Research Article

Research Article

Post-Byzantine Glass from Sites of the Peloponnese: Investigating the Complex Glass Network of Southern Greece

Eleni Palamara1*, V. Valantou1, Dimitrios Palles2, Efstratios I. Kamitsos2 and Nikolaos Zacharias1

1Laboratory of Archaeometry, Department of History, Archaeology and Cultural Resources Management, University of the Peloponnese, Kalamata, Greece

2Theoretical and Physical Chemistry Institute, National Hellenic Research Foundation, Athens, Greece

Eleni Palamara, Laboratory of Archaeometry, Department of History, Archaeology and Cultural Resources Management, University of the Peloponnese, Kalamata, Greece.

Received Date: May 01, 2023; Published Date: July 25, 2023

Abstract

The current project focuses on the chemical analysis of utilitarian glass objects of the post-Byzantine period, from two sites in mainland Messenia, Peloponnese, southern Greece: Androusa and Alagonia. The assemblage consists of 48 glass fragments of vessels, drinking vessels and glass panes. The vast majority of the samples are colourless or naturally coloured, although there are also a few blue, green and amber samples; few samples present decoration, primarily with engraved and enamel patterns. Their exact date is uncertain; they are placed between the 15th and 19th c. Based on the chemical and mineralogical analysis (carried out via SEM/EDS, p-XRF and Raman) a complex image emerges, suggesting the use of varied raw materials (Na- or K-rich plant ash, potash, saltpetre as the alkali source; manganese and arsenic as decolourants; tin oxide and calcite as opacifiers). Given that during this period there was a high diversity in the manufacturing technologies used in glass workshops from different areas, it is possible to identify glasses originating from both the eastern regions of the Ottoman Empire (following the Islamic tradition of glass making) and from Europe (e.g., Bohemian glass). Comparing the glasses of these two sites with previously studied assemblages from Messenia provided with valuable new information regarding the production and trade of glass in mainland Greece during the post-Byzantine period. Overall, a complex trading network is suggested, both for low-quality utilitarian objects and for higher quality luxurious glasses, which is even more intriguing given that neither of these sites had a port and, therefore, direct access to the significant marine trading networks of the period.

Keywords: Post-Byzantine glass; Androusa; Alagonia; Production technology; Enamels

Introduction

During the Middle Ages, ground-breaking innovations took place that completely changed the production of glass in Europe. During the 9th c. the main source of alkalis changed from natron to plant ash [1]. Additionally, the production model gradually changed, with the introduction of local workshops which carried out both the activities of glassmaking and glass working. These two changes marked the beginning of a period of experimentation, with an emphasis on the use of new raw materials, local and easily accessible, as well as the introduction of new production methods. At the same time, the production of older types of high-quality glass continued, using traditional raw materials. As a result, glass produced between the 14th and the 19th c. in Europe and the Middle East is characterised by exceptional chemical diversity, with Na-rich (Byz antine, Islamic, Venetian and ‘façon de Venise’ glass), K-rich (forest glass, High-Alumina Low-Alkali, crystal, Bohemian and English lead glass) and Mixed Alkali glass produced to cover the need for different qualities of glass objects. An overview of the main chemical groups and manufacturing centres is given elsewhere [2,3].

Although the post-medieval glass of central and northern Europe has been extensively studied, the production, distribution, and use of glass of the same period in the territories of the Ottoman Empire remains almost unknown. It has been documented that Venice mass produced glass, intended for the markets of the East and the Balkans, following local aesthetic standards [4]. After the end of the 17th c. - and especially during the 18th c. - Bohemia became one of the most significant glass production centres and mass exported glass both towards western and northern Europe and to the Ottoman Empire [5]. In the regions of present-day Turkey and the Middle East, small quantities of glass were produced by local workshops throughout this period, but only at the end of the 18th c. there was a significant increase in production, especially in the Beykoz district of Istanbul, with strong influences from Venetian and Bohemian glass [6]. Chemical studies have been carried out in few assemblages (i.e., glass from Istanbul [7] and from limited locations in the Balkans [8 -and references therein-, 9]). These studies showed strong heterogeneity in the chemical composition of glass, indicating the parallel introduction and use of glass from many different centres of the East and the West. In Greece, the existence of small glass working - or even glassmaking - workshops cannot be ruled out, although there is no clear historical or archaeological evidence to support this hypothesis. The only workshop that has been found to date is in the area of the Agora in Corinth, but it dates much earlier (to the 11th c.) [10]. In addition, there is no clear historical information about the main glass import centres and the possible trading networks.

Until this point, archaeometric analysis of post-Byzantine glass in Greece has focused on sites in southern Greece with ports to the west (Kyparissia and Methoni [3,11]), and on the city of Mystras, which was the administrative, commercial, and cultural centre of the late Byzantine and post-Byzantine period [12,13]. In Kyparissia and Methoni, glass samples were recovered from two public bathhouses, whereas in Mystras all samples were recovered from the Palace complex. In all cases, the chemical analysis indicated a remarkable chemical heterogeneity, and consequently the importation of glass from many glass centres both from the West and the East. Additionally, there were some indications of a local production of HLLA (High-Lime Low-Alkali) glass in Methoni [11]. The present study focuses on the chemical study of two assemblages of utilitarian glass objects, primarily small bottles and drinking vessels of the post-Byzantine period, recovered from two sites in Messenia, southern Peloponnese, Greece: Androusa and Alagonia (Figure 1). Contrary to the other sites of Messenia studied so far, both these sites are in mainland Messenia and do not have direct access to ports; therefore, they can offer significant information regarding the distribution and trade of imported glass objects within mainland Greece.

Materials and Methods

Sites

Androusa is located approximately 18 km from the Messenian Bay, at an altitude of 120 m. It was founded by William II of Villehardouin during the mid-13th c. and flourished particularly in the 14th c., during the period of the first Venetian occupation. In 1432 it was conquered by the Byzantines, and approximately 30 years later it was conquered by the Ottomans. For a short period in the late 17th c. the city was occupied for a second time by the Venetians (1686-1715), and after this period it remained under Ottoman occupation until 1821 [14]. The samples under study were recovered in the Castle of Androusa, during the restoration of its eastern part by the Ephorate of Antiquities of Messenia (2012-2015) [14]. The Castle of Androusa was built by William II of Villehardouin in the 13th c. (1245-1278) [15]. In 1381 it became the seat of the Navarrese Company. The walls of the castle are reinforced by round, rectangular and polygonal towers and they enclosed the settlement of Androusa. Alagonia is located at an altitude of 800 m on mount Taygete’s. The position of the village was strategic, since it was controlling the land route connecting Messenia with the city of Mystras, the administrative centre of the broader region. In the 8th c., during the Slavic migrations to the Balkans, Alagonia received large numbers of new population and was renamed Sitsova. Between the 13th and the 19th c. it underwent consecutive periods of Byzantine, Venetian, and Ottoman occupation, similar to Androusa. From the 13th c. till 1836 it belonged administratively to the Despotate of Mystras (Despotate of the Morea), whereas before and after this period it belonged to Messenia [16] . The glass samples under study were recovered during restoration work on the Holy Church of Agios Nikolaos in Mesorouga, Alagonia, which was carried out by the Ephorate of Antiquities of Messenia (2012-2015) [17]. The church was built in the early 14th c., and then underwent restoration during the second half of the 17th c. Several features of the church show close relationship to the architectural and artistic tradition of the Despotate of Mystras.

Samples

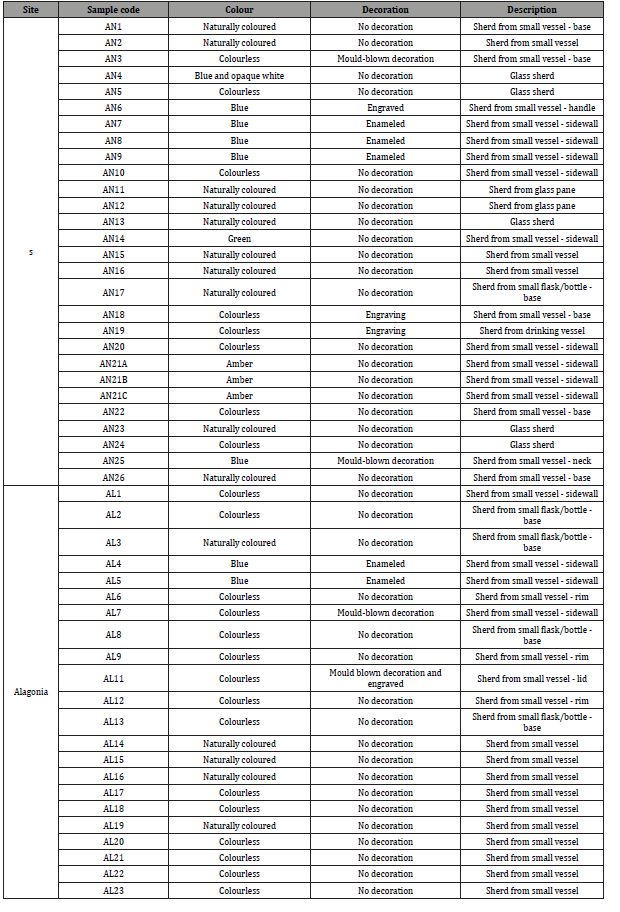

The 48 glass samples under study are presented in Table 1. Their exact date is uncertain given the continuous use of both sites for multiple centuries; it is estimated between the 15th and early 19th c. (K. Gerolymou, personal communication). The vast majority of the fragments belong to utilitarian objects (drinking vessels, bottles, flasks, etc.); several fragments of glass panes were also recovered in Androusa, two of which were included in the present study (AN11 and AN12). It should be noted that most of the fragments are small and do not allow a secure typological determination. The majority of the samples are colourless or naturally coloured (with a green tinge), while there are also seven blue, three amber and one green sample, predominantly from Androusa. One fragment of blue and opaque white glass is also present (AN4). Most fragments are undecorated; two examples of engraved samples present intricate patterns, while the enameled fragments present simple decorative patterns with white enamel. Finally, a few examples of mouldblown patterns are also present (Figure 2).

Table 1: Summary of the main characteristics of the samples under study.

Methodology

Prior to the chemical analysis, all samples were examined with a portable LED microscope (Moritex I Scope). Areas with strong corrosion were documented and the most suitable areas for micro- sampling were selected. On their outer surface, the samples show common effects of corrosion, such as iridescence, dulling, milky weathering, and pitting. The composition of the major elements was evaluated using a Scanning Electron Microscope (JEOL JSM-6510LV), combined with an Oxford Instruments Energy Dispersive Spectrometer. To avoid the chemical effects of corrosion, micro-samples were cut off, embedded in resin, and polished. For each sample, three to four analyses were performed in different areas. The analyses were performed in high vacuum and at a voltage of 20 kV. The spectra were obtained in areas of 300x400 μm (x100 magnification) and with a collection time of 300 s. Quantitative data were obtained with INCA software, based on a pre-existing internal calibration of the device. The accuracy and precision of the quantitative procedure, which was evaluated using certified reference glasses NIST612 and NIST620, are presented in detail elsewhere [12]. Shortly, the SEM/EDS results show an overall good agreement with the certified values; all major oxides in glass present high accuracy (relative error <5%), with the exception of CaO which presents a deviation from the true value by approximately 8.5%. The achieved precision of the analysis varies, with deviations from the mean value usually ranging between 5 and 10% for all major oxides.

The presence of trace elements of particular interest for the determination of the raw materials (such as As, Sn, Sb, etc.) was determined using a portable X-Ray fluorescence spectrometer (Bruker S1 Titan). To avoid corrosion alterations, the analyses were conducted on the fresh cut of the micro-samples, before embedding in resin, in high-energy excitation mode (high voltage set at 40 kV and current of 12 μA). The collection time of each measurement was 120 s. Finally, undissolved particles present in the opaque glasses and the enamels were examined using Raman spectroscopy. Raman spectra were collected on a Renishaw in Via Reflex confocal micro-Raman spectrometer using the excitation line at 488 nm of an argon ion laser. All Raman spectra were measured at room temperature with 2 cm−1 resolution in the frequency range from ca. 120 to 2000 cm−1. More detailed information on the settings is described by Möncke et al., [18].

Results and Discussion

Chemical groups

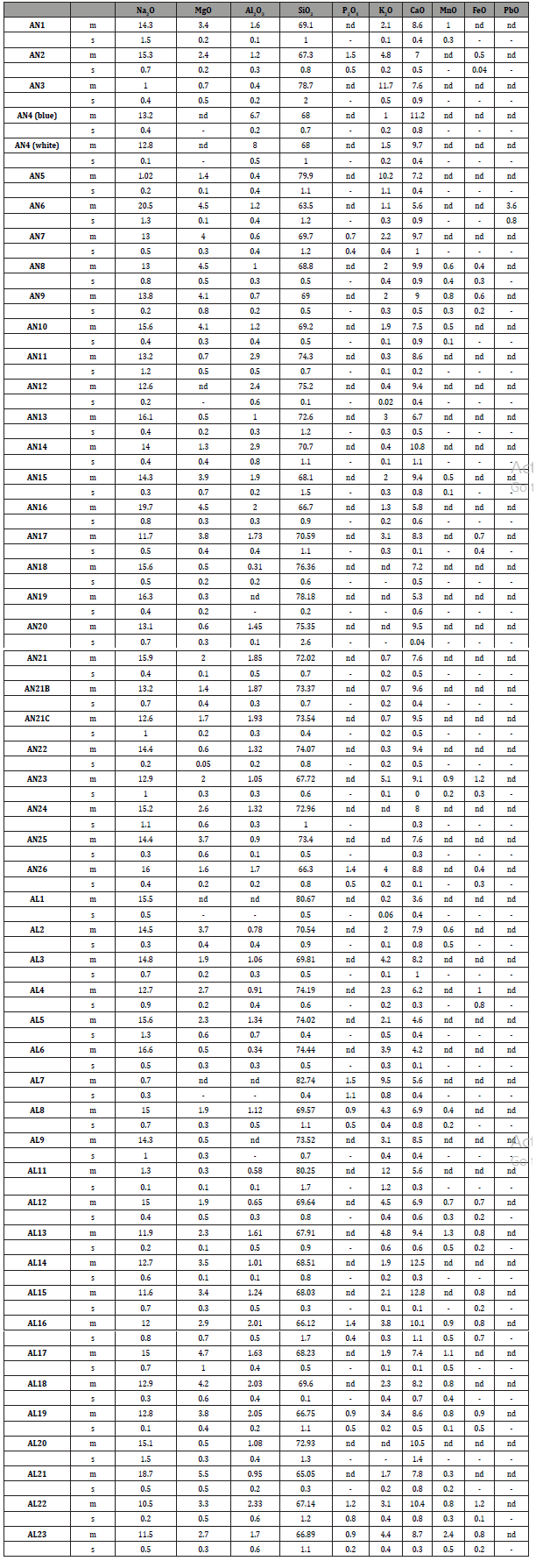

The concentration of the main oxides for the samples under study are presented in (Table 2). Based on the diagrams of (Figures 3 & 4), and the categorization proposed by Schalm et al., [2] (Figure 4), two broad chemical groups can be distinguished, which are discussed in more detail below:

Table 2: Composition of major elements (mean value “m” and standard deviation “s”) of the glass samples estimated by SEM/EDS. The mean values are given as oxides in wt%, normalized to 100% (“nd”: not detected). Samples with Na2O> 6wt% are characterized as Na-rich glass, whereas samples with Na2O<6 wt% (highlighted rows) are characterized as K-rich glasses.

a) The majority of the samples, including all coloured glasses, belong to the category of Na-rich glass, and more specifically to the type of soda glass.

b) Two colourless samples from each site belong to the K-rich glasses, and more specifically to the category of potash glass. It should be highlighted that all four samples of this group are very clear colourless glass; three out of four present some form of decoration (mould-blown decoration or engraving), while the fourth sample is a very small fragment without any identifiable decoration. Overall, it appears that this group represents higher quality, more luxurious glass objects.

Soda glass

Alkali source: The soda glass samples present an overall heterogeneous composition of their major elements and they do not form any clearly distinguishable groups. However, seven of the samples present exceptionally low concentration in potassium, magnesium and aluminium, suggesting that the alkali source in this case is either plant-ash which has undergone a specific preparation technique, or mineral natron. Regarding the latter possibility, similar glasses were produced in Jordan during the Mamluk and Ottoman Period [19]. For the rest of the samples, the alkali source is Na-rich plant ash.

Decolourants: Of special interest is the identification of the decolourant used for the colourless glasses. Glass workers of the period under study could achieve very good control over the raw materials and the manufacturing process. Furnace control was achieved by the careful consideration of a number of parameters during firing, such as fuel selection, air supply, crucible shape, maximum temperature and the time that the melt was held at the maximum temperature [20]. Additionally, the use of new and more efficient furnaces, as well as the replacement of wood with mineral fuels in the early 17th c., allowed the consistent production of better-quality glass [21,22]. As a result, medieval and post-medieval colourless glass was produced with the addition of very limited quantities of decolourants. The most common decolourant was manganese, added in the form of pyrolusite (MnO2). From the 17th c. onwards, arsenic trioxide (As2O3) was also used [1]. In Venice, As2O3 was used either on its own or along with small quantities of manganese; in central Europe it was widely used on its own for the production of clear colourless glass (crystal glass, chalk glass) [23]. Thirteen of the soda glasses under study present manganese content above 0.5 wt%, suggesting that manganese was added purposefully as a decolourant. Arsenic was not identified in any of these samples. Most of the remaining samples, primarily the clear colourless ones, seem to be opacified using small amounts of arsenic; therefore, they were produced after the 17th c. Finally, a small number of samples, primarily naturally coloured ones, do not present either arsenic or significant amounts of manganese. In most of these samples the iron content is very small (below detection limit via SEM/EDS), suggesting a careful selection of raw materials to produce colourless glass.

Presence of lead: Of special interest is the composition of sample AN6, a blue handle of a small vessel with engraved decorative patterns. The sample has a high Na2O and especially MgO content (20.5 and 4.5 wt%, respectively) and a relatively low CaO content (5.6 wt%). However, the sample is primarily differentiated by the rest of the assemblage due to the presence of lead (3.6 wt%). When lead is present in the glass in such small quantities it does not serve as the main network modifier and it seems generally improbable that it could significantly affect physical properties of glass, such as melting temperature, viscosity etc. [24]. Small quantities of lead (<5 wt%) have been identified in various colourless glasses of the period under study, which do not present other peculiar traits in their chemical composition (e.g., Na-rich glass - [25]; K-rich glass [3, 26]. However, it is not certain whether the introduction of lead in these cases was done on purpose or was accidental.

In blue glasses, the low amounts of lead detected in some glasses are attributed to the cobalt source used as a colourant [27]. More specifically, based on the work of Gratuze [28], there are two cobalt ores with lead: (1) A Co-As-Ni-Fe + Pb-Sb-Sn-Zn ore with a likely origin from the Iranian ores of Kashan, which was used from the end of the 7th or the beginning of the 8th c. in the Near East; (2) A Co-Zn-Pb-In-Fe ore from Germany, which was used from the end of the 12th to the end of the 15th c. At this point it is impossible to specify whether the detected lead was introduced in the glasses via the colourant or if instead the sample was the result of mixing of a colourless glass with a low lead content with cobalt (from a Pb-free source). A more detailed examination of the trace composition of the sample is required to better understand its manufacturing technology and its likely provenance.

Potash glass

The four potash glasses present very similar chemical composition, although the Androusa samples have a higher calcium content. All samples present low concentration of magnesium and phosphorus, therefore the alkali source cannot be K-rich plant ash, as is the case for forest glass. The absence of iron and manganese is an additional indication that the samples do not belong to the type of forest glass, as this glass contains relatively high concentrations of iron as a mixture in the raw materials, and manganese, which is added as a decolourant [2,24,29]. Instead, in these samples’ arsenic was identified via p-XRF analysis.

The overall composition of the potash glasses shows significant similarities with two types of glass produced in central Europe from the 17th c. onwards: crystal glass (which should not be mistaken for English lead crystal or Venetian cristallo) and Bohemian glass. Crystal glass, is a K-rich glass, produced using siliceous pebbles, saltpetre (potassium nitrate) as the alkali source, chalk and arsenic as the decolourant [30]. Bohemian glass, often called ‘chalk glass’ is a similar type of glass, invented in Bohemia. It is of slightly lower quality than crystal glass, with similar raw materials with the exception of the alkali source. In this case the flux added was potash (potassium carbonate), sometimes combined with saltpetre [23].

After the invention of Bohemian glass, and especially during the 17th and 18th c., Bohemia became one of the most significant glass production centers in Europe and a large exportation center [5]. Glass of this type has so far been identified in all studied sites in southern Peloponnese [3,11,12]. As is also the case in Androusa and Alagonia, in all Greek sites this type of samples are among the most luxurious glass objects, often showing complex engraving patterns. Due to difficulties in achieving precise typological characterization, no direct correlation has been found so far between the Bohemian glasses recovered in southern Peloponnese and specific types of objects; additional study of better documented material is however needed to better understand the importation of this type of glass.

Overall, based on the available information it can be suggested that Bohemian glass was imported in Greece to cover specific needs for high quality, luxurious glass objects. It is interesting to note that with the exception of Methoni (where very few colourless glasses were recovered, all belonging to the potash group), in all other studied sites the amount of potash glass is similar (between 12 and 25% of the overall number of colourless glasses) (Figure 5). It appears, therefore, that potash glasses were widely traded in southern Greece, both in port-cities and in mainland locations, providing clear evidence for the existence of an extensive trading network of sea- and land-routes.

Opaque glass and enamels

Opaque glass: As mentioned before, one of the samples from Androusa (AN4) consists of blue translucent glass and white opaque glass. Both glasses belong to the soda glass type and show very similar chemical compositions (Table 2). During the early post-Medieval period, tin was the most common opacifier for opaque glasses and enamels. Later, other white opacifiers were also used, such as calcium antimonate (since the end of the 16th c. in Venice), lead arsenate (since the 17th c.), and bone fragments (in Bohemia) [31,32]. It is interesting to note that none of these common opacifiers was identified by SEM/EDS on the opaque white glass; additionally, p-XRF analysis suggested that Sn and Sb were present in trace quantities, which would not be enough to cause opacification. Undissolved particles analyzed via Raman spectroscopy suggested the presence of calcite (Figure 6). Opacification of glass using undissolved calcite grains is considered a relatively rare technique [33]. The undissolved calcite phases may have either remained in the glassy matrix due to the low melting temperature or the short duration of the melting process [34].

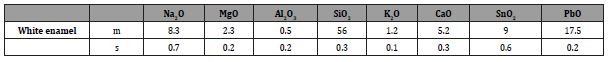

Enamels: For the enameled samples from Androusa it was impossible to analyze areas of the enamel decoration, without completely destroying the fragments. Therefore, only the white enamels from Alagonia samples were analyzed; the average composition of the white enamels present on several fragments is presented in Table 3. All the examined enamels were made using a soda-lime-silica glass. They were opacified by tin-oxide particles, also containing significant amounts of lead. The tin oxide (approximately 9 wt%) occurs as abundant fine particles (a few μm wide), while the lead oxide (17.5 wt%) is completely dissolved within the glass matrix (Figure 7). Raman analysis of the undissolved particles verified that they consist of tin oxide (Figure 6). Additionally, in a few spectra the main bands of calcite (at approximately 1085 cm-1) and quartz (at approximately 463cm-1) are also noted. The overall composition of the enamels is very similar to Islamic enamels of the 13th-14th c. [35,36]. On the contrary, Venetian enamels of the 13th-16th c. contain typically larger amounts of tin oxide (above 12 wt%, but most commonly around 20 wt%) [31,37], and are therefore differentiated from the enamels of Androusa.

Table 3: Average composition of major elements (mean value “m” and standard deviation “s”) of white enamels estimated by SEM/EDS. The mean values are given as oxides in wt%, normalized to 100% (“nd”: not detected).

Opaque glass and enamels

Opaque glass: As mentioned before, one of the samples from Androusa (AN4) consists of blue translucent glass and white opaque glass. Both glasses belong to the soda glass type and show very similar chemical compositions (Table 2). During the early post-Medieval period, tin was the most common opacifier for opaque glasses and enamels. Later, other white opacifiers were also used, such as calcium antimonate (since the end of the 16th c. in Venice), lead arsenate (since the 17th c.), and bone fragments (in Bohemia) [31,32]. It is interesting to note that none of these common opacifiers was identified by SEM/EDS on the opaque white glass; additionally, p-XRF analysis suggested that Sn and Sb were present in trace quantities, which would not be enough to cause opacification. Undissolved particles analyzed via Raman spectroscopy suggested the presence of calcite (Figure 6). Opacification of glass using undissolved calcite grains is considered a relatively rare technique [33]. The undissolved calcite phases may have either remained in the glassy matrix due to the low melting temperature or the short duration of the melting process [34].

Enamels: For the enameled samples from Androusa it was impossible to analyze areas of the enamel decoration, without completely destroying the fragments. Therefore, only the white enamels from Alagonia samples were analyzed; the average composition of the white enamels present on several fragments is presented in Table 3. All the examined enamels were made using a soda-lime-silica glass. They were opacified by tin-oxide particles, also containing significant amounts of lead. The tin oxide (approximately 9 wt%) occurs as abundant fine particles (a few μm wide), while the lead oxide (17.5 wt%) is completely dissolved within the glass matrix (Figure 7). Raman analysis of the undissolved particles verified that they consist of tin oxide (Figure 6). Additionally, in a few spectra the main bands of calcite (at approximately 1085 cm-1) and quartz (at approximately 463cm-1) are also noted. The overall composition of the enamels is very similar to Islamic enamels of the 13th-14th c. [35,36]. On the contrary, Venetian enamels of the 13th-16th c. contain typically larger amounts of tin oxide (above 12 wt%, but most commonly around 20 wt%) [31,37], and are therefore differentiated from the enamels of Androusa.

Conclusion

The chemical and mineralogical analysis of 48 glass samples of the post-Byzantine period from two sites in Messenia, Androusa and Alagonia, led to the determination of their chemical composition and raw materials. Despite the fact that both sites are located in the mainland, without direct access to a port, the analysed glass samples reveal a complex image, suggesting the use of varied raw materials and techniques (Na- or K-rich plant ash, mineral natron, potash and/or saltpetre as the alkali source; manganese and arsenic as decolourants; tin and calcite as opacifiers). Based on the raw materials and the technologies identified, the importation of glasses from both the eastern regions of the Ottoman Empire and from Europe can be verified.

More specifically, the majority of the samples belong to the category of soda glass, whereas four samples belong to the category of potash glass. The provenance of the soda glasses cannot be determined based on the composition of the major elements. However, a small subgroup characterized by low K, Mg and Al resembles glass made with mineral natron in workshops in Jordan. Additionally, the determination of different decolourants (manganese and arsenic), suggest different manufacturing technologies, which could be attributed either to different workshops or to glasses produced in different time periods (i.e., arsenic was only used as a decolourant after the 17th c.)

The composition of the potash glasses suggests that they likely originate from Bohemia. Similar glasses have been identified in all Messenian sites, suggesting that Bohemian glass was imported in Greece to cover specific needs for high quality, luxurious glass objects and was transferred both via marine and land trade routes. The examination of the enamels of Androusa shows that they were produced using soda-lime-silica glass, opacified with tin oxide and with the addition of relatively large amounts of lead. The overall composition is similar to enamels used for the decoration of Islamic glasses. The only white opaque glass of the assemblage on the other hand, is opacified via undissolved grains of calcite, a less common technique.

Comparing the glasses of Androusa and Alagonia with previously studied assemblages from port cities in Messenia provided with valuable new information regarding the production and trade of glass in mainland Greece during the post-Byzantine period. The glasses from all sites show significant variety in terms of chemical composition, manufacturing, and decorative techniques. Additionally, with a few exceptions, similar types of glasses are present on all sites, with a selective preference in the trade and use of certain specific types. The position of Alagonia was strategic, since it was controlling the land route connecting Messenia with the city of Mystras. Androusa, on the other hand, is considered relatively less significant as a commercial centre. Overall, glass in the post-Byzantine period was evidently widely transferred throughout the settlements of southern Greece, both via marine and land routes; this applies both for low-quality utilitarian objects and for higher quality luxurious glasses.

Acknowledgements

The authors acknowledge permits granted by the Greek Ministry of Culture and Sports to enable the study of the assemblage and the contribution of Ms. Stavroula Papanikolopoulou, who provided the samples from the Holy Church of Agios Nikolaos in Mesorouga, Alagonia. This project was implemented within the scope of the “Exceptional Laboratory Practices in Cultural Heritage: Upgrading Infrastructure and Extending Research Perspectives of the Laboratory of Archaeometry”, a co-financed by Greece and the European Union project under the auspices of the program “Competitiveness, Entrepreneurship and Innovation” NSRF 2014-2020.

Conflict of interest

The authors declare that there is no conflict of interest.

References

- Verità M (2013) Venetian soda glass. In: Janssens (Eds.), Modern methods for analysing archaeological and historical glass. John Wiley and Sons Ltd, Chichester, pp. 515-536.

- Schalm O, Janssens K, Wouters H, Caluwé D (2007) Composition of 12th-18th century window glass in Belgium: Non-figurative windows in secular buildings and stained-glass windows in religious buildings. Spectrochimica Acta Part B 62: 663-668.

- Palamara E, Zacharias N, Germanidou S, Gerolymou K, Palles D et al., (2017) Technology and Provenance Analysis of Glass Fragments from an Ottoman Bathhouse (Hamam) in Kyparissia, Peloponnese, Greece. STAR: Science & Technology of Archaeological Research 3(2): 376-390.

- Wenzel M (1977) A reconsideration of Bosnian Medieval glass. Journal of Glass Studies 19: 63-76.

- Václav L (1981) The exportation of Bohemian glass: A historical review. Journal of Glass Studies 23: 56-63.

- Whitehouse D (2012) Glass. A short history. The British Museum Press, London.

- Canav-Özgümüş U (2012) Recent glass finds in Istanbul. In: Ignatiadou, A. Antonaras (Eds.), Annales du 18e Congrès de l’ Association Internationale pour l’ Histoire du Verre. Ziti Publications, Thessaloniki, pp. 326-332.

- Topić N, Bogdanović Radović I, Fazinić S, Skoko Ž (2016) Analysis of Medieval and Post-Medieval Glass Fragments from the Dubrovnik Region (Croatia). Archaeometry 58: 574-592.

- Šmit Ž, Stamati F, Civici N, Vevecka-Priftaj A, Kos Μ et al., (2009) Analysis of Venetian-type glass fragments from the ancient city of Lezha (Albania). Nuclear Instruments and Methods in Physics Research B 267 (15): 2538-2544.

- Davidson GR (1940) A Medieval Glass-Factory at Corinth. American Journal of Archaeology 44(3): 297-324.

- Palamara E, Zacharias N (forthcoming) Technology and provenance analysis of everyday glass objects of the post-Byzantine period from Methoni, Messenia, Greece. In: Annales du 22e Congrès de l’ Association Internationale pour l’ Histoire du Verre.

- Palamara E, Valantou V, Palles D, Kamitsos EI, Zacharias N (2023) Fragments of luxury: Decorated glass from the Palace of Mystras. Journal of Archaeological Science: Reports 49: 103983.

- Palamara E, Palles D, Kamitsos EI, Das PP, Tirado JI, et al., (forthcoming) Fragments of luxury: Opaque glass from the Palace of Mystras. Journal of Archaeological Science: Reports.

- EFAMES (2012-2015) Ephorate of Antiquities of Messenia. Restoration of the eastern section of the Castle of Androusa. Ministry of Culture and Sports, Ephorate of Antiquities of Messenia.

- Kontogiannis DN (2012) The fortifications of Messenia: From the Byzantine Empire to the modern Greek State. In: AΝ Doulaveras, IK Spiliopoulou (Eds.), Messenia: Contributions to history and civilisation. Papazisis Publications, Athens, pp. 285-328.

- Bitsanis H (2007) History lessons in the streets of Kalamata. Kalamata.

- EFAMES 2011-2015, Ephorate of Antiquities of Messenia. Restoration of the Holy Church of Agios Nikolaos in Mesorouga, Alagonia. Ministry of Culture and Sports, Ephorate of Antiquities of Messenia.

- Möncke D, Palles D, Zacharias N, Kaparou M, Kamitsos EI, et al., (2013) Formation of an outer borosilicate glass layer on Late Bronze Age Mycenaean blue vitreous relief fragments. Physics and Chemistry of Glasses: European Journal of Glass Science and Technology, Part B 54: 52-59.

- Boulogne S, Henderson J (2009) Indian glass in the Middle East? Medieval and Ottoman glass from central Journal of Glass Studies 59: 53-75.

- Henderson J, P Adams, J Mann (2005) Medieval and Post-Medieval Glass Finewares from Lincoln: An Investigation of the Relationships between Technology, Chemical Compositions, Typology and Value. Archaeological Journal 162(1): 256-322.

- Charleston RJ (1978) Glass furnaces through the ages. Journal of Glass Studies 20: 9-33.

- Crossley D (1991) Current Research on English Glass Furnaces. In: Mendera (Eds.), Archeologia e storia della produzione del vetro preindustriale. University of Siena, Firenze, pp. 411-422.

- Kunicki-Goldfinger J, Kierzek J, Kasprzak AJ, Malozewska-Bucko B (2003) Analyses of 18th century central European colourless glass vessels. In: Annales du15e Congrès de l’ Association Internationale pour l’ Histoire du Verre. AIHV, Nottingham, pp. 224-229.

- Dungworth D, Cromwell T, Ashurst D, Cumberpatch C, Higgins D et al., (2006) Glass and pottery manufacture at Silkstone, Yorkshire. Post-Medieval Archaeology 40 (1): 160-190.

- Kunicki-Goldfinger J, Pańczyk E, Dzierżanowski P, Waliś L (2008) Trace element characterization of medieval and post-medieval glass objects by means of INAA and EPMA. Journal of Radioanalytical and Nuclear Chemistry 278 (2): 307-311.

- Kunicki-Goldfinger J, Kierzek J, Kasprzak AJ, Dzierzanowski P, Malozewska-Bucko B (2003) Lead in central European 18th colourless vessel glass. Archäometrie und Denkmalpflege. Kyrzberichte 2003, Berlin, pp. 56-58.

- Zlámalová Cílová Z, Gelnar M, Randáková S (2021) Trends in Colouring Blue Glass in Central Europe in Relation to Changes in Chemical Composition of Glass from the Middle Ages to Modern Age. Minerals 11(9): 1001.

- Gratuze B (2013) Provenance analysis of glass artifacts. In: Janssens (Eds.), Modern Methods for Analyzing Archaeological and Historical Glass. John Wiley & Sons, Ltd., West Sussex, UK, pp. 321-323.

- Wedepohl KH, Simon K (2010) The chemical composition of medieval wood ash glass from Central Europe. Chemie der Erde 70: 89-97.

- Kunicki-Goldfinger J, Kierzek L, Dzierzanowski P, Kasrzak AJ (2005) Central European crystal glass of the first half of the eighteenth century. In: Annales du 16e Congrès de l’Association Internationale pour l’Histoire du Verre. AIHV, Nottingham, pp. 258-262.

- Biron I, Verità M (2012) Analytical investigation on Renaissance Venetian enamelled glasses from the Louvre collections. Journal of Archaeological Science 39(8): 2706-2713.

- Langhamer A (2003) The legend of Bohemian glass: a thousand years of glassmaking in the heart of Europe. Tigris, Zlí

- Colomban Ph (2019) Colouring Agents for Glass, Glaze and Enamel: Tracing Innovation and Exchange Routes Supplementary information for Raman Spectroscopy in Archaeology and Art History RSC book 2.

- Farahnaz K, Colomban Ph, Pikirayi I, Prinsloo LC (2019) Glass Beads, Markers of Ancient Trade in Sub-Saharan Africa: Methodology, State of the Art, and Perspectives. Heritage 2(3): 2343-2369.

- Freestone IC, Stapleton CP (1998) Composition and technology of Islamic enameled glass of the thirteenth and fourteenth centuries. In: Ward (Eds.), Enameled glass from the Middle East.

- Wypyski M (2010) Compositional Study of Medieval Islamic Enameled Glass from the Metropolitan Museum of Art. Metropolitan Museum Studies in Art, Science and Technology 1: 109-132.

- Freestone IC, Bimson M (1995) Early Venetial enameling on glass: Technology and origins. In: Materials Issues in Art and Archaeology IV, Materials Research Society Symposium Proceedings 352.

-

Eleni Palamara*, V. Valantou, Dimitrios Palles, Efstratios I. Kamitsos and Nikolaos Zacharias. Post-Byzantine Glass from Sites of the Peloponnese: Investigating the Complex Glass Network of Southern Greece. A Technological and Social Overview. Open Access J Arch & Anthropol. 4(5): 2023. OAJAA.MS.ID.000598.

-

Bohemian glass, Antiquities, Church, Crystal glass, Potassium nitrate

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.