Mini Review

Mini Review

An Approach for In-Situ Evaluation of the Efficiency of Coatings Applied to Metal Cultural Objects Using Non- Destructive Electrochemical Measurements

Douglas J Mills1* and Katarzyna Schaefer2

1University of Northampton, UK

2National Maritime Museum, Gdansk, Poland

Douglas J Mills, Dept. of Engineering and Technology, University of Northampton, Northampton, UK.

Received Date: January 08, 2019; Published Date: January 18, 2019

Introduction

Metal archaeological objects excavated from the sea need application of a removable, invisible coating to protect them from further corrosion during display in the museum and/or storage. Typically, these coatings are applied by brush and sometimes by spray. These coatings are often based on wax e.g. paraffin wax although more specific acrylic types (the Paraloid series) are also used. A protection provided by the coating is challenged by two aspects. First, normally applicators are not aware as to how thick the coatings are after application to real objects. Secondly, users have no way of discovering the optimum number of coats; or of monitoring the performance of the coating in service. Therefore, a numerical assessment method is required. This work looks at developing such a method.

Previously, non-intrusive electrochemical (EC) techniques like electrochemical noise measurement (ENM), electrochemical impedance measurement (EIS) and DC resistance can be used to assess the level of protectiveness provided by an organic coating (paint) to the underlying metal. A work where ENM and EIS were applied to measure the extent to which a coated cultural artefact made of metal has degraded due to corrosion when exposed to an external environment, showed how these techniques can be taken out onto site [1]. These techniques also have applicability to the thinner transparent type of coatings used to protect archaeological artefacts. More recently [2] an attempt has been made to apply electrochemical methods to assess such coatings. The work described herein follows on from that work. This short paper provides a case study for application of the technique to objects from the National Maritime Museum in Gdansk indicating protection provided by coatings on actual archaeological items recovered from shipwrecks at the Baltic sea. These are displayed in the Museum collection and/or in storage room. The technique of choice has been ENM. Further discussion about this technique can be found later in this note [3]. Results were obtained from a coated piece of steel hull, from the sabre of a non-commissioned officer in the Russian Navy, from a bronze bell and from brass bowls. The results show that coatings on real objects can be measured in situ and an actual number (Rn) can provide the level of protection of each coating.

Samples

The samples shown in Figure 1 are the Bell from Gen. Carleton shipwreck (1777), part of the hull from Otago ship (1869) and brass bowl from cargo of wooden shipwreck (XVI-XVII C).

Procedure

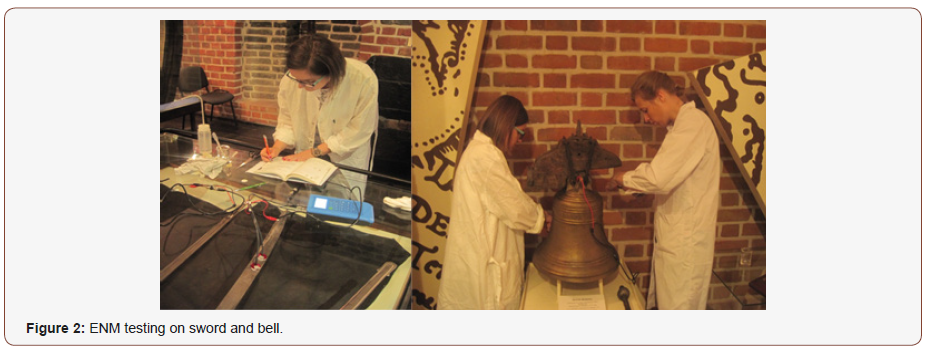

The bell, the Otago hull and an officer’s sword on display in the museum were removed from their cases and their coatings were assessed by use of a non-destructive method via Electrochemical Noise measurements (ENM). Additionally, brass bowls in storage were measured. Probes based on Ag/AgCl electrodes were left in place for fifteen minutes then data was gathered (twice) over 5 mins Filter paper saturated with 3% NaCl was inserted between the electrode and coated object. Probes were held in place with magnets (steel objects) or tape. Figure 2 shows testing of a noncommissioned officer sword of the Russian Navy (1871-94) and the bell (1777 - 1785). From the V and I noise values, Rn is calculated. Further information on the method is available [3].

Thickness Measurement

This was performed by Defelsko Positest thickness DFT gauge range 0-500μm, precision +/-3%. Each area examined was measured in five places and the average thickness was calculated. Also, minimum thickness was noted. The values for the bowls varied between 22.6 μm and 45.4 μm. There was evidence of correlation between thickness values and Rn values.

Rn values

Values obtained from all the objects are given below. All are average of two. Generally, reproducibility between the two readings was good (within +/- 20%).

Otago 1= 3.8 x 105, Otago 2 = 1.6 x 106

Sword 1= 38 Sword 2 = 39

Bell 1 = 322 Bell 2 = 414

Bowl 1 (area 1) = 2090, Bowl 1 (area 2) = 2550, Bowl 1 (area 3) = 250

Bowl 2 (area 1) = 170, Bowl 2 (area 2) = 60, Bowl 2 (area 3) = 210

Bowl 3 (area 1) = 2900, Bowl 3 (area 2) = 1540, Bowl 3 (area 3) = 570

Summary and Conclusion

particularly if minimum thickness is plotted. The work allowed obtaining promising results hence it was continued. The following work included testing four different polymer coatings typically used by the National Maritime Museum for the protection of objects recovered from sea water immersion. These were investigated on steel Q panels and pure copper using the DC resistance method in a laboratory situation [4].

Acknowledgement

The authors would like to thank the following people: Piotr Dziewanowski for his help in the application of coatings and intern: Katarzyna Mielcarek and Monika Radzewicz for performing electrochemical measurements and the DCVG company for loan of the ProCoMeter; also to Tomasz Wityk and Tian Yang Lan for assistance with data gathering and plotting.

Conflict of Interest

No Conflict of Interest.

References

- Jamali SS, Zhao Y, Gao Z, Li H, Hee AC (2016) In situ evaluation of corrosion damage using non-destructive electrochemical measurements-A case study. J Ind Eng Chem 43: 36-43.

- Schaefer K, Mills DJ (2017) The application of organic coatings in conservation of archaeological objects excavated from the sea. Progress in Organic Coatings 102: 99-106.

- Mabbutt S, Mills DJ (2001) Recent UK work investigating anti-corrosive organic coatings using the electrochemical noise method (ENM). Surface Coatings International Part B: Coatings Transactions 84(4): 277-283.

- Mills DJ, Schaefer K, Wityk T (2018) In-Situ evaluation of the protectivity of coatings applied to metal cultural artefacts using non-destructive electrochemical measurements. Proceedings EUROCORR, Kracow, Poland.

-

Douglas J Mills, Katarzyna Schaefer. An Approach for In-Situ Evaluation of the Efficiency of Coatings Applied to Metal Cultural Objects Using Non-Destructive Electrochemical Measurements. Open Access J Arch & Anthropol. 1(1): 2019. OAJAA.MS.ID.000505.

-

Electrochemical Measurements, Cultural Artefact, Corrosion, Shipwrecks, Polymer, Immersion, Dziewanowski, Katarzyna Mielcarek, Procometer, Electrochemical Noise Measurement, Electrochemical Impedance Measurement.

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.