Research Article

Research Article

Curtainwalls’ Resistance of Building Movements including Seismic Effects

Peter Lalas, Janus Facades Pty Ltd, Sydney Australia.

Received Date: June 24, 2022; Published Date: July 12, 2022

Abstract

A curtain wall is a building cladding system, made of contiguous elements, which envelopes the building structure on which it hangs like a curtain and excludes wind and weather, at the same time including the conditioned internal environment. A curtain wall absorbs building movements and resists no building loads. The manner in which a curtainwall absorbs building movements and remains weatherproof is a matter of determined design, proven by performance testing and years of satisfactory in-service performance. The writer’s curtainwall experience comes from Australia which has typically been seismically stable for recorded history, New Zealand which has been seismically active for the same time and other parts of Asia. This paper shows that it is possible to design a curtainwall with whatever movements are written into the curtainwall specification.

Introduction

This paper considers the performance requirements of curtainwalls in the Australia and New Zealand region. Building movements in general and seismic movements in particular are discussed. Also discussed is how expected movements have been quantified and movement joints in curtainwalls have been designed from the 1980s to the present. Aluminium / glass curtainwalls have been commonly used in commercial facades in Australia and New Zealand since the mid- 1970s.

A curtainwall must,

1. resist weather and applied loads, mainly wind loads.

2. be structurally adequate.

3. have an adequate in-service longevity, usually fifty years.

Structural adequacy is usually assessed in terms of limit states.

The two most important limit states are;

1. Serviceability Limit State (SLS), usually based on 25-year

return loads. Any application of an SLS load must result in no

loss of function and no damage that requires rectification or

special maintenance; and

2. Ultimate Limit State (ULS), usually based on 1000-year return

loads for commercial buildings. Any application of a ULS

load must result in no collapse that may endanger occupants

leaving the building.

[1] “Recent earthquakes such as the Mexico earthquake of 1985 have indicated that there is widespread damage to glazing systems causing glass to fall down the building. After the San Francisco Earthquake (1989), local press interviews and reports indicated that there exists grave concern about the behaviour of glass curtain wall systems during an earthquake. The concern is both for the safety of pedestrians in the vicinity of buildings, and of occupants trying to escape from buildings”. Understanding and quantifying movements which apply to buildings and their claddings such as curtainwalls is a fundamental requirement of cladding design. Movements due to thermal effects are easily determined by calculation but movements of the structure due to wind sway, concrete creep and seismic effects must be advised by the building structural engineer, i.e., the building’s structure designer. The joints of the curtainwall must be designed to absorb these SLS movements without damage and ULS movements without collapse.

Types of Curtainwalls

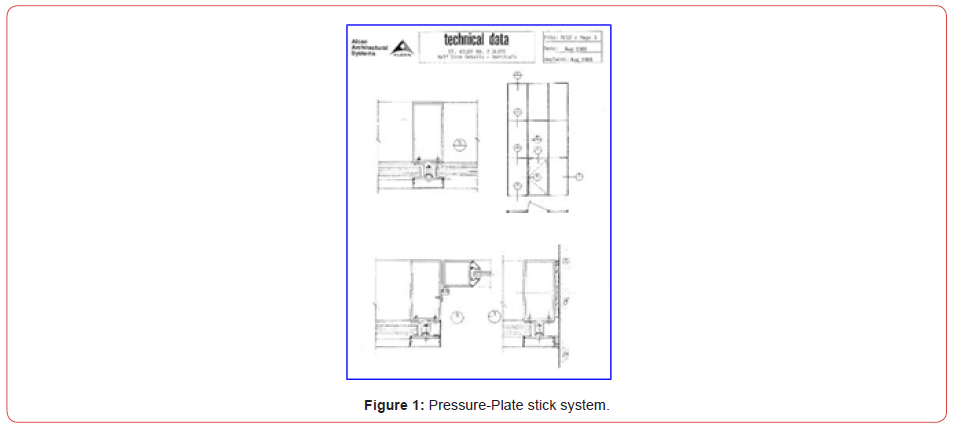

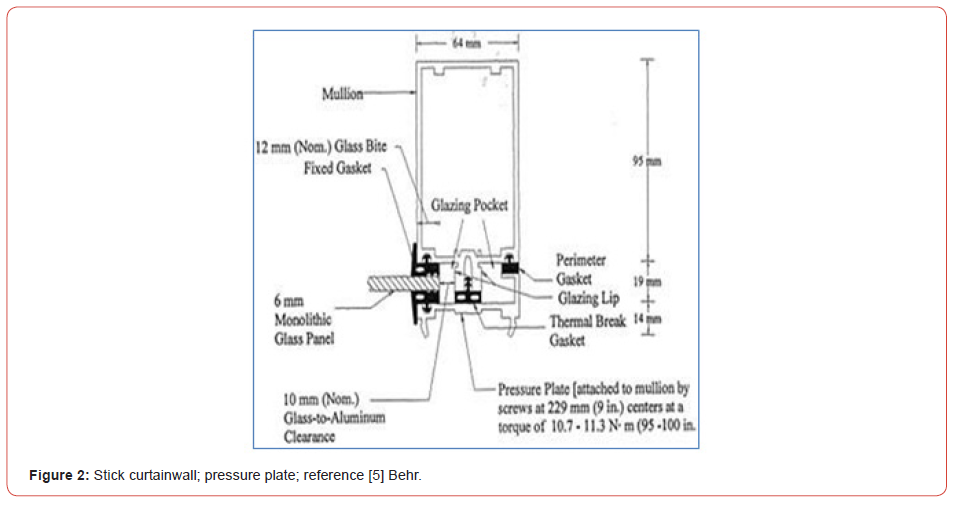

The two most common curtainwall types are stick and unitized (or panelized) systems. These two types of curtainwalls have been illustrated in many references including as long ago as 1979 in [2] AAMA CW-DG-1-79Curtainwall Design Guide. The stick system arrives on site as ‘sticks’ of aluminium and un-glazed glass lites. The brackets to the structure are installed first, followed by the vertical mullions, the horizontal transoms and then the glass and other panels. The most common stick system has been the pressure-plate system, similar to the [3] ALCAN St Kilda Suite (Alcan Technical Data 1985), shown in Figure 1. Also illustrated in Figure 2 is a more modern pressure-plate system (Behr [4] and Arnold et al. [5] Figure 8;). Although dated 2016 this example shows monolithic glass rather than and insulated glass unit (IGU) (Figures 1,2).

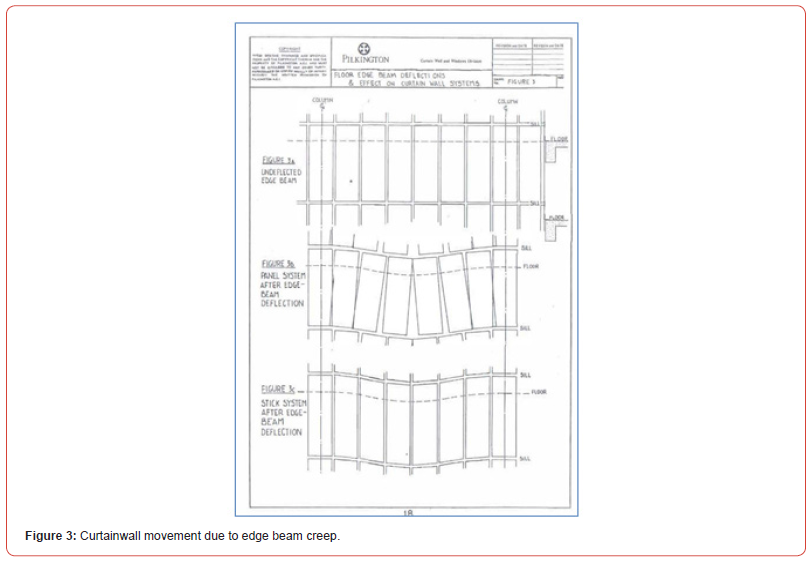

There is very little movement capability in these systems. They rely substantially on the clearances between the glass edges and the aluminium frame. The glass must not touch aluminium during a seismic event. Seismic racking can break the mullion to transom joint seals and allow water ingress. Seismic racking movements of a untised curtainwall are taken up in the joints between panels. The unitized panels remain rectangular and effectively rigid. the glass and other panels remain within their frame and do not have any forces due to structural movements imposed on them. The panels can rotate and the joints between the panels open and close (refer Figure 3).

Joint Sizes

The author has been analyzing building movements since he started in curtainwall design in the early 1980s. At that time, it was very difficult to obtain expected building structure movements from the structural engineers. This is because building movements quantification is not usually part of the building structural engineer’s scope. Most high-rise buildings in Australia since the early 1960s have a concrete structure. The concrete edge beams will creep, and this must be considered in the curtainwall design. Figure 3, from 1989 [6] Lalas shows a diagram of curtainwall movement due to concrete edge beam creep. This shows the differences in movement effects of stick and unitised curtainwalls. The joints of a curtainwall must be designed for all expected movements and tolerances which can affect the joint size (Figure 3).

Unitised curtainwalls have a much greater capacity to accept large building and seismic movements as the joint sizes can simply be enlarged as required at the design stage. The curtainwall joints must be designed to allow for manufacture and installation tolerances, thermal and building movements, including concrete edge beam creep, live loading of steel floors and column shortening. Seismic movements which do not occur concurrently are usually adequately accommodated without adding extra to the above allowances.

Curtainwalls and Seismic Movements

There have been recent seismic events in Australia, including.

1. In Newcastle in NSW, Australia on 28 December 1989; 5.6

magnitude scale; and more recently,

2. Mansfield, approximately 180kn NE of Melbourne Victoria on

22 September 2021; magnitude 5.9. In contrast, historically,

New Zealand has experienced many large earthquakes, for

example;

3. Wairarapa earthquake in 1855; The biggest NZ recorded

earthquake magnitude 8.2;

4. The Nelson Earthquake 3 February 1931 magnitude 7.8;

killing 256, injuring thousands and devastating the Hawke’s

Bay region;

5. Christchurch 22 February 2011 magnitude 6.3; killing 185

people,

6. Kaikoura 14 November 2016; shallow, magnitude 7.8

earthquake; Tens of thousands of landslides were generated

over 10,000 km2 of North Canterbury.

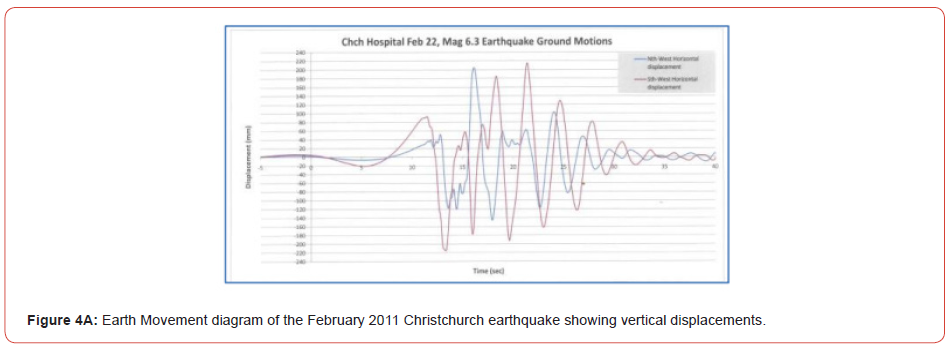

Often, the only advice from Structural engineers is in terms of inter-storey drift, which is differential movement between adjacent floors. This is typically given as 0.5% Serviceability Limit State (SLS) and 2% Ultimate Limit State (ULS) of floor-to- floor height. For a typical floor height of 3.8metres 0.5% of the floor height is 19mm SLS movement; 2% of the floor height is 72mm. These numbers are often not derived by calculation by the building structural engineer. It is the number that the structural engineer says that applies when working to the Concrete Structures Standard (Figure 4A).

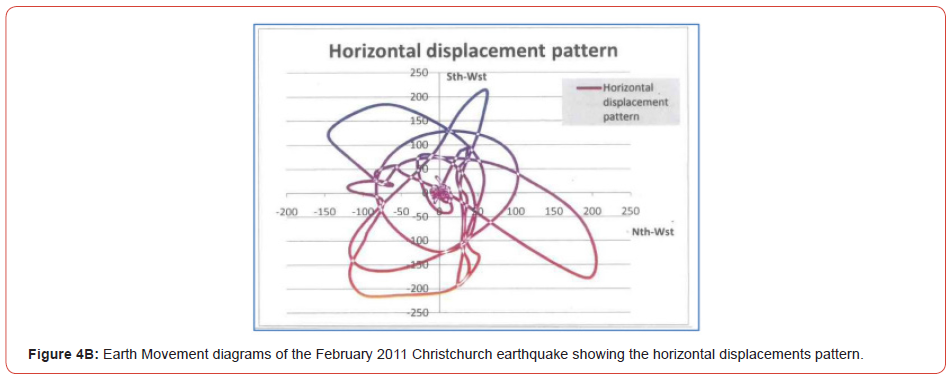

In considering the Christchurch 2011 earthquake, the movements were much more complicated and moved in a 3D spectrum and were not just inter-storey drift, i.e., sideways in one direction (Figure 4B).

It is possible to do a geometric study to determine exactly the dimension that joints will open and close due to particular seismic movements of known displacements. Such calculations are provided in [4],[5] Behr. However, as with most of such references, calculations are provided only for stick systems. Unitised curtainwall joints are typically larger than for glass edge clearances of stick systems. This is simple geometry as unitised panels span floor-to floor whereas vision panels in a stick system span sill transom to head transom and may be less in height by one meter or more.

These calculation studies typically assume rigid panels. Such calculations tend to be conservative. Unitised curtainwalls actually perform much better than indicated by these geometric studies. This has been shown in performance tests with which the author has been involved and in post-earthquake observations. The unitised curtainwall of the 14-floor PWC Centre building at 119 Armagh St [8], Christchurch was assessed in February and May 2011 after the earthquake. The curtainwall did not lose any glass panels even though mullion and transom joints were only a nominal 6mm.

Performance Testing Curtainwalls

The [1,9] Building Research Association of New Zealand (BRANZ) carried out two studies of curtainwall racking testing to simulate inter-storey drift in the early nineteen nineties. These indicated that curtainwalls can resist seismic movements and confirmed that the theoretical studies indicated above are conservative. Unfortunately, these tests only included the structural racking tests and did not include any weather testing. Continued weather resistance after an SLS seismic event is also an essential feature of curtainwalls. As weather resistance is a primary requirement of curtainwalls, then weather testing should be included in performance tests in curtainwalls. As indicated by [1] BRANZ testing, curtainwalls typically absorb seismic movements up to the SLS racking without visible evidence of damage. This does not mean that there is no invisible damage. A measure of damage can be obtained by running an air infiltration (air leakage) and water penetration test both before and after the seismic racking test and comparing the before and after results. The prototype must pass both the before and after seismic tests. Usually, the prototype’s air leakage is more after the seismic test, and this is an effective measure of its performance loss due to the seismic racking (Figure 5).

Inter-story drift movements can be applied to curtainwall prototypes in performance tests. Figure 5 shows a prototype of a curtainwall for a 7-storey building. This is a test of a prototype of a bespoke curtainwall for a particular project in New Zealand. The prototype is 2 floors tall, and the central beam (indicated with the white arrow) is racked horizontally, back and forth to simulate inter-storey drift for the seismic test. This view shows the internal face of the prototype. The external face is facing the inside of the test chamber where the pressure is applied, and the water sprays are installed.

Other Testing

Recent testing by [10] Professor Tim Sullivan, College of Engineering, University of Canterbury, New Zealand has shown that the weather-resistance of windows can be substantially reduced by minor seismic racking. Nether of the window Standards of New Zealand NZ 4211 nor Australia AS 2047 include a requirement for seismic testing. Mandatory seismic testing of windows would probably lead to a requirement for seismic frames around all windows. Seismic frames around the perimeters of windows would isolate them from the seismic movements. The façade test Standard, AS/NZS 4284 includes non-mandatory seismic testing. This is carried out for bespoke facades, but only if the requirement is included in the project façade specification.

Local Requirements

Standards giving design seismic movements have been available for some time. New Zealand Standards, such as such as [11] NZS 4203: 1992 and more recently [12] AS/NZS 1170.2 part 5 which was updated after Christchurch (February 2011) have been in common use. However, such Standards give the building structural engineer information to design the structure, but it is not helpful in the design of the building’s façade, be it curtainwall or other cladding types. They give accelerations but not displacements, which can only be determined with knowledge of the building structure. Documents such as the [13] New Zealand Building Code and Australia’s [14] National Construction Code require that a curtainwall must remain serviceable after SLS events and not collapse in a ULS event. These performance requirements are not helpful in the design of joint sizes, which are particular to a building project and bespoke curtainwall.

There are no local Standards which give instructions or even guidance on how to design the sizes of curtainwall joints. It is possible to argue that seismic testing is not required for curtainwalls and windows installed in Australia. However, recent earthquakes in New Zealand indicate that all building components including all curtainwalls and windows to be installed in New Zealand, should be seismically tested to show that they can resist seismic racking and remain weathertight.

Conclusions

Stick curtainwalls have a limited capability to resist seismic movements compared to unitised curtainwall systems. However, both types can be adequate in service, when properly designed. The curtainwall designer must obtain expected movement, in terms of dimensions and directions, from the building design engineer. These movements must be used to design the curtainwall joints. A curtainwall will perform better in service than anticipated by calculation, due to inherent deflections and twists within the curtainwall components. Curtainwall prototypes, both in New Zealand and Australia (and preferably windows also) should be seismically tested for all buildings.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- KYS Lim, AB King Lim (1990) Building Research Association of New Zealand (BRANZ) Study Report SR 39 The Behaviour of External Glazing Systems Under Seismic In-Plane Racking Reference. Judgeford.

- (2005) AAMA CW-DG-1-79 Curtainwall Design Guide and AAMA. AAMA CW-DG-1-96 Editorial Revision: 5/2005 Curtain Wall Design Guide Manual.

- ALCAN St Kilda Suite (Alcan Technical Data 1985).

- Richard A Behr (2009) Architectural glass to resist seismic and extreme climatic events. Woodhead Publishing ISBN 978-1-84569-369-5.

- Behr [1]; Building code seismic requirements for architectural glass: the United States; RE Bachman, RE Bachman Consulting Structural Engineers, USA and SM Dowty, SK Ghosh Associates Inc., USA

- Design Engineering Criteria of Curtain Walls on High Rise Buildings. P Lalas Senior Design Engineer, Pilkington Australia Walls and Windows 1989 ACEA Conference.

- Behr [1]; Glazing and curtain wall systems to resist earthquakes; AM memari, The Pennsylvania State University, USA and TA schwartz, Simpson Gumpertz & Heger, US.

- Performance of a Curtainwall in the Christchurch Earthquake; Peter Lalas; Janus Facades Pty Ltd, Sydney Australia, ICBEST 2014 June 09-12-2014, Aachen, Germany.

- SJ Thurston, AB King (1992) Building Research Association of New Zealand (BRANZ) Study Report No. 44 Two-Directional Cyclic racking of Corner Curtainwall Glazing.

- (2021) Earthquakes and leaky buildings By Professor Tim Sullivan, College Of Engineering, University Of Canterbury; ‘Build 183’ magazine April/May 2021 (BRANZ publication).

- (1992) Standards New Zealand. NZS 4203: 1992 New Zealand Standard: Code of Practice for General Structural Design and Design Loadings for Buildings; known as the Loadings Standard. Volume 1. Code of Practice Part 4 Earthquake Provisions.

- (2002) Standards Australia Limited / Standards New Zealand. AS/NZS 1170.4:2002 Structural Design Actions Part 4. Earthquake Actions and part 5 New Zealand Earthquake actions.

- New Zealand Building Code, New Zealand Government Ministry of Business, Innovation and Employment. n.d. Clause B1 Structure.

- (2012) National Construction Code of Australia. Structural Provisions. Volume 1, Section B Structure; Part B1.

- (2017) GeoNet. 2011. M 6.3, Christchurch, 22 February 2011—Earthquake.

-

Peter Lalas. Curtainwalls’ Resistance of Building Movements, including Seismic Effects. Cur Trends Civil & Struct Eng. 9(1): 2022. CTCSE.MS.ID.000703. DOI: 10.33552/CTCSE.2022.09.000703.

-

Building, Environment, Curtainwall, Earthquake, Structural engineer, Geometric

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.