Short Communication

Short Communication

The Effect of High-Temperature Liquid Crystal on Haze and Voltage Improvements of Dye-Doped Polymer Dispersed Liquid Crystal Film

H Hakemi*

Plastic Liquid Crystal Technology Consultant, Via Lambro 80, 20846 Macherio (MB), Italy

H Hakemi, Plastic Liquid Crystal Technology Consultant, Via Lambro 80, 20846 Macherio (MB), Italy.

Received Date:May 31, 2025; Published Date:June 12, 2025

Abstract

The current commercial PDLC film and glass products are mainly utilized for internal privacy applications. In this work we studied the effect of process line speed on electro-optical properties of model dye-doped PDLC formulations consisting of high-temperature and standard liquid crystal materials. The results indicated that, in comparison to standard PDLC, the high-temperature PDLC exhibited a significantly lower on-state haze and switching voltage. This study provides a road map for further systematic studies on external applications of PDLC smart glass.

Keywords:High-temperature, Liquid crystal, Dye, Optical transmission, Haze, Applied voltage.

Introduction

The Polymer Dispersed Liquid Crystal (PDLC) technology has been the subject of many studies in the past few decades resulting to rich scientific publications, industrial manufacturing and commercialization of various products worldwide. The published literature on PDLC technology by most academic and some industrial research have included the effect of matrix and liquid crystal [1-10], material composition [11-21], curing parameters [22-36], thickness [37-39], nanoparticles [40-42] and dyes [44-47] on the morphology and electro-optical properties of PDLC films. The correlation between materials and process conditions with electro-optical performances of PDLC are essential on the kinetics of phase separation and dynamics of matrix polymerization and for industrial manufacturing of flexible PDLC products.

In this respect, we have reported a series of studies on the effects of material and process parameters on morphology and electro-optics on industrial-scale flexible PDLC films [8,18-20, 28,30,34,35,38,39]. These studies have shown the effects of material and process parameters on matrix micro-structure; liquid crystal droplet size and number density; optical transmissions; switching voltages and response times in various UV-cured and thermoset PDLC formulations. Although the effect of various chemical and physical parameters on the performances of PDLC have been published extensively, the choice of high-temperature liquid crystal has not yet been published by industrial studies. Namely, by introducing high-temperature in PDLC formulation, it is expected not only to improve the phase separation, polymerization kinetics, morphology and electro-optical performance of PDLC products but also could provide the opportunity to expand their utilization for external application.

In the present work, we studied the effect of high-temperature liquid crystal in a dye-doped PDLC formulation on optical transmissions and switching voltage as a function of UV curing intensity and the process line speed in comparison with those in the same formulation with standard liquid crystal. It should be pointed out that, the main objective of this study is that, in contrast to current PDLC products for internal privacy markets, to provide an alternative road map for industrial development and commercialization of PDLC film and glass products for external applications.

Materials, Preparation and Methods

The utilized materials in PDLC formulations of this study include the standard liquid crystal QYPDLC142 (Q142) [Tni = +105°C, Tin = -20°C, no=1.525, Δn = 0.251] and high-temperature liquid crystal QYPDLC20603 (Q20603) [Tni = +125°C, Tnc = -20°C, no = 1.518, Δn = 0.205], both procured from Qingdao (CN); prepolymer N65 (NOA65) [np =1.524] obtained from Norland Optical Adhesives (USA); blue dichroic dye DBA purchased from Mitsui Fine Chemicals (JP); photo-initiators Irga-Cure 819 (819) and Irga- Cure 814 (814) obtained from Ciba (CH); UV absorber Tinuvin 400 (TV400) procured from BASF (DE); Acrylic Acid (AA) diluent procured from Kaitai (CN) and 25mm plastic micro-spacer Nano- Micron (NM) obtained from Suzhou Nano-Micro (CN). The utilized material compositions in dye-doped PDLC formulations in weight percent (%W) were as follows: Q142 or Q20603 = 40%; N65 = 51%; DBA = 0.5%; 819 = 0.2%; 184 = 1%; TV400 = 4%; AA = 4%; NM = 0.6%.

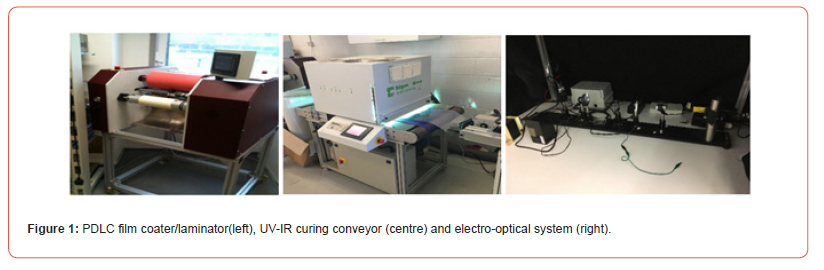

All materials were utilized as-such without further purification. The PDLC formulations and curing were carried out by Polymerization Induced Phase Separation (PIPS) technique with UV radiation method. The homogeneous mixtures of materials were placed in a vail and mixed with magnetic stirrers for 3 hours at 45°C. The uncured PDLC formulations were pre-heated at 50°C for 10 minutes and then, as presented in Figure-1, were poured between the vertical gap of two support ITO-PET film rolls on a custom-made coater/laminator system. Under the coating rolls the uncured PDLC sandwich were passed through a pressure roll to insure the uniformity of PDLC film. The thickness homogeneity of PDLC layers were insured by 25mm plastic NM micro-spacers. As presented in Figure-1, The uncured PDLC film samples were then cured on a custom-made UV-IR conveyor belt machine equipped with a high-pressure UV mercury lamp and infrared heater. The curing was accomplished by PIPS phase separation technique at UV intensity of 72 mW/cm2 and at the line speeds of 0.15, 0.3 and 0.45 meters/minute, respectively.

Each PDLC formulation was carried out on three samples and the reported electro-optical results were the average values of the three samples. Also as presented in Figue-1, the electrooptical properties of PDLC samples were carried out on a specially constructed bench-top photometric system mounted on an optical rail consisting of white light source, sample holder, photometer, amplifier, function-generator and electronic data acquisition network.

The optical transmissions and switching voltage of PDLC films were measured at room temperature through transmission-voltage curves with VAC square-wave at 100 Hz frequency. The total onstate transmission and haze of the PDLC samples were measured by BYK-Gardner Haze-Guard with a white light source.

Results and Discussion

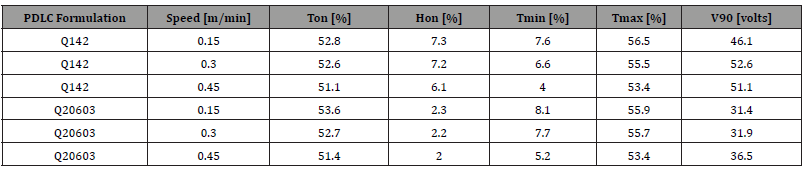

In Table-1, we tabulated the optical transmissions including the total transmission Ton, and haze Hon; specular transmissions Tmin and Tmax and the saturation voltage V90 in standard Q142 and high-temperature Q20603 of dye-doped PDLC films as a function of coating line speed. According to the experimental data of Table-1, the Ton (total transmission) range of Q142-PDLC (52.8 - 51.1%) and Q20603-PDLC (53.6 - 51.4%) are not affected by the line speed. Similar results are observed for Tmax (on-state specular transition), where its range in both Q142-PDLC (56.5 - 53.4%) and Q20603-PDLC (55.9 - 53.4%) are of the same order of magnitude of Ton as a function of the line speed. Also as provided in Table-1, the line speed does not show noticeable differences on the values of Tmin in both formulations.

Table 1:Effect of line speed on optical transmissions & operating voltage of Q142-PDLC & Q20603-PDLC films.

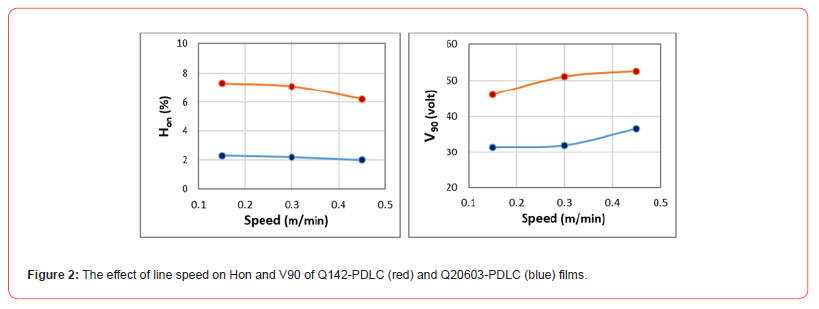

However as highlighted in Table-1, the line speed shows substantial differences on Hon (on-state haze) and V90 (saturation voltage) values between Q142-PDLC and Q20603-PDLC films. According to data of Table-1, in Figure -2, we present the behavior of Hon in Q142-PDLC and Q20603-PDLC films as a function of line speed in the two PDLC formulations. The results clearly demonstrate that Hon exhibits a significant decreasing values in Q20603-PDLC (2.3-2.0%) with respect to Q142-PDLC (7.3-6.1%) within the studied line speeds. The reduction of Hon by three times seems to arise from higher crystal-nematic transition and lower no values in Q20603-PDLC with respect to those in Q142-PDLC. In addition, the significant reduction of Hon could be also due to the presence of high polarity fluoro and cyano groups in Q20603 structures, which results to more efficient phase separation in Q20603-PDLC.

Also with reference to Table-1, in Figure-2, we present the V90 (saturation voltage) in Q142-PDLC and Q20603-PDLC as function of line speed. These results also reveal that, within the utilized line speeds, the V90 in Q20603-PDLC (31.4-36.5 volts) are decreased by 10-15 volts with respect to that in the Q142-PDLC (46.1-52.6 volts). Although we did not explore the morphology of PDLC films in the present, but knowing that the switching voltage and morphology have a reciprocal relation, it is clear that the origin of lower V90 values in Q20603-PDLC should be as a result of more efficient phase separation, larger liquid crystal droplet dimensions and number density, in comparison with those in Q142-PDLC films. The 20°C higher nematic-isotropic transition temperature and more functional groups of Q20603 (125°C) results to more favorable phase separation, polymerization kinetics and morphology that provides significant reduction of Hon and V90 in high-temperature Q20603-PDLC films.

Conclusion

The intention of this study was to develop high-temperature PDLC film with improved electro-optical performances for external applications. Accordingly, we utilized a base formulation and prepared dye-doped PDLC films including high-temperature Q20603 and standard Q142 liquid crystals. A comparison of electro-optical properties of model Q20603-PDLC and Q142 PDL films as a function of line speed demonstrated decreasing values and trends of total on-state haze (Hon) and saturation voltage (V90) in Q20603-PDLC films. It should be noticed that, in comparison to Q142-PDLC, the lower Hon and V90 values of Q20603-PDLC is significant for industrial development and manufacturing. Namely, the low Hon is a crucial parameter for visual quality; the low V90 is important energy saving factor and the high-temperature is an essential parameter for external utilization of PDLC products. This work provides a road-map for future systematic studies on other material and process parameters for industrial development of smart glass products for outdoor applications and markets.

Acknowledgement

This study has been funded by Gauzy Ltd and was carried out at the company’s R&D laboratories as a part of PDLC industrial development program during 2015-2016 period.

References

- JW Han (2002) Effect of the nematic-isotropic phase transition on the electro-optical characteristics of polymer-dispersed liquid crystal films. Journal of Korean Physical Society 40(5): 849-855.

- T J White, V Lalgudi Natarajan, J Bunning, CA Guymon (2007) Contribution of monomer functionality and additives to polymerization kinetics and liquid crystal phase separation in acrylate‐based polymer‐dispersed liquid crystals (PDLCs). Liquid Crystals 34(12): 1377-1385.

- W Li, H Zhang, L Wang, C Ouyang, X Ding, et al. (2007) Effect of a Chiral Dopant on the Electro-Optical Properties of Polymer-Dispersed Liquid-Crystal Films. Journal of Applied Polymer Science 105(4): 2185-2189.

- W Li, Y Cao, M Kashima (2008) Effects of the structures of polymerizable monomers on the electro-optical properties of UV cured polymer dispersed liquid crystal films. J Polym Sci Part B: Polym Phys 46(13): 1369-1375.

- J J Koo, Y S No, C W Jeon, J H Kim (2008) Improvement of Electro-Optic Properties in PDLC Device by Using New Cross-Linker for the Control of the Contrast Ratio. Response Time and Driving Voltage, Mol. Cryst, and Liq. Cryst 491(1): 58-66.

- M M Dzhons, S A Bulgakova, I A Pantyukhina, I A Kazantzeva (2011) Effects of chemical structure and composition of the polymer matrix on the morphology & electro-optical performance of polymer-dispersed liquid crystal films. Liquid Crystals 38(10): 1263-1268.

- Yuan-Di Chen, Andy Ying-Guey Fuh, Ko-Ting Cheng (2012) Particular thermally induced phase separation of liquid crystal and poly (N-vinyl carbazole) films and its application. Optics Express 20(15): 16777-16784.

- H Hakemi (2022) The Switching Voltages in Few Industrial-Scale Polymer Dispersed Liquid Crystal Formulations. Intern J Mod Res Eng Tech 7(2): 26-29.

- N H Nataj, A Jannesari, E Mohajerani, F Najafi, H Jashnsaz (2012) Photopolymerization Behavior and Phase Separation Effects in Novel Polymer Dispersed Liquid Crystal Mixture Based on Urethane Tri-methacrylate Monomer. J Appl Polym Sci 126: 1676-1686.

- Zuowei Zhang, Xian He, Luoning Zhang, Jianjun Xu, Baohua Yuan, Chao Chen, et al. (2024) A novel low-voltage fast-response electrically controlled dimming film based on fluorinated PDLC for smart window applications. Chemical Engineering Journal 479: 147668.

- U Maschke, A Traisnel, J D Turgis, X Coqueret (1997) Influence of Liquid Crystal Concentration on the Electro-Optical Behavior of Polymer Dispersed Liquid Crystal Films Prepared by Electron Beam Processing. Mol Cryst Liq Cryst 299(1): 371-378.

- MK Malik, P G Bhatia, RR Deshmukh (2012) Effect of nematic liquid crystals on optical properties of solvent induced phase separated PDLC composite films. Indian Journal of Science and Technology 5(10): 3440-3452.

- S A Bulgakova, A I Mashin, I A Kazantseva, D E Kashtanov, M M Jones, et al. (2008) Influence of composition of polymer matrix on electrooptical properties of films with a dispersed liquid crystal. Russian Journal of Applied Chemistry: 81(8): 1446-1451.

- R R Deshmukh, M K Malik (2008) Effects of the Composition and Nematic–Isotropic Phase Transition on the Electro-Optical Responses of Unaligned Polymer-Dispersed Liquid Crystals. I. Composites of Poly (methyl methacrylate) and E8. J Appl Polym Sci 108(5): 3063-3072.

- Cuihong Zhang, Dongrui Wang, Hui Cao, Ping Song, Chaoyong Yang, et al. (2013) Preparation and electro-optical properties of polymer dispersed liquid crystal films with relatively low liquid crystal content. Polymers for Advanced Technologies 24(5): 453-459.

- Kim J, I Han (2014) Effect of liquid crystal concentration on electro-optical properties of polymer dispersed liquid crystal lens for smart electronic glasses with auto-shading and auto-focusing function. Electronic Materials letters 10(3): 607-610.

- Ahmad F, Jamil M, Jeon YJ (2011) Comparative study on the electrooptical properties of polymer-dispersed liquid crystal films with different mixtures of monomers and liquid crystals. J Appl Polym Sci 121(3): 1424-1430.

- H Hakemi (2021) The Effect of Liquid Crystal Concentration on Morphology of Flexible PDLC Formulations Films. Mat. Sci. & Eng. Intern. Journal 5(5): 153.

- H Hakemi (2023) The Effect of Liquid Crystal Concentration on Electro-Optical Properties of Few Flexible PDLC Formulations. Material Sci. & Eng. Intern. Journal 7(5): 217-221.

- H Hakemi (2024) The Electro-Optical Performances of Flexible Polymer Dispersed Liquid Crystals as a Function of Liquid Crystal Concentration. Trends Tech. Sci. Res 7(1): TTSR.MS.ID.555704.

- Jae-Wook Seok, Yoon Soo Han, Younghwan Kwon, Lee Soon Park (2006) Structural effect of photo-initiators on electro-optical properties of polymer-dispersed liquid crystal composite films. Journal of Applied Polymer Science 99(1): 162-169.

- S A Carter, J D Le Grange, W White, J Boo, P Wiltzius (1997) Dependence of the morphology of polymer dispersed liquid crystals on the UV polymerization process. J Appl Phys 81(9): 5992-5999.

- J D LeGrange, S A Carter, M Fuentes, J Boo, A E Freeny, et al. (1997) Dependence of the electro-optical properties of polymer dispersed liquid crystals on the photo-polymerization process. Journal of Applied Physics 81: 5984.

- E Nastał, E Żurańska, M Mucha (1999) Effect of curing progress on the electrooptical and switching properties of PDLC system. Journal of Applied Polymer Science 71(3): 455-463.

- F Z Abdoune, L Benkhaled, X Coqueret, L Mechernene (2004) Effects of Ultraviolet-curing conditions on the electro-optical behavior of polymer dispersed liquid crystal films. Mol. Cryst. Liq. Cryst 422(1): 163.

- K J Yang, K P Kim, D H Kim, B D Choi (2009) The Effects of Conditions for Polymerization Induced Phase Separation Processes on the Electro-Optic Characteristics of Polymer Dispersed Liquid Crystals. Mol. Cryst. Liq. Cryst 498(1): 163-172.

- Jung‐Dae Cho, Sang‐Sub Lee, Su‐Cheol Park, Yang‐Bae Kim, Jin‐Who Hong (2013) Polymer‐dispersed liquid crystal by controlling photocure rate. J. Appl. Polym. Sci 130: 3098-3104.

- H Hakemi (2022) The Effect of Process Parameters on Morphology and Electro-Optics of a Polymer Dispersed Liquid Crystal Formulation. Intern. J. Mod. Res. Eng. Tech 7(2): 1-13.

- A D Kiselev, O V Yaroshchuk, L Dolgov (2004) Order of droplets and light scattering in polymer dispersed liquid crystal films. J. Phys.: Condense. Matter 16: 7183-719.

- YI Changhong, HU Gang, ZHU Bailin, CHEN Hongxiang, WU Jun, et al. (2022) Thermosetting Epoxy-based Polymer Dispersed Liquid Crystal (PDLC) Film Prepared by Quenching Process and Optimization of Their Optical Switching Properties. Materials Reports 36(8): 21010229-8.

- R R Deshmukh, M K Malik (2008) Effect of temperature on the optical and electro‐optical properties of poly(methylmethacrylate)/E7 polymer‐dispersed liquid crystal composites. J. Appl. Poly. Science 109(1): 627.

- S Dong, B Yan, X Wan, C Zhang Y Wang (2009) Effect of Macro-Initiator and Curing Time on Electro-Optical Properties of Polymer Dispersed Liquid Crystal. Device Technology & Physics 24(1): 48.

- S H Choi, J A Kim, G S Heo, H G Park (2022) Electro-optical characteristics of polymer-dispersed liquid crystal containing copper (II) phthalocyanine as a function of UV irradiation time. Journal of Molecular Liquids 363: 119821.

- H Hakemi (2020) The Effect of Cure Temperature & Time on the Morphology & Electro-Optical Properties of Flexible Thermoset PDLC Films. Mol. Cryst. Liq. Cryst 703(1): 1.

- H Hakemi (2020) The Effect of Cure Temperature on the Morphology & Electro-Optical Properties of Flexible UV-cured PDLC Films. Recent Progress in Materials 2(4): 11.

- Mujtaba Ellahi, Yanzi Gao, M Y Rafique (2013) Influence of enhanced curing temperature of epoxy monomers structure on the electro-optical properties and morphology of polymer-dispersed liquid crystal films. American Journal of Engineering Research 2(3): 1-6.

- Yamaguchi, S Sakurai (2014) Cell Thickness Dependence on Electric Optical Property of Reverse Mode Liquid Crystal Display. J. Photopolymer Scie. & Technology 27(3): 287.

- H Hakemi (2019) Effect of Thickness on Morphology & Electro-optics of a Plastic Thermoset Polymer Dispersed Liquid Crystal. Mol. Cryst. Liquid Crystals 681(1): 12.

- H Hakemi (2019) The Effect of Thickness on Electro-Optical Properties of a UV-Curable Polymer Dispersed Liquid Crystal. Mol. Cryst. Liquid Crystals. 689(1): 34.

- Wenbo Li, Mengjun Zhu, Xiaokang Ding, Bofu Li, Wei Huang, et al. (2009) Studies on Electro-Optical Properties of Polymer Matrix/LC/SiO2 Nanoparticles Composites. Journal of Applied Polymer Science 111: 1449-1453.

- Farzana Ahmad, Mohammad Luqman, Muhammad Jamil (2021) Advances in the metal nanoparticles (MNPs) doped liquid crystals and polymer dispersed liquid crystal (PDLC) composites and their applications - a review. Mol. Cryst. Liq. Cryst. 731(1): 1-33.

- F Ahmad, A Ri Jeon, Y J Jeon, M Jamil (2022) A novel technique of fabrication of nanoparticle acrylate doped polymer dispersed liquid crystal (PDLC) film. Journal of Dispersion Science and Technology. 43(10): 1506-1511.

- P Kumar, V Sharma, C Jaggi, K Kumar Raina (2016) Dye-dependent studies on droplet pattern and electro-optic behavior of polymer dispersed liquid crystal. Liquid Crystals 44(4): 757-767.

- P Malik, P Kumar, KK Raina (2006) Guest-Host Polymer Dispersed Liquid Crystal Display Device: Role of Dichroic Dye. Proceedings of ASID’06: 172-175.

- A Y G Fuh, CC Chen, C K Liu, K T Cheng (2009) Polarizer-free, electrically switchable and optically rewritable displays based on dye-doped polymer-dispersed liquid crystals. Optics Express 17(9): 7088.

- P Malik, K K Raina (2009) Dichroic dye-dependent studies in guest–host polymer-dispersed liquid crystal films. Physica B 405(1): 161-166.

- C P Chen, D S Kim, C G Jhun (2019) Electro-Optical Effects of a Color Polymer-Dispersed Liquid Crystal Device by Micro-Encapsulation with a Pigment-Doped Shell. Crystals 9(1): 364.

-

H Hakemi*. The Effect of High-Temperature Liquid Crystal on Haze and Voltage Improvements of Dye-Doped Polymer Dispersed Liquid Crystal Film. Mod Concept Material Sci. 7(2): 2025. MCMS. MS.ID.000658.

-

High-temperature, Liquid crystal, Dye, Optical transmission, Haze, Applied voltage, Electro-optical properties, Nanoparticles, PDLC products

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.