Research Article

Research Article

Extraction and Characterization of Starch from Butula Lenta Plant

Lejalem Haile*

Ethiopian institute of Textile and Fashion Technology (EiTEX), Bahir Dar University, Ethiopia

Lejalem Haile, Ethiopian institute of Textile and Fashion Technology (EiTEX), Bahir Dar University, Bahir Dar, Ethiopia

Received Date: August 08, 2020; Published Date: August 25, 2020

Abstract

The extraction and processing of starch from agricultural commodities is one of the most important agro industries in the world. Starch was designed by nature as a plant energy reserve, but man has extended the use of starch far beyond this original design. Starch is a product commonly used in different industrial applications and is mainly sourced from food crops. In order to fulfil the current needs of starch, alternative nonfood products are required. Butala lenta is a common plant that is widely grown in many parts of Ethiopia. However, Butula lenta bark contains large amount of starch that could be extracted and used for industrial application. This work focused on extraction of starch from Butala lenta plant to supplement the existing costly starch-based products in the country, specifically for textile industries. The starch was extracted from Butula lenta bark through a wet starch extraction method and its applicability in textile sector particularly in sizing application was tested. The starch yield was 55.6% (on dry weight basis). The performance of extracted starch in textile sector is comparative with commercial starch obtained from Enset. Collection and extraction of starch from Butula lenta plant can be a new source of employment and creates job opportunities and income generations

Keywords: Butula lenta; Starch; Bark; Sizing; Textile

Introduction

Starch is the major carbohydrate reserve in plant tubers and seed endosperm where it is found as granules each typically containing several million amylopectin molecules accompanied by a much larger number of smaller amylose molecules. It is a glucose biopolymer and is the major storage component of most economically important crops: cereal (e.g. wheat, rice, Waxy rice, corn, Waxy corn, oat, barley); root/tuber (e.g. potato, sweet potato, arrowroot); leaves (sweet potato); legume (e.g. lentil, bean and pea) and yam (Dioscorea). It exists as water- insoluble granules, generally ranging in size between 3 and 60 micrometers.

Starch has many uses in both foods (e.g. binder, bulking agent, texture modifier, fat replacer) and nonfood (e.g. paper, cardboard, mining, pharmaceutical) industries.

Commonly, Isolation and purification of starch could be done sequentially starting from Supply /cleaning [ inspection of raw ma terial and separation of contaminants], steeping [for getting high yield and good quality product], Coarse grinding and de-germination [to free up the germs], Fine grinding and extraction [to completely disrupt the cells of the endosperm and release the starch granules], Gluten separation[ for separation of dissolved proteins or gluten through centrifugal separation method], Starch refining [reduction of fiber and protein content] and Dehydration and drying [to reduce water content from 65% to 40 %]. Since starch granules are insoluble in water and have high density (~1.5g/ml), most procedures for laboratory starch isolation from plant materials have used excess water to slurry or wash starch, and centrifugation to separate starch from other plant components [1].

Because of its wide application, still there is a huge gap in availability of starch in the market. In order to narrowing the gap, extraction and characterization of starch from different sources is a crucial aspect.

This research work focuses on extraction of starch from Starch rich waste material Butala lenta plant to supplement the existing costly starch-based products in the country, specifically for textile industries.

Materials and Methods

Materials, equipment’s and chemicals

Warp Yarn, Butala lenta bark, FTIR machine, Fabric, Beaker, Stove, Thermometer, PH meter, Dryer, Laboratory Sizing Machine, Portable yarn strength tester, Wet milling machine, high speed Stirrer and abrasion tester are required. Additionally, chemicals like Sodium bi-sulphate, Sodium hydroxide, Sodium hydrosulphite and Potassium bromide are used as anti-oxidizing agents during extraction.

Methods

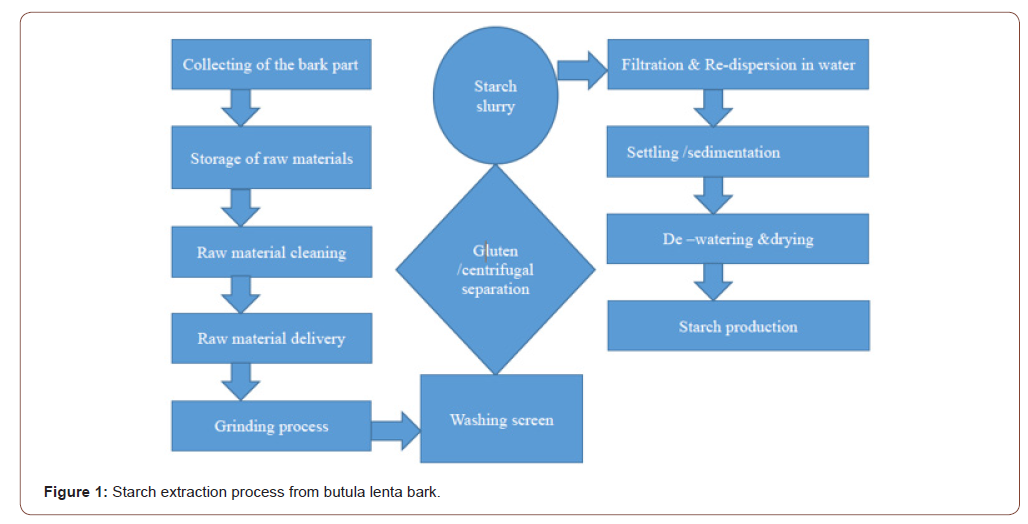

Starch Extraction: Initially, harvesting and collection of Butula lenta bark is done manually. After collection, external part of bark was removed by mechanical system. The collected bark was dried by sun light for two days (48 hrs.) in a temperature of 32 °C. The dried bark was stored in plastic bags at room temperature, 20-30 °C. However, the duration of the drying of the bark vary time to time depending upon the moisture content of the plant which is the result of maturity level of the plant. Particle size reduction (grinding) of dried bark was carried out to increase the mass transfer efficiency of the extraction. Once grinding operation is performed, filtering screen was washed for centrifugal separation of wastes like proteins, oils and so on. After centrifugation, filtration and re-desperation of starch slurry in the water were carried out. Then finally, settling/ sedimentation of produced starch and dewatering and drying was carried out for obtaining final product (Figure 1).

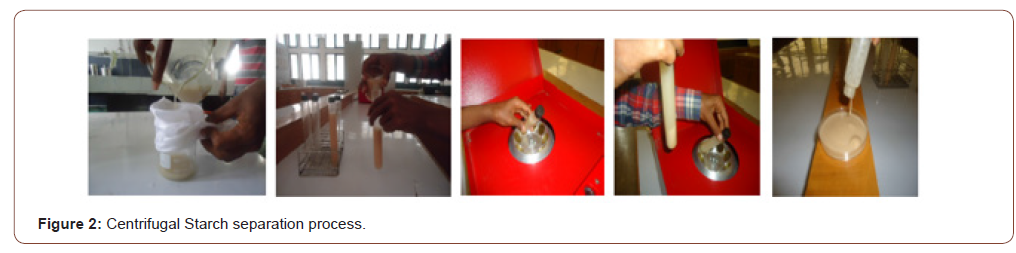

Gluten/centrifugal separation process: Butula lenta bark in powder form, distilled water, Circular centrifugal separator machine, Beakers and Oven dryer machine were used during separation of starch from gluten or protein parts. Preparation of powder pest, filtering of solution using filter paper, Addition of the filtered solution to 8 small beakers and inserting them in to circular centrifugal separator machine, removal of samples from the machine after 5 minutes’ rotation and finally, addition of sediment starch to petri-dish are sequential activates done during gluten separation (Figure 2).

Starch characterization functional group analysis: The chemical structure of sample was analyzed by a Spectrum Perkin Elmer ATR- FTIR covered by diamond reflection accessory for attenuated total reflectance. This analysis was done for identification of chemical compounds found in the sample through directing infrared ray towards the sample from which some of them are absorbed and the rest are passed (transmitted). The scan was done between 4000 cm-1 and 400 cm-1 averaged for each spectrum at intervals of 1 cm-1 with a resolution of 4 cm-1.

Iodine Test and pH: It is a test done to know whether the starch is present or absent. Once the starch and oil components are separated centrifugally, a drop of iodine solution is added on centrifugally separated sediments for approval of existence of starch. The result is approved by looking the color change seen after drop of iodine solution. In order to evaluate acidity and basicity of samples produced, PH test were carried out. The test was done by inserting litmus paper in a starch solution and looking color change of litmus paper.

Moisture content analysis: Since natural plant barks consists of large amount of moisture, this has to be removed 1st before start of extraction. Here the Moisture content is calculated on a wet weight basis and expressed to one decimal place. For samples tested without pre-drying the following formula were used to calculate the moisture content of a sample.

Here the amount of percentage yields that we get from the extraction depends upon; amount of theoretical yield, care taken during extraction of actual yield, the type of samples & other parameters.

Use of the extracted starch in textile applications: Product evaluation was carried out by application of extracted starch in textile sector particularly on cotton yarn and its performance were compared with standard starch sample. Finally, important characteristics of yarn that were controlled by sizing including strength regain after application was evaluated.

Sizing: The final product (extracted starch) was mixed with cold water and stirred using metal rod for 5 min. Additional water was added and the mixture was cooked for 45 minutes at 100 °C. application of sizing past on 5 cons of 20 count warp yarn was carried out by using laboratory scale sizing machine with running speed of 20m/min having cylinder drying temperature of 140 °C.

Strength regain and elongation at break: Initially the samples were allowed to be conditioned for 24 hrs., and tensile properties of warp yarn before sizing and after sizing were evaluated by using single yarn strength tester having 250mm gauge length. The test was carried out by using ASTM D-2256 taking breaking time of 20±2 s. the test was repeated for five times and the mean was calculated.

Results and Discussion

Functional group analysis

Calibration of FTIR machine, Coating Butula lenta powder pest on FTIR slide and observing two dimensional diagrams which mean by sample background verses frequency graph using computer interface device are sequential activities done during testing. After test, the following wave number versus transmittance results were obtained and the existing functional groups are detected by looking search-match software and by using large data base of standard compounds.

FTIR spectra in Figure 3 shows the functional groups of extracted starch sample. From the spectra, peaks in the range 3700–3600 cm−1; shows O–H stretching; 3400 and 3300 cm−1 N– H stretching; 2930 cm−1 C–H bond; 3000–2850 cm−1 range; C–H aliphatic stretching; 1830– 1650 cm−1; carbonyl stretching, C=N stretching at 1830–1650 cm−1 , 1080 cm−1 to 1158 cm−1 C–O–H bonds [2]. Using search-match software and large data base of standard compounds, all the above spectrum indicates the presences of starch and other constituent elements (Table 1).

Table 1:Results obtained after experiment.

Iodine test and pH

A drop of iodine solution was poured to centrifugally separated and prepared Butula lenta starch paste. The result showed a deep blue color (Figure 4) confirming the presence of laboratory scale starch in Butula lenta plant bark. Using litmus paper test, the pH value of 7.0 is obtained and indicating that, the PH value of pest solution is in acceptable range which was within 4.5 and 7.0. (National Starch and Chemical Company 2002).

Percentage of moisture content

Taking the initial weight of 90g Butula lenta bark, oven dry weight of 58.5g was obtained. Here after substitution of initial weight and oven dry weight in Equation 4, 35% of moisture content was obtained from the sample [3,4].

Percentage yield

The following general mechanisms has been used to evaluate percentage yield of a product.

Here the amount of percentage yields that we get from the extraction depends upon; amount of theoretical yield, care taken during extraction of actual yield, the type of samples and other related parameters (Table 2).

Application of the extracted starch in textile application

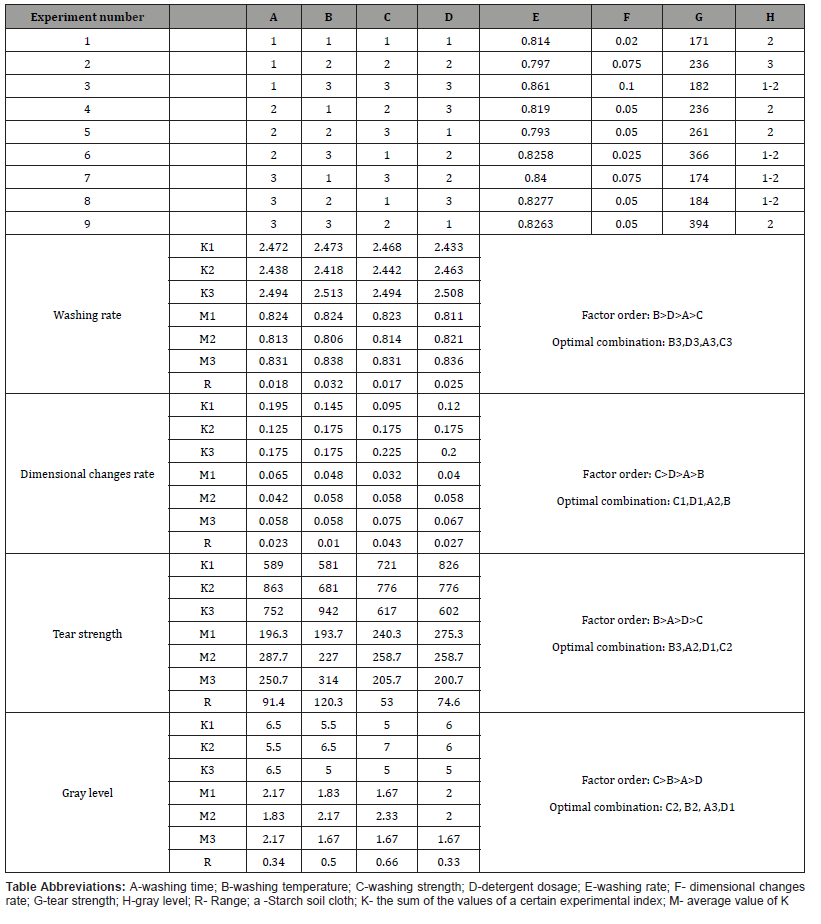

Yarn strength regains and elongation test: Universal yarn strength tester machine, sized and un-sized yarn are required for testing yarn strength regain and elongation. Here machine adjustment, yarn preparation and testing are sequential activities done during analysis. And finally, size regain were evaluated by using the following equation 5.

Where;

SR=yarn strength regains,

Sa=strength of yarn after sizing,

Sb=strength of yarn before sizing

Since the strength regain of sized yarn is within the recommended range i.e in between 15% - 40%, the result is so satisfactory (Tables 3&4).

Yarn abrasion test: using abrasion tester: A technique is described for the determination of yarn abrasion-resistance free from other wear factors such as flexibility, strength, elongation, and fabric construction [5,6] (Table 5).

Table 2:Yarn strength regains and elongation.

Table 3:Yarn strength test: using universal strength tester.

Table 4:Yarn abrasion test.

Conclusion

bark. The product yield analysis gives 56% starch and its presence was detected by using FTIR analysis and iodine test. Applicability of starch in textile sector is an indicative of its performance as a standard starch sample. Chemical concentration, time and temperature were parameters that was controlled during analysis and the response factors such as starch yield and its existence was evaluated in the meanwhile. Extraction of starch from Butula lenta bark is not that much sophisticated technology except its water consumption during extraction, the process has lower environmental impact. Technological and economic feasibility study of starch production and designing experimental plant for production were future works of this research [7-9].

Acknowledgement

None.

Conflict of Interest

None.

References

- ASTM D2256/D2256M-10 (2015) Standard test method for tensile properties of yarns by the single-strand method. ASTM International, West Conshohocken, PA, USA.

- Silverstein RM, Webster FX, Kiemle D, Bryce DL (2014) Spectrometric identification of organic compounds, (8th edn), Wiley, New York, USA.

- National Starch and Chemical Company (2002) 100 years starch history.

- Ellis RP, Cochrane MP, Dale MFB, Duffus CM, Lynn A, et al. (1998) Starch production and industrial use. J Sci Food Agric 77(3): 289-311.

- Jayakody L, Hoover R, Liu Q, Donner E (2007) Studies on tuber starch. II. Molecular structure, composition and physicochemical properties of yam (Dioscorea) starch grown in Sri Lanka. Carbohyd Polym 69(1): 148-163.

- Musa H, Gambo A, Bhatia P (2011) Studies on some physicochemical properties of native and modified starch from Digitaria Iburua and Zea mays. Int J Pharm Sci 3(1): 28-31.

- Nutan MT, Soliman MS, Taha EI, Khan MA (2005) Optimisation and characterisation of controlled release multi-particulate beads coated with starch acetate. Int J Pharm 294(1-2): 89-101.

- Tesfaye T, Johakimu JK, Chavan RB, Sithole B, Ramjugernath D (2018) Valorisation of mango seed via extraction of starch: pre- liminary techno-economic analysis. Clean Technol Environ Policy 20(1): 81-94.

- Ubalua A (2007) Cassava wastes treatment options and values addition alternatives. Afr J Biotech 6(18): 2065-2073.

-

Lejalem Haile. Extraction and Characterization of Starch from Butula Lenta Plant. 6(4): 2020. JTSFT.MS.ID.000642.

-

Butula lenta, Starch, Bark, Sizing, Textile, Coarse grinding, Centrifugation, Starch

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.