Mini Review

Mini Review

Pulse Discharge Technology for Strengthening of Foundations

Sokolov NS, Chuvash State University, Russia.

Received Date: April 09, 2021; Published Date: May 06, 2021

Abstract

The problem of increasing the bearing capacity of a foundation is always an urgent one in today’s geotechnical construction. With significant loads transferred to foundations, the use of traditional technologies is not always justified. There is often an urgent need to use non-standard methods of strengthening the foundations. In many cases, the geotechnical situation is aggravated by the presence of weak underlying layers with unstable physical and mechanical characteristics in the engineering-geological sections. When reinforcing such foundations with the help of traditional piles, the latter can receive negative friction, which significantly reduces their bearing capacity on the ground, sometimes reaching zero values. This can lead to additional precipitation of objects being erected and objects already erected in the zone of geotechnical influence. The use of Electric Discharge Technology (EDT) piles in most cases successfully solves many complex geotechnical problems.

Keywords: Geotechnical construction; Soil-concrete pile; Electric discharge technology; Electric discharge technology bored injection pile; Intermediate broadening (thrust bearing); Escapes

Mini Review

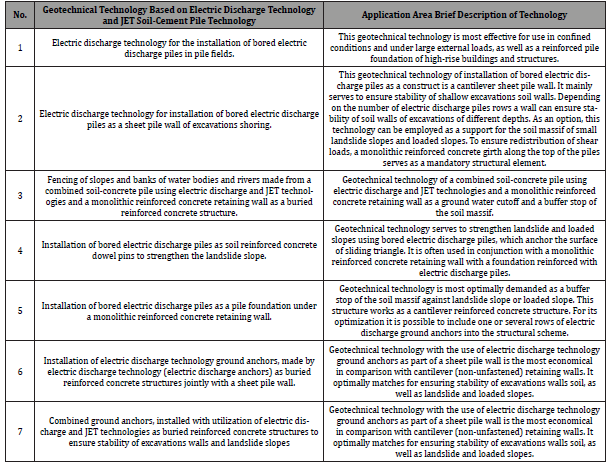

Electric discharge technology possesses a number of technical and technological advantages [1-29] and is widely used in geotechnical practice for the installation of bored electric discharge piles in pile fields, underpinning piles of basements and foundations, fixing foundation bases, slopes, when installing dowels, etc. Its technological advantage is the explosive transformation of electrical energy into mechanical energy. In this case, the energy density of electro-hydraulic shock reaches up to 150.0 J/m3 for a very short time (fractions of microseconds). An electro-hydraulic shock to the soil of the walls of a well hole filled with fine-grained concrete corresponds to a static load on it of up to 200.0 kPa. As a result of exposure to such high pressures and temperatures, a cavity is formed in the soil due to gravity forces, which is filled with fine-grained concrete. Thus, widening occurs at a specific section along the height of the electric discharge pile. Hereinafter, this widening will be called the “thrust bearing” [17-29]. Thus, an additional support appears, statically working together with the piles along the lower surface of the widening and increasing its bearing capacity along the ground. In the first approximation, the geometric parameters of the widening shape can be taken as a sphere. Such sphere parameters, for example, as diameter d and its height h, depend on the energy of the electrohydraulic shock, porosity, moisture, and the type of treated soil. Widening diameter d can be determined by the value of the maximum decrease in the level of fine-grained concrete in the well hole, or by ‘escapes’ as geotechnical specialists say. It should be noted, of course, that the values of ‘escapes’ vary significantly during electrohydraulic processing (which is why, when installing electric discharge piles, the level of fine-grained concrete should always be kept at the level of the earth’s surface) and over time. ‘Escapes’ over time from the beginning of pouring concreting to the beginning of concrete hardening can range from several centimeters to several meters. First of all, such large depressions are related to specifics of the soil as a porous material. These vertical movements of the fine-grained concrete are further increased by the electro-osmotic suction of the cement milk into the soil structure (Table 1).

Table:Brief description of technology.

It should be said that with maximum volumes of cement milk suction into the soil pores, the bearing capacity of an electric discharge technology pile would increase many times due to involvement of the strength characteristics of soil mass such as specific cohesion and the angle of internal friction in joint work with a pile. This process is prevented by the fact that during fine-grained concrete mixing and electro-hydraulic processing, the former is magnetized, which contributes to the formation of cement colloids. At the same time, their sizes are many times larger than the soil pore sizes. Unfortunately, there is no technology yet to prevent the cement milk from clumping. This is only possible when demagnetizing the water bipoles in concrete. It is necessary to pay attention to another aspect related to a possible increase in the bearing capacity of the foundations reinforced with bored piles. Among design engineers, the opinion is that the larger the diameter of bored pile, the greater its bearing capacity on the ground. Yes, this is correct. In our opinion however the criterion for assessing the bearing capacity Fd on the ground should not be a pile diameter and length, but ‘specific bearing capacity on the ground’, i.e. bearing capacity of one cubic meter of a bored pile, as well as ‘specific design load’, i.e. design load of one cubic meter of a bored pile. With this approach, by analyzing calculations results for the bearing capacity of electric discharge piles and bored piles of different diameters, it can be concluded that with an increase in the diameter of the bored piles, the specific bearing capacity decreases, approaching a certain asymptote. At the same time, the most optimal in terms of specific characteristics are “micropiles”, i.e. electric discharge piles made by electric discharge technologies.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Cai F, Ugai K (2000) Numerical analysis of the stability of a stope reinforced with piles. Soils and Foundations 40(1): 73-84.

- Hassiotis S, Chamcau JL, Gunaratne M (1997) Design method for stabilisation of slopes with piles. Journal of Geotechnical and Geoenvironmental Engineering 123(4): 314-323.

- Lee JH, Salgado R (1999) Detervination of pile base resistance in sands. Journal of Geotechnical and Geoenvironmental Engineering 125(8): 673-683.

- Mandolini A, Russo G, Veggiani C (2005) Pile foundations: experimtntal investigations, analysis and design. Ground Engineering 38(9): 34-38.

- Ilichev VA, Mangushev RA, Nikiforova NS (2012) Experience of Development of Russian Megacities Underground Space. Soil Mechanics and Foundation Engineering 2: 17-20.

- Ulickij VM, Shashkin AG, Shashkin KG (2010) Geotechnical Support of Urban Development. St. Petersburg, Georeconstruction Publ P.551.

- Ilichev VA (2004) Deformations of the Retaining Structures Upon Deep Excavations in Moscow, Russia pp: 5-24.

- Ilyichev VA (2007) Computing the evaluation of deformations of the buildings located near deep foundation tranches 2: 581-585

- Nikiforova NS (2011) Geotechnical cut-off diaphragms for built-up area protection in urban underground development.

- Nikiforova NS (2004) The use of cut off different types as a protection measure for existing buildings at the nearby underground pipeline installation, pp: 338-342.

- Petrukhin VP (2003) Effect of geotechnical work on settlement of surrounding buildings at underground construction.

- Triantafyllidis Th (2007) Impact of diaphragm wall construction on the stress state in soft ground and serviceability of adjacent foundations, pp: 683-688.

- Sokolov NS (2018) Ground Ancher Produced by Electric Discharge Technology, as Monolithic Reinforced Concrete Structure. Key Engineering Materials 771: 76-81.

- Sokolov NS (2018) Use of the Piles of Effective Type in Geotechnical Construction. Key Engineering Materials 771: 70-74

- Sokolov NS (2018) One of Geotechnological Technologies for Ensuring the Stability of the Boiler of the Pit. Key Engineering Materials 771: 56-69.

- Sokolov NS (2018) Regulated injection pile-electric discharge technology with multiple pile enlargements posed as an underground reinforced concrete structure with a controlled load capacity pp: 601-608.

- Sokolov NS (2018) One of the geotechnical technologies to strengthen the foundation base in constraint environment in the addition of 4 floors. 18: 513-522.

- Sokolov NS, Viktorova SS (2018) Method of aliging the turches of objects targe-sized foundations and increased loads on them. Key Engineering Materials pp:1-11.

- Sokolov NS, Sokolov AN, Sokolov SN, Glushkov VE, Glushkov AE (2017) Calculation of Increased Bearing Capacity Bored Piles. Housing Construction 11: 20-26.

- Sokolov NS (2017) The Foundation of Increased Bearing Capacity Employing Bored Electric Discharge Piles with Multi-seat Broadening. Housing Construction 9: 25-29.

- Nikolay Sokolov, Sergey Ezhov, Svetlana Ezhova (2017) Preserving the natural landscape on the construction site for sustainable ecosystem. Journal of applied Engineering Science 15: 518-523.

- Sokolov NS (2018) Ground Ancher Produced by Electric Discharge Technology, as Monolithic Reinforced Concrete Structure. Key Engineering Materials 771: 76-81.

- Sokolov NS (2018) Use of the Piles of Effective Type in Geotechnical Construction. Key Engineering Materials 771: 70-74.

- Sokolov NS (2018) One of Geotechnological Technologies for Ensuring the Stability of the Boiler of the Pit. Key Engineering Materials pp: 56-69.

- Sokolov NS (2018) Regulated injection pile-electric discharge technology with multiple pile enlargements posed as an underground reinforced concrete structure with a controlled load capacity. pp: 601-608.

- Sokolov NS (2018) One of the geotechnical technologies to strengthen the foundation base in constraint environment in the addition of 4 floors. pp: 513-522.

- Sokolov NS, Viktorova SS (2018) Method of aligning the lurches of objects with large-sized foundations and increased loads on them. Key Engineering Materials pp: 1-11.

- Nikolay Sokolov (2020) Electroimpulse Device for Manufacture of Continuous Flight Augering Piles. Current Trends in Civil and Structurual Engineering.

- Nikolay Sokolov (2020) Approach to Increasing the Carring Capacity of the Pile Base. Current Trends in Civil and Structurual Engineering.

-

Sokolov NS. Pulse Discharge Technology for Strengthening of Foundations. Cur Trends Civil & Struct Eng. 7(2): 2021. CTCSE.MS.ID.000660.

-

Geotechnical construction, Soil-concrete pile, Electric discharge technology, Electric discharge technology bored injection pile, Intermediate broadening (thrust bearing), Escapes

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.