Research Article

Research Article

Assessment of Scaffolding Systems in Addis Ababa Public Building Projects; Current Practice, Related Problems, and Potential Solutions

Samson D Gelmessa1, Werku K Hareru2 and Tewodros Ghebrab3*

1,2Department of Construction Technology and Management, School of Civil Engineering and Architecture, Institute of Technology, Dire Dawa University, 1362, Dire Dawa, Ethiopia

3Departemnt of Civil, Environmental and Construction Engineering, Texas Tech University, Texas, USA

Tewodros Ghebrab, Departemnt of Civil, Environmental and Construction Engineering, Texas Tech University, Texas, USA

Received Date: June 14, 2024; Published Date: June 28, 2024

Abstract

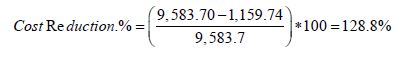

The assessment of the current practice and related issues of the scaffolding systems in Addis Ababa public building projects are presented. Public building construction projects of at least five stories high were studied using both qualitative and quantitative data analysis. This research was conducted using the Stratified sampling method, in which 120 copies of the questionnaires were distributed to respondents, and 112 of them responded. The research findings indicated that eucalyptus wood dominated the current practice of scaffolding materials in Ethiopia building construction. Of the selected buildings, 43.75% used eucalyptus wood, 31.25% used metal, and the remaining 25% used combinations of both scaffolding materials. The financial capacity of the main contractors, the initial cost of the material, and the foreign currency problem in importing the construction materials were identified as the main factors limiting the implementation of modern scaffolding materials. The study identified that 77.5% of the contractors preferred to use wooden scaffolding due to its lower initial cost. Generally, most contractors prefer to use metal scaffolding over eucalyptus wood; however, the associated higher initial cost forced most of the contractors to use eucalyptus wood material for scaffolding. However, RHS H-frame metal scaffolding with diagonal bracing offers a superior lifespan (50 years) compared to the conventional eucalyptus tree scaffolding, resulting in 128.8% cost reduction in scaffolding expenses, particularly for large-scale projects.

Keywords: Scaffolding system; eucalyptus wood; metal scaffolding; temporary structures; Addis Ababa

Background

Ethiopia is a developing country with rapid urban expansion. Due to the increased population and business activities, many highrise buildings are being constructed in the urban areas, especially in the capital city, Addis Ababa, and reginal and Federal cities: Dire Dawa, Adama, Sheger City, Hawassa, Mekele, Jigjiga, and Bahir Dar. All stakeholders in the construction industry are interested in achieving a successfully completed project. Thus, managing successful building construction projects requires addressing the issues related to the cost, speed, quality, and safety of the construction project [1]. The scaffolding system is one of the key factors that determine the success of building construction projects. It greatly affects the construction cost, especially in constructions involving heavy concrete work. According to the ACI [2], the cost of formwork in the United States can be as much as 60% of the total cost of concrete structures.

Scaffolding is a formwork system used in building high-rise construction projects. It creates a safe and stable working platform for workers and also serves as a temporary storage of construction materials [3]. If it is not properly designed and assembled, scaffolding could negatively impact project performance, create workspace conflicts, and cause safety hazards [4]. According to Anumba and Roofigari-Esfahan [5], a significant number of failures of temporary structures, such as scaffolding and temporary support systems, are recorded every year resulting in approximately 100 deaths, 4500 injuries, and $90 million in financial losses annually. Ethiopia is one of the many countries in the world that mainly use conventional scaffolding and other temporary structure systems in the construction of high-rise buildings. Owing to the growing urbanization in the country, it is crucial to conduct a detailed study on the system to improve the existing trends in the use of scaffolding and other temporary structures. The use of eucalyptus wood for conventional scaffolding has a negative impact on project activity. For instance, the erection of eucalyptus scaffolding takes longer time which can cause a delay in the construction time of the project; the reusability of the material is very low due to the sustained damages during the initial construction and exposure to various environments, which incurs additional cost. To upgrade the scaffolding systems in the country, it is imperative to assess and understand the current practice and identify the factors that could impede upgrading the systems.

Literature Review

Temporary Structures

Temporary structures in construction are any system constructed to provide temporary support, accessibility, safety, etc. in construction projects. Falsework, scaffolding, formwork, shoring, bracing, platforms, and underpinning are some of the commonly used temporary structures. Most temporary structures are removed when the project is completed or the permanent structure gains sufficient strength. These structures have a significant influence on the quality, safety, speed, and economy of a project [6]. Temporary supporting structures such as scaffolding, shoring, and underpinning are structures that provide a safe working environment to the workers when performing construction activities at higher elevations or temporary support to the permanent structural components until they achieve the required strength [7,8]. However, these structures could cause catastrophic accidents unless they are designed and constructed with high safety provisions [8].

Scaffolding

Scaffolding is a temporary structure constructed to provide the construction crew with an elevated platform to work on and easy access to difficult spots in the project. Scaffolds are common because they are convenient, versatile, and economical [9]. Scaffolding materials are required for all types of structures constructed above ground level. They are commonly used in various construction activities such as new construction, renovation, wall construction, painting, surface preparations, plastering, etc. [10].

According to Wylde [10], shoring and scaffolding materials are used as access in addition to supporting the workers and the permanent structures. Access scaffolds are used to support small to medium loads and provide safe movement access for the construction workers, and temporary storage for the construction materials and equipment [10]. However, the failure of these structures accounts for the major accidents that resulted in largescale injuries and fatalities worldwide [8]. According to Halperin and McCann [11], scaffolding-related accidents could be either due to the falling of workers or objects from the scaffolding or the collapse of the scaffold itself. According to Kim and Teizer [12], successful project completion is also influenced by the scaffolding; however, the planning, construction, and management of scaffolding do not get proper attention in most construction activities [4,13,14]. Thus, scaffolding could influence project performance, impose safety concerns, and create workspace conflicts [4,14]. Therefore, to account for a safe, efficient, and profitable project, the proper selection of the type of scaffolding and the scaffolding materials and sound design and construction of the scaffolding is very important.

There are several scaffolding types used in the construction industry including supported scaffolding, suspended scaffolding, cantilever scaffolding, mobile scaffolding, and aerial lifts scaffolding [15]. Each type of scaffolding has its advantages and limitations. According to Mesaros and Mandicak [16], the modern method of construction of scaffolding is influenced by the following factors: cost of the project, skills and experiences of the workforce, quality of construction, and construction pace and time. Construction managers are required to make selections of the appropriate type of scaffolding which is crucial for the successful execution of the project [17]. During the selection of scaffolding systems, consideration should be given to technical efficiency, commercial viability, financial viability, and availability [10]. Steel, timber, or bamboo are the commonly used scaffolding materials. Steel scaffoldings have good longevity and can be reused many times, unlike timber which has limited reuse. Thus, most contractors prefer to use steel formwork and scaffolding because of the material reusability and longevity [17]. Proper selection of scaffolding also requires basic knowledge of site conditions and the type and scope of the project [18].

Safety Provisions in Building the Scaffolds

The design, construction, and management of scaffolding are crucial for the safety and successful delivery of a project. The construction of scaffolding following the proper safety standards could eliminate the risk of catastrophic failures [4]. Many standard codes of practice specify the construction details of scaffolding with regard to the provision of working platforms, their minimum width, guard rails, and toe boards. The codes also provide broad guidelines for the bracing and tying of scaffolds [9].

Research Methodology

The objectives of this study were to assess the current practice of scaffolding systems in Addis Ababa, identify the key factors affecting the transition to using modern scaffolding materials, compare the conventional and modern scaffolding systems, and finally suggest solutions that could improve the current practice of scaffolding systems in Addis Ababa, Ethiopia. The research objective was achieved by employing a pilot survey, desk study, site observations, and questionnaire. The questionnaire was designed to collect information helpful to fulfill the research objectives. The data collection targeted the stakeholders in the public building projects in Addis Ababa: the contractors, the consultants, and the owners in the public building sectors. The survey specifically targeted project engineers, project managers, office engineers, resident engineers, resident architects, and owner representatives. In addition to encouraging respondents to provide a narrative to supplement their responses, the questionnaire contained Likert-type questions that asked the respondents to rate the provided possible factors affecting the transitioning to modern scaffolding systems from 1 to 5 (1 = not influential and 5 = extremely influential). The study design was descriptive and exploratory. A purposive sample selection method was used to determine sample size. The target population for this research was building construction projects that comprised all target groups: the employer, the consultant, and the contractor. Quantitative and qualitative data were used in this study and analysed using SPSS software and Microsoft Excel tools. Out of 120 distributed questions, 112 responses were obtained with 93.3% response rate. The number of responses was enough to proceed with the next steps of the study.

Results and Discussion

Reliability of the collected data

The Cronbach’s alpha coefficient calculated from the collected data was 0.99, which indicates greater internal consistency of the items in the scale.

Identification of Respondent’s information

Based on the information gathered, 71% of the respondents were from the contractor side, 26.5% from the consultant side, and 2.5% from the owner’s side.

Identification of Respondent’s job position

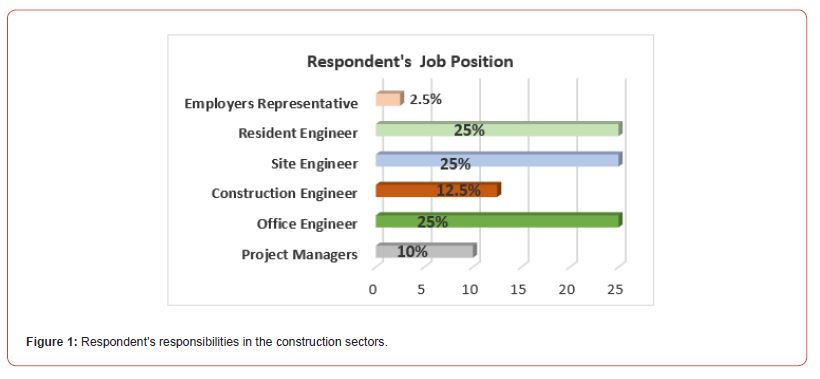

The distribution of the respondents in titles and job assignments in the construction sectors is summarized in Figure 1.

Identification of Respondent’s Experience

The work experiences of the respondents were as follows: 17.5% have over ten years, 37.5% from five to ten years, and 45% from two to five years of experience.

Identification of the common scaffolding materials

Eucalyptus wood, metal, or a combination of both is the commonly used scaffolding material in construction projects in Addis Ababa. According to the results obtained from the survey questionnaire, 31.25% of the public building projects in Addis Ababa used metal/steel scaffolding, 43.75% used wood/eucalyptus scaffolding, and the remaining 25% used a combination of both metal and wood scaffolding materials. The results further indicated that most of the contractors preferred to use wood scaffolding over metal due to the lower initial cost of the former. Metal/steel scaffolding has better quality in relation to safety, durability, and reusability, despite the higher initial cost. However, it is primarily used in high-rise buildings in Addis Ababa. In general, the results indicate that traditional materials are still dominating the current practice of scaffolding systems in Addis Ababa.

Wooden scaffolding material

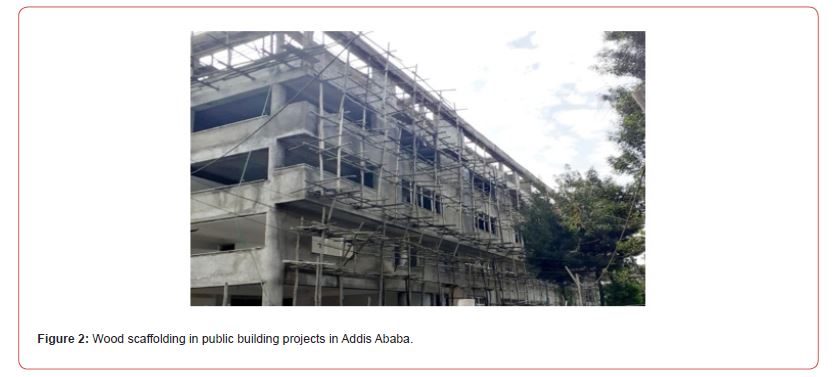

The study results indicated that wood (mainly eucalyptus) is the most common material used for scaffolding in the construction of public building projects in Addis Ababa (43.75 %). Due to its versatility, eucalyptus wood provides cheaper solutions and is best suited for light jobs and irregularly shaped building structures. It is an ideal solution for low-rise buildings; however, its durability and quality are easily affected by bad weather conditions, which could lead to the failure of the structural elements. The spacing and amount of scaffolding material depend on the selected material and the method of construction. For the construction of the wooden scaffolding structure, the building projects used 10 cm and 12 cm diameter posts spaced at 60 cm and 100 cm intervals in the longitudinal direction along the perimeter of the buildings. The spacing of the eucalyptus posts depends on the shape and height of the building. Figure 2 shows a sample public building project in Addis Ababa where wooden scaffolding materials were used.

Metal scaffolding material

Metal or steel scaffolding materials are also common materials, next to eucalyptus wood (31.25%). Most public building construction uses H-frame rectangular hollow sections (RHS) metal scaffolds. Figure 3 shows a sample public building where metal scaffolding materials were used.

Combined metal and wood scaffolding material

This is another option to minimize the cost of the scaffolding material. 25% of the public building projects in Addis Ababa use a combined wood and metal scaffolding when working on irregularly shaped buildings. Since the wooden material can be cut and fixed at any dimension it is possible to construct on the irregular part of the building. The results showed that four public building projects used such types of scaffoldings.

Identification of scaffolding systems

The materials and methods used for constructing scaffolding vary from one building project to another. From 16 selected public building projects, 4 (25%) used a suspended scaffolding system, 10 (62.5%) used a supported scaffolding system, and the rest 2 (12.5%) used a supported and suspended scaffolding system. Most of the public buildings in Addis Ababa used a supported scaffolding system. In this system, many workers can work simultaneously from different sides of the building because the temporary structure is already constructed around the exterior part of the building. The next popular method is a suspended scaffolding system shown in Figure 4, in which the scaffolding material is typically suspended from the rooftop and adjusted in an elevated direction.

Source of scaffolding material

The scaffolding materials were obtained from various sources: 81.25% were purchased from local markets, 6.25% were fabricated by the companies, and 12.5% were imported. Therefore, there should be a balanced supply of scaffolding materials in the local market.

Factors affecting the implementation of modern scaffolding systems

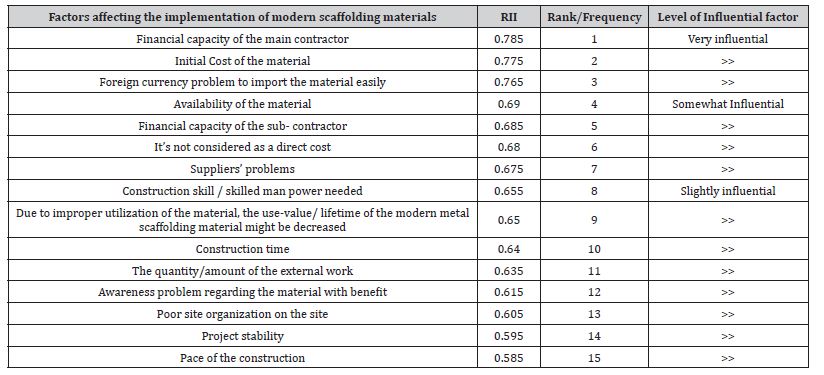

Table:1 Rank of factors affecting the implementation of modern scaffolding material.

The researchers listed some factors obtained from the pilot survey and included them in the questionnaire to be ranked by the respondents. The respondents’ ratings of the factors based on their degree of significance and their relative importance index (RII) are shown in Table 1.

In agreement with Waziri and Vanduhe [19], the rating of at least 0.76 was considered as the most significant. The results in Table 1 indicated that the financial capacity of the main contractor, the initial cost of the material, and the foreign currency problems to import the material are the very main factors significantly affecting the employment of modern scaffolding systems. The availability of the material, the financial capacity of the sub-contractors, the material not being considered as a direct cost, and the supplier’s problems were ranked as significant (0.67-0.75).

The financial capacity of the main contractor

According to the respondents, the financial capacity of the main contractor was rated as one of the most influential factors in the employment of modern scaffolding systems. Of the sixteen public building projects selected for the study, more than 80% were constructed by Grade-1 contractors (GC-1) and 43.75% of the projects used eucalyptus wooden scaffolding materials. A significant number of GC-1 contractors use eucalyptus scaffolding due to its relatively low initial cost. This indicates that most of the main contractors face financial challenges in introducing a modern scaffolding system.

The initial cost of the scaffolding material

The initial cost of the metal scaffolding material is very high compared to that of eucalyptus wood. Therefore, most contractors prefer to use conventional wooden materials to minimize the initial expenses. There is a huge cost difference between the wooden and metal scaffolding materials. This vast price difference could be one of the key reasons for the popularity of bamboo scaffolding in China and Hong Kong [20].

Foreign currency problem to import the material

Getting foreign currency to import construction materials is a serious problem in most developing countries. The resulting fluctuations in the exchange rate impact the price of materials. Thus, the contractor’s financial capacity to import the required modern materials gets challenged by the market instability.

Comparison of Conventional and Modern Scaffolding Material

Regarding material cost

The survey response indicated that 77.5% preferred wooden scaffolding because of its low initial cost while the rest 22.5% preferred metal scaffolding material.

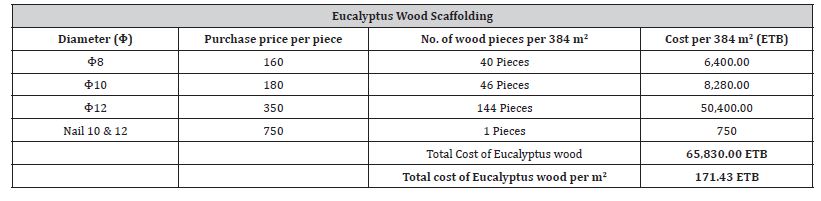

Table:2 Cost of eucalyptus wood scaffolding material per 384 m2 construction area.

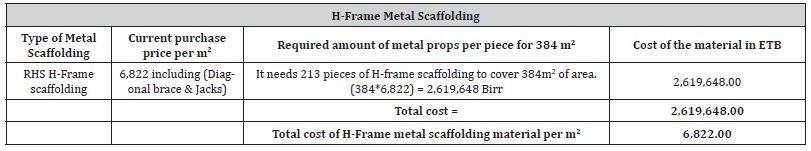

Table:3 Cost of H-Frame metal scaffolding material per 384 m2 construction area.

Case study for cost comparison

The costs of wooden and metal scaffolding materials commonly used in Ethiopia were assessed based on the data collected from local contractors and presented in Tables 2 & 3, respectively. The price is given in Ethiopian Birr (ETB).

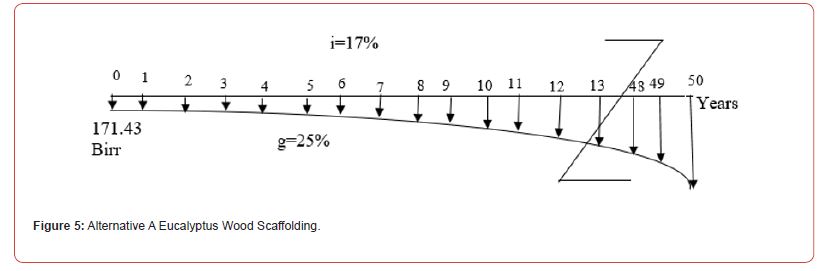

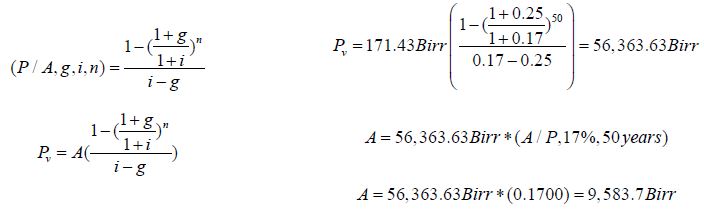

Alternative A: Eucalyptus Wood Scaffolding

Insert Figure 5 here

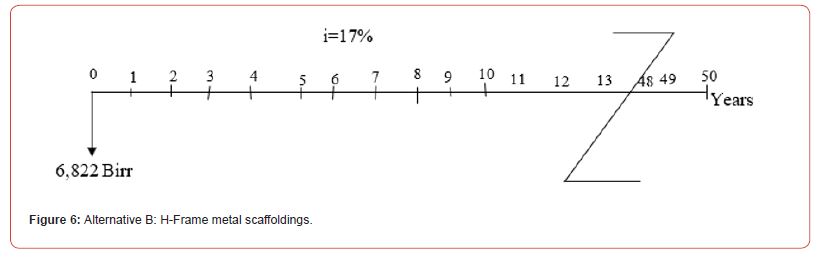

Alternative B: H-Frame Metal Scaffolding

To compare the cost of wooden and metal scaffolding materials, the service life of the wooden and RHS H-frame metal scaffoldings are 1 year and 50 years respectively. As a case study the researcher evaluated the actual current cost of both materials for the construction of scaffolding. In order to construct 1m2 scaffolding using eucalyptus wood material, the diameter of 8, 10 and 12 eucalyptus woods cost 171.43 Birr (USD 2.96). The price of eucalyptus wood varies from one place to another. For the comparisons and precious average cost of different regions were taken. For metal scaffolding there is RHS H-frame metal scaffolding with diagonal bracing materials. The current purchase price of H-Frame metal scaffolding material is also fluctuating from time to time. According to the current purchase price, it’s 6,822 Birr (USD 117.67) per 1m2 area. The actual cost of both materials per m2 is listed in detail in Figure 4 and Figure 5. Current bank rate is 17% interest and g=25 % which is the constant rate of change by which amounts increase from one period to the next were considered. In general, the initial cost of metal scaffolding surpasses that of wooden initially, however, metal scaffolding has a longer lifespan (50years). The cost per square meter of both metal and wooden scaffolding varies from one project to another. The primary factor contributing to this cost discrepancy in scaffolding is the condition of the scaffolding utilized in construction projects. A detailed breakdown of the direct costs of wooden and metal scaffolding is presented Figure 4 and Figure 5 illustrates the cost breakdown for wooden and metal scaffolding. Consequently, RHS H-frame metal scaffolding with diagonal bracing offers a superior lifespan (50 years) compared to the conventional eucalyptus tree scaffolding, resulting in 128.8% cost reduction in scaffolding expenses, particularly for large-scale projects.

If the contractor only considers a single project on his hand, he might be profitable by using wooden material due to the initial cost being very low, however, though it has a relatively high initial cost, metal scaffolding material could be more profitable in long term due to its durability, longevity, and reusability.

Impact of labor cost

The survey response indicated that 80% of the respondents expressed that metal scaffolding has less labor cost than wooden scaffolding. Both scaffolding materials are constructed by the same skilled laborers (carpenters) who demand the same labor cost per hour/day. However, the amount of time required to construct scaffolding varies. Since the erection and demolition processes of metal scaffolding are very simple and take little time relative to wooden scaffolding materials, it is possible to minimize the overcost of labor. The current cost of a carpenter and daily laborer in Addis Ababa are 500 ETB and 250 ETB per day, respectively.

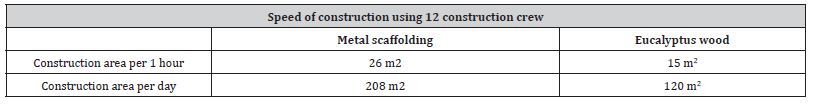

Impact of construction time

Based on the construction time, 90% preferred metal to wooden scaffolding. Metal scaffolding materials are more easily erected and disassembled compared to wooden scaffolding materials. Metal scaffolding has prearranged connection joints to easily assemble the system and create a stable structure in a short period. Thus, the extra time required for the erection and disassembling processes can be reduced. Further, the metal scaffolding erection and disassembling process is safe for workers. During the scaffolding erection and demolition processes, both materials have their systems. The erection process of wooden scaffolding materials mainly depends on the skills and experiences of the carpenter and the quality of the wood. Since there is no specific manual, the labor may use an excess amount of wooden material and nails. The overall process may also take a long time. In general, metal scaffolding has several advantages in terms of cost and time. Table 4 shows that using metal scaffolding for the external part of the building is 73% faster than using eucalyptus wood material. On a single working day, it is possible to construct 208 m2 scaffolding using a metal scaffolding material. This indicates that the amount of work that can be conducted using metal scaffolding is more advantageous than wooden materials in maintaining the construction progress on a schedule. In addition, it is possible to minimize the construction time and prevent project cost overrun problems.

Table:4 Speed of construction for metal and wooden scaffolding materials.

Comparison of safety

According to the survey data, all of the respondents preferred metal scaffolding for safety, especially for high-rise buildings in which safety is of the highest priority. However, most contractors are discouraged by the associated initial cost of employing metal scaffolding.

Comparison of Quality

The controlled fabrication methods provide metal scaffolding of higher quality than wooden scaffolding materials. The survey response attests to the fact that 97.5% of the respondents preferred metal scaffolding to wooden scaffolding. This could be attributed to the durability of the material and availability of the predesigned assembly joints. Wooden materials are more susceptible to bad weather conditions, do not have specific joints, and are easily damaged during construction processes.

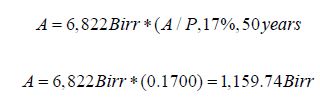

Identification of re-usability of scaffolding material

According to the data shown in Figure 5, 72.5% of the respondents agreed that wooden scaffolding material cannot be reused more than one or two times. 20% of the respondents agreed wooden scaffolding materials can be re-used more than three times. The rest 7.5% believed that wooden material can be re-used more than four or five times. The reusability of wooden materials is limited. However, the extent of reusability depends on the method of erection and disassembling processes and the level of exposure to harmful weather conditions. The skills of the carpenters could also affect the extent of the reusability because the system requires proper assembling and disassembling processes. Figure 6 also shows that 95% of the respondents agreed that metal scaffolding can be re-used over five times (50 times) while the remaining 5% agreed on four or five times. If metal scaffolding is properly used and maintained, it can be reused for a longer period; otherwise, its service lifetime might be short and incur unnecessary expenses.

Conclusions

a) In Addis Ababa building projects, eucalyptus wood and metal are the two types of materials commonly used for scaffolding construction.

b) The use of conventional eucalyptus wooden scaffolding systems dominated the construction of the public building projects in Addis Ababa. The use of metal scaffolding; however, is limited to about 31% though it is durable, reusable, and efficient. This could be due to its relatively higher initial cost that discouraged the contractors with a limited resource.

c) According to the results, 25% of the selected building projects used a combination of both materials. This is mostly recommended for irregularly shaped buildings.

d) According to the results, 62.5% of projects used a supported scaffolding system. Supported scaffoldings were symmetrically constructed from the bottom upward. This is the most common scaffolding system used in building projects in Ethiopia.

e) The second was a suspended scaffolding system. Approximately 25% of the projects used this scaffolding system. The structure is typically suspended from the roof of the building. This is most commonly used where it is not possible to construct scaffolding from the base upwards of the structure.

f) Most of the contractors also preferred to use metal scaffolding material according to the safety of the workers, construction time including the erection and demolition process of the scaffolding material, and the quality of the scaffolding material and related work. 72% of the respondents believed that wooden scaffolding could not be reused more than once or twice. According to the survey results, 95% of the respondents agreed that metal scaffolding could be reused many times.

g) In general, the current practice of scaffolding systems and materials should be improved to enhance the project success and safety of workers. It is also not considered as a direct cost of the project. Therefore, most professionals focus on temporary structures

h) Lastly, the usage of temporarily assembled metal scaffolding is advised to promote Ethiopian government policy’s green legacy and reduce the number of trees that are cut down and used for scaffolding systems in the building business.

Conflict of Interest

“The author declares that there is no conflict of interest regarding the publication of this paper.”

Funding Statement

No government or private funding was received for the study.

Acknowledgments

The authors would like to express their sincere gratitude to the Dire Dawa University and the Addis Ababa City construction workers.

References

- BA Sida (2015) Cost, Quality and Speed Comparison of Steel and Timber Formwork System Used for Building Projects (A Case Study in Addis Ababa). Master of Science Master's Thesis, School of Civil and Environmental Engineering, Addis Ababa University, Addis Ababa, Ethiopia.

- (2014) ACI-347, Guide to Formwork for Concrete. ACI PRC-347-14(21): 2014.

- Scaffolding eTool. U.S. Department of Labor.

- Z Yin, C Caldas (2020) Scaffolding in industrial construction projects: current practices, issues, and potential solutions. International Journal of Construction Management 22(4).

- C Anumba, N Roofigari Esfahan (2020) Cyber-Physical Systems in the Built Environment.

- R Ratay (2004) Temporary Structures in Construction – USA Practices. Structural Engineering International 14: 292-295.

- SP a. B, Arora SP (2010) The Text Book of Building Construction. India: Dhanpat Rai & Co. pp. 350.

- HB Ismail, KDA Ghani (2012) Potential Hazards at the Construction Workplace due to Temporary Structures. Procedia - Social and Behavioral Sciences 49: 168-174.

- K Jha (2012) Formwork for Concrete Structures.

- HC Wylde (1989) The Selection and Operation of Construction Plant and Equipment. Civil Engineer's Reference Book, LS Blake (Eds.), 4th ed Butterworth-Heinemann, USA pp. 36/1-17.

- KM Halperin, M McCann (2004) An evaluation of scaffold safety at construction sites. Journal of Safety Research 35(2): 141-150.

- K Kim, J Teizer (2014) Automatic design and planning of scaffolding systems using building information modelling. Advanced Engineering Informatics 28(1).

- K Kim, Y Cho, S Zhang (2016) Integrating work sequences and temporary structures into safety planning: Automated scaffolding-related safety hazard identification and prevention in BIM. Automation in Construction 70: 128-142.

- Z Yin, C Caldas (2022) Scaffolding in industrial construction projects: current practices, issues, and potential solutions. International Journal of Construction Management 22(13): 2554-2563.

- E Kelemework (2017) Assessment in current practice of shoring and scaffolding systems in building construction in Addis Ababa. MSc, Addis Ababa University.

- P Mésároš, T Mandičák (2015) Factors affecting the use of modern methods and materials in construction. IOP Conference Series: Materials Science and Engineering 71: 012053.

- E Elbeltagi, P Eng (2012) Lecture notes on construction planning and scheduling. Mansoura University.

- L Wu, Y Mohamed, H Taghaddos, U Hermann (2014) Analyzing Scaffolding Needs for Industrial Construction Sites Using Historical Data pp. 1596-1605.

- BS Waziri, Vanduhe BA (2013) Evaluation of Factors Affecting Residential Building Maintenance in Nigeria: Users’ Perspective. Civil and Environmental Research 3(8): 19-24.

- WK Yu, KF Chung, SL Chan (2005) Axial buckling of bamboo columns in bamboo scaffolds. Engineering Structures 27(1): 61-73.

-

Samson D Gelmessa, Werku K Hareru and Tewodros Ghebrab*. Assessment of Scaffolding Systems in Addis Ababa Public Building Projects; Current Practice, Related Problems, and Potential Solutions. Cur Trends Civil & Struct Eng. 11(2): 2024. CTCSE. MS.ID.000757.

-

Scaffolding system; eucalyptus wood; metal scaffolding; temporary structures; Addis Ababa; Iris Publishers; Iris Publishers Group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.