Mini- Review

Mini- Review

Using Mathematical Modelling to Solve Reliability Problems in the Power Industry

Radin Yu, Kontorovich T* and Pikhlakas A

Peoples’ Friendship University of Russia named after Patrice Lumumba, OJSC Mosenergo

Kontorovich T, Peoples’ Friendship University of Russia named after Patrice Lumumba, OJSC Mosenergo

Received Date:June 08, 2024; Published Date:July 10, 2024

Abstract

Keywords:mathematical modeling; reliability justification problems; power industry; power equipment; thermal stress state calculations; gas dynamics calculations

Introduction

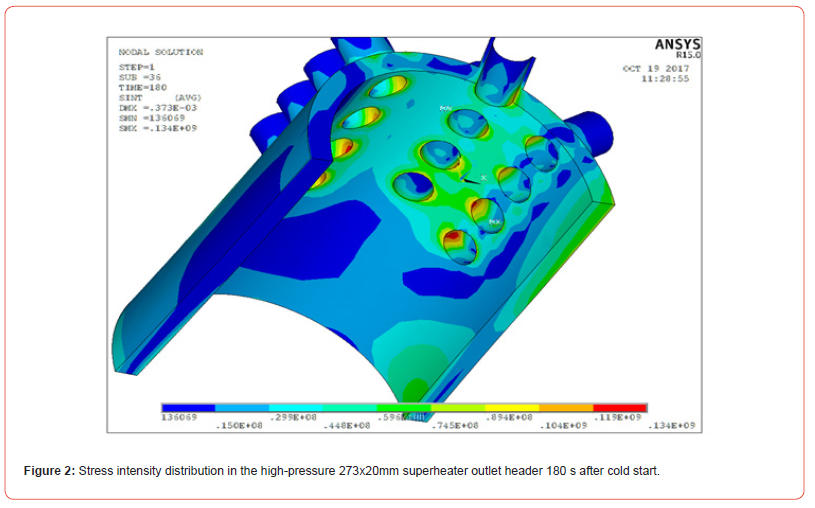

Mathematical modelling occupies a special place in solving reliability justification problems in the power equipment. It is used to design new equipment, to optimize its operating modes, to estimate its residual life and to predict the damage occurrence in highly stressed parts of boilers and turbines. The use of mathematical modelling to search for regularities in the nature of physical processes in power equipment can be demonstrated using the examples of the high-pressure T-295/335-23,5 turbine rotor (Figure 1) and the HRSG high-pressure superheater outlet header (Figure 2) thermal stress state calculation. It was found that the uneven distribution of steam flow through the supply pipelines causes the maximum stress to occur first in the central part of the header. As steam flows through an increasing number of supply tubes, the zone of maximum stress shifts from the center of the header to the outlet. At the same time, the maximum stresses themselves decrease towards the header outlet.

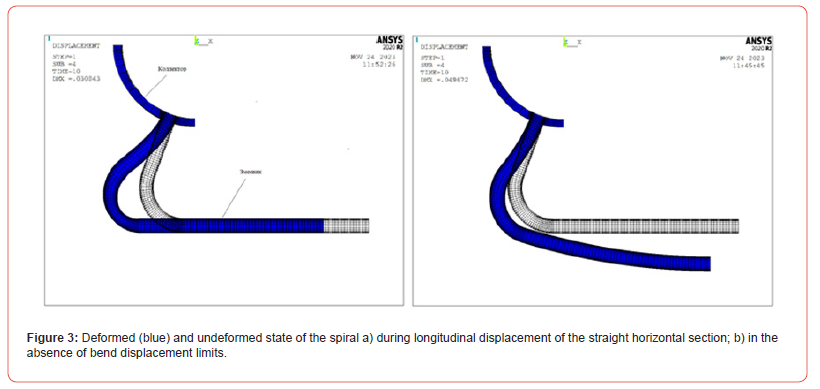

Figure 3a, b shows the computational study results of the damage caused to the tubes of the HRSG low-pressure evaporator heating surfaces outlet header. The calculations show that the tube bend cracks are caused by restriction of the straight tube section displacements in all directions except the longitudinal direction. The fairness of the solution adopted is confirmed by a sharp stress reduction in the bend, provided that there is no restriction of its displacements in all directions (Figure 3b).

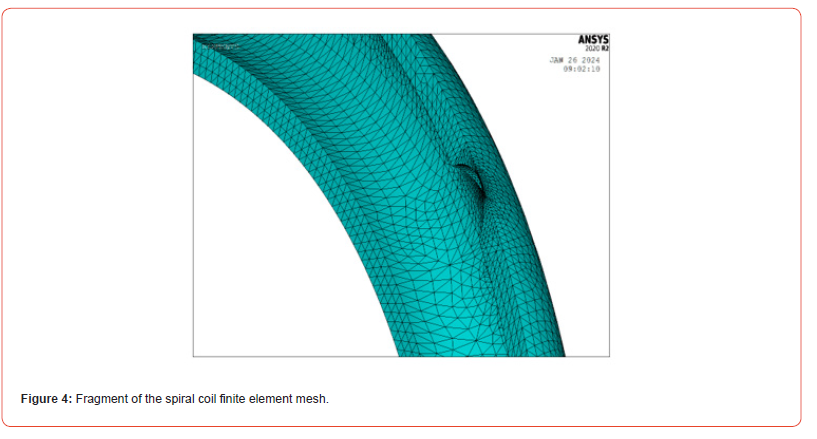

Analysis of the damage causes to the bi-plane spiral coil connecting the high-pressure heater inlet and outlet headers, was carried out using a mathematical model. This model made it possible to consider the influence of the pitting corrosion ulcer depth found on the inner surface of the 32x5mm tube on the stress magnitude occurring in it. It was shown that at an ulcer depth of approximately 4 mm, the stress in the tube exceeded the tensile strength of the material from which it was made.

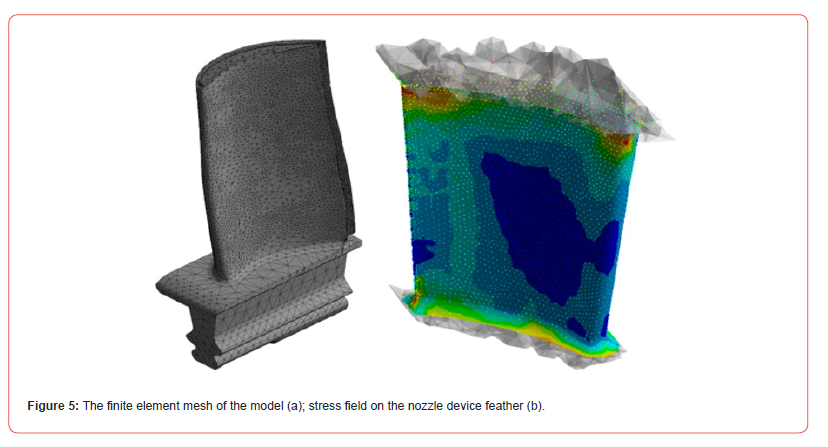

Using a mathematical model of cooled gas turbine blades, it has been possible to estimate a gas turbine unit inter-service interval, both with and without a reduction in the upstream turbine gases temperature. The working blade finite element mesh is shown in Figure 5 (a). Numerical modelling is used to calculate the gas dynamics, temperature and strength of the nozzle and working blades. It allows the working and guide (Figure 5 b) blades stress-strain state to be determined most accurately and low cycle fatigue calculations to be performed. The correctness of the model construction and the accuracy of the calculations performed have been confirmed experimentally.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

-

Radin Yu, Kontorovich T* and Pikhlakas A. Using Mathematical Modelling to Solve Reliability Problems in the Power Industry. On Journ of Robotics & Autom. 3(1): 2024. OJRAT.MS.ID.000555.

mathematical modeling, reliability justification problems, power industry, power equipment, thermal stress state calculations, gas dynamics calculations

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

- Abstract

- Introduction

- Precision, Efficiency, and Collaborative Robotics (Cobotics)

- Energy Conservation and Green New Work

- Flexibilization of the workplace and ecological benefits

- Waste reduction, circular economy, and cobotic synergy

- Reduction of Harmful Emissions

- Challenges and Considerations

- Conclusion

- Acknowledgement

- Conflict of Interest

- References