Research Article

Research Article

Technology Banks: A Fifth Generation of Automation Control Systems for Compact of Old Machines in Textile Industries

Elsayed Ahmed Elnashar*

Professor of Textiles &Apparel, Kaferelsheikh University, Egypt

Elsayed Ahmed Elnashar, Professor of Textiles &Apparel, Kaferelsheikh University, Egypt

Received Date:November 07, 2023; Published Date:November 17, 2023

Abstract

Automation-digital: the fifth-generation automation textiles and clothing technology are a class of automation-digital in service from around 1980 to the present and represent design concepts of the 1970s. Fourth-generation designs are heavily influenced by lessons learned from the previous generation of automation textiles and clothing technology for the digital future. Fifth-generation automation textiles and clothing were often designed primarily as future supportive, being projectile of Sulzer machines around speed and automation to automation-digital. While exceptionally fast in a straight line, as rapier weaving machines, many third-generation automation textiles and clothing of control systems as technology banks by mechatronics a severely lacked in dynamic, the sensor fusion and machine perception frontier in automation textiles s industrial Robotics for intelligent manufacturing as doctrine solar energy held that traditional insertions of, we would be impossible at supersonic speeds.

Keywords:Technology banks; Fifth Generation; Control Systems; Automation; textiles industries

Introduction

Sustainable technology of automation textiles and clothing refers to the technology IT system integration as technology banks by mechatronics by solar energy, which caters the needs of the present without compromising the ability of future generation to meet their own needs? It enables more valuable use of the natural resources & greatly reduced ecological impact among other technological benefits. Though sustainable technology deals of automation textiles and clothing with energy efficiency, reduction in pollution, use of renewable sources, it should also be economically sustainable of the sensor fusion and machine perception frontier in automation textiles industrial robotics for intelligent manufacturing for the digital future, [1-3].

Automation control systems by Solar energy as technology banks by mechatronics, in practice, automation to automationdigital automation textiles and clothing technology of the time, despite being responsible for the vast majority of automation to automation-digital increasing productivity, were relatively unreliable and automation-digital-technology would quickly become subsonic and close-range. This would leave thirdgeneration automation textiles and clothing vulnerable and illequipped, renewing an interest in maneuverability for the fourth generation of automation textiles and clothing technology the Sensor fusion and machine perception frontier in automation textiles industrial robotics for intelligent manufacturing [4-6]. meanwhile, the growing costs of automation textiles s machinery automation to automation-digital in automation textiles industry in general and the demonstrated success of automation textiles and clothing technology such as the rapier waving machine gave rise to the popularity of automation to automation-digital in automation textiles s industry in parallel with the advances marking the socalled fourth generation.

Fifth generation: 5G is the fifth generation of wireless

technology of machines in textile industries. Its increased speed,

lower latency, and improved reliability stand to revolutionize

a wide variety of textiles industries. automation 3D textiles

industries including spinning, waving, 3D Printing and clothing

prototype model, the term fifth generation is often used to refer

to new or enhanced technology banks, which appeared beginning

in the 1990s, and incorporated some features, regarded as fifth

generation, but lacked others [7-9]. The fifth-generation technology

banks are therefore generally less expensive, less complex, and have

a shorter development time than true fifth-generation technology

banks, while maintaining capabilities significantly in advance

of those of the original fourth generation. Such capabilities may

include advanced sensor integration, transformation radar for data,

super cruise capability, increasing wefts super maneuverability,

broad multi-role capability, and reduced rapier strips cross-section

[10-12], and four key use-case archetypes, which will require

5G to deliver on its promise of evolutionary change in network

performance of machines in textile industries are:

a) Enhanced mobile broadband.

b) Internet of Things (IoT).

c) Mission-critical control.

d) Fixed wireless access.

The fifth-generation automation textiles and clothing have introduced integrated rapier systems, such as the weaving featuring the optronique secteur frontal integrated technology banks of the sensor fusion and machine perception frontier in automation textiles industrial robotics for intelligent manufacturing. The producers introduced automation textiles and clothing machines, which were also retrofitted to earlier production models. The super attached was also fitted with technology banks, although not integrated but rather as a pod that needs to attach on one of the hard points [13-15]. As advances in stealthy materials and design methods enabled vibrations and noise and clothing machines, such technologies began to be retrospectively applied to existing clothing machines. Many fifth generation of technology banks incorporate some low-observable features. Low-observable radar technology sensor fusion and machine perception emerged as an important development in the sensor fusion and machine perception control frontier in automation textiles industrial robotics for intelligent manufacturing [16,17].

The strategic goals of this technology

a. It is the re-operation of old machines according to modern

and advanced scientific theories...

b. Providing environmental protection by maintaining

various environmentally friendly technological options

c. Providing 70% of the capital of companies and

manufacturers

d. Localization of the local hardware industry

e. Strategy for saving hard currency (Euro & Dollars) ...

f. Providing new job opportunities

g. Exporting Egyptian industry machinery and equipment

(Made in Egypt)

Aims and Objective

For the digital future in this design of textile industries such as “sewing stitches bank” and weaving machine are an electronic device aimed at achieving with modifications of using automationmechatronics and sensor fusion and machine perception “radar” the following.

Sewing stitches bank [1-3]:

Intelligent control and modelling frontier to construct a sewing

stitches bank that will be able to charge all types of sewing machine.

a) Machine learning, adaptation and imitation of a sewing

machine that is capable of supplying 90 stitches current.

b) Innovative computations of a sewing machine with short

circuit protection.

c) Neural networks, neural computation sewing stitches

bank that as over-charging protection.

d) Micromachines control the frontier of a sewing machine

so that the sewing stitches is rechargeable.

e) The Sensor fusion and machine perception frontier in

sewing stitches industrial robotics for intelligent manufacturing.

Weaving Machine Bank [1]:

Sensor fusion and machine perception to construct a weaving

machine bank that will be able to charge all types of weaving

machine.

a) Multi-sensor fusion and perception control of weaving

machine bank that is capable of supplying many kinds of woven

fabric structures.

b) Machine learning and intelligence of a weaving machine

bank with short circuit protection.

c) Novel and emerging applications of weaving machine

bank that as over-charging protection.

d) Automated mining frontier weaving machine that the

weaving machine is rechargeable.

e) Digital image processing in weaving machine bank

industrial robotics for intelligent manufacturing

f) Adjustments in the inclinations of the rapier tapes for

passing wefts to achieve an increase in speed and productivity

rates in the specified time automatically.

g) Nuovo Pignon/SMIT machine repair, improvement

and machinery maintenance, repairs, maintenance and

improvements of weaving looms and automation textiles

machinery and increasing productivity and speed of the Sensor

fusion and machine perception frontier in industrial Robotics

for intelligent manufacturing in weaving machine model 1998

by change the inclination angle of the rapier bar to increase

speed and productivity to compete with modern models.

Methodology

Methodology is the study of research methods. However, the term can also refer to the methods themselves or to the philosophical discussion of associated background assumptions of automation and technical education for the digital future. A method is a structured procedure for bringing about a certain goal of technology banks in textiles industries, like acquiring knowledge or verifying knowledge IT system integration for compact of old machines in textile industries. This normally involves various steps, like choosing samples of Egyptian Nefertiti sewing machine and weaving “NuovoPignon/SMIT” model 1998, collecting data from this sample, and interpreting the data [18,19]. The study of methods concerns a detailed description and analysis of these processes. It includes evaluative aspects by comparing different methods.

Impact of 5G the manufacturing industry on machines in textile industries

a. Cloud control of machines.

b. Augmented reality.

c. Perceptive AI eyes on the factory floor.

d. High-speed decision-making.

e. Shopfloor IoTs.

Results and Discussions

The technology banks use a diverter less supersonic inlet, while

some producers use carbon-fiber composite in manufacturing.

The automation-digital used a sample duct automation intake to

prevent waves from reflecting off the engine compressor blades,

an important aspect of fifth-generation automation textiles and

clothing machines to reduce frontal vibrations and noise [20,21].

These are a few of the preferred methods employed in some

fifth-generation automation textiles and clothing machines, to

reduce vibrations. In addition to the introductory sections on the

mechatronics concept and design methodology and the impact

of advance in technology the digital future on the mechatronics

concept [22,23]; at the present time, to transform the lives of people

not heavily invested in textile industries, for instance.

a) To update purchases and “business class” plans.

b) Selling 5G-enabled experiences.

c) Using partnerships to deliver 5G-enabled experiences.

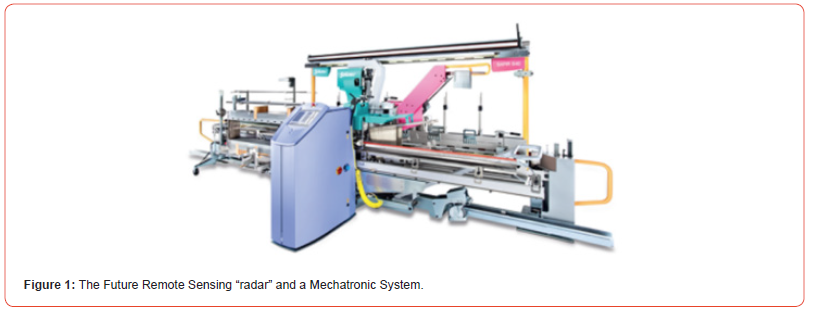

The importance of the mechatronic design in the automation textiles industries is highlighted, as in figure1 together with many examples of artificial intelligence applications in the automation textiles industries include:

a) Exploration and security robotics and mechatronics in the

design of automation textiles machinery, such as 3D braiding.

b) Exploration and security robotics of weaving and

LAN systems for weaving as digital future; Yarn tension

compensation of systems and control engineering.

c) Fuzzy control of texturing and 3D printing.

d) Machine learning, adaptation and imitation of spinning:

measurement automation and diagnosis, knowledge-based

expert systems;

e) Multi-sensor fusion and perception “radar” and automated

garment manufacture and assembly; and

f) Sensor fusion and machine perception of automation

apparel manufacture.

This title is unique in that it brings together many applications

of mechatronics in automation textiles machinery and controls

systems design. In engineering technology of automation

mechatronics in textiles sectors for the digital future:

a) Multi-sensor fusion and perception by mechatronics in

automation textiles s sectors

b) Sensor fusion and machine perception and the

mechatronics design process

c) Design models and methods for mechatronics with

wireless technology and wireless networks

d) Sensor fusion and machine perception as advancements

in technology and its impact on the future developments of

mechatronics concept

e) Intelligent artificial automation textiles machines and

systems of remote sensing “radar”

f) Recent developments in yarn and fabric forming machines.

g) Some aspects of control of automation textiles processes

by solar energy

h) Constant bulk false twist texturing

i) Measurement automation and diagnosis in spinning

j) Monitoring and knowledge-based expert systems in

spinning

k) Mechatronically designed magnetic bearings for highspeed

spindles and rotors.

l) Tension compensation for fixed delivery cone winding: a

mechatronic approach

m) Mechatronics in the design of automation textiles

machines

n) Mechatronics applications in three-dimensional braiding

o) Design of an automation weaving machine for 3D net

shapes

p) Development of a LAN system for weaving factories

q) Compatible sensor fusion and machine perception with

computer-aided design and manufacturing: an automation

textiles-apparel perspective

r) Multi-sensor fusion and perception with mechatronics in

automated garment manufacture

s) Sensing in garment assembly

t) Neurocomputing technologies and applications with

mechatronics in the devises design of automation textiles s

testing. Figure1

Technology banks of IT system integration in clothes industries, for the digital future and what is the industrial automation-Digital transformation in the field of automation textiles industries?

The sensor fusion and machine perception frontier

in automation textiles s industrial Robotics for intelligent

manufacturing of automation textiles s industries by automationdigital

transformation as “automation-mechatronics” refers to a set

of innovation solutions of technology banks and the transition to

new business models and revenue streams consisting of three main

pillars:

a) Technology banks of production the technological

automation-mechatronics in the field of producing automation

textiles industries.

b) Visualization technology banks of improving

manufacturing processes in the field of automation textiles

industries.

c) Technology banks to improve production in the field of

automation textiles industries.

d) The sensor fusion and machine perception frontier

in automation textiles s industrial robotics for intelligent

manufacturing as IT system Integration by solar energy is

a name that has been repeated since ancient times, and each

of its stages has different developments, until we reached the

technology banks of industrial IT system integration in its form

different from the rest of the other control systems in greatly

advances the industries.

Re-Building old sewing machine

Visualization technology banks of IT system integration of

sewing stitches for the digital future and the benefit of this design

include.

a) Charging of sewing stitches when it runs out of old sewing

machine with modifications of using automation –mechatronics

by solar energy.

b) It is portable, is neither heavy nor inconvenient to carry.

c) It has multiple sockets for all kinds of old sewing machine

with modifications of using automation -mechatronics.

d) It can charge all kinds of old sewing machines with

modifications of using automation-mechatronics.

e) It can run for several systems and keeps feeding old

sewing machine with a modification of using automation

-mechatronics.

f) The sewing stitches bank is a very affordable tool.

Technology banks of automation control systems

The sensor fusion and machine perception frontier in sewing stitches industrial robotics for intelligent manufacturing for the digital future, this frontier project is the design and construction of 90 sewing stitches bank for use in residential homes, commercial homes, offices etc. to charge sewing stitches with a modification of using automation-mechatronics of the Sensor Fusion and machine perception frontier in sewing stitches industrial robotics for intelligent manufacturing. The limitation of these designs is that it can only be used for the charging of sewing machine with modifications of using automation-mechatronics and it should not in any case used to charge other high current consumption sewing machine such as very old machine with modifications of using automation-mechatronics, etc [3-5]. We find that the Egyptian sewing machine “Nefertiti Egyptian sewing machine”, which was produced by the Egyptian military factories in the fifties and sixties of the previous century, has stopped production, and the Egyptian factories and families for the production of ready-made garments have begun to import sewing from machines and tools, and Egyptian machines are now included in international museums such as the British museum in London as shown in Figure 2,

Egyptian Nefertiti sewing machine art foundation:

We are now in the process of exposing the largest technological change in the field of sewing industries that humanity has not witnessed before, and that the changes that will occur contribute to saving the great time and effort that a person used to spend in the past, and now the frontier Re-Building old sewing machine by the technology banks of industrial control systems and automationdigital transformation in the field of automation textiles industries of the sensor fusion and machine perception frontier in sewing stitches industrial robotics for intelligent manufacturing by solar energy: In the recent period, there has been talk of a big boom in the world of automation textiles industries and talk of technology banks of industrial control systems, every day huge progress. the visualization technology banks of textiles industrial control systems [6-8]: it is the emergence of new technological devices and technologies, “the automation-mechatronics” in the field of automation textiles industries, which will help discover the world as a whole, but will positively affect the technological, economic and social aspect, in the twenty-first century after a century of surprises and developments, where many smart devices will be discovered.

Which will replace the labor force, which makes everyone

think about the importance of technological progress, as well as

thinking about human labor, which will decrease with the advent

of these devices?, Artificial intelligence devices will replace the

workforce in the field of automation textiles industries, economic

and capital savings in order to achieve improvement in economic

aspects, in conditions of increasing population that requires more

production with technical specifications consistent with functional

performance, which is not easy for countries, as they want to obtain

development, which contributes to increasing the production

process, and at the same time they fear unemployment, Remote

control frontier is the concept of technological sustainability in

the field of automation textiles industries with the three pillars of

sustainability this paved the way for the most common definition of

sustainability and sustainable technological development:

a. Sensor fusion and machine perception of automation

textiles automation-mechatronics

b. Wireless technology and wireless networks of

environmental technology of automation textiles

c. Systems and control engineering control frontier in the

economy of automation textiles

d. Remote control frontier in sustainable technological

by solar energy to development of automation textiles is

development that meets the needs of the present time without

compromising the ability of future generations to meet their

own needs.

e. Sensor fusion and machine perception in sustainable

technological development in the field of automation textiles

industries requires reconciliation between social, technological,

solar energy environmental and economic demands, which are

the three pillars of sustainability.

Re-Building and repairing old weaving machine:

The three pillars of sustainability are not mutually exclusive,

but rather mutually reinforcing.

a) What is the sustainability of technology banks

development of automation textiles?

b) What should be its objectives of visualization technology

banks for automation industrial textiles?

c) How technology banks can these goals be achieved of

automation industrial textiles?

Re-Building by the remote-control frontier of machine of “NuovoPignon/SMIT”

In textiles industrial Robotics for intelligent manufacturing in weaving machine of model 1998, by changing inclination angle rapier tape in malfunctions due to age of battery units in weaving machine model 1998 as shown in Figure3 [12,15].

Technology banks of machine filling insertion:

Double rapier face to face carpet weaving machine, weaving

machine: double rapier double weaving machine made for weaving

with different types of weaving yarn, such as cotton, wool, viscose,

silk, polyester, acrylic, technical yarn.

a) Machine, repair of weaving machines and automation

industrial textiles machinery.

b) Maintenance of weaving machines and automation

industrial textiles machinery.

c) Improvements of weaving machines and automation

industrial textiles machinery.

In the area of filling insertion there have been a lot of developments and implementation has been done in the last few years. These are discussed following solar energy. Versatility in colour insertion by electronic insertion the weft color selectors of today’s rapier weaving machine are microprocessor controlled, compact sized ones and can be available in 8 or 2 colors, was developed the quick step filling presenter since of model 1988, but the speed is limited, operates with independent module, each consisting of an electronically controlled stepper motor with presenter needle. The color and weave pattern are microprocessor or Jacquard controlled. After the left gripper has taken the presented yarns, the quick step needle returns to an intermediary position, so the course of the filling yarn is straight, and the tension of the yarn is low and remains constant.

The machine was the electronic color selector (ECS) and the

electronic filling tension device with integrated filling stop motion

(EFC), is based on state-of-the-art stepping motor technology and

are controlled by an external CAN-BUS. The control systems are

limited need visualization technology banks with machine picking

speed in harnesses weaving up to 8 weft colors give a wide variety

of patterning option. The G6500 offers a machine speed of up to

700 rpm and a maximum weft insertion rate of 1620 m/min.

A. It is monitored by machine of automation textiles,

weaving machine microprocessor so timing for presenting for

filling yarn is perfectly synchronized with machine speed and

weave pattern.

B. The course of filling yarn is low and remains constant.

C. The filling presenter also provides an ideal position for

threading.

D. The modules of quickstep are interchangeable automation

textiles.

Technology banks of machine secure filling transfer

During center transfer from the left-hand to the right-hand rapier, the filling is positively controlled and thus securely transferred. The filling is released after the rapier has exited the shed in the open shed position and under absolute control conditions [9,10]. In the rapier weaving machine, the highest peak yarn tension is extremely low due to the low rapier speed and positive control. Soft thread clamps with hard metal inserts and precision-controlled transfer enable even coarse filament yarns of DTex with 450 filaments to be securely clamped and inserted.

Technology banks of free flight rapier

Flight means that hooks no longer guide the rapier tape, so the hooks can no longer damage the yarns by diving into the warp. Developed free flight rapier in their rapier-weaving machine, which has been specially developed for weaving delicate fabric. Light and small Rapier head the new lightweight guided gripper version enables higher speeds, and since the easier presentation into the gripper clamp requires less filling tension, the number of filling stops is reduced. The light gripper is also smaller, which results in a smoother entrance of the gripper in the shed, ensures less friction on the warp yarns. This reduces the warp breaks. Visualization technology banks of machine versatile and synchronized weft cutter a perfectly efficient weft cutter mechanism is required for use of a wide range of yarn in rapier weaving machine. The weft cutter has direct gear drive, ensuring constancy and precision and reducing yarn wastage. The rapier head inserts any kind of weft. With the “Roto cut” in electronically controlled weft cutter, the timing of weft cutting is optimized.

The “Roto cut” always cuts the weft at the best possible moment, irrespective of yarn type and material. The technology banks of machine electronic filling tension controller it controls the filling brake ensures a current yarn tension at any time during insertion cycle. In visualization technology banks of rapier weaving machine, each pre winder is equipped with programmable filling tensioner (PFT). This PFT is microprocessor controlled and ensures optimum yarn tension during the complete insertion cycle. Reducing the basic tension is an important advantage when piecing up weak yarn, while adding tension is an advantage at transfer of the yarns and avoids the formation of loops. This ensures weaving of strong or weak yarns at even higher speeds and also drastically reduces the amount of filling stops and reduces the waste length.

Technology banks of machine versatility

Rapier weaving machines can be equipped with tappet motion with up to 12 harnesses: positive cams, maximum 12 harness frames.

Technology banks of Machine Controllable Shed Geometry

Modern rapier weaving machine offers shed opening free from setting and optimization of the shed geometry. The shed opening is easily adjusted to suit the style in production. The symmetrical shed geometry and very small, shed offer lower stress on both the warp threads and filling. Automatic shed leveling prevents starting mark due to yarn stretch caused by a stop at open shed. In the shed opening offers optimum geometry combined with a wide range of backrest positions. Small or large shed opening can be easily set to suit the article being woven [12,15].

Electronic setting of shed crossing

A unique technology bank of feature using AKM allows the weaver to control the aspect and hand of the fabric without even touching the drive chain. A few simple keystrokes on the display are all it takes to let reset its crossing points. The fabric quality can be checked, and the setting copied to another machine within a short time.

Technology banks of machine variable shed geometry:

The variable shed opening angles and setting options result in unprecedented precision of the shed geometry in rapier machine. The shed closure timing is easily set at the touch-screen terminals. Shortest drive path technology banks of automation-mechatronics and sensor fusion and machine perception direct driven of the main shaft and the shedding motion through the main motor. This results in reduced noise levels and consumes less energy.

Let-Off Mechanism in Technology Banks of Machine.

The electronic motor driven let-off supplies the loom with

necessary wrap yarn, maintaining the yarn tension constant from

full beam to empty beam. Let-off speed is automatically calculated

in context with loom speed, weft density, wrap beam diameter &

close loop tension control. Accurate synchronization with main

motor in forward & reverse direction in addition with remarkable

latest features supports to minimize the beginning & ending marks

thus, enhancing the grade & quality of the fabric. Besides this, it

enables cramming/density design possible [12,15]. The let-off &

take up is synchronized rigidly with main motor in forward as well

as reverse direction. With the take up electronic system the weft

density variation doesn’t need any more mechanical interruptions

on the loom, it just needs setting parameters on the fly of the key.

Technology banks of Machine the great advantages are:

a) Automation-mechatronics cramming pick findingforward

& reverse.

b) Automation-Mechatronics controlled synchronized

movement during start, stop & running.

c) Automation-Mechatronics boosts the quality & efficiency

of the product.

d) Automation-mechatronics is a great value addition to the

weaving machine.

Visualization technology banks of machine the accurateness in settings & functioning introduces an easy way to adjust weft density for highest fabric weight & least yarn consumption. The most remarkable thing is that it creates lots of alternatives for the weaver to manage the fabric marks & quality. In addition, PC connectivity & internet options offer loom data monitoring either locally as well as from a sensor fusion and machine perception place too.

Technology banks of machine the let-off motion is electronically

controlled with load cell for different setting. Warp tension can be

set by digital system. Warp beams with 800, 1000 and 1200 mm

with following configuration can be available:

a) Automated mining of twin beam with differential drive.

b) Automated mining of twin beam with bilateral let-off.

c) Automated mining of double simple beam or double twin

beam.

Take-Up Mechanism in Technology banks of Machine

The take-up motion is also electronically controlled and synchronized with let-off motion of technology banks. Inside the machine the cloth is wound on to a 600 mm diameter cloth beam. External cloth beam on to batching motion up to 1800 mm cloth roll diameter is also available. The required pick density can be programmed on the microprocessor keyboard or the jacquard control unit in technology banks. The accuracy of the setting ensures easy to adjust of the pick density of the fabric for optimum fabric weight and minimum yarn consumption. The electronic take-up also makes it possible to weave fabric with variable pick densities [12,15].

Drive to the Reed and Rapier in Technology banks of Machine

The rapier drive system is derived from positive cams, manufactured from a single piece of steel, which also incorporates the cams for the drive of technology banks. High speeds are possible due to the special profile of the cams governing the movement laws of the rapier. The profile is designed to transmit the lowest possible acceleration to the filling yarns. In rapier weaving machine, type PS, the rapier and reed are driven through gearboxes with complementary cam assemblies with exceptionally precise control of technology banks. Two high precision synchronized gearboxes, one at each side of the machine, provide the drive for the filling system and reed beat-up. The compact construction and massive drive dimensioned components create little vibration and a high degree of functionality [23, 24], thus achieving a secure center transfer of the filling.

A continuous lubrication system provides for increased performance, low maintenance, and high longevity of the new gearbox generation. Technology banks developed the oscillating rotational motion of the rapier wheel generated by a simple, robust, three-dimensional crank system, ensuring reliability, and requiring no maintenance or adjustment. The driven by a set of complementary cams with cam followers on both sides of the machine. They run in an ion bath connected to the central lubrication system. The reed holder is perfectly balanced and provides a powerful beat-up over the whole weaving and ensuring less vibration. When weaving heavy and densely beaten fabrics, the machines system has a strategic role. For developed several drive units for narrow loom and three for double-width machine fixed on the main cross bar and coupled to the connecting shafts. The optimized geometry of the kinematics, strengthening of the camshafts in the balancer and cam-reading shaft, centralized lubrication for the drive units all this help to guarantee big advantages in terms of stability.

Automation Start Mark Prevention in Technology banks of Machine:

Automated mining start-mark prevention (ASP) prevents start mark at the source. The simple functionality of automatic startmark prevention saves time and significantly contributes toward quality improvement. All the functions outlined in the illustration can be simply called up on the machine display and changed as required.

Electronic Control Technology in Technology banks of Machine

The electronics of modern rapier weaving machine are based

on multiprocessor architecture with 32-bit technology. Data

transfer between the various subunits of the machine is via a CANBUS,

of technology banks permitting fast and reliable exchange

of data both internally and externally. The terminal has a graphic

display in which various functions of the warp let-off, cloth takeup,

weft feeder, can be programmed easily and. clearly. The modern

electronics by solar energy give the Technology banks following

advantages [12,15]:

a) Control the ease of operation.

b) High fabric quality irrespective of control speed.

c) Pick density alterable while the machine is in operation.

d) Immediate help trouble-shooting problem.

e) Self-adjusting stop position of the machine.

f) Microprocessor controlled central forced lubrication

system.

g) Storage and monitoring of all the production data,

efficiently.

h) Machine function control, pattern weave, warps tension,

pick density.

i) Pick finding control and the elimination of stop marks by

means of pro-set programs.

j) Control and report of style change timing.

k) Quick control of the electronic functions and monitoring

of the machinery functions for protection.

l) Bi-directional communication between the weaving

machine and the central production computer.

m) Speed set-up.

n) Electronic weaving speed variation depending on the

characteristic of the yarn being used.

o) Control of warp let-off and fabric take-up.

p) Electronic control of the filling tension.

q) Transfer of setting and production parameters of a fabric

style, to other machine with the help of memory cards of

Technology banks.

In technology banks of machines, most of the machine functions are digitally controlled. All the machine settings can be digitally stored and transferred. The electronic terminal on technology banks of machine monitors controls all machine functions. Its LCD screen has self-explanatory menus and enables the weaver to set the weaving parameters in a very user-friendly way. Technology banks of machines are also internet-enabled. The technology banks of machine terminal features wireless communication through a USB memory stick or key tag of sensor fusion and machine perception, permitting robust, flexible, handy and reliable operation. Technology banks of machine-intelligent pattern data programming. “Smart weave” offers fabric designer intelligent support in the preparation of weaves design and picks repeats. The g6500 control interface is a user-friendly, internet-ready touch screen terminals.

Main drive-in technology banks of machine

The technology banks of rapier-weaving machines are driven with a continuously running motor over a magnetic brake-clutch unit. Intelligent electronics monitor the acceleration time and control the exceptionally short brakes time. This guarantees the full dynamics of reed beat-up on the first pick, thus eliminating the start mark. Technology banks have developed the sumo main motor. It drives the weaving machine directly, without belt transmission or clutch and brake. The machine speed is controlled electronically, which considerably reduces the setting time. With the sumo motor it is possible to continuously adapt the machine speed pick-by-pick to match the strength of the filling yarn. With the help of this system, it is no longer necessary to keep the machine speed continuously low if there is one weaker filling yarn in multi-channel weaving.

With the sumo motor it is possible to continuously adapt the

machine speed pick-by-pick to match the strength of the filling

yarn. With the help of this system, it is no longer necessary to keep

the machine speed continuously low if there is one weaker filling

yarn in multi-channel weaving. The advantages of sumo motor are:

a) Energy Saving by solar energy consumption of more

than 25% in comparison with conventional clutch and brake

configuration.

b) Machine speed setting is done accurately and completely,

electronically via the keyboard of microprocessor. This reduces

the setting time to zero.

c) Speed setting is easy to copy to other machines either

with electronic set card or with production computer with bidirectional

communication.

d) A technology bank of machine automatic pick finding

becomes faster, which significantly reduces the down times for

repairing filling and warp breakages.

e) Technology banks of machine the machine can always

work at optimum weaving speed in function of quality of the

yarn, the number of frames, and fabric construction.

The idea of sustainable technological development involves the technological ecological economy. From this perspective, the economy is a sub-system of human, the “automation-mechatronics “technology banks. On the one hand, it is necessary to be realistic and scientific in the field of automated mining the textiles industries, and a clear and specific statement of the meaning of the technological point. There is a simple definition of technological sustainability in the field of automation textiles industries” technology banks “, as improving the quality of human life when we live within the absorptive capacity of the supporting technological systems, and with its ambiguity, that is, it gives the idea of technological sustainability quantifiable limits. But sustainability in the field of automated mining textiles industries is also a call to action, and it is important in the progress or technological journey, so it is a political process, and therefore some of the definitions contained define common goals and values. He talked about a sustainable global technological community based on respect for nature, universal human rights, economic justice and a culture of peace.

Consumption and population: and resources in the field of automation textiles industries

One of the most important impacts on humanity on earth’s

systems is the provision of biophysical resources and especially,

earth’s ecosystems. The environmental impact of humanity, the

“automation-mechatronics” as a whole, depends on the population

as well as on the influence of the individual, and in turn depends on

many complex methods related to the resources used technologically

in the field of automation textiles industries and whether they are

renewable or not, and on the size of human activity relative to

the absorptive capacity of the technological systems concerned.

Accurate systems can be applied to manage these resources at many

levels, from economic sectors, such as the manufacturing industry

(in the field of automation textiles industries), agriculture and

industry, to organizing work, and to the patterns of consumption

of households and individuals for individual resources, goods

and services. The technological equation, which was developed

in the twenty-first century, is considered one of the first attempts

to develop a technological mathematical expression that explains

human consumption through three elements:

a) Population at the levels of technological consumption

b) The term affluence is used in the automation-mechatronics

community, despite its different meanings.

c) Automation-mechatronics, which is the impact on each

user resource unit. Named, because this effect depends on the

use.

A Measure of technological sustainability in automation of textiles industries

Technological sustainability scale is the term used to denote the bases of numerical measures used to manage the science of technological sustainability in the field of automation textiles industries based on knowledge. The automation -digital standards used in technological sustainability, which involve technological sustainability in the field of automation textiles , environmental, social and economic industries, whether at the individual level or various combinations in the automation-mechatronics are constantly evolving and they include indicators, standards, audits and standards of technological sustainability in the field of automation textiles industries and certification systems such as trade fair and organic, indexes and accounting, as well as evaluation, and other reporting systems. Which are widely applied at spatial and temporal scales? Some of the best known and widely used sustainability measures include corporate sustainability reports, triple bottom line accounting, global sustainability association and estimates of the quality of individual countries’ sustainability governance using the environmental sustainability index and the automation textiles environmental performance index.

Sustainable technology banks that seek to reduce the individual or community’s use of the earth’s natural and personal resources. Sustainable living practitioners seek to reduce carbon emissions by changing transportation, energy consumption and diet. Proponents of sustainable technology banks aim to make their lives sustainable in a natural, balanced way, respecting human symbiotic relationships with the environment and the earth’s natural cycles. This practice and the general philosophy of ecological living are closely intertwined with all principles of sustainable development. sustainable technology banks in the 21st century is characterized as a shift to renewable energy a shift to renewable energy and a reuse or recycling economy with diversified transportation systems in addition to this philosophy, certain eco-village builders such as the villages aim that the shift to renewable energy technologies will only be successful if they the resulting built environment is attractive to the local culture, and can be preserved and adapted as necessary over generations.

Conclusion

Which affects the investment and establishment of factories in the cost of capital to purchase textile industries machinery from this point of view? It was necessary for us. To recycle these “old machines” to benefit from them in order to achieve rationalization and saving and economy in capital in the return of the local economy. The textile industries banks are an electronic device which produces electric energy for consumption when charge textile industries, it is an external charging automation IT system integration for compact of old machines in textile industries automated mining and technical education for the digital future. Technology banks: a fifthgeneration of automation IT system integration for compact of old machines in textile industries automation and technical education for the digital future has made a lot of impact both on human’s life as a result of the fact that people find it difficult to do away with their textile industries machine switch off or drained out while they are away from their home or offices or which can be as a result of outage or interrupted textile industries supply. It has also improved the economy tremendously as more people buy it as a necessity for the purpose of charging their automation IT System integration for compact of old machines in textile industries automation and technical education for the digital future.

Rapier weaving machines have become fast and exceptionally flexible. It offers a choice of various reed widths, shedding motions, selvedges and filling insertion colors etc. The weft color selectors of today’s rapier weaving machine are microprocessor IT system integration. Repair NuovoPignon/SMIT. Machine, improvement and machinery maintenance, repairs technology banks of machine, maintenance and improvements of weaving looms and automation textiles machinery by using solar energy.

Repair technology banks of machine of weaving machines and

automation textiles machinery, maintenance of weaving machines

and automation textiles machinery, key advantages:

a) Increase the level of machine automation.

b) Extend the life cycles of your equipment.

c) Improve quality and productivity.

d) Improve reliability.

Recommendation

This presentation is recommended for use in technology banks: a fifth generation of automation IT system integration for compact of old machines in textile industries automation and technical education for the digital future and at any locations for the charging of textile industries machines when there is interruption of electronic textile industries bank has supply and should not in any case use to charge high consuming textile industries machine from laptop computer.

Acknowledgement

None.

Conflict of Interest

No Conflict of interest.

References

- Elnashar EA (2023) Sustainability Green Technology, Recycle-Technology of Sewing Technology by Applying the Stitch Bank of old Machines. Engineering: J Current Eng Technol 5: 2.

- Elnashar EA (2023) Stitch Sustainability - Green Technology and Recycle technology of Sewing Technology by Applying the Stitch Bank of old Machines, online magazine for Textiles, Clothing, Leather and Technology 3.

- ElNashar EA (2000) Ph.D. thesis entitles Design of Database for Forecasting the Specification of Woven Fabric Design for Ladies Dresses. University of Helwan, Cairo, Egypt.

- ElNashar EA (1995) M.Sc. Entitle: Effect of warp-ends densities distributions on some esthetical and physical properties of multi- layers woven fabric. Faculty of applied arts, University of Helwan, Cairo, Egypt.

- ElNashar EA (2023)) book Preventive maintenance in the textile industry ISBN: 978-620-4-72406-5, Noor-publishing.

- ElNashar EA (2023) textile equipment, Mechatronics textile equipment, ISBN: 978-620-4-72407-2 Noor-publishing.

- ElNashar EA (2023) Computer applications in topology of textile industries, ISBN: 978-620-5-63422-6, Noor-publishing.

- ElNashar EA (2023) Digital Transformation by Artificial Intelligence for Innovating and Development of Textile Industries in Egypt, the 11th Annual World Congress of Nano Science &Technology (Nano S&T-2023), which will be held in Barcelona, Spain during Session 7-1: Nanotech in Smart Textiles and Wearable Technology.

- ElNashar EA, Assem A, Elnashar Amr (2022) Modern Areas of Artificial Intelligence Applications in the Textile Industries Using Mechatronics Philippine Textile Congress, Intertwining the Philippine Textile Innovation Ecosystem, the Philippine Textile Research Institute of the Department of Science and Technology (DOST-PTRI)!, the Keynote Speakers for Session 7.

- ElNashar EA (2022) Ergonomics Multidisciplinary Approach Of 3d Body scan of Anthropometry, 21st World Textile Conference AUTEX 2022, Passion for Innovation, Lodz, Poland, AUTEX 2022 Conference Proceedings 978-83-66741-75-1 © Lodz University of Technology.

- ElNashar EA, Liliana Indrie, Dorina Camelia Ilieş, Zlatin Zlatev, Grigore Vasile Herman, et al., (2022) Rare Romanian Ethnographic Textiles-Reverse Engineering of Fabrics for Fashion Trends. The Special Issue Sustainability in Conservation of Cultural Heritage.

- ElNashar EA (2022) Applications of mechatronics opportunities in textiles International Robotics & Automation Journal 8(1).

- Elnashar A, Elnashar H, ElNashar EA (2021) The future of development and innovation in Egypt of solar textiles for the needs of the Middle East to increase the economy, Journal of Textile Engineering & Fashion Technology 7(6): 219-226.

- ElNashar EA (2021) Sustainable Textiles Industries in Brand Technology Between Technologies of Brands. 3rd International Webinar Advanced Materials, International Conference on Advanced Materials, Materials Science and Nanomedicine.

- ElNashar EA (2021) Textile Industries Applications in The Modern Era Linking Industry to Scientific Research, Online magazine for Textiles, Clothing, Leather and Technology, pp. 237-254

- ElNashar EA (2021) The Role of Research Towards Achieving Global Sustainable Development Impacted of the Covid-19. Trends in Textile & Fash Design 4(1).

- ElNashar EA (2018) Decision Support System of Global Brands in Fashion Marketing Strategy for Entrepreneurship, Trends in Textile Engineering & Fashion Technology, Crimson Publisher 3(5): 1-2.

- ElNashar EA (2018) Smart Textile Circuitry and Their Application, journal Current Trends in Fashion Technology & Textile Engineering 4(2).

- ElNashar EA (2018) Faculties of Textiles Education Between Challenges and Renaissance in the 21st Century for Labor Market Mobilization, Applied Research in Technics, Technologies and Education Journal of the Faculty of Technics and Technologies, Trakia University, Bulgaria.

- Elsayed A ElNashar, Dmitry Pirogov (2022) Properties of torsion rod in Sulzer projectiles loom Journal of Textile Engineering & Fashion Technology 8(1).

- Elsayed ELNASHAR (2019) Contemporary Fashion and its Artistic Values in the Fifth Generation of Technology, Jornal of Latest Trends in Textile and Fashion Designing (LTTFD).

-

Elsayed Ahmed Elnashar*. Technology Banks: A Fifth Generation of Automation Control Systems for Compact of Old Machines in Textile Industries. On Journ of Robotics & Autom. 2(2): 2023. OJRAT.MS.ID.000535.

Mathematics & Statistics, Modern Warfare, Autonomous Weapons, Robotics, Unmanned vehicles, Drones, Ethics.

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.