Short Communication

Short Communication

Theoretical Study of The Alloying Elements on the Properties of Tib2 Ceramic Reinforced Fe Matrix Composite

Yefei Li1*, Xue Bai1, Honggang Liu2, Xiaojing Zhang2, Qinkun Liu3 and Changmeng Zhou3

1State Key Laboratory for Mechanical Behavior of Materials, Xi’an Jiaotong University, China

2Datang Shengye Science and Technology Co., Ltd, China

3Shandong Huifeng Casting Technology Co., Ltd, China

Yefei Li, State Key Laboratory for Mechanical Behavior of Materials, Xi’an Jiaotong University, Xi’an, 710049, China.

Received Date: June 13, 2019; Published Date: June 17, 2019

Short Communication

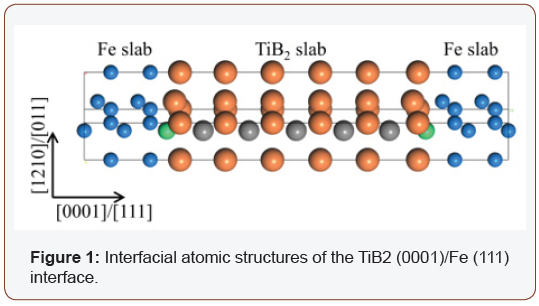

In recent decades, ceramic particles reinforced iron matrix composites (CPRIMCs) are regarded as the main achievements in wear resistant materials area [1-3]. Among many iron matrix composites, Tib2 ceramic reinforced Fe matrix composite (Tib2/ Fe) behaves large elastic modulus, high mechanical strength, and advanced hardness and wear resistance [4,5]. Additionally, the high electrical conductivity of Tib2 ceramic [6] enables machining of Tib2/Fe composite easily using electrical discharge machining. Agarwal and Dahotre [7] discussed the reinforcing mechanism of Tib2/Fe composite, the epitaxial growth of iron on Tib2 particles is revealed, and the orientation relationship was found as Tib2 (0001)/Fe (111). However, much less information is available for the effects of alloying elements on the properties of Tib2/Fe interface.

We use the method proposed in [8] to investigate the atomic structures, chemical bonding, stability and fracture mechanism of Tib2/Fe composite. It is found that B-terminated interface with HCP site behaves the most stable nature and belongs to non-diffusive configuration. Based this configuration, the segregation behavior of alloying additives X (X=Si, Al, Cr, Mn, Ni, Mo) on the interface of Tib2 ceramic reinforced iron matrix composite as well as the effects of these additives on the interfacial adhesion, electronic and magnetic properties were studied. The results indicated that Cr, Mn and Mo may segregate at the Tib2 (0001)/Fe (111) interface because of their low heat of segregation barrier (Figure 1).

Moreover, compared with the work of adhesion of different alloying doping interfaces, the introduction of Cr, Mn improves the adhesive strength of Tib2(0001)/Fe (111) interface through strong covalent interactions between Cr/Mn and B atoms. The best strengthening effect on Tib2 (0001)/Fe (111) interface can be attributed to Mn because of the highest interfacial work of adhesion and critical stress of Mn-doped interface; we also found the interfacial work adhesion energy is high than fracture energy of Tib2 and Fe slabs, indicating the mechanical strength of the interface is more remarkable than both Tib2 and Fe bulks, and the mechanical failure will initiate at the Fe interior.

Conclusion

From the soft carbons/graphite to carbon nanostructures, such as graphene/CNTs/graphdiyne and nanocomposites with CNTs/graphene, the capacities have been boosted obviously and thus the performance of anode has been enhanced. Nano carbons can be also used in cathode as efficient conductive additives. It is foreseeable that Nano carbons will make a major role in the coming new-generation LIBs.

Acknowledgements

This work was supported by the Natural Science Foundation of Shaanxi Province of China (2018JM5002), the Key Research and Development Program of Shaanxi Province of China (2019GY- 182), the Postdoctoral Science Foundation funded Project of China (No. 2018M631152, 2018T111051), the Postdoctoral Science Foundation funded Project of Shaanxi Province of China, the Fundamental Research Funds for the Central Universities of China (xzy012019001), the Guangxi Innovation Driven Development Project (GUIKEAA18242001).

Conflict of Interest

No conflict of interest.

References

- Rest A, Idrissi H, Henry F, Favache A, Schryvers D, et al. (2017) Mechanical behavior of ultrathin sputter deposited porous amorphous Al2O3 films. Acta Materialia 125: 27-37.

- Pohl F, Theisen AMW (2017) Effect of matrix and hard phase properties on the scratch and compound behavior of wear resistant metallic materials containing coarse hard phases. Wear 376-377: 947-957.

- Chen W, Shi H, Xin H, He N, Yang W, et al. (2018) Friction and wear properties of Si3N4-hBN ceramic composites using different synthetic lubricants. Ceramics International 44(14): 16799-16808.

- Springer H, Aparicio Fernandez R, Duarte MJ, Kostka A, Raabe D (2015) Microstructure refinement for high modulus in-situ metal matrix composite steels via controlled solidification of the system Fe–Tib2. Acta Materialia 96: 47-56.

- Cha L, Lartigue-Korinek S, Walls M, Mazerolles L (2012) Interface structure and chemistry in a novel steel-based composite Fe–Tib2 obtained by eutectic solidification. Acta Mater. 60(18): 6382-6389.

- Sun L, Gao YM, Xiao B, Li YF, Wang GL (2013) Anisotropic elastic and thermal properties of titanium borides by first-principles calculations. Journal of Alloys and Compounds 579: 457-467.

- Agarwal A, Dahotre NB (2000) Mechanical properties of laser-deposited composite boride coating using nanoindentation. Metallurgical and Materials Transactions A 31(2): 401-408.

- Li YF, Xiao B, Wang GL, Sun L, Zheng QL, et al. (2018) Revealing the novel fracture mechanism of the interfaces of Tib2/Fe composite from a first principles investigation. Acta Materialia 156: 228-244.

-

Yefei Li, Xue Bai, Honggang Liu, Xiaojing Zhang, Qinkun Liu, Changmeng Zhou. Theoretical Study of The Alloying Elements on the Properties of Tib2 Ceramic Reinforced Fe Matrix Composite. Mod Concept Material Sci. 1(3): 2019. MCMS.MS.ID.000514.

-

TiB2/Fe; Composites; Iron matrix; Mn; Alloy; Cr

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.