Mini-Review

Mini-Review

The Influence of Domestic Washing on the Performance of Conductive Sewing Threads

Serkan Boz1, Derya Tama Birkocak2* and Eda Acar2

1Faculty of Fashion and Design, Ege University, Türkiye

2Department of Textile Engineering, Ege University, Türkiye

Derya Tama Birkocak, Department of Textile Engineering, Ege University, Türkiye

Received Date:May 20, 2024; Published Date:June 03, 2024

Abstract

Smart textiles represent a revolutionary fusion of technology and traditional textiles, prominently featuring conductive threads in various applications. Conductive threads have been adapted for multiple uses in smart textiles, replacing traditional elements with flexible, textile-integrated solutions such as electrical supply lines, sensors, transmitters/receivers (antennas), integration of electrical components, modification of electrical circuit resistances. These diverse applications highlight the versatility of conductive threads in smart textiles, enabling the creation of flexible, washable, and wearable electronics that integrate seamlessly into everyday life. Literature frequently underscores the utility of conductive threads in crafting innovative textile solutions, although most studies focus on their use in surface creation. This mini review aims to systematically explore the diverse applications and durability concerns of conductive sewing threads as evidenced in contemporary research.

Keywords:Smart textiles; Conductive yarns; Domestic washing; Performance evaluation

Introduction

In recent years, the development of smart textile applications has become increasingly widespread, finding its place in numerous sectors. Ensuring that these products move beyond the prototype stage and are widely used is a current and important topic. Regardless of the final application, manufacturers need to aim at maximizing the lifespan of smart textile products, as this is a crucial factor in the decision to purchase innovative products. Therefore, the durability performance of these products, which will be demonstrated through usage, is an essential issue that needs investigation. Conductive sewing threads are frequently chosen materials in smart textile applications. These threads are used in various applications such as integrating electronic components (microcontrollers, resistors, speakers, etc.) into fabrics and producing sensors or antennas. Applied to fabric surfaces via hand or sewing/embroidery machines, these materials possess good resistance to friction. Generally, silver microparticles are used in the production of these materials. However, during the sewing process and throughout the extended use of the final product, these silver microparticles tend to detach from the sewing thread, thereby decreasing the conductivity of the thread. Despite the extensive application of conductive threads, research on their durability, particularly in terms of washing resistance, remains limited. In this mini review, these studies have been systematically examined.

Discussion

The role of domestic washing in the performance and durability of conductive threads integrated into smart textiles is increasingly recognized as critical. Various studies have assessed the impact of washing on different conductive threads used in textile surfaces, exploring how these materials withstand mechanical and chemical stresses during typical laundry cycles. Eskandarian et al. (2020) investigated the effects of home laundering on silver-coated nylon and carbon-infused nylon threads woven into different patterns. The study compared the performance of these textile electrodes before and after several washing cycles with standard hydrogel electrodes, finding comparable performance, thus supporting the potential for continuous monitoring of biopotential signals from the human body [1]. In a related study, Tadesse et al. (2019) developed a conductive elastic knitted fabric treated with PEDOT: PSS and PU binder. The addition of PU significantly improved the fabric’s conductivity retention against mechanical and chemical effects of washing, maintaining reasonable conductivity after 10 wash cycles [2]. Ismar et al. (2018) focused on the mechanical strength and electrical conductivity changes in conductive threads post-washing. They reported a reduction in stitch elongation in both the warp and weft directions and recorded some signal degradation due to the adverse effects of washing cycles on silver-coated threads [3]. Briedis et al. (2019) conducted durability tests by subjecting conductive threads (embroidered into fabrics) to multiple washing cycles. They measured the electrical resistance of the connections made by these threads after each cycle, recommending the most suitable sample for replacing traditional electrical wires and electronic components based on these results [4].

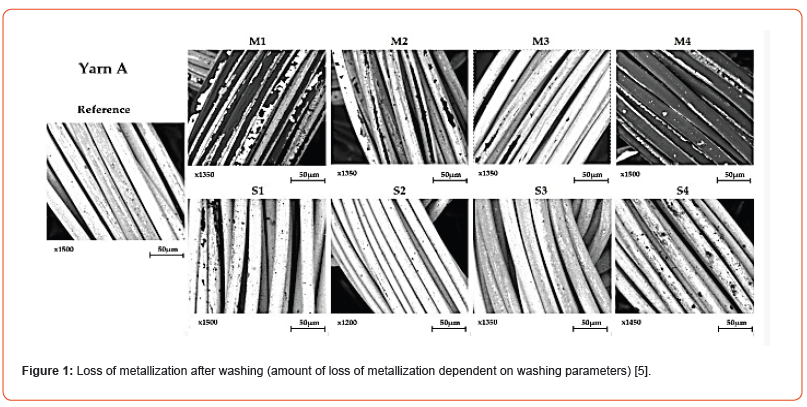

The study, based on the premise that washability is one of the key criteria for the mass adoption of smart textiles, only sensors with silver-coated nylon electrodes, which are the detection part, were taken into consideration in the study. Textile electrodes were evaluated under various washing conditions (including those with and without bleaching agents) by Gaubert et al., (2020) to determine the chemical and mechanical effects of machine washing separately and simultaneously. The removal is shown in Figure 1 obtained by the scanning electron microscope observations. The results indicate a preference for liquid detergents over powdered ones [5].

In another study, Ahmmed et al. (2021) examined the effects of laundry washing on the electrical resistance of wearable e-textile products using Vectran silver-coated (SCV) conductive threads. The study documented significant increases in electrical resistance from 0.84 Ω to 1.9 Ω per 0.3 meters after 25 washing cycles, indicating serious degradation due to repeated laundering [6]. Mechanical forces exerted during washing are considered one of the most damaging factors to e-textile structures. It is assumed that well-known textile comparison tests such as Martindale abrasion and pilling boxes exhibit similar mechanical damage to e-textile structures during washing. In their study, Uz Zaman et al. (2019), the changes in electrical resistance observed after conducting mechanical tests on silver-coated conductive threads used as connection threads in e-textile structures were correlated with washing results to suggest equivalent damage effects without washing [7]. Lam et al. (2022) developed textiles with polymeric optical fibers (POF) and silver-coated conductive threads using a flat knitting machine. The study explored how washing and wear affected the lighting and conductivity properties of interactive POF knit textiles, noting significant resistance changes in half and full milano knitted fabric due to increased loop density in the weft direction [8]. Liu et al. (2020) researched the washability of conductive fabrics laminated with various metal coatings (Cu, Ag, Ni/Cu, Ni/Cu/Co) on common textiles such as spandex, nylon, and denim. The study found that washing led to increases in electrical resistance, with significant peeling and breaking in the metal layers due to mechanical stresses during washing, except in Agcoated fabrics where the superior flexibility and adhesion of silver minimized damage [9].

Won and Yun (2022) assessed the electrical resistances and surface properties of conductive textiles under different maintenance regimes using washing, drying, and steam garment care systems. The study recommended reducing traditional washing and drying cycles and increasing the use of steam garment care to effectively extend the life of smart garments without removing dirt solely through steam [10]. The primary challenge and the most significant barrier to market readiness for smart and electronically connected clothing and accordingly its washability have been investigated. Two different methods for designing, producing, and testing durable, washable, and reliable textronic systems using flexible conductive PCBs (printed circuit boards) were introduced [11]. Different failure modes in e-textiles due to washing are presented, focusing on specific damages to various structures. Influencing factors on e-textile washability, including those from the e-textile’s composition and external processing and cleaning parameters, are listed [12].

Conclusion

The studies collectively underscore the critical need for durable conductive threads that can withstand the rigors of domestic washing, which is pivotal for the broader adoption of smart textiles. Advances in material science and textile engineering are vital to develop conductive threads that balance functionality with durability, ensuring that smart textiles can be both practical and sustainable in everyday use. This review highlights the promising yet challenging aspects of incorporating conductive threads into smart textiles, emphasizing the need for further research to enhance their durability and functional lifespan in real-world applications.

Conflict of Interest

The authors have no financial interest or any conflict of interest to disclose.

Acknowledgements

This research was funded by Ege University, Scientific Research Projects Branch Office, grant number 32156.

References

- Eskandarian L, Lam E, Rupnow C, Meghrazi MA, Naguib HE (2020) Robust and multifunctional conductive yarns for biomedical textile computing. ACS Applied Electronic Materials 2(6): 1554-1566.

- Tadesse MG, Mengistie DA, Chen Y, Wang L, Loghin C, et al. (2019) Electrically conductive highly elastic polyamide/lycra fabric treated with PEDOT: PSS and polyurethane. J Mat Sci 54(13): 9591-9602.

- Ismar E, Zaman S, Bahadir SK, Kalaoglu F, Koncar V (2018) Seam strength and washability of silver coated polyamide yarns. In IOP Conference Series: Materials Science and Engineering. IOP Publishing, Turkey.

- Briedis U, Vališevskis A, Ziemele I, Abele I (2019) Study of durability of conductive threads used for integration of electronics into smart clothing. Key Eng Mat 800: 320-325.

- Gaubert V, Gidik H, Bodart N, Koncar V (2020) Investigating the impact of washing cycles on silver-plated textile electrodes: A complete study. Sensors 20(6): 1739.

- Ahmmed AS, Malengier B, Tadesse MG, Van Langenhove L (2021) Study the effect of laundry on the electrical resistance of silver coated vectran conductive yarn for the application of e-textile. In Materials: 2021 International Conference on Materials: Advanced and Emerging Materials, China.

- Uz Zaman S, Tao X, Cochrane C, Koncar V (2019) Launderability of conductive polymer yarns used for connections of e-textile modules: Mechanical stresses. Fibers Polym 20: 2355-2366.

- Lam NYK, TanJ, Toomey A, Cheuk KCJ (2022) Washability and abrasion resistance of illuminative knitted e-textiles with POFs and silver-coated conductive yarns. Fashion and Text 9(1): 39.

- Liu W, Shangguan D, Lee JC (2020) Evaluation of launderability of electrically conductive fabrics for E-textile applications. IEEE Transactions on Components, Packaging and Manuf Technol 10(5): 763-769.

- Won AY, Yun C (2022) Effects of Maintenance and Wear on the Electrical Resistance of Silver-Based Conductive Textiles. Fibers Polym 23(4): 977-984.

- Tao X, Koncar V, Huang TH, Shen CL, Ko YC, et al. (2017) How to Make Reliable, Washable, and Wearable Textronic Devices. Sensors 17: 673.

- Rotzler S, Schneider Ramelow M (2021) Washability of E-textiles: failure modes and influences on washing reliability. Textiles 1(1): 37-54.

-

Serkan Boz, Derya Tama Birkocak* and Eda Acar. The Influence of Domestic Washing on the Performance of Conductive Sewing Threads. On Journ of Robotics & Autom. 2(5): 2024. OJRAT.MS.ID.000550.

Smart textiles, Conductive yarns, Domestic washing, Performance evaluation

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.