Mini Review

Mini Review

3D-printing of Houses

Qasim Mohammed Shakir*

University of Kufa, Faculty of Engineering, Civil Department, Iraq

Qasim Mohammed Shakir, University of Kufa, Faculty of Engineering, Civil Department, Iraq

Received Date: November 21, 2024; Published Date: December 13, 2024

Introduction

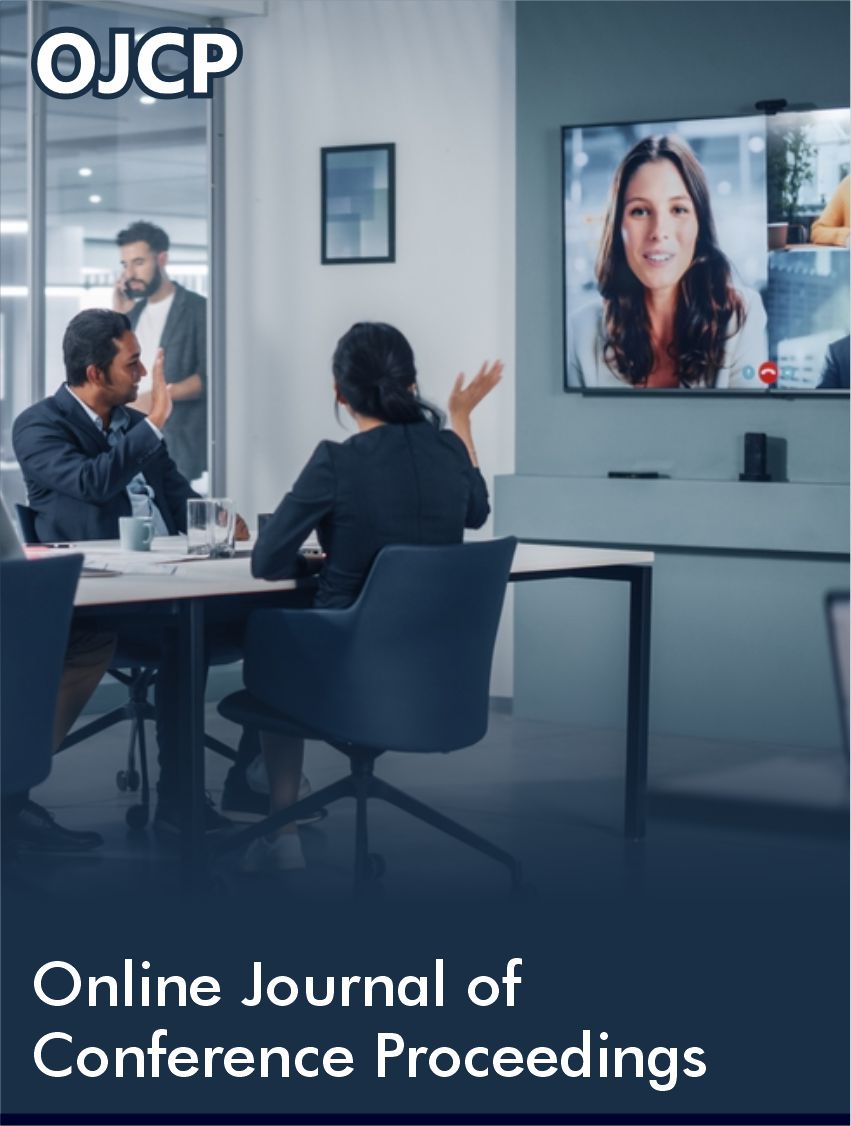

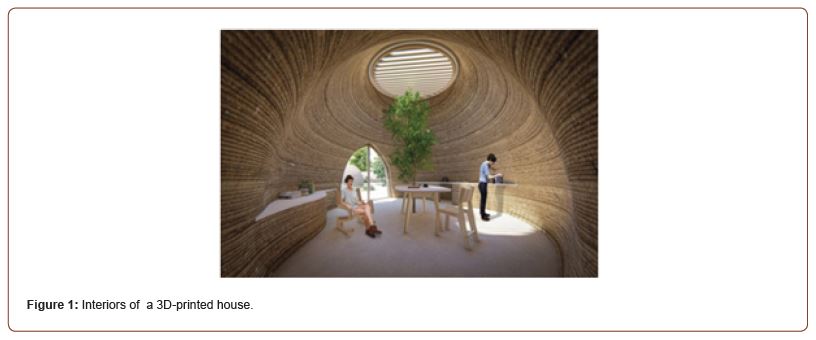

Three-dimensional printing of homes, Figure 1 is a modern structural method in which material objects are created by distributing materials in layers based on a digital scheme to create a three-dimensional model of real size. In 2004, Dr. (Behrokh Khoshnevis) from the University South Carolina built the first 3D printed wall [1]. Since then, many improvements have been made to this innovation and it is now possible to build a house in just 20 hours. The machine consists of a head robot that moves in and out to distribute the building material and produces a paste-like substance (such as toothpaste), layer after layer, Figure 2.

Conventional concrete cannot be used in 3D printing because each layer needs sufficient hardening before the next layer is applied to support its own weight [2]. Therefore, concrete is used with additives that precipitate hardening of concrete; coarse aggregates are also not used therein. The wall thickness is about 24 cm, and it is made of an inner and outer layer of material, connected by winding surfaces of the same printing material. There is still apprehension about the use of 3D printing on bridges and skyscrapers.

To create the 3D shape, the program with the device will start analyzing the data file describing the 3D geometry, after which it will “split” the shape into a large number of horizontal layers. The part is built, starting from the bottom layer, and adding successive layers over the other until the top is reached. Instead of taking months to build, it may take a few days. A company in China announced that it had built 10 homes in less than 24 hours in 2014, and all of its materials came from recycled waste materials.

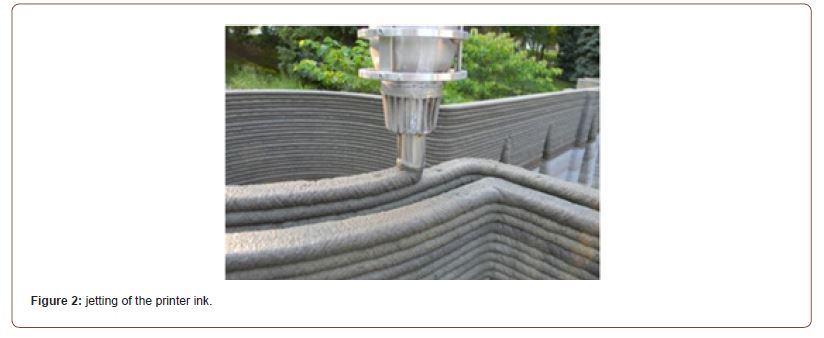

This system of construction was used in many other countries around the world such as Japan, Russia, Canada, India, Mexico, Australia and South Africa [3]. As for the Arab world, the United Arab Emirates is the first Arab country to adopt the threedimensional method of printing houses, where Dubai announced, which includes the first triple printed office Worldwide Dimensions, plans for 3D printing for a quarter of the city’s buildings by 2030. In order to achieve this, the city is developing legislation and codes for the use of 3D printing in the construction of future buildings. Dubai hopes that through its plan it will be able to position itself as a global hub for 3D printing by the target date, and the construction of a two-story house has recently been completed, depending on the 3D printing technology as shown in Figure 3. The Kingdom of Saudi Arabia also plans to print 1.5 million homes within the coming years.

The Italian company WASP is one of the most famous companies that works with the technology of 3D printing for homes. It developed a plan that aims to create more sustainable buildings where it developed one of the largest 3D printers in the world and is able to build houses from materials from local sources using solar energy, wind energy or energy Hydro [4]. This is useful for completing work in remote areas that have not been served by the electricity service.

Winson has come up with a paste consisting of cement, sand, and fiber (for tensile strength) mixed with additives in water and chemicals to give it the right mix of flowability and rapid preparation properties. This mixture is prepared in mixers and then pumped to the printer through a flexible tube. Industrial waste is also used in this mix as support to the philosophy of sustainable construction [5].

Features

1) Economy in the use of construction materials: The printer uses only the necessary amount of construction materials. This means less cost and less construction waste.

2) Lower transportation costs if products are printed on site (although the cost of moving a printer can be costly due to the size of printers).

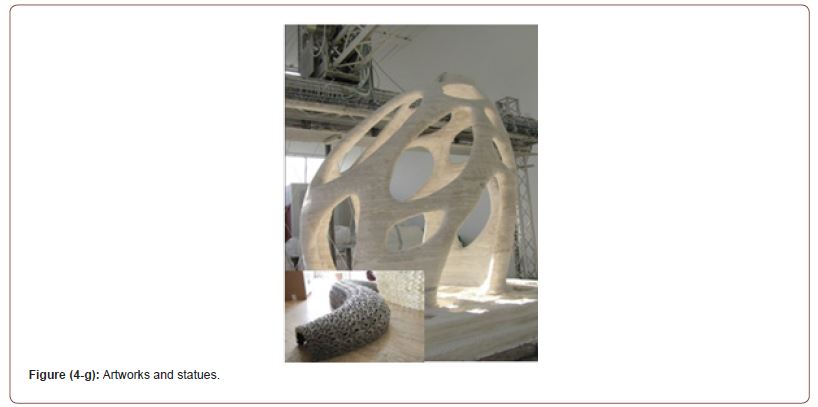

3) The ability to create many different architectural designs such as 3D printing can achieve shapes that cannot be easily achieved with traditional techniques.

4) Low labor costs. As most of the work is automatized.

5) The low cost of the assigned design if the design is repeated many times, as in the residential complexes.

Disadvantages

1) Need special equipment and precautions to be considered.

2) More expensive than traditional construction due to the high cost of the 3D printer and the lack of engineering and technical personnel needed to carry out the work. 3D printing also includes additional costs for creating the digital model.

3) A limited number of materials are currently being used, although studies are underway to produce printers capable of using multiple materials that are environmentally friendly and relatively economical.

4) 3D printers may need large space to work and therefore difficult to put on site. Some house may not be suitable.

5) Printers are slow compared to traditional construction, but their ability to operate 24 hours a day, seven days a week makes them more productive.

6) Any malfunction or problem with the printer’s operation may cause a delay in work.

3D printing system applications:

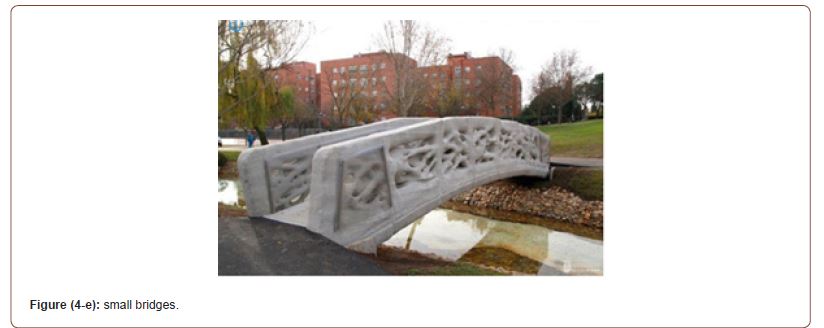

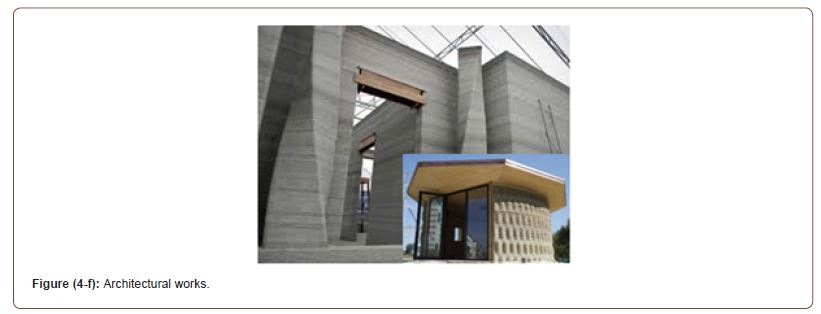

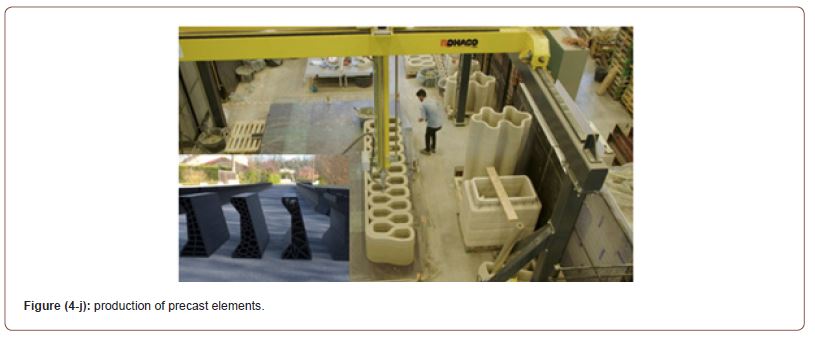

Figure 4 shows some 3D printing applications in construction and building.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Nadarajah N (2018) Development of concrete 3D printing. Thesis, Aalto University.

- M Yossef, Chen A (2015) Applicability and Limitations of 3D Printing for Civil Structures, Iowa State University.

- T Ahmed MS Ibrahim, Rod R Jose, Amr N Rabie, Theodore L Gerstle, Bernard T Lee, Samuel J. Lin, (2015) Three-dimensional Printing in Developing Countries, PRS Global Open, 3(7): e443.

- Sarhan A (2014) Print Your Concrete House with 3D Printer.

- Sakin M, Kiroglu YC (2017) 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM, 9th Conf. on Sustainability in Energy and Buildings, Greece, 134: 702-711.

-

Qasim Mohammed Shakir*. 3D-printing of Houses. Onl J of Conf Procee. 1(2): 2024. OJCP.MS.ID.000508.

-

dimensional printing; 3D printed; skyscrapers; construction; digital model

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.