Research Article

Research Article

EFFiTILL: An Efficient Tillage System for Tractors Fuel Consumption Reduction and GHG Emissions Mitigation

Zisis Tsiropoulos*, Michail D. Kaminiaris, Evangelos Skoubris, Michael Voskakis, Aliki Tsiropoulou and Aikaterini Maria Michailidou

Agricultural and Environmental Solutions (AGENSO), Markou Mpotsari 47, Athens, Greece

Zisis Tsiropoulos, Agricultural and Environmental Solutions (AGENSO), Markou Mpotsari 47, Athens, 11742, Greece

Received Date: August 03, 2023; Published Date: August 17, 2023

Abstract

The current economical worldwide instabilities highlight the need for efficient solutions in agricultural production, in order to reduce production costs, increase productivity, and address climate change mitigation. The use of fossil fuel by agricultural tractors constitutes a major part of the carbon footprint of agricultural industry. EFFiTILL system operates as a useful tool in the hands of farmers, aiming to offer tillage optimization. The system’s hardware is composed of a 3D dynamometer of 6 loadcells, which is being hitched to the tractor and the implements, for monitoring of forces applied, and by a flow metering system for fuel quantity monitoring. The software of the system consists of a web platform and an Android app and allows real-time support of decision-making during tillage session. This way, tractor’s fuel consumption may be mapped, and improvement of tillage efficiency conditions can be achieved. Field experiment results indicate that a significant reduction of fuel consumption can be achieved with the use of EFFiTILL mapping software, together with the appropriate gear selection and engine speed during the session. This can be translated to a reduction of GHG emissions, as CO2 emissions are proportional to fuel consumption.

Keywords: Precision agriculture, Tillage, Tractor, Fuel, Consumption reduction, Tillage optimization, Energy efficiency, Agricultural equipment, GHG emissions, Climate change

Introduction

Tillage constitutes one the most early exercised agricultural practices. Existing evidence indicates that tillage was performed in the valleys of Euphrates and Nile rivers since 3000 B.C. [1]. The first tillage applications were manually performed with the use of animals. However, the technological process made during the 19th century allowed the use of fuel engine vehicles/tractors for exercising the agricultural practices. The technological evolution of the 20th century empowered the wide use of tractors for mechanized tillage application in order to improve the seedbed, soil moisture conservation, as well as crop residues’ management and weed, pest, and disease management in both perennial and annual open-field crops.

Nevertheless, as agricultural tractors use fuel, their operation contributes to the GHG emissions via carbon dioxide (CO2) emission. In general, the agri-food production chain contributes to the total GHG emissions with a percentage of around 31% [2]. Within food systems, crop production/land use and pasture are significant contributors to CO2 emissions, as being responsible for around 14% of the annual anthropogenic CO2 emissions. Furthermore, it is estimated that 10% of the aforementioned, is directly linked to agriculture [3]. As a result, precision agriculture technologies have arisen, with multiple benefits for farmers and the environment, by providing a significant contribution to the reduction of GHG emissions [4].

Within this framework, during the last decades, there has been remarkable research on modelling the technological process of tillage, aiming to optimize the tillage process [5]. In addition to that, the energy demand and GHG emissions by tractors has led to further modelling of the fuel engines’ emissions [6]. Thus, research has been carried out for the calculation of the various GHG emissions by tractors (CO and CO2) with special attention to rotational engine speeds and fuel injection, leading to a possible 76% reduction of CO2 emissions [7].

Furthermore, since the 1980s, there has been a serious attempt to significantly address the reduced tillage or even no tillage approaches for enabling conservation techniques [8]. Based on the aforementioned approaches, restoration processes have been introduced for restoring soil carbon and assessing its impact on crop intensification [9]. The significance of soil carbon sequestration (SCS) for the reduction of GHG emissions is especially highlighted under different tillage practices [10] and the reduction of fossil fuel use in agriculture.

Simultaneously, during the 1980s and after the first portable and micro computers were developed, the first attempts to record the agricultural tractor operating data such as fuel consumption, ground speed, torque and slip were performed [11]. The aforementioned attempts have led to monitoring of agricultural machinery communication protocols such as SAE J1939 [12] and ISO 11783 or ISOBUS [13]. These protocols remain important for precision agriculture as they allow the efficient exchange of information and data between sensors, controllers and software packages from different manufacturers for the same tractor type [14].

However, the current global instable financial circumstances have resulted in an enormous increase of fuels’ prices, putting farmers in a defective position. Thus, farmers seek alternative solutions, as well as management tools and systems, for reducing fuel consumption and increasing energy efficiency under a sustainable framework. Farmers who may lack the ability to access such solutions and tools, are more prone to facing an uneven growth of their production costs, leaving them with less profit margin that derives from the reduced productivity and the increased production costs.

Concerning the operation of tractors, Gear-up throttle-down (GUTD) method is a fuel-saving operating practice that is based on using an angular speed of the engine which is lower than the rated revolutions per minute (RPM). This is possible under lighter drawbar loads and reduced power takeoff (PTO) speed. As a result, engine efficiency is increased and can be improved by keeping its load high with the engine angular speed at 60 to 80% of the corresponding nominal [15].

Further studies have demonstrated that fuel savings of up to 20% can be achieved using the GUTD method [16]. Nevertheless, the correct application of the GUTD method requires a significant experience from the agricultural tractor operator, so that the operator is able to perceive the minimum fuel consumption zone for a specific load and select the appropriate gear ratio to keep the work rate at high level [17]. This way, fuel consumption can be reduced, leading to a corresponding reduction of the GHGs’ emissions.

With the use of such software, the vast amount of data generated by agricultural activities can effectively be managed for allowing better decision making at farm level [18]. The ability to monitor, collect and record the operating data of an agricultural tractor can significantly contribute to fuel-saving decisions.

EFFiTILL comes to close the gap of the available knowledge and the practical implementation of such technologies for the optimization of tillage applications with multiple benefits for the farmer and the environment, in terms of fuel consumption reduction and mitigation of GHG emissions. Thus, the purpose of the current study is to demonstrate the designation and development of a system able to record fuel consumption and spatially monitor consumption, having as ultimate aim the reduction of fuel consumption and the mitigation of GHG emissions.

Materials and Methods

Software development

The EFFiTILL software consists of 2 sub-applications: A mobile application and a web platform, working in close cooperation. The mobile software component is an Android native app written in Java. It is compatible with portable smart devices that are capable of broadband Internet connection, support Bluetooth and are equipped with an onboard GNSS receiver. This component serves as the listener of the various sensors retrofitted on the tractor (such as flowmeters and loadcells) and coordinates the operator in calculating the optimal tillage parameters, requesting their input where needed. Subsequently, during tillage operations, it monitors the session parameters like speed, geographical position and fuel consumption as well as any potential deviation from the optimals ascertained earlier, recording data throughout the session. Periodically, it relays data deltas (increments) to the backend of the web application, thus allowing near real time telematic observation of the tillage progress. At the end of such an operation, the total data set is uploaded as well.

The web application is based on the popular Laravel framework and maintains its own database to aggregate information in a centralized manner, while the Android app is based on Android SDK. It provides services that include user sign-up and registration of their agricultural assets. These actions are necessary prior to any actual tillage, as the mobile app will consult the web backend to verify any access credentials input therein and retrieve information of land assets and machinery the corresponding authenticated user wishes to use. During an active tillage session, authorized users may elect to monitor the operation on the web app by visualization of data sent by the mobile app. In addition, they are able to browse historical data of concluded sessions projected in the form of statistics dashboards, i.e., containing relevant tables and graphs.

Equipment and hardware

The EFFiTILL software receives and/or processes data from three different sources. Namely, the smart device’s GPS receiver to obtain the position and the velocity of the tractor; the flowmeters to obtain the amount of fuel used; and a 3D dynamometer used to measure the applied forces on the towed vehicle and the agricultural machinery attachments.

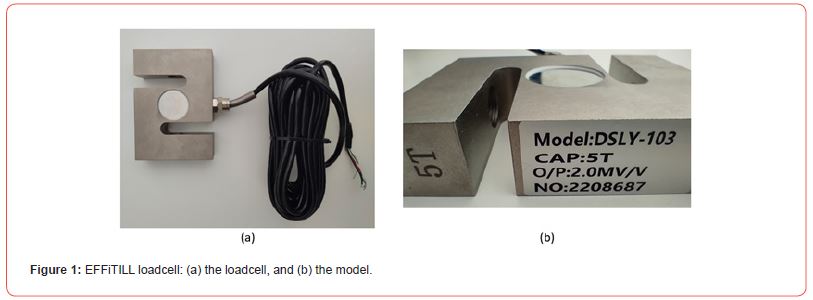

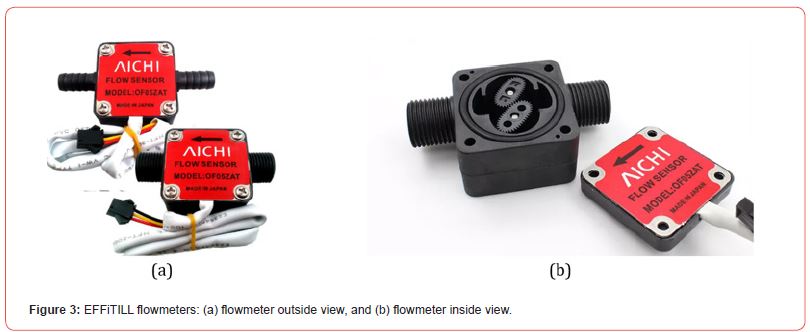

EFFiTILL’s 3D dynamometer consists of 6 loadcells (Figure 1) for measuring forces in three dimensions. More specifically, loadcells were S type full-bridge loadcells with a capacity of 5 T, model DSLY-103, and output of 2.0mV/V.

Three of them are (one for each of the tractor’s 3-point suspension points) placed horizontally and parallel to the direction of movement to measure attraction forces, two of them (one for each lifting arm) are placed vertically to measure vertical forces, while the sixth (telescopic axis) is placed horizontally in the direction of travel to measure lateral forces.

All six loadcells are supplied with 5 V DC power and their electrical signals are fed into 6 loadcell pre-amplifiers (model type HX711). An Arduino pro-mini microcomputer is responsible for reading and processing the output signals from the preamplifiers. A custom method has been followed to calibrate each loadcell, as well as to obtain and store its calibration coefficients to the microcomputer. The signals together with the calibration coefficients provide the final force measurements. The EFFiTILL 3D dynamometer’s structure is presented in Figure 2.

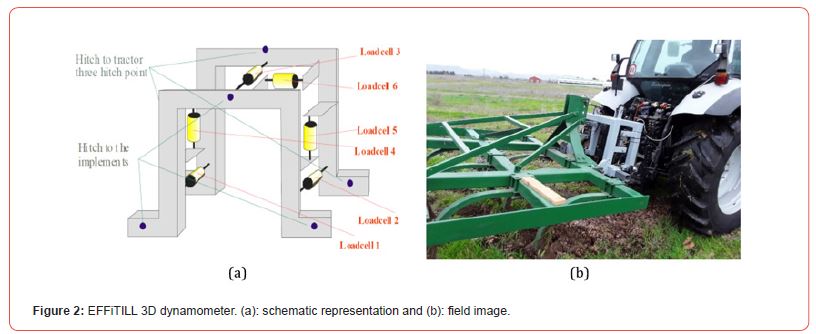

Moreover, in order to monitor the fuel consumption of the tractor, two precision gear flow meters were placed on the fuel line. More specifically, one to measure the fuel inlet (INfuel) towards the engine, and one to measure the output of fuel excess returned from the engine (OUTfuel). The following equation provides the calculation of the total fuel consumption:

Total fuel consumption=INfuel- OUTfuel

The flowmeters used for EFFiTILL development were purchased by Wenzhou Bingo Imp. & Exp. Co., Ltd.; model 0F05ZAT (Figure 3). Accuracy of flowmeters was 0.5% (typical fan type flowmeters have +- 10% or even 20%). Output signal was pulse signal of 2.5mL/P. This was fixed for the entire measuring range. Other meters tend to have significant drift on their transfer equation when reaching the measuring limits. This product is mainly used to measure oil, milk, chemicals (weak acid and base), and various other liquids such as fuels, where typical fan-type flow meters are not suitable. For the aforementioned reasons, this specific type of flowmeter has been selected.

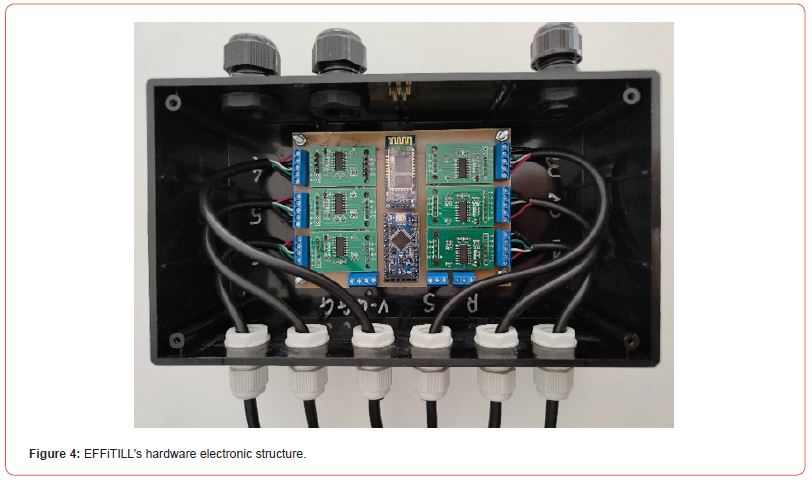

The Arduino microcomputer establishes a wireless connection with the android device, using Bluetooth technology. Through this connection Arduino transmits data to the android device with a rate of 1 sec. With the suggested system development, it was possible to perform several measurements, which measurements are presented in Table 1. The overall electronic structure of the hardware system is presented in Figure 4.

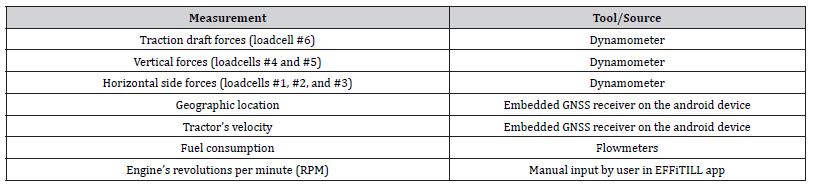

Table 1: EFFiTILL measurements and corresponding tool sources.

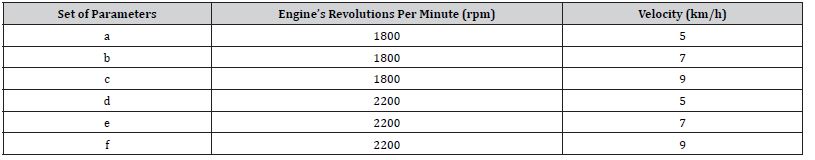

Field experiments

Field experiments were conducted using a Lamborghini R6.130 tractor, in a 0.4-hectare field in Larissa, which consists of one the most prominent open-field cultivation areas in Greece. The experimental field was divided into 12 sub-fields of 50m x 3m size. In each sub-field, a modification of the tractor’s operating parameters was applied. More specifically, 3 distinct velocity values were used in 2 different engine revolutions per minute (RPM). All sets of parameters are presented in Table 2.

Table 2: Sets of parameters for field experiments.

For each set of parameters, two replicates of the experiment were conducted. RPMs were selected aiming to have 1 value within the 60-80% of the optimum values for the engine, and one out the range.

Results

Software

EFFiTILL Web app: preliminary steps: Initially, user needs to visit the web platform/application to register and create an account identified by email address and protected by a password. Upon successful login/registration, a user may create one or more fields by providing a name and the cultivation type for each one. Optionally, users may also draw landparcel boundaries on the interactive map.

Additionally, the user adds to their asset’s machinery (i.e., implements) hoisted on tractors, to be used during tillage applications. The app provides a preset list of such implement types. Users can also add the current financial price of diesel per liter under the Settings menu. This allows the app to provide users with estimates of the monetary cost incurred by each tillage session.

EFFiTILL Android app: Optimization and tillage session: Having conducted the aforementioned preliminary set-up steps, farmers may now perform tillage optimization in situ, by using the Android application on a smart device carried on the tractor. After login with the same credentials used in the web component, the user is presented with the list of fields previously registered online. Similarly, the next step allows the user to select one of the already allocated tillage implements fitted on the tractor.

The next two steps that the Android app guides the users through, are absolutely crucial to the minimization of fuel consumption for the selected tillage configuration, i.e., the combination of field, tractor and machinery:

• The first optimization step is the determination of the tractor speed (velocity) in which the tillage produced, given the configuration, is acceptable. Movement at inappropriate speeds causes machinery to bounce out of the ground, thus leaving the soil not adequately mixed. Specific formulae are employed on the forces’ measurements, to deduce whether and when such disturbances occur.

• Continuing movement at the previously ascertained optimal speed, the final optimization action regards the calculation of the engine speed that minimizes fuel consumption. At this point, it should be noted that tractors’ transmission systems are equipped with far more gear ratios than those offered by a typical passenger car, thus allowing for a possibility of many different engine speeds at a set velocity. While those still fall into a discrete set, they are numerous and closely situated enough to approximate a continuous range granted that minute deviations from the engine speeds proposed by the app, have negligible effects to fuel consumption.

For the duration of the two above steps, the application monitors discrepancies among the power cells. Beyond certain levels of deviation among their measurements, the calculations’ accuracy can suffer, so the operator is notified accordingly. Remediation typically includes levelling of the implement so that its weight and the forces generated during tillage are evenly distributed across it.

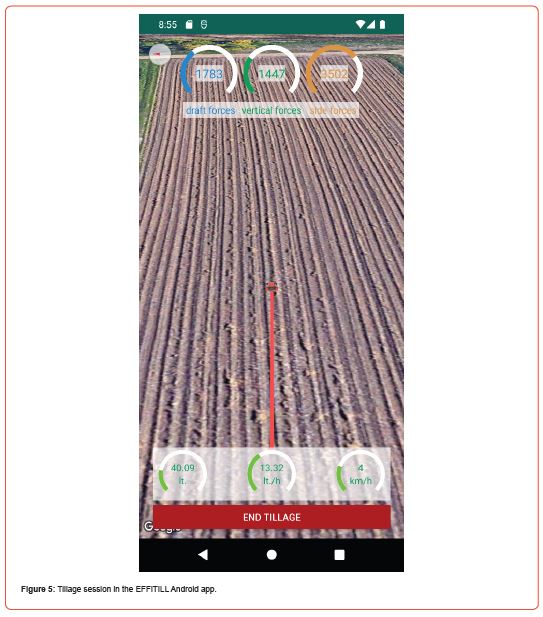

After the optimization phase has been completed, the mobile app announces the velocity and engine speed that’s in the operator’s best interest to adhere to, in order to curtail fuel expenditure to a minimum, while simultaneously not sacrificing tillage quality. An optional step pertains to the guidance of the user to an actual, full tillage session meant for production purposes with the same configuration. The app monitors fuel consumption, forces exerted on the machinery and velocity, to ensure that the user stays within optimal fuel consumption at all times (Figure 5).

EFFiTILL Web app: Real-time telemetry and historical data: During the session, data increments are relayed to the web application in real time, potentially allowing third parties to monitor the operator’s performance in the “Telematics” tab. At the end of the operation on the field, the total session data is uploaded from the mobile device as well, and the web app records them for future reference. The stored data can be retrieved by clicking the tab “Dashboard”. Each record corresponds to a tillage session and includes information on distance covered, the field that was traversed, the machinery used, the total fuel consumption, hourly consumption and total tillage duration, among others. The exact itinerary followed in each tillage recording can also be viewed on a map. Finally, users may further exploit data by exporting the desired information to a spreadsheet on their device, locally.

All software components are designed and implemented in a manner that frugally depletes batteries of handheld devices and conserves resources on server infrastructure. Furthermore, interface screens across components integrate the auxiliary functionality users expect of modern applications, such as filtering of lists, search widgets etc.

Field experiments

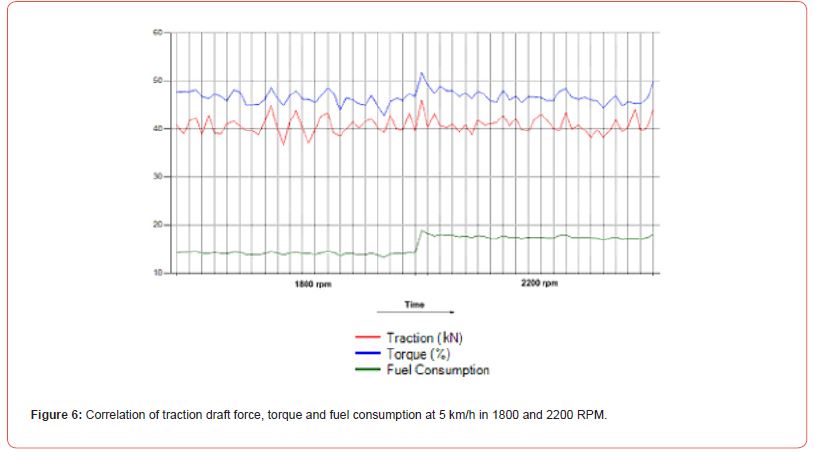

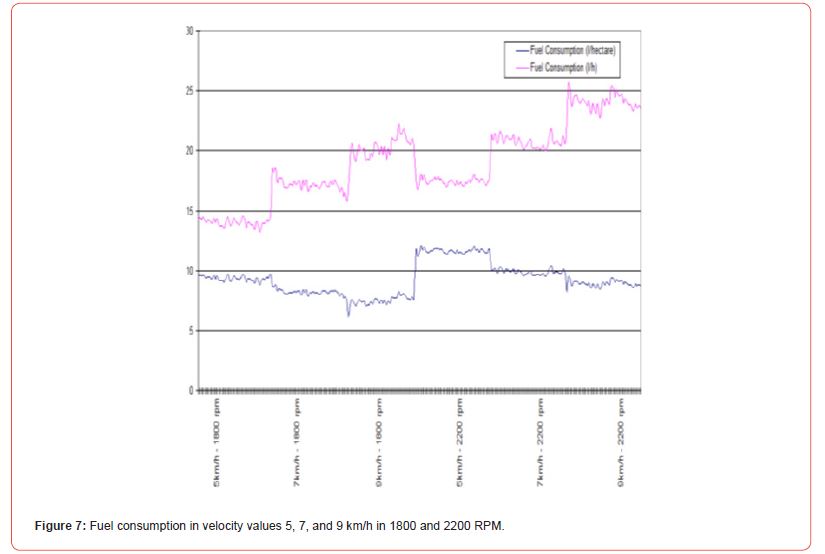

Results of the field experiments indicated that the fuel consumption and the torque are related to the angular velocity of the engine and the velocity of the tractor. More specifically, fuel consumption was higher at 2200 RPM, compared to 1800 RPM at all driving speeds. Additionally, fuel consumption is was higher at the velocity of 5km/h, compared to 9km/h. Figure 6 depicts torque, consumption and traction draft force at 5km/h in 2 different rotational engine speeds (1800 and 2200 RPM), while Figure 7 represents fuel consumption in liters per hectare (L/ha) and liters per hour (L/h) for different velocity values (5, 7, and 9 km/h) and different rotational speeds (1800 and 2200 RPM).

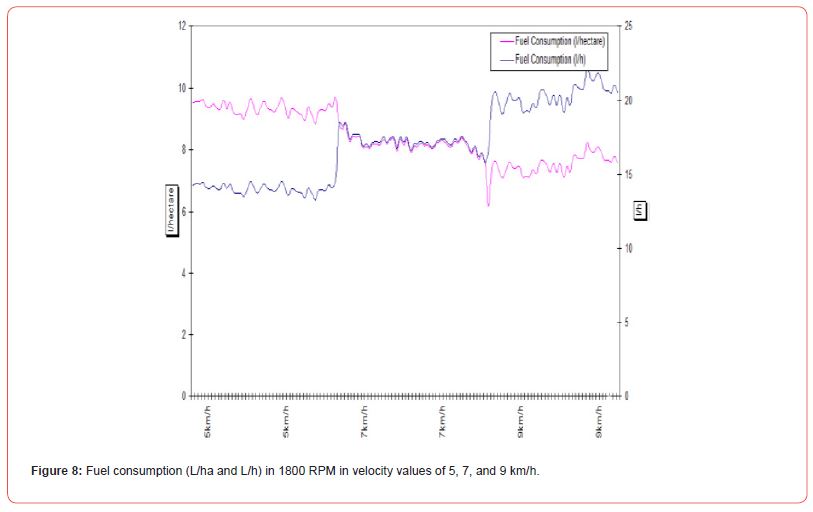

As depicted in Figure 8, fuel consumption per hour varied from fuel consumption in l/ha depending on the distinct velocity values. More specifically, at 5 km/h velocity, higher consumption was monitored per hectare, than per hour. In 7 km/h the fuel consumption per hectare did not vary from the corresponding per hour, while in 9 km/h the consumption per hour was higher than the respective per hectare.

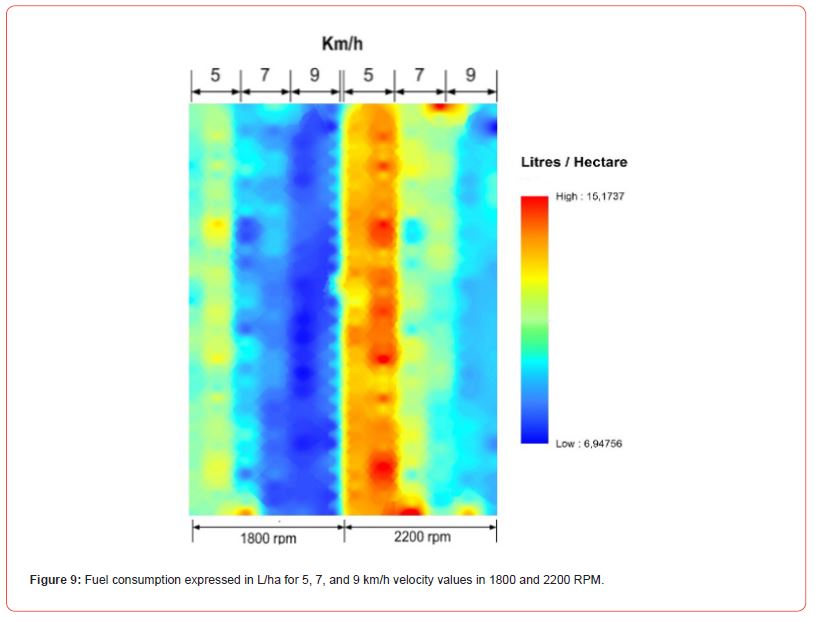

Regarding the fuel comparison in 1800 and 2200 RPM, field experiments demonstrated that the higher fuel consumption (L/ ha) occurred at 5 km/h in 2200 RPM, while the lowest consumption was monitored at 9 km/h in 1800 RPM (Figure 9).

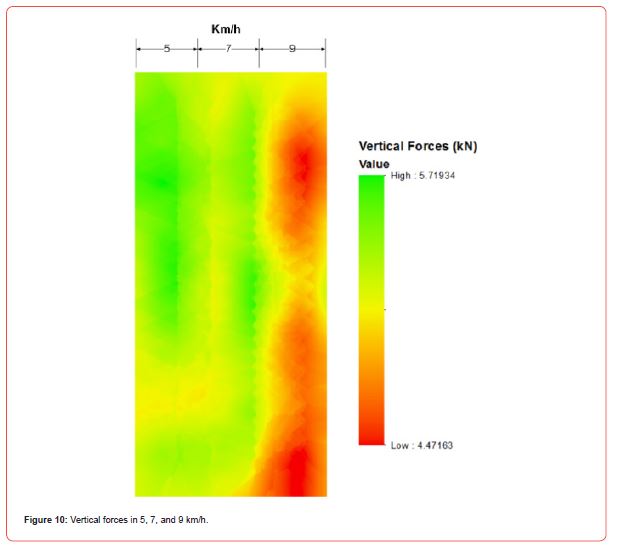

However, increased velocity can affect the quality of soil operations, due to the increased vibrations observed in the machine. For this reason, monitoring the forces is mandatory to determine the maximum acceptable tractor velocity that does not allow the development of any bounce effects on tillage machinery. As depicted in Figure 10, vertical forces during movement with a velocity of 9 km/h are significantly lower than in 5 and 7 km/h, due to the bouncing effects, leading to a recommendation for reduced velocity (<9 km/h) for achieving optimum tillage results and a simultaneous reduction of fuel consumption.

Conclusions and Discussion

It is apparent that during the last years, there has been significant research on the optimization of tillage operations with special respect to the mitigation of climate change, GHG emissions and the reduction of fossil fuels’ use. Within this framework, several tillage approaches have been suggested for increasing energy efficiency [19]. An efficient and sustainable crop production system involves lower energy use and reduced carbon emission [20]. For this reason, traction power indices during the application of tillage and cultivation operations have been assessed [21].

Moreover, research results have demonstrated the significance of measuring tillage implement forces for reducing fuel consumption and increasing efficiency without affecting tillage depth [22]. In addition to that, several no-tillage approaches have been introduced for reducing energy input and carbon footprints [23]. Crop rotation has also been identified as a key factor impacting productivity of cropping systems, apart from tillage [24]. Indirectly, higher yield may also be achieved as properly cultivated soil is associated with more robust and healthy plants, and consequently with less need for pesticide input and fertilizer input. In addition to that, it is clear that improper tillage application may lead to soil erosion that directly reduces yield from 5% to 75%, depending on the soil degradation due to erosion [25].

Nowadays, a vast number of tools and technologies exist in the agricultural machinery industry, which support the achievement of the aforementioned objectives and facilitate agricultural practices exercised. The widespread use of sensors and electronic control units are part of almost every new agricultural machine, enabling data acquisition, collection, and monitoring of operation data. As a result, some real-time tillage monitoring systems and decision support systems have been developed [26,27], taking into account parameters such as vibration, bulk density, slippage ratio, fuel consumption, tillage depth, and field’s characteristics. Moreover, mathematical modelling has been performed for the prediction of tractor [28], and heavy-duty vehicles’ [29] fuel consumption. However, there is a lack of developed systems that take into account the engine’s revolutions per minute (RPM).

EFFiTILL comes to address this lack in innovative systems, offering a holistic tillage approach by exploiting real-time data that can be stored and used to assess tillage efficiency. The applications developed offer a simple and friendly user interface, which can easily be adopted by farmers. The system can be used in any agricultural tractor and is a low-cost effective solution for reducing fuel consumption that contributes in the GHG emissions mitigation. This provides the ability of further profit for farmers, and simultaneous greater reduction of the carbon footprint by the food production chain.

Field results have indicated that there is a strong correlation between torque, consumption and tractive force. A fuel reduction was possible by applying the optimum tractor velocity and engine speed. As GHG emissions are proportional to fuel consumption [30], the introduced fuel consumption reduction by the use of EFFiTILL, can be translated to a reduction of the GHG emissions during tillage operations.

Preliminary tests carried out prior to the experimental use of EFFiTILL have showed a bounce effect at velocities higher than 9km/h using a deep cultivator machinery, resulting in inefficient use of the cultivator, based on records obtained by the 3D dynamometer. Thus, velocities below 9km/h were selected for the purposes of the current work. Further experiments will be conducted, taking into account more operating parameters in order to optimize the results acquired.

The EFFiTILL software will undergo further development, aiming to allow the incorporation of more features and new operating information of the tractor system. This attempt is expected to produce an integrated system that will provide useful information and spatial analysis tractor operators for farmers, allowing better management of the agricultural equipment and machinery, prevention of major machinery damage, as well as the optimization of agricultural operations, aiming to fuel consumption reduction and GHG emissions mitigation.

Acknowledgement

The “EFFiTILL: An efficient tillage system for tractors fuel consumption reduction and GHG emissions mitigation” publication has been performed in the framework of the project “EFFiTILL: An innovative system for EFFiciency optimization of TiLLage operations”, Grant agreement no. Τ1ΕΔΚ-05243, which was funded by the Greek National ESPA EPAnEk 2014-2020 (Co-funded by the European Union), under the call of the operational program “Competitiveness, Entrepreneurship, Innovation”.

Conflicts of Interest

No conflict of interest.

References

- McKyes E (1985) Introduction to tillage and earthmoving (Chapter 1). Develop in Agric Eng 7: 1-10.

- Tubiello FN, Karl K, Flammini A, Gütschow J, Obli-Laryea G, et al. (2022) pre-and post-production processes increasingly dominate greenhouse gas emissions from agri-food systems. Earth Syst Sci Data 14: 1795–1809.

- Lynch J, Cain M, Frame D, Pierrehumbert R (2021) Agriculture's Contribution to climate change and role in mitigation is distinct from predominantly fossil CO2-emitting sectors. Front Sustain Food Syst Sec. Climate-Smart Food Systems.

- Balafoutis A, Beck B, Fountas S, Vangeyte J, Wal TVd, et al. (2017) Precision agriculture technologies positively contributing to GHG emissions mitigation, farm productivity and economics. Sustainability 9: 1339.

- SG Mudarisov, II Gabitov, YP Lobachevsky, NK Mazitov, RS Rakhimov, et al. (2019) Modeling the technological process of tillage. Soil and Tillage Research 190: 70-77.

- Mantoam EJ, Romanelli TL, Leandro M Gimenez LM (2016) Energy demand and greenhouse gases emissions in the life cycle of tractors. Biosyst Eng 151: 158-170.

- Janulevičius A, Juostas A, Čiplienė A (2016) Estimation of carbon-oxide emissions of tractors during operation and correlation with the not-to-exceed zone. Biosyst Eng 147: 117-129.

- Unger PW, McCalla TM (1980) Conservation tillage systems. Contribution from agricultural research, science and education administration. US Department of Agriculture, in cooperation with the Texas and Nebraska Agricultural Experiment Stations, Editor(s): NC Brady, Advances in Agronomy 33: 1-58.

- Das A, Babu S, Datta M, Kumar S, Singh R, et al. (2022) Restoring soil carbon in marginal land of Indian Himalayas: Impact of crop intensification and conservation tillage. Journal of Environm Manag 318.

- Bhattacharyya SS, Leite FFGD, France CL, Adekoya AO, Ros GH, et al. (2022) Soil carbon sequestration, greenhouse gas emissions, and water pollution under different tillage practices. Sc of the total envir 826: 154161.

- Schmidt D, Rockwell SK, Bitney L, Sarno EA (1994) Farmers adopt microcomputers in the 1980s: educational needs surface for the 1990s. Jour of exten 32(2): 2FEA9.

- Society of Automotive Engineers (SAE) (1995) Surface Vehicle Recommended Practice J1939-73.

- International Organization for Standardization (ISO) (1997) Tractors, machinery for agriculture and forestry. Serial control and communications data network, parts 1 to 5 (ISO 11783).

- Stafford JV (2000) Implementing Precision Agriculture in the 21st Century. Jour of Agric Eng Res 76: 267–275.

- Grogan JD, Moris A, Searcy SW, Stout BA (1987) Microcomputer based tractor performance monitoring and optimization system. Jour of Agric Eng Res 38: 227–243.

- Chancellor WJ, Thai NC (1984) Automatic control of tractor transmission ratio and engine speed. Transactions of the ASABE, 27(3): 642-646.

- Mondal P, Rao PN (2005) Digital throttle gear optimizer for better fuel economy of tractors. SAE paper no 2005-26-066.

- Fountas S, Wulfsohn D, Blackmore S, Jacobsen HL, Pedersen SM (2006) A model of decision making and information flows for information intensive agriculture. Agricultural Systems 87: 192- 210.

- Pratibha G, Srinivas I, Rao KV, Raju BMK, Shanker AK, et al. (2019) Identification of environment friendly tillage implement as a strategy for energy efficiency and mitigation of climate change in semiarid rainfed agro ecosystems. Jour of Clean Prod 214: 524-535.

- Kumar R, Sarkar B, Bhatt BP, Mali SS, Mondal S, et al. (2021) Comparative assessment of energy flow, carbon auditing and eco-efficiency of diverse tillage systems for cleaner and sustainable crop production in eastern India. Jour of Clean Prod 293: 126162.

- Md-Tahir H, Zhang J, Xia J, Zhou Y, Zhou H et al. (2021) Experimental investigation of traction power transfer indices of farm-tractors for efficient energy utilization in soil tillage and cultivation operations. Agronomy 11: 168.

- Tsiropoulos Z, Fountas S, Gravalos I, Augoustis A, Arslan S, et al. (2015) Importance of measuring tillage implement forces for reduced fuel consumption and increased efficiency without affecting tillage depth. Precision agriculture 15: 353–360.

- Nisar S, Benbi DK, Toor AS (2021) Energy budgeting and carbon footprints of three tillage systems in maize-wheat sequence of north-western Indo-Gangetic Plains. Energy 229: 120661.

- Marja J, Erja H, Heikki J, Katja K, Mari N, et al. (2021) Effects of crop rotation on spring wheat yield and pest occurrence in different tillage systems: a multi-year experiment in finnish growing conditions. Frontiers in Sust Food Syst 5.

- FAO, Chapter 7 - Economic consequences of land degradation.

- Kim YS, Kim TJ, Kim YJ, Lee SD, Park SU Kim WS (2020) development of a real-time tillage depth measurement system for agricultural tractors: application to the effect analysis of tillage depth on draft force during plow tillage. Sensors 20: 912.

- Fawzi H, Mostafa SA, Ahmed D, Alduais N, Mohammed MA, Elhoseny M (2021) TOQO: A new tillage operations quality optimization model based on parallel and dynamic decision support system. Jour of Clean Prod 316: 128263.

- Grisso RD, Kocher MF, Vaughan DH (2004) Predicting tractor fuel consumption. Appl Eng in Agriculture 20(5): 553−561.

- Pantoja Gallegos JL, Dominguez Vergara N, DN Dominguez Perez (2022) Calculation of the fuel consumption, fuel economy and carbon dioxide emissions of a heavy-duty vehicle. J Phys Conf Ser 2307: 012025.

- Shaheen SA, Lipman TE (2007) Reducing greenhouse emissions and fuel consumption: Sustainable approaches for surface transportation. IATSS Research 31(1): 6-20.

- ISSN: 2641-6379

- DOI: 10.33552/WJASS.2023.08.000700

- Volume 8 - Issue 5, 2023

- Open Access

-

Zisis Tsiropoulos*, Michail D. Kaminiaris, Evangelos Skoubris, Michael Voskakis, Aliki Tsiropoulou and Aikaterini Maria Michailidou. EFFiTILL: An Efficient Tillage System for Tractors Fuel Consumption Reduction and GHG Emissions Mitigation. World J Agri & Soil Sci. 8(5): 2023. WJASS.MS.ID.000700.

-

Precision agriculture, Tillage, Tractor, Fuel, Consumption reduction, Tillage optimization, Energy efficiency, Agricultural equipment, GHG emissions, Climate change

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.