Mini-Review

Mini-Review

From Industry 4.0 To Industry 5.0: The Evolution of Robotics and Automation

Yusuff Babatunde Olujobi* and Ayorinde Oduroye

Caleb University, Lagos, Nigeria

Yusuff Babatunde Olujobi, Caleb University, Lagos, Nigeria

Received Date:May 31, 2025; Published Date:June 23, 2025

Introduction

This paper examines the trajectory from Industry 4.0 to Industry 5.0, addressing how intelligent automation is reshaping industries and societies globally. The ongoing digital transformation necessitates a closer look at how technologies like artificial intelligence (AI), robotics, and the Internet of Things (IoT) are moving beyond efficiency and productivity to embrace human-centric, sustainable, and value-driven goals. Industry 5.0 is built on the progress made in Industry 4.0. While Industry 4.0 brought about smart factories and connected technologies, Industry 5.0 takes it further by blending the unique strengths of people, like creativity and problem- solving, with the speed and accuracy of machines. This, therefore, changes how we think about the goal of the industry, not only about technology improvement. it also queries the fairness in innovation, the responsible use of technology, and how jobs will evolve. In addition, this paper takes a look at all these and also explores the potential advantages and possible disadvantages.

Historical Overview: From Industry 1.0 to 5.0

There is an interesting history of industrialization and industrial

revolutions. The history offers valuable insights into how production

and society have evolved:

• Industry 1.0 (Late 18th Century): Industry 1.0 severely

changed the world. It was more than just a change in how things

were made, it was a change in how people lived. This is the period

of the advent of mechanization using steam power and water. Me

chanical manufacturing equipment was introduced during this rev

olution which is responsible for the transformation of textile and

agriculture-based economies into industrial powerhouses.

• Industry 2.0 (Late 19th Century): This is the period when

electricity was widely adopted and assembly line procedure

also started for manufacturing, resulting in efficiency by the

widespread adoption of electricity and the development of

assembly line production. Innovations like the telegraph, railroads,

and internal combustion engines also are responsible

for significant increase in productivity and accessibility.

• Industry 3.0 (Mid 20th Century): this revolution started with

the rise of electronics, IT, and early automation. This is also followed

by the introduction of computers, semiconductors, and

programmable logic controllers (PLCs) revolutionized data

processing, paving the way for mass customization.

• Industry 4.0 (Early 21st Century): This is the revolution

built on digital technologies. The building blocks of this industry

4.0 are concepts like artificial intelligence (AI) and machine

learning (ML), which let machines get smarter on their own.

Then there’s the Internet of Things (IoT), which connects devices

to talk to each other and share information. And let’s not

forget Big Data - this is all about crunching huge amounts of

information to make smarter decisions. - cyber physical

• Industry 5.0 (Emerging): this is industrial revolution that can

be said to be an enhancement revolution instead of being a replacement

like its predecessors. It changes position of humans

to be at the center of industrial innovation with emphasis on

collaboration between people and intelligent machines to foster

personalization, sustainability, and resilience.

Understanding Industry 4.0

Industry 4.0 signifies a significant technological leap that connects digital systems with physical manufacturing. Its fundamental purpose is to automate and simplify industrial activities using interconnected machinery and strong analytics.

Key Features:

• Cyber-Physical Systems (CPS): This is a system that involves

digital and physical processes in real-time. Cyber-Physical

Systems (CPS) are engineered systems that integrate computational

elements with physical processes.

• Industrial Internet of Things (IIoT): Enables machine-to-machine

communication and real-time monitoring.

• Big Data and Analytics: It provides insights from vast data

streams for predictive maintenance and performance optimization.

• Cloud Computing: It offers scalability, data storage, and remote

processing capabilities.

• Smart Manufacturing: Automated systems that can adapt and

optimize production with minimal human intervention.

Impact on Industry:

• Enhanced operational efficiency and flexibility.

• Improved supply chain transparency.

• Introduction of autonomous systems in logistics and production.

Despite its many advantages, Industry 4.0 also raised issues with regional digital divides, expensive infrastructure expenditures, and employment displacement.

Emergence of Industry 5.0

The trend toward greater integration of human duties in the industrial environment is what Industry 5.0 is, not a departure from the past. It emphasizes values like innovation, sustainability, and human decency.

Defining Characteristics: Human-Centric Approach: Prioritizes

the well-being of workers and focuses on enhancing human-machine

collaboration.

• Personalized Production: Enables mass customization, satisfying

individual customer needs.

• Sustainability: Advocates eco-conscious manufacturing practices.

• Resilience: Builds adaptive systems that can withstand disruptions

(e.g., pandemics, cyber threats).

Drivers of the Transition:

• Societal push for ethical and responsible technology.

• Demand for personalized and sustainable products.

• Limitations of full automation in complex, creative tasks.

Industry 5.0 aims to create intelligent ecosystems where machines augment rather than replace human capabilities.

Key Technologies Driving Intelligent Automation

The convergence of several cutting-edge technologies underpins

the transformation toward Industry 5.0:

• Artificial Intelligence (AI): Facilitates decision-making, quality

control, and process optimization.

• Collaborative Robots (Cobots): Work safely and effectively

alongside humans on manufacturing lines.

• Digital Twins: Virtual replicas of physical systems used for

simulation and monitoring.

• Edge Computing: Reduces latency by processing data closer to

the source.

• Augmented Reality (AR): Enhances real-time interaction and

training by overlaying digital information onto physical environments.

• Blockchain: Ensures secure, transparent, and tamper-proof

transactions across supply chains.

These technologies are not only increasing productivity but also enabling human operators to make smarter, faster, and more informed decisions.

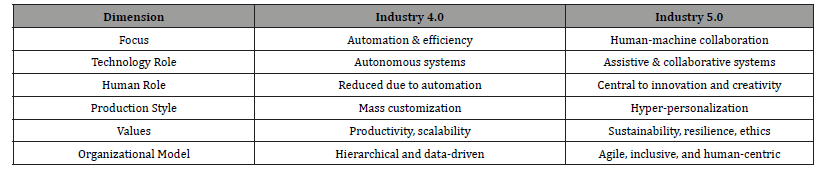

Comparative Analysis: Industry 4.0 vs. Industry 5.0

Understanding the key differences and synergies between Industry 4.0 and 5.0 helps in charting future strategies:

Table 1:

Instead of discarding the technologies of Industry 4.0, Industry 5.0 builds upon them to create a sustainable, ethical, and balanced future. Industry 4.0 concentrated on digitizing and automating processes, while Industry 5.0 reintroduces the human element as a vital innovation driver.

Applications of Industry 5.0 in Modern Sectors

Industry 5.0 technologies are being applied across multiple sectors,

delivering transformative results:

• Manufacturing: Human-centric cobots and AI-driven customization

enable agile production.

• Healthcare: AI supports diagnostics, robotic surgeries, and

personalized treatments.

• Agriculture: Smart farming utilizes IoT, drones, and AI to optimize

yield and sustainability.

• Retail: AR, AI, and data analytics personalize customer experiences

and supply chains.

• Education: Virtual reality and AI-powered tutors offer immersive

and adaptive learning.

These applications demonstrate how Industry 5.0 is advancing human potential and social progress.

Ethical, Social, and Environmental Implications

As technologies become more advanced, addressing their

broader impact becomes crucial:

• Ethical AI: Transparent, fair, and accountable AI systems must

be prioritized.

• Data Privacy: Secure handling of personal and industrial data

is imperative.

• Job Transition: Workers must be upskilled to thrive in new collaborative

roles.

• Environmental Sustainability: Green technologies and circular

economies help reduce industrial waste and carbon footprints.

• Digital Inclusion: Access to technology and skills must be equitable.

Policymakers and industries must work together to ensure technology supports inclusive and sustainable growth.

Future Outlook and Challenges

While Industry 5.0 promises a human-centric and intelligent

future, several challenges remain:

• Integration Complexity: Seamlessly blending human input

with AI and robotics.

• Cybersecurity Threats: Protecting complex networks from

evolving cyber risks.

• Regulatory Frameworks: Developing global standards for AI,

data use, and robotics.

• Cultural Adaptation: Encouraging acceptance of new technologies

and work models.

Nevertheless, the continued evolution toward Industry 5.0 offers a powerful vision where technology enhances human life and societal well-being.

Conclusion

Industry 5.0 is a clear shift in industrialization because it fuses human creativity and empathy with the efficiency of technology. it is built on the digital underpinnings of Industry 4.0, and offers a more sustainable and inclusive future vision. Organizations and society may achieve unprecedented levels of productivity, resilience, and well-being by adopting ethical principles, technological innovation, and human collaboration.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Xu X, Xu Y, Li L (2021) Industry 4.0 and Industry 5.0: Current status and future trends. Journal of Intelligent Manufacturing 32(3): 1-18.

- Nahavandi S (2019) Industry 5.0-A human-centric solution. Sustainability 11(16): 4371.

- European Commission (2021) Industry 5.0: Towards a sustainable, human-centric and resilient European industry.

- Javaid M, Haleem A (2020) Industry 5.0: Potential applications in COVID-19. Journal of Industrial Integration and Management 5(04): 507-530.

- Wang K, Lee J (2022) Intelligent manufacturing systems: A roadmap to Industry 5.0. Procedia CIRP 100: 68-75.

- Aderounmu GA (2021) ICT and sustainability in the Industry 5.0. ITPulse.

-

Yusuff Babatunde Olujobi* and Ayorinde Oduroye. From Industry 4.0 To Industry 5.0: The Evolution of Robotics and Automation. On Journ of Robotics & Autom. 4(1): 2025. OJRAT.MS.ID.000579.

Industry; Artificial intelligence (AI); Internet of Things (IoT); Machine Learning (ML); Cyber-Physical Systems (CPS); Cloud Computing

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

- Abstract

- Introduction

- Precision, Efficiency, and Collaborative Robotics (Cobotics)

- Energy Conservation and Green New Work

- Flexibilization of the workplace and ecological benefits

- Waste reduction, circular economy, and cobotic synergy

- Reduction of Harmful Emissions

- Challenges and Considerations

- Conclusion

- Acknowledgement

- Conflict of Interest

- References