Mini Review

Mini Review

3D Printing in Modern Fashion Industry

Danmei Sun, School of Textiles and Design, Heriot Watt University, UK.

Received Date: March 21, 2019; Published Date: March 26, 2019

Abstract

The paper reported how 3D printing technology was integrated into fashion garment production process. It covers the discussions of design preparation and modelling tools, printing machine and related input material selection that suitable to be used for garments where flexibility and comfortability are required. The design and assembly processes have also been discussed using an example of a fashion tope with 3D printed sections.

Introduction

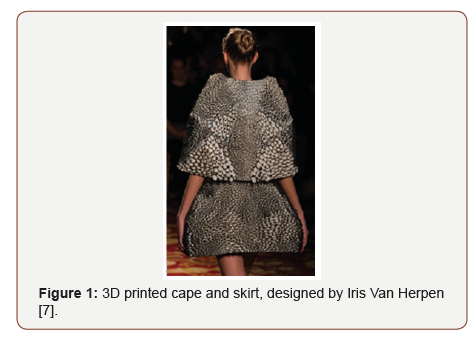

3D printing opens up new frontiers for making completed structures through a one-step process. 3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file [1]. In recent years 3D printing has been used for various application areas such as for reinforced metal composites [2], dental implants [3], industrial components [4], mobile devices [5] etc. 3D printing has become more popular to see that some designers try and make wearable garments made with AM, it is more widely used in manufacturing jewelries rather than full garments [6]. This can be explained by the fact that compared to full size garments, accessories are much smaller and have a wider range of available materials to be printed with. 3D printing technology has also been seen amongst fashion shows although in a much less instances compared to 3D printed accessories. One of them being the 3D printed cape and skirt that were designed by the high-fashion Dutch designer Iris Van Herpen [7], shown in Figure 1. It was printed by unique object connex multi-material 3D printing technology which allows a variety of material properties to be printed in a single build. The printing technology and choice of materials that both hard and soft make the garment crucial to the movement and texture of design.

3D Garment Manufacturing Techniques and Materials

As can be understood, nowadays, a wide selection of 3D Printers are available in laboratory scale with majority of them being 3D Printers that are small in size and their printing area, and commercial use for large scaled production applications. For manufacturing 3D printed garments FDM, SLS and PolyJet are the most often used, this is mainly due to the fact that the input materials allowed can provide good flexibility of the printed items. As flexibility is directly related to the comfortability of a garment to wears that is one of the most important aspects of wearable garments. As for the materials, mainly polymers or polymer composites are used due to being lighter in weight and flexible to allow movement [6].

A wide selection of filament types as input materials for 3D printing is available for commercial use and manufacturing. ABS is a type of low-cost material that is suitable for printing durable products applied in high temperature environment. PLA is made for dimension accuracy purpose applications. PETG can provide water resistance and provides the printed item smoother surface finish. Carbon fiber filled filament helps with printed products that require high strength and stiffness for the end use requirement. Polypropylene is excellent for high-cycle, low strength applications due to its fatigue resistance, semi-flexible and lightweight characteristics. PVA as a water dissolvable material is used as a type of support material for complex prints. Flexible filaments such as TPE and TPU are for printing easily stretch and bend products due to their good elasticity performance [8]. A relatively recent development has become available that filaments have added characteristics especially proving more flexible feature to the printed items. It still does not provide the same abilities as silk filament, for example, but allows the finished garment to move much more easily.

Design and Modeling Tools

The process of 3D printing starts with the creation of a 3D geometric model – a design file and the format of the file needs to be comparable with the software that is built into the 3D printer being used for 3D printing and manufacture. The 3D geometric model can be created either in 3D modelling software or generated through 3D-scanning an objective shape to be printed. The software developed for a specific printer gives directions to the printer’s components of what needs to be completed and preparing such files is rarely an uncomplicated process [9].

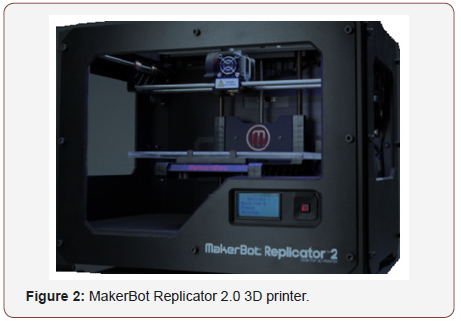

In this study, different types of 3D printers were tried on for making designed pieces to be welded together with fabric to make a full fashion garment. After many trials and error processes it was realized that the best printer available to meet with demands of the final product was the MakerBot Replicator 2.0, shown in Figure 2, which has a built-in slicing software called MakerBot Make ware.

To model 3D printable designs, software’s widely used by architects and engineers for industrial design, usually complete the files by a computational algorithm. But for designers, who are not familiar with CAD modeling, generative parametric designing tools prove to be more useful [6].

Another widely used design software is Google Sketchup – a no cost, easy to navigate program popular amongst beginners [9]. Adding to that, this software was also trialed during this research but proved to be too simplistic for the designs necessary to be developed.

It needs to be mentioned, that even though the designing of a 3D printable object is important, an even more crucial and difficult part of it is the final stage of re-assuring the file is compatible to be printed. Lipson, et al. [9], note quite frequently that if the design file is faulty, it slows down the manufacturing process massively. The file format used most frequently in 3D printing is the STL, which has been one of the formats used the longest by the industry, is proving not always to be able to keep up with the advanced printing technology and design softwares of today.

“After a design file has been converted to STL, the STL “wraps” the design object’s digital “shape” inside a virtual surface, called a mesh, that’s made up of thousands (or sometimes millions) of interlocked polygons. Each interlocked polygon (triangles are frequently used) in the surface mesh holds information about an object’s shape [9].

Design and Assembly Processes of Fashion Top

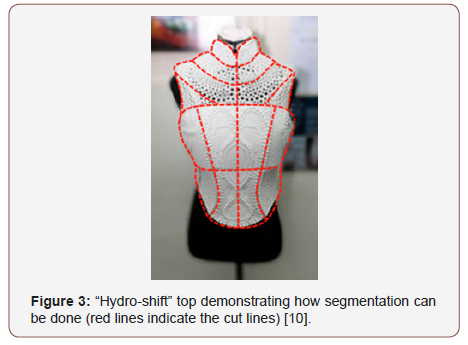

Due to the small available printing area are for most widely used commercial 3D printers, it is almost impossible to print a whole garment in one setting. For this research the print was done in parts and then assembled together with other part of the garment where needed. These parts will be created through segmentation of the whole design/pattern. This technique has been practiced by Lim, et al. [10], who developed an innovative Hydroshift Top and won the top prize in a Singapore International Fashion 3D Printing Competition. They challenged entrants to mix 3D printing with fashion. Their work exhibited ‘substainability’ with water as inspiration that brings together the elements of fluidity in nature, tradition, art and the unlimited potential offered by 3D printing, shown in Figure 3.

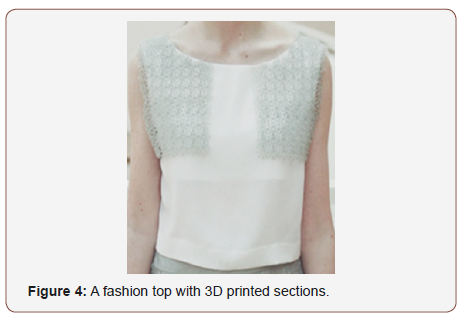

Figure 4 shows the completed fashion top with 3D printed sections shown in light green color. It shows different capabilities of 3D printed garment. Through its placement and components, it demonstrates that it can bend and adapt to the human form exactly like the top part made from fabric.

It was made using the Circle Knot Chainmain and by extruding one component of the chain. The pieces were then assembled together and made changes in dimension to get the right size panel for the fashion top. As a guideline for the fit the adapted blouse block was used and separated into different parts that would be the right size for the printing area as shown in Figure 5. An accurate size of a vector is then created to guide and check the panel that ensures the exact needed size.

The panel was separated into three parts for each size of the garment, and the top part is presented in Figure 6, showing the pattern and size of the part to be printed, for the designing stage of the research work. During the printing process it was understood that the 3D printer took a relatively longer time to complete all the printable sections of the two pieces for the garment.

Once the parts were printed, they then were melted together, and hand sewn on at the seam of the top made from fabric. There are many possibilities for the assembly of the parts, and it is up to the designer to choose which is more suitable for the end product. A few ways assembling the panels:

• Bond with adhesive;

• Bond by melting together;

• Through special physical joining mechanisms like hooks, screws etc. [6].

Such application process would not be feasible for mass production, but if the product is intended for the high-end market it is not uncommon to have certain embellishment parts constructed in such a design and production approach.

Conclusion

With 3D printing technology, it allows fashion designers and technologists to create innovative fashion garment partially or entirely. By trialing certain structures of chainmail, it is possible to reach a final decision on appropriate structures for the design.

The initially set out designs were fully completed in achieving the aim of producing a garment which cohesively featured two methods of garment constructing, 3D printing and sewing. Though, the research met with several obstacles, the concept was carried out and proven that both methods of manufacture can coexist and result in a wearable garment. So, in the sense of the main aim of the project which was to produce a collection, which featured these components, were met.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- (2019) What is 3D Printing?

- Hu Z, Chen F, Xu J, Nian Q, Lin D, et al. (2018) 3D printing graphenealuminum nanocomposites. Journal of alloys and compounds 746: 269- 276.

- Londono J, Tadros M, Salgueiro M, Baker PS (2018) Digital design and 3D printing of an implant-supported prosthetic stent for protecting complete arch soft tissue grafts around dental implants: A dental technique. J Prosthet Dent 120(6): 801-804.

- Sathish T, Vijayakumar MD, Ayyangar AK (2018) Design and fabrication of industrial components using 3D printing. Materials today: proceedings 5(6): 14489-14498.

- Lara-Prieto V, Brava-Quirino, E, Rivera-Campa M, Gutierrez-Arredondo JE (2015) An innovative self-learning approach to 3D printing using multimedia and augmented reality on mobile devices. Procedia computer science 75: 59-65.

- Yap YL, Yeong WY (2014) Additive manufacture of fashion and jewellery products: a mini review. Virtual and physical prototyping 9(3): 195-201.

- (2019) Iris van Herpen Debuts Wearable 3D Printed Pieces at Paris Fashion Week. Materialise.

- (2019) Ultimate 3D Printing Materials Guide.

- Lipson H, Kurman M (2016) Fabricated: The new world of 3D printing. Indianapolis: Wiley, John & Sons, USA.

- O’Neal B (2015) This 3D printed ‘hydroshift top’ symbolizes water as energy.

-

Danmei Sun and Agita Valtasa. 3D Printing in Modern Fashion Industry. J Textile Sci & Fashion Tech. 2(2): 2019. JTSFT.MS.ID.000535.

-

Procurement, Management, Supply Structures, Manufacturing, Geographical, Chains, Knitwear, Consumer, Interstitial spaces, Managerial investigation, Design-engineering, Theoretical framework, Chain risk, Innovative, Literature, Momentum, Economic-financial effects.

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.