Research Article

Research Article

Development of a Dynamic Model for Predicting Humic and Fulvic Acids Production in a Composting Process Using Olive Mill Wastes

Christina Tsiodra, Anestis Vlysidis, Dimosthenis Tsivas and Apostolos Vlyssides*

School of Chemical Engineering, National Technical University of Athens, Greece

Apostolos Vlyssides, School of Chemical Engineering, National Technical University of Athens, 9 Heroon Polytechniou, Zographou, Athens, Greece.

Received Date: March 18, 2019; Published Date: April 02, 2019

Abstract

In this work, a dynamic mathematical model for the prediction of fulvic (FA, g/kg) and humic acids (HA, g/kg) production during the humification stage of an olive mill waste residues (OMWR) composting process was developed. The dynamic modeling technique was applied successfully to the data record from an industrial composting process using OMWR as organic substrate collected from different III-phase olive mills. The applied prediction technique was based on time series theory and on regression analysis by residuals. The effect of pH, of Water Holding Capacity (WHC, %), of Electrical Conductivity (EC, mS/cm) and of ammonium nitrogen concertation (N-NH4, g/kg of TS) on FA and HA production was examined using daily measurements of all the above parameters for the last sixty days of the composting period. The experimental results show a strong reverse interrelation between FA and HA verifying that the HA production is based on FA reduction. The adequacy of the created dynamic models was checked by the x2 test giving reliable result.Foragers and Food Production in Africa: A Cross-Cultural and Analytical Perspective. Paper for the 48th annual Society for Cross-Cultural Research (SCCR) meetings, Jacksonville, Florida, February 13-16, 2019.

Keywords: Humic acids; Fulvic acids; Composting; Humification; Dynamic model; Olive mill waste residues (OMWR)

Introduction

Humic substances are very important components of soil organic matter (humus) that affect physical and chemical properties and improve the fertility of the soil [1,2]. The humic substances consists of three components: the humins that is the water insoluble component of organic matter (OM) for all ranges of pH, the fulvic acids (FA) that is the soluble component of OM in strong alkaline conditions and the humic acids (HA) that is the insoluble component in strong acidic condition. During the composting period (thermophilic and mesophilic) the initial amounts of humic substances are enriched with the cellular membranes of dead microorganisms. During the maturity period (mesophilic period) the bio-transformation of humic substances into humic acids passes through the development of fulvic acids. The humification period is signed when the fulvic acids start to bio-transformed into humic acids [3]. The humification period is the most important period of a composting process as marketable compost products target to contain as much as possible humic acids. The production of fulvic and humic acids is not a well-known biological procedure, and hence, the control of the humification process becomes problematic. On the other hand, there is not any on-line method for measuring humic substances and the laboratory analysis of all humic compo nents require a considerable amount of time (1-2 days). Taking into consideration that there is a great number of routine measurable parameters that affect the efficiency of humification, a dynamic mathematical model based on time series analysis of these parameters is of major importance for controlling the process.

The aim of this work is the development of a dynamic mathematical model for controlling the humification period of an OMWR composting process using of a suitable methodology based on time series analysis and data analysis by residuals.

Materials and Methods

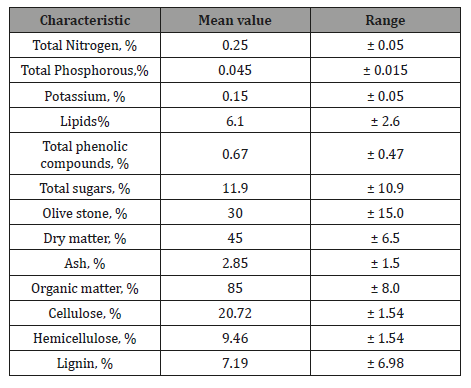

In this study, multiple linear regression was used to develop a discrete dynamic model for an Olive Mill Waste Residues humification composting process. For the construction of the dynamic model a historical data record from two windrow open type composting reactors was employed in which OMWR from III-phase olive oil processing mills was used as organic substrate. The characteristics of the raw organic substrate used for the composting procedure are presented in Table 1. The composting reactors (windrow open type) were of about 100 m3 volume each with a solid’s retention time of about 100 days.

Table 1: Main characteristics of OMWR used for the composting procedure.

In order to control the operation and efficacy of the examined windrows, various parameters such as ammonia and nitrates nitrogen content (N-NH4 and N-NO3, mg/kg), fulvic (FA, g/kg) and humic (HA, g/kg) acids content, Electrical Conductivity (EC, mS/ cm), pH and Water Holding Capacity (WHC, %) were measured in a daily basis. All the presented measurements are the mean values of the examined windrows. Also, from each windrow, three samples were taken each time and mixed together, one from the center of the windrow and two from each side. All samples were collected approximately 40-50cm from the surface of the windrow. The fluctuations of FA and HA characterize the evolution of the humification stage of composting. From all above seven independent parameters the pH, EC, WHC and N-NH4 can be easily and quickly measured. However, for a precise measurement of HA and FA many samples are required and at least one day of laboratory analysis. Thus, the main objective of this study is to correlate the easy daily measured operational parameter pH, EC, WHC and N-NH4 with the HA and FA of the data record with a time lag up to 10 days. In order to construct the dynamic model, the theory of time series analysis [2] as well as the theory of regression by residual analysis [4] were used as described by Tsiodra et al. [5].

The humic substances was analyzed according the method described by Velasco et al. [6] All the other analytical measurements were carried out according to Standard test methods of TMECC [7] and the Standard Methods for the Examination of Water and Wastewater (APHA-AWWA-WPCF, 1989). The statistical analysis of the results was carried out utilizing the techniques given by Taylor [8].

Results and Discussion

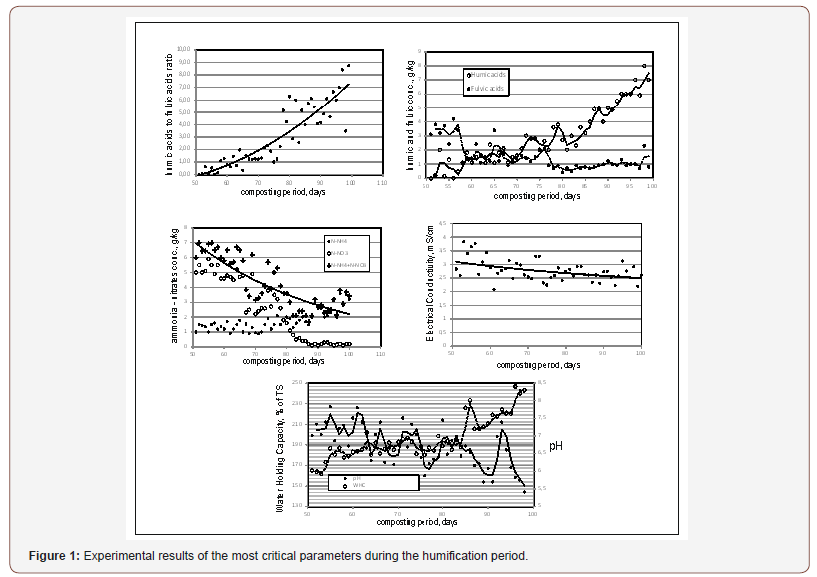

The humification period of a composting process starts when the production of humic acids is initiated. The latter takes place approximately on the 50th day from the starting of the composting process. All the experimental results during the last fifty days of the maturity period are shown in the diagrams of Figure 1. The moisture of the composting material was maintained in the first weeks to 50- 60% by adding pretreated Olive mill wastewater (OMWW) while during the final stages of the composting process the moisture was dropped to 43%. The Water Holding Capacity (WHC) was increased from 144% to 282%. The pH range was between 5.5 to 8.7 while the electrical conductivity was reduced from 3300 mS/cm to 2700 mS/ cm. Moreover, the phytotoxicity values showed that the composting material at the end of the process has been bio converted to a nontoxic soil conditioner. The HA concentration was increased from 0 % to 3.4 g/kg while the FA concentration was decreased from 8.0 to 0.8 g/kg.

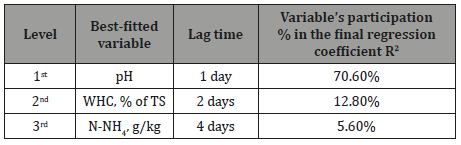

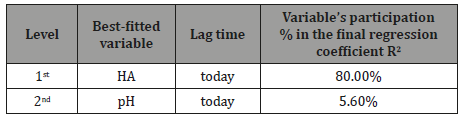

The variables that were strongly correlated with the HA concentrations are the pH, the WHC and the N-NH4 whereas for FA are the today values of HA and the pH. The consecutive levels of regression analysis for HA and FA are shown in Tables 2 & 3.

Table 2: Levels of the regression by residual analysis for the HA model.

Table 3: Levels of the regression by residual analysis for the HA model.

According to the obtained composting data (Figure1) and the methodology followed in this study, the equations 1 and 2 were developed for predicting the concentrations of HA and FA, respectively. The R2 for the HA model is 89.0% while the one for the FA model is 85.4%.

HAt = 3.15 (pH)t-1 – 0.0185 (WHC)t-2 + 0.4739 (N-NH4)t-4 – 16.197 (R2 = 89%) Eq.1

FAt = 53.617/(pH)t + (HA)t/(1.232(HA)t-0.447) - 7.29 (R2 = 85,4%) Eq.2

Where t is the present day and t-n is the lag time of n days.

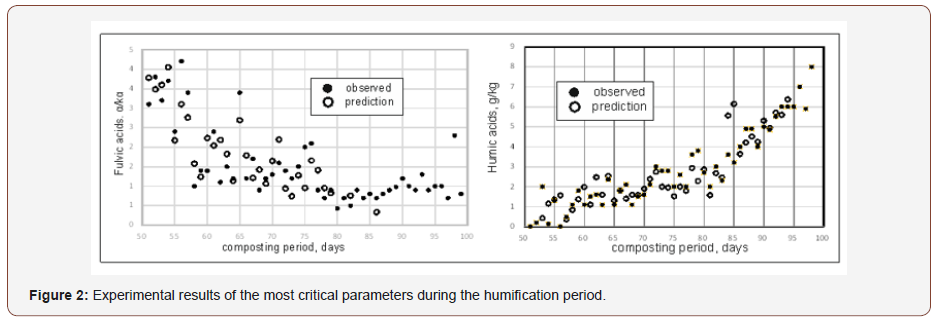

In order to check the model, a different composting process at a different time period but with the same initial substrate was running and the results of the observed and predicted values for HA and FA are presented in Figure 2. The X2 test [9] of the comparison of the two sets was calculated equal to 0.783 for four degrees of freedom which reveals that the model can be a satisfactory prediction tool for this maturation period of the above composting process.

Conclusion

The methodology of regression analysis by residuals for the construction of a dynamic model proved to be satisfactory [10,11]. It is worth noticing that for this kind of model construction it is not necessary to conduct tedious factorial experiments, but instead routine determinations in an industrial plant are sufficient. The models that arise from these data can be used as powerful tools for controlling the maturity and humification period of a composing process.

Acknowledgement

This work was supported by the composting industry ORGANOHUMIKI THRAKIS IKE.

Conflict of Interest

No conflict of interest.

References

- Aiken GR, Mc Knight DM, Wershaw RL, Mac Carthy P (1985) An introduction to humic substances in soil, sediment, and water. In: Aiken GR, Mc Knight, DM, Wershaw RL, Mac Carthy P (Eds.) Humic Substances in Soil, Sediment and Water: Geochemistry, Isolation, and Characterization. Wiley, USA, pp. 1-9.

- Box PEG, Jenkins MS (1976) Time Series Analysis: Forecasting and Control. 1st edn, Holden-Day Inc San Francisco.

- Plaza C, Senesi N, Brunetti G, Mondelli D (2007) Evolution of the fulvic acid fractions during co-composting of olive oil mill wastewater sludge and tree cuttings. Bioresource Technology 98: 1964-1971.

- Ingels RM (1980) How to use the computer to analyze test data. Chem Eng 145-156.

- Tsiodra Ch, Stathakis E, Vlysidis A, Vlyssides A (2018) Development of a dynamic model for degradation of Fats, Oils and Greases during cocompostig of olive mill solid and liquid wastes. Fresenius Environmental Bulletin (FEB) 27(7): 4900-4903.

- Velasco MI, Campitelli PA, Ceppi SB, Havel J (2004) Analysis of humic acid from compost of urban wastes and soil by fluorescence spectrometry. Agriscientia 21(1): 31-38.

- Thompson HW (eds) (2002) Test Methods for the Examination of Composting and Compost TMECC. The US Department of Agriculture and the US Composting Council.

- Taylor KJ (1990) Statistical Techniques for Data Analysis. 1st edn, McGraw-Hill, Inc New York.

- Hansen LJ, Fiok EA, Hovious CJ (1980) Dynamic modeling of industrial wastewater treatment plant. J WPCF 52: 196-197.

- APHA-AWWA-WPCF (1989) Standard Methods for the examination of water and wastewater. 17th edn, APHA Washington D.C.

- Chen Y, Chefetz B, Hadar Y (1996) Formation and properties of humic substance originating from compost. In: Bertoldi M, Sequi P, Lemmes B, Papi T (Eds.) European Commission International Symposium. The Science of Composting, Blackie Academic & Professional, England, pp. 382-393.

-

Apostolos Vlyssides, Christina Tsiodra, Anestis Vlysidis, Dimosthenis Tsivas. Development of a Dynamic Model for Predicting Humic and Fulvic Acids Production in a Composting Process Using Olive Mill Wastes. World J Agri & Soil Sci. 1(5): 2019. WJASS.MS.ID.000525.

-

Humic acids, Fulvic acids, Composting, Humification, Dynamic model, Olive mill waste residues (OMWR)

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.