Mini Review

Mini Review

Development of the Trenchless Installations for Underground Structures in Highway Systems

Carl M. Duan*

Senior Bridge Engineer and Specialist of Culverts and Underground Structures, California Department of Transportation, USA

Carl M. Duan, Senior Bridge Engineer and Specialist of Culverts and Underground Structures, California Department of Transportation, USA.

Received Date: September 09, 2019 Published Date: September 12, 2019

Characteristics of HSLA Steel

There are many underground structures, such as culverts, tunnels and vehicle undercrossing in transportation systems throughout the world. These structures are used to convey water, wildlife, fish, pedestrians and vehicles. Their roles are just as important as surface structures, such as bridges. Cut-and-cover, immersing and trenchless installations are the three major methods to construct underground structures. For an installation of buried structure, the specific method should be chosen based on the factors such as geotechnical properties in subgrade, environment impact, cost and the degree of disturbance to the highway traffic above it. Currently, it is becoming more popular to use trenchless installations including tunneling methods for new structures and trenchless replacement method for existing structures. Comparing to cut-and-cover method, trenchless installations provide much less impact to the roadway traffic and the environment.

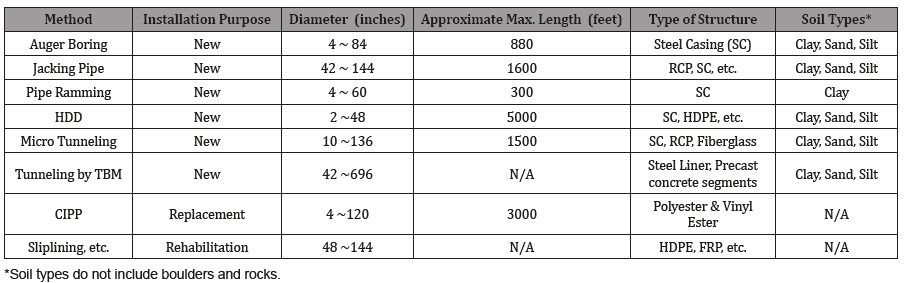

The trenchless installation method can be used to install a utility line with a small cross-sectional size of 4 inches in diameter for hundreds of feet long as well as a large facility with a width of 51 feet for 5.6 miles, as in the case of Chongming Tunnel across Yangtze River in Shanghai. Trenchless technology (TT) consists of a wide range of methods, materials, and equipment for installing new or rehabilitating existing underground structures. Frequently used tunneling methods include Pipe Jacking for pipes or concrete boxes, Horizontal Direct Drilling (HDD) for pipes, Auger Boring using steel casing (SC), Pipe Ramming using SC, Micro-tunneling, Tunneling by Tunneling Boring Machin (TBM) and so on. On the other hand, Cured-In-Place-Pipe (CIPP) is an effective method to replace existing pipes in place, and Slipling is used to rehabilitate existing pipes. Major trenchless installation methods, size limits and approximate maximum lengths are summarized in Table 1.

Table 1:Major Trenchless Installation Methods

Installation

Proper geotechnical investigation of site, planning, design, and selection of compatible construction methods, materials, and equipment are very important for the successful installations of the underground structures in highway systems. One concern in trenchless installations is the road surface settlement when a hole underneath is created and a gap between the pipe and the adjacent soil exists. This is typical when a tunneling structure has a relatively shallow earth cover above it. An assessment to the roadway surface settlement during planning is needed to see if the amount of roadway subsidence is acceptable. Some tunneling methods can make this subsidence decreased during installation. For example, tunneling by TBM can reduce this concern by using a self-adjustable tunnel liner system such as rib and lagging liner system. The significant benefit of the rib and lag liner is the ability of the jacked casing to expand the tunnel liner after it exits the jacking shield against the adjacent soil to reduce potential for roadway subsidence. Structural analysis needs to be performed to check the integrity of the tunneling structures during construction under loadings such as horizontal jacking force, earth pressure, distributed live load from trucks and so on. Currently, there is a lack of unified methods to conduct this analysis. In addition, standard specifications for tunneling installations are another important document for the owners to adopt a specific method of installation.

Design for Service Life

If a tunneling structure is used as a permanent structure, it shall be designed for its service life. Currently, the structures in the U.S. highway system are designed using LRFD methodology. There is a large discrepancy in determining the appropriate soil or rock pressures applied to the tunneling structures. Improved methods in soil-structure interaction analysis should be developed for the safety, durability and the cost of the project. In the past, most of the buried structures in highway systems are not designed for seismic loading. But underground structures without seismic design in many countries suffered damages in the past earthquakes. For important utility lines and for large size tunneling structures, i.e., when the span is over 20 feet, seismic design is needed. AASHTO Technical Manual for Design and Construction of Road Tunnels has covered seismic design only for the tunnels used for traffic. Most of the methods used in seismic design are based on structural analysis using software. Experimental model tests and corresponding structural analysis are needed to validate those methods. Practical seismic design criteria using performance-based design methodology need to be established [1-3].

Development in the Future

With future forecast of traffic density higher and higher, trenchless installations, with least impact to traffic, will be used more frequently. The innovated trenchless installations have been developed in recent years to meet the project needs. The trenchless technology, design and installation specifications should be improved to keep up with the trend.

Acknowledgement

The author would like to express his deep appreciation to K.C. Liu in California Department of Transportation for his review and valued comments.

Conflict of Interest

No conflict of interest.

References

- AASHTO (2010) Technical Manual for Design and Construction of Road Tunnels. American Association of State Highway and Transportation Officials. Washington, DC, USA.

- Tom Iseley and Gokhale Sanjiv (1997) Trenchless Installation of Conduits Beneath Roadways—A Synthesis Practice. NCHRP Synthesis 242, Transportation Research Board, Washington DC, USA./a>

- Carl M. Duan and Wai-Fah Chen (2015) Analysis and Design of Buried Structures under Earthquake Loading. Access Science, McGraw Hill Education, USA.

-

Carl M. Duan. Development of the Trenchless Installations for Underground Structures in Highway Systems. Cur Trends Civil & Struct Eng. 3(5): 2019. CTCSE.MS.ID.000573.

-

Underground structures, Culverts, Tunnels, Transportation systems, Surface structures, Environment, Tunneling, Construction

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.