for the characteristic deep red colour of ripe tomatoes and their products [23]. (Table 1) shows the lycopene content (in mg/100g) of dried tomato slices which ranged from 5.52±0.06 to 9.81±0.08 and that of fresh sample was 1.74±0.06. Lycopene content significantly (at p< 0.05) increased with increase in temperature and decrease in the moisture content (i.e in concentration). Sample T2 had significantly greater lycopene content than the control sample and samples T1, T3, and T4 respectively. The increase in lycopene during drying confirms the findings of [24], who reported that thermal treatment could increase the release of phytochemicals from the matrix of the tomato, as well as [25] who reported increase in lycopene of hot air-dried tomato. The increase in lycopene content in all dried samples could be due to break down of cell walls by thermal process, which weakens the bonding matrix between lycopene and tissue matrix and hence, make lycopene more accessible [26].

Comparing the oven dried tomato slices, samples dried at 50 °C had the highest lycopene value (9.81±0.08) followed by that dried at 60 °C (9.13±0.00) and at 40 °C (7.88±0.06). Sun dried tomato slices had lycopene content lower than oven dried samples (5.52±0.06), but higher than the control (1.74±0.06), the fresh sample, which could be attributed to its high moisture content. The lycopene content of sun-dried tomato slices was higher than the value (1.58mg/100g) obtained by [27] (Table 1).

Microbiological analysis

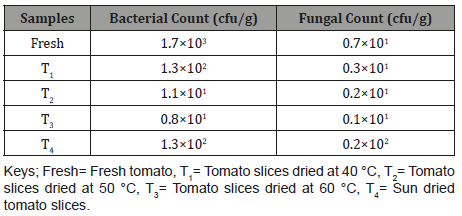

Microbiological quality is a common criterion used to determine the acceptability and shelf life of dehydrated plant-based products. Some microorganisms are destroyed in the process of drying, though the process is not lethal enough for all microbes. Microbial count of the dehydrated foods depends on handling quality of utensils used during the processing period [28]. Fresh and dried tomato slices had both bacteria and fungi when isolated on both nutrient agar and potato dextrose agar. The microorganisms reduced with drying temperatures and conditions as shown in (Table 2). From the results, the viable bacterial count ranged from 0.8×101 to 1.3×102 cfu/g with fresh tomato slices having the highest value (1.7×103cfu/g). Samples T4 (1.3×102cfu/g), T1 (1.3×102cfu/g) and T2 (1.1×101) respectively. The least was obtained from sample T3 (0.8×101cfu/g). The differences in the observed values may be attributed to the drying time, the characteristics of the drying environment, intensity of temperature [5]. Low temperature and long drying time may favoured the growth of bacterial and fungi [5] and could be responsible for the results obtained in this research work.

Table 2: Microbial Evaluation of Fresh and Dried Tomato Slices.

Fungal growths were generally lower than bacterial growths and this may be since bacteria are able to withstand the temperatures at which the samples were dried. The total bacterial and fungal count of samples were within the accepted range by [29], where values of 105 for bacteria and 103-104 for fungi are stipulated (Table 2).

Conclusion

From this study, it could be concluded that oven dried tomato slices gave better results in terms of all the parameters studied, compared to sun dried samples. Tomato slices dried in the oven can be preserved longer than sun dried sample due to lower moisture content and microbial load. Lycopene and beta-carotene contents of the tomato slices increased significantly after drying with samples dried at 50 °C having the highest values. Ascorbic acid concentration was highly diminished among all the samples dried. We could also say that sun drying and oven drying can be adopted by these low-income tomato farmers to preserve their numerous tomato output and equally increase their income generation.

Further studies are needed to determine the optimum storage conditions, suitable packaging materials and yield of dried tomato slices. Also, subsequent studies should include sensory evaluation to determine consumers’ preference.

However, l will recommend the use of oven drying at 50 °C and sun drying for these numerous peasant farmers in Nigeria and even in other developing countries in order to have their bumper tomato harvests preserved and equally increase their income with these simple technologies.

Conflict of Interest

No conflict of interest.

Acknowledgment

None.

References

- Waitrose (2016). Food glossary-Tomato products.

- Ibitoye DO, Akin Idowu PE, Ademoyegun OT (2009) Agronomic and lycopene evaluation in tomato (Lycopersiconlycopersicum Mill.) as a function of genotype. World Journal of Agricultural Science 5(5): 892- 895.

- Brushlyanova B, Petrova T, Penov N, Karabadzhov O, Katsharova S (2013) Drying kinetics of different fruit pomaces in a heat pump dryer. Bulgarian Journal of Agricultural Sciences 19(4): 780-782.

- Anyaogu DC (2013) The production of yam flour. Published project. Caritas University Amorji-Nike, Emene, Enugu State, Nigeria.

- USDA National Nutrient Database for Standard Reference (2010). SR23- Reports by Single Release 23. US Department of Agriculture Research Service Nutrients pp 1-26.

- Fawole MO and Oso BA (2007) Laboratory Manual of Microbiology. Spectrum Books.

- Thompson KA, Marshal MR, Sims CA, Wei CI, Sargent SA, et al. (2000) Cultivar, maturity and heat treatment on lycopene content in tomatoes. Journal of Food Science 65(5): 791-795.

- SPSS (2007) SPSS 16.0 for Windows SPSS Inc, Chicago, IL, USA.

- AOAC (2005) Official Methods of Analysis of the Association of Official Analytical Chemists, 20th (edn), pp 1058-1059.

- Dewanto V, Wu XC, Adom KK, Liu RH (2002) Thermal processing enhances the nutritional values of tomato by increasing total antioxidant activities. Journal of Agriculture and Food Chemistry 50(10): 3010-3014.

- Sahlin E, Savage GP, Lister CE (2004) Investigation of the antioxidant properties of tomatoes after processing. Journal of Food Composition and Analysis 17(5): 635-647.

- Zazoni B, Peri C, Giovanelli G, Nani R (1999) Study of antioxidant heat damage during tomato drying. ActaHorticulturae (ISHS) 487: 395-400.

- Wilson CL, Wisniewski ME, Biles CL, Mc Laughlin R, Chalutz E, et al. (1991) Biological control of postharvest disease of fruits and vegetables: alternative to synthetic fungicide. Crop protection 10(3): 172-177.

- Babarinde GO, Akande EA, Anifowose F (2009) Effect of different drying method on physico-chemical and microbial properties of tomato (Lycopersiconesculentum) var. Roma. Global Science Book 3(1): 37-39.

- Jay JM (2000) Preservation by drying, In: Modern Food Microbiology. 6th (Edn). An Aspen Publication, Aspen Publishers Inc Gaithersburg Maryland pp 363-374.

- Chang CH, Lin HY, Chang CY, Lu YC (2006) Comparisons on the antioxidant properties of fresh, freeze dried and hot-air- dried tomatoes. Journal of Food Engineering 77(3): 478-485.

- ICMSF (International Commission on Microbiological Specification for Foods) [van Schothorst M, Secretary] (1998) Principles for the Establishment of Microbiological Food Safety Objectives and Related Control Measures Food Control 9: 379-384.

- Olayemi FF, Adegbola, JA, Bamishaiye EI and Daura AM (2010) Assessment of postharvest challenges of small-scale farm holders of tomatoes, Belland Hot pepper in some LGA of Kano State. Bayero Journal of Pure and Applied Science 3: 39-42.

- Adejo GO, Agbali FA and Otokpa AS (2015) Antioxidant, Total Lycopene, Ascorbic Acid and Microbial Load Estimation in Powdered Tomato Varieties Sold in Dutsin-Ma Market. Open Access Library Journal 2: 1-7.

- Kumara DM, Reddy S and Upadhyay RC (2011) Antioxidant Activity of three Species of Wild Mushroom Genus Cantharellus Collected from North-Western Himalaya, India. International Journal of Agricultural Biology 13: 415-418.

- Marfil PHM, Santos EM, Telis VRN (2008) Ascorbic acid degradation kinetics in tomatoes at different drying conditions. Food Science and Technology 41(9): 1642-1647.

- Babalola DA, Makola YO, Omonona BT and Oyekanmi MO (2010) Determinants of post-harvest losses in tomato production: A case study of Imeko-Afon area of Ogun State. Journal of Life and Physical Science 3(2): 14-18.

- Sagar VR and Kumara SP (2010) Recent advances in drying and dehydration of fruit and vegetables: a review. Journal of Food Science and Technology 49(1): 15-26.

- FAO (2010) Global hunger declining still unacceptably high: International Hunger Targets Difficult to Reach. Economic and Social Development. Rome: FAO, Rome, Italy.

- Pila N, Gol NB and Rao TVR (2010) Effect of postharvest treatments on physicochemical characteristics and self-life of tomato (Lycopersiconesculentum mill) fruits during storage. American Eurasian Journal of Agricultural and Environmental Science 9: 470-479.

- Kutama AS, Aliyu BS and Mohammed I (2007) Fungal pathogens associated with tomato wicker baskets. Semantic Web Journal 2: 38-39.

- Kora C, Mc Donald MR, Boland GJ (2005) Occurrence of fungal pathogens of carrots on wooden boxed used for storage. Plant pathology 54(5): 665-670.

- Kolawole OM, Adeyemi BJ, Kayode RMO, Ajibola TB (2010) The drying effect of colour light frequencies on the nutrient and microbial composition of cassava. African Journal of Agricultural Research 4(3): 171-177.

- Olaniyi JO, Akanbi WB, Adejumo TA, Akande OG (2010) Growth, fruit yield and nutritional quality of tomato varieties. African Journal of Food Science 4(6): 398-402.

-

Adegbola Dauda, Olufunmilola Abiodun, Tari Salami, Olaide Akintayo. Chemical and Microbiological Evaluation of Dried Tomato slices for Nigerian System. Glob J Nutri Food Sci. 1(5): 2019. GJNFS.MS.ID.000521.

-

Microbiological Evaluation, Chemical Evaluation, Moisture Content, Beta-Carotene, Ascorbic Acid, Bacterial and Fungi, Drying, Tomatoes, Shelf Life, Chemical Components, Microbial Load, Vegetable Crops, Vitamin E, Vitamin C, Vitamin A, Neurological Diseases, Folic Acid, Potassium, Trace Elements, Enzyme Action, Preserving Foodstuffs, Food Preservation Technique, Agar Culture Media, Sterilized Peptone Water, Nutrient Agar, Potato Dextrose Agar.

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.