Opinion

Opinion

Pneumatic Textile Actuators for Transformable Spaces in the City of the Future

Simon Burmeister*, Bastian Baesch, Christoph Riethmüller and Götz T Gresser

German Institute for Textile and Fiber Research Denkendorf (DITF), Germany

Simon Burmeister, Smart Living Textiles Technology Center, German Institute for Textile and Fiber Research Denkendorf, Germany.

Received Date: July 01, 2021; Published Date: July 19, 2021

Opinion

Today more than ever, urbanization is a global trend. More and more people around the world are living in cities, making cities very important problem solvers of tomorrow’s world. This addresses ever new questions about connectivity and mobility, but also about urban planning itself. One focus is the future design of buildings. Pneumatic textile actuators can positively influence the need for active tensioning of textile facade elements for the construction of the future.

Initially, urban growth was strongly limited by the productivity of neighboring agriculture, as its surplus was the basis of supply [1]. However, this necessity was soon overcome, urban growth increased massively and in 2008, for the first time, more people lived in cities than in rural areas [2]. By 2030, the United Nations Population Federation projects 5.2 billion urbanites [3]. Cities have long since developed into conurbations, and there is increasing talk of redensification in their planning and organization. This refers to the use of vacant land in the area of existing developments and the increase in the volume of building space within existing developments.

In this way the building density increases (i.e. the space per built-up area) and additional apartments, stores and offices are created [4].

In the future, active facades will play a central role in the redensification of urban development projects and are a prerequisite for their implementation. The functional multiple use of addressed areas can make a positive contribution to this discussion. For such multiple uses of surfaces and spaces, a temporary redesign and transformation of these spaces will be necessary. Ecological and sustainable transformability can be achieved by active or activatable lightweight construction. In the form of activatable membranes, shading and noise protection elements, but also safety-relevant functions, such as active protection against high snow loads, can be switched on as needed. This prevents an oversized design and at the same time allows effective use of space as well as efficient use of required resources, since these are only needed and consumed when necessary. However, the basic prerequisite for active textile facades is the presence of large line forces and their exact control.

One promising approach to address the above problem is pneumatic textile actuators (PTA) as a new class of actuators. These flexible, lightweight and large-area actuators can be produced economically and quickly. They are manufactured as multilayer one-piece woven (OPW) fabrics close to the final contour with many degrees of freedom with regard to shaping. In the interests of economical surface sealing, the fabric surfaces are laminated from roll to roll in a subsequent process. The final shape can be achieved in individual cases by cutting by hand, but also by automated fabrication, e.g. using a cutting laser.

By design of PTA geometry leads to definable chamber with many degrees of freedom. Filling PTA with fluid both pressure conversion and pressure conduction are possible. They can be used directly after the laminating process, the cutting out from the fabric web and the connection to a compressed air system (Figure 1).

As shown schematically in Figure 1, the flooding of pneumatic textile actuators results in a shortening of the main geometry. This shortening is used in PTA to realize forces and movements.

The mode of operation of a PTA is very different compared to conventional pneumatic actuators. While in most pneumatic actuators the effective surface for the pressure remains aligned normal to the direction of the force during operation, the alignment of the effective surfaces in PTA changes during operation. This has both advantages and disadvantages. The main disadvantage is that, for this reason, the force of a PTA does not depend on the internal pressure alone, but also on the current length. The shorter a PTA becomes, the smaller the force it can still apply. At a shortening of 67 % of the initial length, no more additional force can be applied. However, PTAs also offer significant advantages such as their low weight.

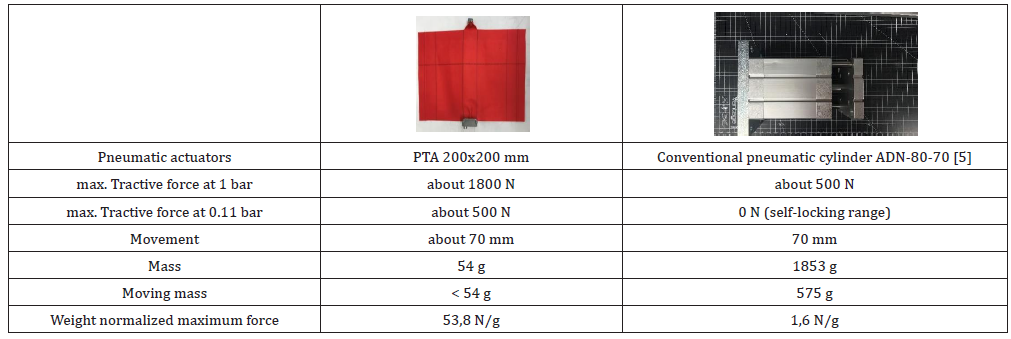

About 54 Newtons/gram actuator weight can be generated with a PTA. This is over 30 times more than a conventional pneumatic cylinder. Compared to conventional pneumatic actuators, PTAs have very low internal friction. Material friction only occurs in the contact areas of the two effective surfaces. Due to the yarn materials used, both the friction surfaces and the movements and additionally the friction values are very small in these areas. As a result, PTA can be operated at small differential pressures of well below one bar. Stick-slip effects, as in conventional pneumatic drives with pistons, therefore, do not occur. Energy efficiency can be significantly improved by reducing the operating pressure to well below 7 bar and by reducing leakage.

The following Table compares a PTA with a conventional cylinder:

Table 1:Comparison.

Due to their completely different mode of operation, PTAs have very different properties compared to conventional pneumatic actuators. Because of their characteristic as flexible textiles, they can only apply tensile forces without the use of further design elements. They are therefore ideally suited to the realization of line forces. A line force is a force with a two-dimensional point of application and not with a one-dimensional point of application.

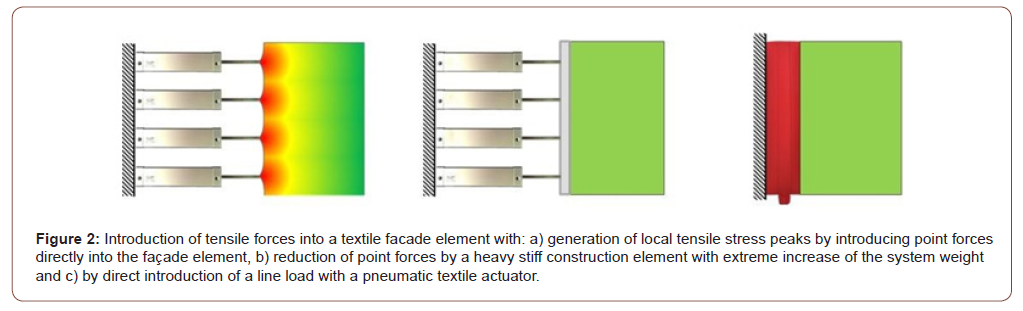

To create a line like force in the simplest case several point forces are distributed on an acting surface. By the approach of triggering different point forces as simultaneously as possible, a line force is generated and introduced into an object to be moved (Figure 2).

Here, the behavior of two or more-point loads added to a resulting line force is difficult to control. When several point loads are used, their force application cones overlap. Areas with different force vectors, especially not in the same direction, occur. Unclean designs and local deformations on force-converting and -transmitting structures lead to uneven tensions or to inhibitions or blockages in motion sequences, up to the destruction of textile facades.

Pneumatic textile actuators address this problem. This also makes them ideal for activatable convertible textile structures for architectural applications. These actuators can introduce forces uniformly into large textile surfaces, thus triggering actuating movements for the textile surfaces. In addition, PTAs can be equipped with textile sensors to ensure proper operation [6].

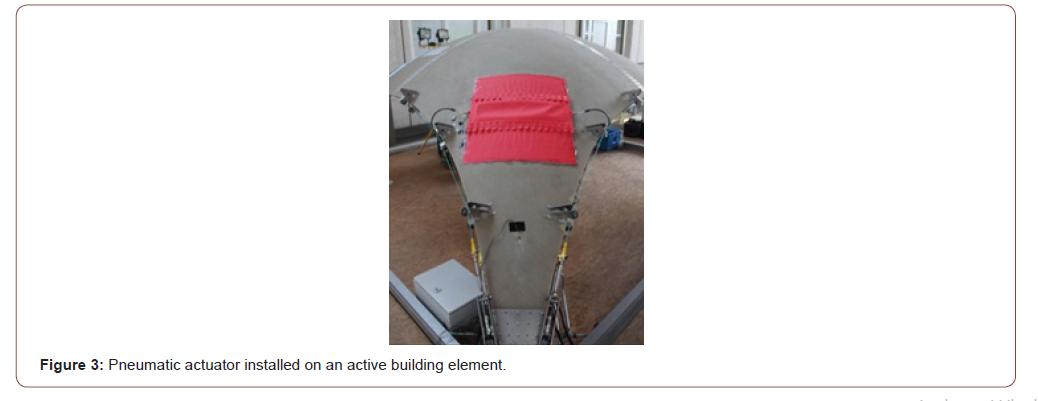

The DITF Denkendorf are engaged in various projects with the implementation of PTA in construction and facade applications. With PTA, new types of facades and sun protection systems can be controlled. The movement of entire supporting structures is also possible. In one project, for example, the maximum stresses occurring in a sheet metal structure were reduced by more than 30% by applying PTA. The additional weight required for the structure is negligible. Within the project, PTA was bonded to a sheet skeleton to enable replacement. In the real application, PTA can be integrated directly into the supporting structure surfaces. In real applications, PTA can be integrated directly into the structural surfaces, which can save more than 30 % of the building material or increase the spans by more than 30 %. The following illustration shows the surface structure with the applied PTA [7] (Figure 3).

Acknowledgement

This research project was sponsored by Deutsche Forschungsgemeinschaft e.V with Grant number FOR981A4.

Conflict of Interest

Authors declare no conflict of interest.

References

- Ibn-Mohammed T, Mustapha KB, Godsell J, Adamu Z, Babatunde KA, et al. (2020) A critical review of the impacts of COVID-19 on the global economy and ecosystems and opportunities for circular economy strategies. Resources, Conservation and Recycling 164: 105169.

- Khlaif ZN, Salha S, Fareed S, Rashed H (2021) The hidden shadow of Coronavirus on education in developing countries. Online Learning 25 (1): 269-85.

- El Said, Ghada Refaat (2021) How Did the COVID-19 Pandemic Affect Higher Education Learning Experience? An Empirical Investigation of Learners’ Academic Performance at a University in a Developing Country. Advances in Human-Computer Interaction.

- Darling-Hammond L, Flook L, Cook-Harvey C, Baron B, Osher D (2020) Implications for educational practice of the science of learning and development. Applied Developmental Science 24(2): 97-140.

- Kim S, Seong H, Her Y, Chun J (2019) A study of the development and improvement of fashion products using a FDM type 3D printer. Fashion and Textiles 6: 9.

- Kwon YM, Lee YA, Kim SJ (2017) Case study on 3D printing education in fashion design coursework. Fashion and Textiles 4: 26.

- Papachristou E, Chrysopoulos A, Bilalis N (2020) Machine learning for clothing manufacture as a mean to respond quicker and better to the demands of clothing brands: a Greek case study. International Journal of Advanced Manufacturing Technology: 12.

- Singha K, Kumar J, Pandit P (2019) Recent Advancements in Wearable & Smart Textiles: An Overview. Materials Today-Proceedings 16(3): 1518-1523.

- Park M, Im H, Kim DY (2018) Feasibility and user experience of virtual reality fashion stores. Fashion and Textiles 5: 32.

- Shou D, Fan J (2018) An all hydrophilic fluid diode for unidirectional flow in porous systems. Advanced Functional Materials 28(36): 1800269.

-

Simon Burmeister, Bastian Baesch, Christoph Riethmüller, Götz T Gresser. Pneumatic Textile Actuators for Transformable Spaces in the City of the Future. 8(5): 2021. JTSFT.MS.ID.000696.

-

Pneumatic textile actuators, Textile, Stores, One-piece woven, Fabrication

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.