Research Article

Research Article

The Presence of Au and Ag in Pb-rich Slags from Hellenistic Pistyros, N. Greece: Some Observations

Nerantzis Nerantzis1*, Effie Photos-Jones2

*1Laboratory of Archaeometry, University of the Peloponnese, Kalamata, Greece

2Analytical Services for Art and Archaeology (Ltd), Glasgow, UK - School of Humanities, University of Glasgow, Glasgow, UK

Nerantzis Nerantzis, Laboratory of Archaeometry, University of the Peloponnese, Old Camp, 24133, Kalamata, Greece

Received Date:May 01, 2023; Published Date:January 04, 2024

Abstract

Pistyros, in NE Greece, is a small fortified urban settlement founded by Thasians on the mainland in the 7th c. BCE; it displays, uniquely for the region, a considerable amount of well contextualized and dated (4th-3rd c. BCE) metallurgical waste (in excess of 1.2 tons); further, the Pb-based metallurgical waste displays presence of Au and Ag. In an area famous, both on historical and geological grounds, for its base (Cu, Pb, Fe) and precious (Au, Ag) metals deposits, there exists, still today, no good evidence for their routine extraction and processing and on a large scale. The questions that arise are related to what was urban Pistyros’ main function. Was it intent on making metals and which ones? Was it making only metals or metal derivatives (oxides or carbonates) as well? We have at this stage no definitive answers.

In this paper we focus on the presentation of EPMA (Electron Probe Micro Analysis) results from three slag sample-types (silicate slag, iron arsenides, lead oxides). We examine the presence and distribution of Au and Ag within, and suggest that the two metals probably play a secondary role to the site’s main involvement, i.e. Pb-based metallurgy; be it for the production of antimonial lead and its ‘purification’ for the production of lead oxide and/or for the further processing of iron arsenides. Pistyros polymetallic metallurgical waste interpretation requires careful assessment of what it means to carry out high temperature metallurgical activities for the purpose of acquiring not just metals but possibly, also, metallic mineral derivatives within urban centers; such centers tend to be rare, nuanced, and certainly challenge us to look beyond the ‘precious metal-for-coinage’ axis we have been accustomed to.

Keywords:Pistyros, Thasos, Skapte Hyle, metallurgy, gold, silver, lead, EPMA

Abbreviations:Th: Thucydides, History of the Peloponnesian War, Zen: Zenobius Paroemiographus, Epitome collectionum Lucilli Tarrhaei et Didymi, Arist: Aristoteles Philosophus Stagirites, Fragmenta, Str: Strabo, Geographia, D.S: Diodorus Siculus, Bibliotheca historica. App: Appianus Historicus Alexandrinus, Bella Civilia

Introduction

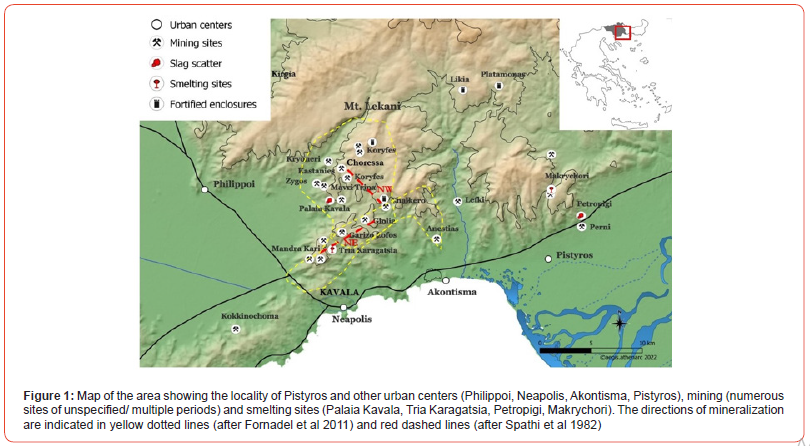

Ongoing excavation (2014-2022) of a Thasian fortified settlement, associated with ancient Pistyros, near Kavala in Northern Greece provided, for the first time, a rare opportunity to study large-scale metallurgical activities within an urban context, in the Hellenistic period (4th-3rd c. BCE). Pistyros was a Thasian colony established at the foothills of the Lekani mountain range (Figure 1) in the late 7th c. BCE and was inhabited until the 1st c. BCE [1-3]. It displayed the characteristics of a polisma (small urban settlement) with both civic (sanctuary) and ‘agricultural/industrial’ buildings (granary/winery). The weighed amount of recovered slag from excavated contexts is c. 1.2 tons, while an undisclosed amount is still waiting examination; further to the above, there are areas in the immediate vicinity of slag heaps waiting further excavation. These findings are significant as they represent the first, securely dated evidence for urban metallurgical practices in this region.

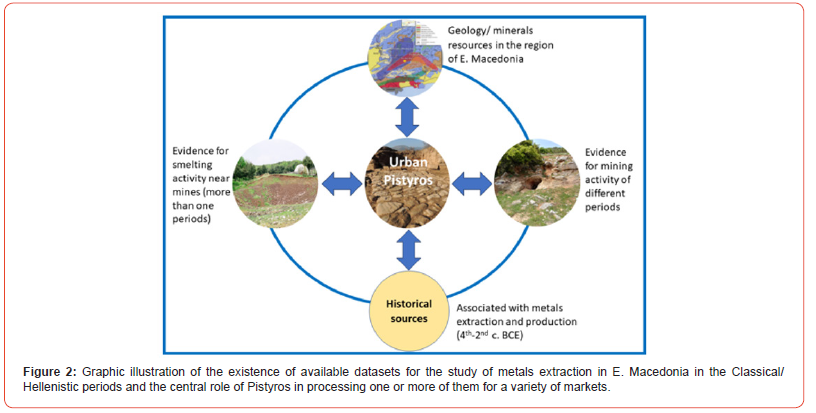

Although there are several mentions in ancient literary sources of the extraction of precious metals in this region of NE Greece, the actual chronology for mining and smelting activities on the Lekani massif remains unclear and as such is in much need of further investigation. Literary sources refer to a particularly rich mining area that the Thasians had under their control on their mainland territory (Thasian continent or Peraia) that was called Skapte Hyle (dug forest), the exact location of which still remains a matter of debate. Such historical documents are useful to consider as they tie in the archaeological evidence with significant events of the region’s economic history. Pistyros with its wealth of well contextualized finds resulting from metallurgical activities and secure chronological framework, is in a unique position to bring together four already existing data sets, in a coherent way, a task that was not possible to achieve before. These data sets include a. the well-researched geology/minerals resources of the area, b. the associated ancient mining activities, c. historical sources and d. the various studies of pyrometallurgical remains belonging to unspecified/broadly outlined periods in the vicinity of the mining sites (Figures 1 & 2). We examine, in brief, each one of these data sets (Figure 2).

Skapte Hyle and other metalliferous areas in the vicinity of Pistyros

The mines on Eastern Macedonia were always the goal behind attempts by the Athenians to break up the Thasian hegemony in that region and in the process colonise the area. They eventually did succeed in gaining control and founded a colony, Amphipolis, only to lose it at the start of the Peloponnesian war (430 BCE). The earliest literary reference concerning Skapte Hyle could be found in Herodotus Histories, dated 493 BC1. Allegedly, this mining region was so rich that the Thasians earned between 80 and 200 or even 300 talents per year, an enormous sum that is considered with some skepticism by modern researchers.

Eventually Skapte Hyle came under Athenian control with the expedition of Cimon between 465 and 463 BCE. Plutarch2, at the end of the conflict between Thasos and Athens in 463 BCE a significant mining region that was exploited by the Thasians passed into the hands of the Athenians. Although the name of the region in question is not given, it has been suggested that the mines mentioned in this context should be identified with those of Skapte Hyle [5].

It should be also mentioned that. Thucydides locates the emporia coordinating such mining activity opposite of Thasos3, which excludes Mount Pangaion and the Strymon region. Along the same lines, Plutarch refers to mines beyond, or opposite the island4. The gold mines of Krenides-Philippi on the western Lekani massif are mentioned for the first time in the 360s BCE, when the exiled Athenian politician Kallistratis persuaded the exiled Athenians of the region to settle on the opposite shore of the lake, at the Thasian settlement of Krenides, by alluring them with the area’s gold riches5.

When Philip II founded Philippi6 in 356 BCE at the exact location of Krenides, the mines of the region passed under Macedonian control. At the time of Philip II, Aristotle mentions the auriferous veins of the mining region near Philippi while the later testimonies by Strabo7 and Diodorus Siculus8 give an account of the policy of Philip II and his desire to exploit the mining areas near Philippi. Both authors mention the immense income that Philip II was able to obtain through the exploitation of these mines. Interestingly later historical sources refer to this mining region with its Latin name, Skaptensule, and as a silver producer in addition to gold9. Lastly, Appian writing in the second c. AD mentions the gold mines near Philippi under the name Asyla10 (lingual alteration from Skaptesyla?). The above literary references show the long history of gold mining in the region of Lekani covering at least from the mid-5th c. BCE up to the 2nd c. AD.

Brief outline of regional geology/ minerals resources

Over the years, there have been a number of studies regarding the region of Palaia Kavala (Figure 1) and its diachronic exploitation for Au/Ag in antiquity and in later periods. In the early 1980’s Spathi and co-authors [6] drew a broad outline around that area which includes the villages of Palaia Kavala, Zygos, Kirgia and Makrychori (Figure 1). The authors reported that the area consists of schists with marbles and granitic offshoots. The mineralization occurs at the contact of marbles and mica schists and is developed along two zones, i.e., along a NE and NW direction. The former follows the line of occurrences at the sites Mandra Kari, Garizo Lofos and Giolia, while the NW occurrence is evident at the village of Chalkero and the site of Choressa (see Figure 1 for the direction of this mineralization).

Interestingly, they suggested that the two directions of mineralization are quite distinct in both chemical and mineralogical terms. In the NE the iron manganese ores are associated with Pb, Zn and Ag, while in the NW it is associated with Cu and Au and occasionally Bi. Arsenic is present in both. More recently Fornadel and co-authors [7] refined on the observations of Spathi and coauthors [6] and highlighted 150 minor Fe–Mn (Pb ± Zn ± Ag), Fe-Mn-Au, Fe-As-Au, Fe-Cu-Au, and Bi-Te-Au occurrences that occur primarily in quartz–calcite–sulfide veins [7]. As we shall demonstrate below the Pistyros slags demonstrate presence, apart from Au and Ag also Ta, Pt and Hg (see Tables 1-3) which point to other sources as well, yet to be researched.

The largely undated pyrometallurgical activities near the mines

There is already substantial research that has focused on mining sites and the voluminous slag deposits away from urban centers tentatively dated to the Classical/Hellenistic periods, as deduced from associated pottery [8-12]. For example, near the modern villages of Perni and Petropigi (Figure 1) and only about 2.5 km to the NE of Pistyros there is evidence for mining galleries of square profiles, usually attributed to the Classical period; also evidence for small scale smelting activities [5, 8]. Further north, near the village of Makrychori, not far from mining galleries, the hills are covered by voluminous slag heaps across an extended area. Based on surface pottery, these slag deposits are conventionally dated from the 4th to the 2nd centuries BCE [9]. Therefore, Pistyros with its excavated metallurgical finds, securely dated to the Hellenistic period is, as of now, the single most important site to illuminate ancient metals extraction practices in the broader NE Greek territories.

Archaeological evidence for urban metallurgy at Pistyros

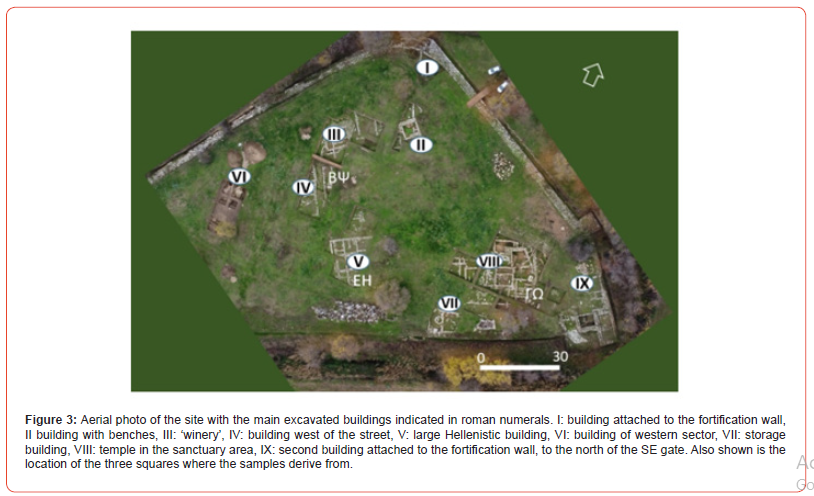

During the course of excavations at Pistyros (2014 to present),

the excavator, S. Papadopoulos, gradually brought to light primarily

Hellenistic levels [3]. Hellenistic Pistyros is characterised by a range

of civic (sanctuary-Figure 3, VIII) and industrial buildings (granary-

Figure 3, VII/winery-Figure 3, III). Yet the central part of the site

(which still awaits excavation) is largely dominated by a substantial

amount of metallurgical waste. We maintain that it is unlikely

that such a large amount of slag has been brought in the fortified

settlement, in order to be used as foundation material, and instead,

was left there unused. Although there is so far no clear evidence

for furnace(s) or hearths, nevertheless, furnace wall fragments and

stones with slag adhering on their surface were recovered from the

street and its adjacent open courtyard in square ΒΨ (IV in Figure 3).

So, whether ores were being smelted within the site or not has to

remain, for now, an open question. There are further issues:

a. Evidence for charcoal is rather modest (it has not been

quantified), given the large quantity of slag.

b. Slag size is relatively small (c. 98% of the slag measures

between 1 and 5 cm in diameter) suggesting breaking,

presumably to release metallic inclusions within. There is at

present no evidence for working floors or relevant tools which

would indicate extensive manual slag-processing on site, let

alone hearths, which may have been associated with secondary

heating. So again, secondary manual processing (slag break-up)

remains an open question.

c. The majority of slag is found in the immediate proximity of

the ‘winery’ which although likely to have been in operation on

a seasonal basis, could in principle have been affected (building

facilities and equipment) from the metalworking furnaces, if

they turn out to have indeed been located nearby.

d. The fortified site is relatively small (it covers c. 4 acres or

15000 square meters) with private houses and public places

(granary/winery/sanctuary); this means that space must have

been tight particularly since a large portion of the site has been

taken up by the slag heap.

In short there are a number of intriguing questions that await

the outcome of further excavations. In the absence of structural

remains of metallurgical nature attention has been turned to the

detailed examination of three samples of metallurgical waste, each

representing a type-piece (Figures 4a-c):

a) SL9.2, an Fe-Pb oxide/silicate-rich slag, constituting the

majority of finds.

b) SP2, an iron arsenide-rich slag, of the type often referred to as

‘speiss’ (only 9 such samples have been recovered); L3.

c) L3, a PbO-rich material often referred to as ‘litharge’ (only 23

such samples have been found).

The three samples presented here are well dated by association to coinage and to the period between the middle 4th c. and the end of the 3rd c. BCE [4].

Dates and context for each sample are given as:

a. sample SL9.2 (oxides/silicates) found in square ΕΗ, derives

from the south of building V, in the vicinity of a circular stonebuilt

feature, labelled K1 (Figure 3, V); the structure had a clay

backing externally and internally it was filled with slag; two

coins date the context to the 3rd c. BCE;

b. sample SP2 (iron arsenide) comes from square ΓΩ, the

sanctuary area (Figure 3, VIII), from a context that yielded a

coin of Antigonus Gonatas, dating to 277-239 BCE [4].

c. sample L3 (PbO-rich) was found in square ΒΨ, from a street

deposit filled with slag (Figure 3, IV). Two coins, one of

Alexander III, 336‑323 BCE and a second of Abdera, 311-281

BCE provide the chronological framework for this sample [4].

Materials and Method

Electron Probe Micro Analysis (EPMA) took place at the University of Strathclyde’s Department of Physics. The instrument is a JEOL JXA-8530F field-emission electron probe micro analyser. Energy Dispersive X-ray analysis was used for all elements with the exception of four which used the following wavelength Dispersive X-ray diffracting crystals: TAPH (Fe Lα), TAP (Au Mα), PETH (Ag Lα). For the elemental maps, a 20 kV accelerating voltage and a 40 nA beam current was used. A total of 28 elements were sought. Their concentrations are listed as normalised by weight % (Tables 1-3). The LOD for each element (in ppm) is also given to highlight the distribution of possibly indicative (for future studies) trace elements, apart from Au and Ag and in particular Ta, Pt, Hg, Sb, Bi, As; also, Pd (always below LOD).

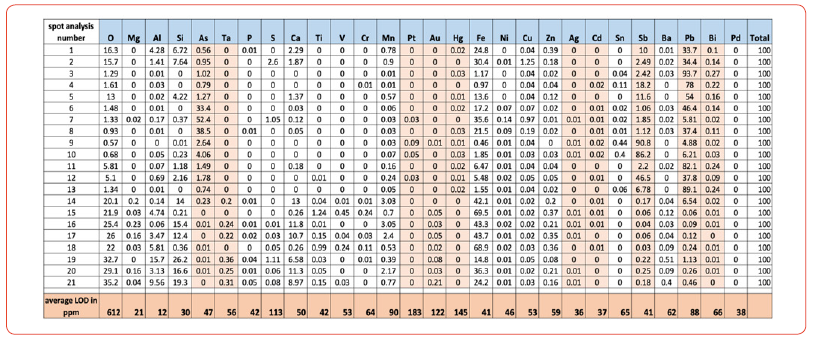

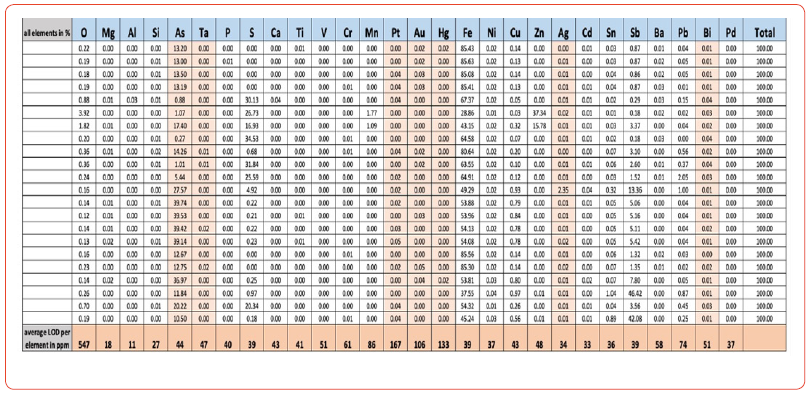

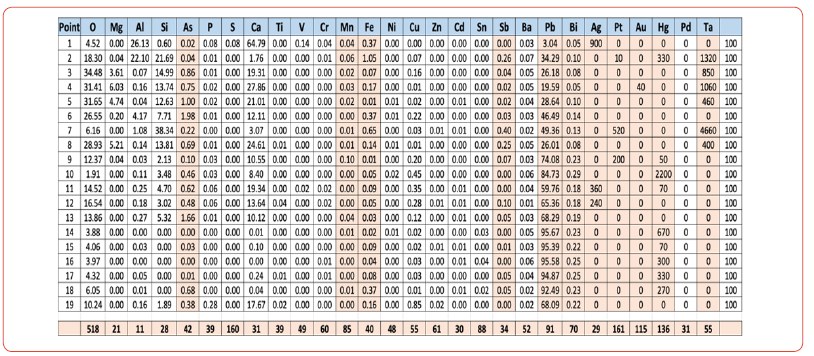

All elements are presented in normalised weight %. Key/ precious elements are highlighted. Average Limit of Detection for each element is shown at the bottom of the table. It follows that Table entries reported as zero are < =LOD. Conversion parameter: 1%= 10000ppm.

Results and Discussion

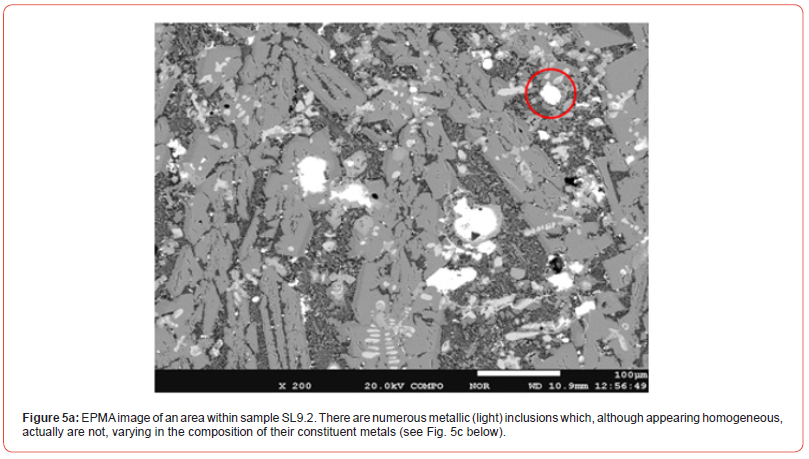

EPMA analysis of sample SL9.2, silicate-rich

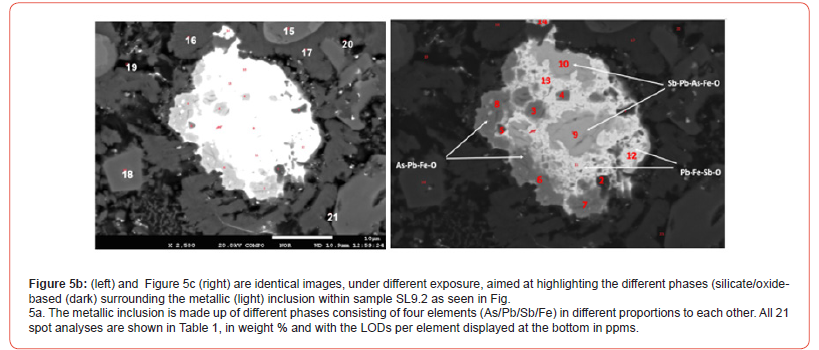

Figure 5a shows sample’s SL9.2 distinct micro-crystallinity consisting of largely both oxide/silicate with small metallic inclusions (prills) dispersed throughout the matrix. Regarding the former, there are globular dendrites of FeO (light grey), long lathes of Ca-Fe-Si-O (dull grey) and an interstitial non-crystalline/glassy phase (dark grey); all three are common phases encountered in ancient slags and the crystalline ones are referred to as wüstite and kirschsteinite, after the minerals that match their composition. We focus on the area circled within Figure 5a.

In examining Table 1, the first observation is that this is a Pb-rich slag; Pb partitions preferentially not in the Ca-Fe oxide/ silicate phases (Table 1, spot analyses 15-21) but rather within the small metallic inclusions of Pb-Sb-Fe-As in different relative concentrations to each other. The silicate phase consists of average of c.29%Pb/23%Fe/13%Sb and with no As (average values taken from Table 1). Mn is not particularly prevalent. Au and Ta correlate well and are to be found within these phases, while Hg concentrates in the metallic ones -see below.

The metallic constituent is a mixture of metals of roughly 40%Pb/25%Sb/15%Fe/15%As composition (average values taken from Table 1) as can be surmised from the analysis of the metallic inclusion in Figure 5c & Table 1. What is of interest is that contrary to what one might have expected, these Pb/Sb-rich metallic prills are Au/Ag ‘poor’. As already mentioned, the reverse seems to be true for the Pb-poor silicate phases, both crystalline and glassy: i.e., they are richer in Au/Ag and in Ta in particular (Table 1).

The presence and distribution of the above many elements suggest that: a. a polymetallic ore(s) was charged into the furnace; b. a relatively fast cooling rate (i.e., the slag cooled/ran out soon after forming) took place on account of the small size of each crystalline phase and the multitude of small metallic inclusions which had little time to coalesce into larger ones. This fast cooling may argue against the idea of a conventional tall, shafted furnace where the ore is allowed to sit over long(er) periods of time, and more towards a low shaft, hearth-like arrangement. However, again at this stage, this can only be a working hypothesis.

Assuming this is a typical Pistyros smelting slag, we can argue that two types of metals could in principle come out of this furnace: one consisting primarily of antimonial lead (Pb-Sb) and another of iron arsenides (Fe-As). There is no physical evidence, so far, for the former, only for the latter (see section below).

Pb-Sb alloys have a melting point of 252°-360°C. Had the Pistyros furnace produced that type of ‘alloy’, then antimonial lead would run out of the furnace first i.e., at that low temperature range. On the other hand, iron arsenides (Fe-As) have a much higher melting point (c. 1000°C). Different combinations of Pb-Sb- Fe-As would have a melting point of somewhere in between.

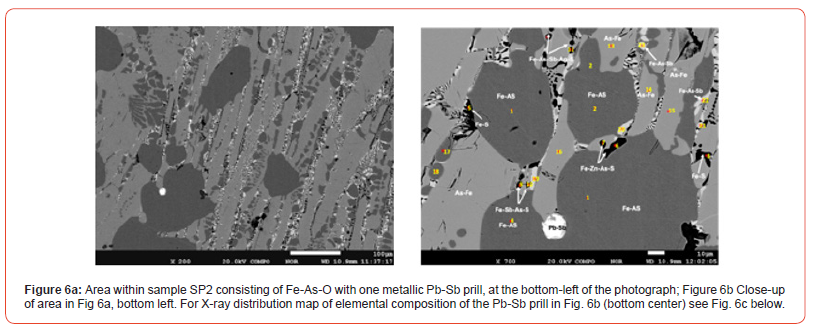

EPMA analysis of sample SP2- rich in iron arsenides

As mentioned, there are no fragments of antimonial lead; instead, we have examples of iron arsenides with Pb-Sb inclusions. Fe-arsenides are usually referred in the literature by their 19th century German name i.e., speiss. Although this term is also used in archaeometallurgy, and even in a prehistoric context, we shall nevertheless endeavor to avoid using it here and will simply refer to it as a metallic mixture of Fe-As (with Pb-Sb) and with a small oxygen component, as the data in Table 2 suggest.

Table 1:EPMA analyses of oxide/ silicate (pink) and metallic (yellow) phases within SL9.2

Table 2:EPMA analyses of different iron arsenide phases within SP2.

Table 3:EPMA analyses of different Pb-rich phases within L3.

Table 2 shows spot analyses labelled from 1-22 as illustrated in Figure 6b. There is a variety (at least two) of iron arsenide phases: one, rather globular, Fe-As (dark grey) and a second, As-Fe, (long lathes), the difference between the two being in the ratio of the two elements As/Fe (Figure 6a & 6b). Thoroughly dispersed within these two iron-arsenide phases are a fine, very light grey, Sb-rich phase: also a fine, very dark grey/black Fe-Zn-Sb-S rich phase. Ag/ Au are thoroughly dispersed throughout the different Fe-As phases which overall all lack any substantial quantities of Pb.

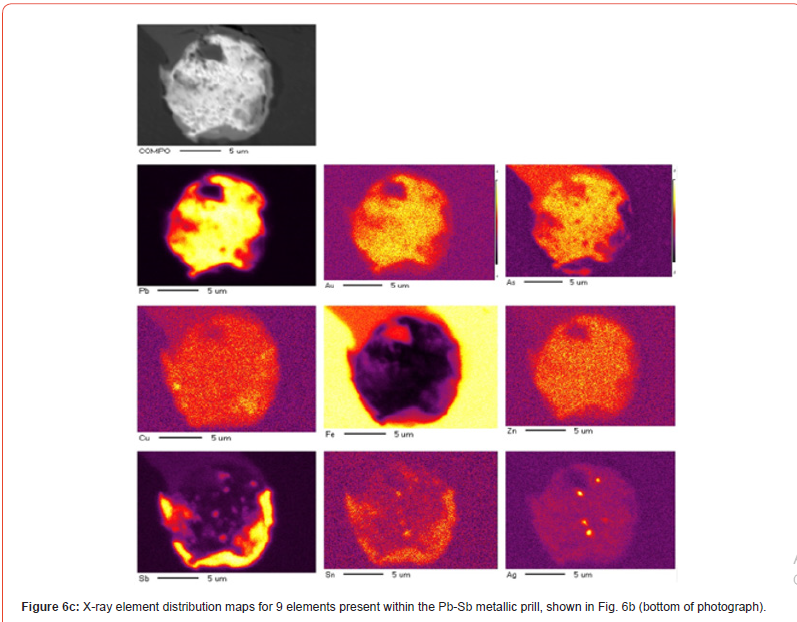

At the bottom of the picture in Figure 6b there is a metallic prill labelled Pb-Sb. We have no elemental composition for this prill; only X-ray element distribution maps (Figure 6c). From the latter it is clear that Pb and Sb are not miscible, Sb lying in the periphery of Pb. Au is finely dispersed within Pb. Ag is also to be found within Pb but concentrated in particular ‘spots’. Sn is dispersed within Sb rather than Pb. Fe surrounds Pb but is absent within; finally, Cu and Zn are only finely dispersed within Pb. This is a one-pic analysis of a single metallic prill and hardly representative but helps to illustrate the fact that precious metals may indeed concentrate within the iron arsenide phase of the slag.

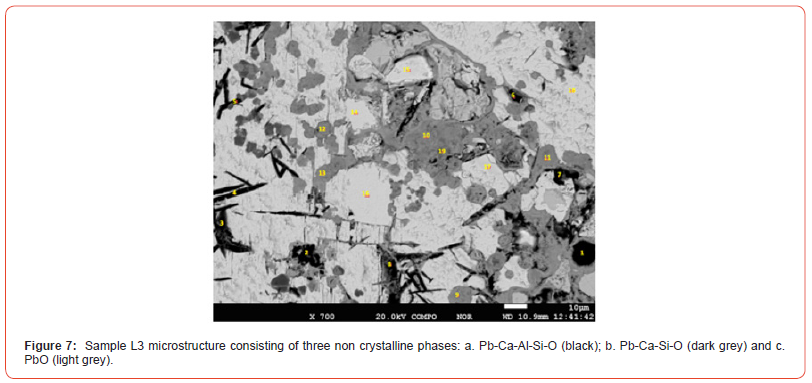

EPMA of sample L3, lead oxide-rich

The third sample presented here consists of largely PbO. This type of materials are referred to in the archaeometallurgical literature as litharge. However, this is not the mineral litharge (i.e., pure PbO). Rather Pb is a constituent of three distinct phases. More specifically there are: a. Pb-Ca-Al-Si-O (black) and b. Pb-Ca-Si-O (dark grey) and c. a lighter phase which is near pure PbO (Figure 7). Bi is present within the litharge while Au/Ag are, as expected, low/absent (Table 3). Of interest is the presence of Ta associated with the Pb-Ca-Si (dark grey/black) phases. The trace elements Ta, Hg, Pt reported in the analyses here and their association with Au/ Ag form currently the topic of an ongoing investigation into these complex materials (Photos-Jones et al, forthcoming) [18].

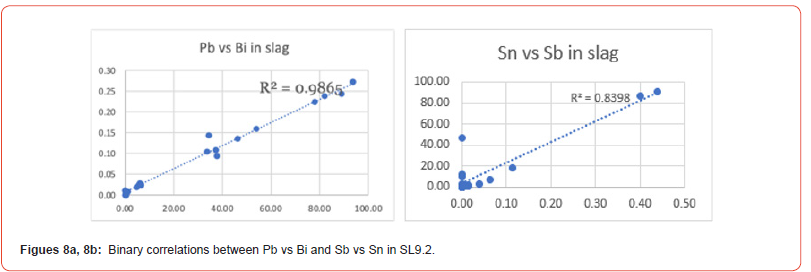

Relationship between SL9.2/SP2/L3

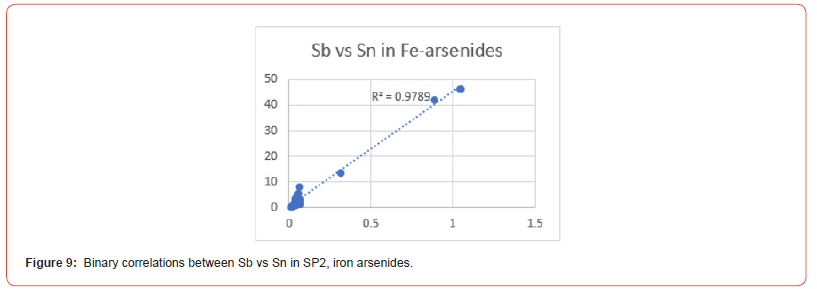

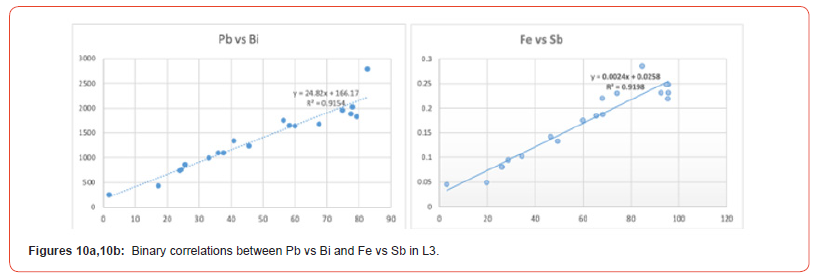

This section attempts to establish whether there exists some relationship between the three samples by looking closely at some binary ratios between key elements, from the data obtained with the EPMA. There is good correlation between samples SL9.2 and L3 with regards to Pb vs Bi (Figure 8a); there is a good correlation between samples SL9.2 and SP2 with regards to Sb vs Sn (Figures 8b & 9); finally, there is a good correlation in L3 between Fe vs Sb (Figures 10a & 10b). The first correlation (Pb vs Bi) suggests that the Pb (with Sb) metal emerging out of the smelting furnace that produced sample SL9.2, is the same (compositionally similar) to that which underwent oxidation resulting in the production of L3. The second correlation (Sb vs Sn) suggests that SP2 was either formed within the furnace together with SL9.2 or independently of it following a subsequent treatment/melting. These correlations are suggestive rather than conclusive since the paucity of analyzed finds does not allow for overriding conclusions.

Short Discussion and Conclusion

The period between the 4th and the 3rd c BCE is one known from historical accounts to be fraught with (both, friendly and hostile) interactions between the many diverse ethnic groups inhabiting the area i.e., Thracians, Thasians, Athenians, Spartans and other Greek colonists and Macedonians. They continuously formed, upturned and reformed alliances with and against each other [5]. It is certain that the economically viable mineral wealth of the region in the vicinity of Pistyros (Au, Ag, Pb, Cu or Fe) was well known to all and access to the underground resource and the ability to ‘exploit it’ for their own benefit must have weighed heavily in their mind.

What type of ‘ore’ did Pistyros slag derive from? The good correlation between samples SL9.2 (silicates) and SP2 (iron arsenides) and with respect to Pb and Bi (Figure 8a), as is the presence of Au and Ag within, point to Pistyros having access to Palaia Kavala ores and of the variety highlighted by previous investigators. The source(s) of Ta, Pt, Hg, all above the EPMA’s LOD, needs to be investigated further and may point further afield. The recent publication of 18 lead ingots found in a shipwreck near Comacchio Italy [14] dating to the 3rd/2nd decade BCE revealed presence of trace elements like Bi/Ag/Sb/Cu ‘reminiscent’ of the Pistyros furnace metallic ‘load’. In this case, Sb is present in trace amounts rather than as a major/minor constituent.

What type of metal would this ‘ore’ generate? The slags both in their silicate/oxide and in some of their metallic phases are first and foremost Pb-rich. Metallic Pb is formed in association with Sb as shown in Figures 6b and 6c; whether antimonial Pb was indeed tapped out of the furnace, in large quantities, or not, remains a point of conjecture. The slags also produced a second metallic phase, i.e., iron arsenides, rich in Au/Ag. How were these metallic compounds further processed, and for what purpose (extraction of precious metals?) we cannot, presently, be sure.

Regarding the one sample of PbO (L3), this is devoid of Sb. Has antimonial lead been de-antimoniated i.e., heated (at low temperatures and on a hearth basis) whereupon Sb was concentrated in the (melting) slag that was formed? Again, there is a need for further investigation. Why make PbO? PbO, referred as litharge, when encountered in archaeolometallurgical sites, is almost always assumed to be the waste product of desilverisation of Pb for the production of silver bullion. However, PbO, the lithargyros of the texts (Dioscorides De Materia Medica, V, 88) does not equate with that waste product at all [15]. Instead, it was clearly manufactured on its own right for its own purposes and as a medicinal mineral.

The proximity of the Pistyros metal waste to the ‘winery’ also raises issues regarding possible psimythion (PbCO3) making on site. Recently we had the opportunity to reevaluate the Theophrastus (On Stones, 57) method for psimythion preparation requiring large supplies of ‘oxos’ (poor wine) and lead metal [16]. There are no known workshops dedicated to psimythion making for that period, the only facilities required (at least in a Classical/ Hellenistic setting) being considerable supplies of both (oxos and metal) and large pithoi where the reaction took place [17]. Again, Pistyros’ possible involvement in psimythion manufacture has to remain a hypothesis.

So, there are presently many scenarios regarding the

metallurgical activities of the Pistyrians’ in the well-dated

Hellenistic contexts:

I. They may have been smelting within their city walls, from

polymetallic ores recovered from the immediate vicinity.

II. They may have been manually processing (hand breaking) the

slag physically transported from the vicinity of the mines for

the recovery of metallic inclusions within, be it antimonial lead

or iron arsenides or both with and without precious metals.

III. They could be making metallic Pb, both as ingots and as

raw material to synthesize minerals like psimythion (lead

carbonates) via ambient temperature reactions. In that case

the Pb would have likely required the removal of antimony.

IV. They could be making lithargyros, as per the ancient mineral

medicine, as well.

V. In short there is a possibility that Pistyros indulged in a

complex network of metallurgical activities requiring both

high-temperatures (c. 1000°C) and low-temperatures (300-

600°C) and yet more activities requiring simply ambient

temperatures.

To conclude, with its intensive, potentially multi-varied, Pb-based metals activities taking place in parallel with others (agricultural-based) and in the confines of a fortified settlement, with private and public buildings, Pistyros is in a unique position to shine light on the multi-faceted life of Hellenistic Macedonia [17, 18]. It uniquely presents us with the opportunity to examine potentially interdependent metallurgical and other processes, that are the hallmark of urban sites, vis a vis the more ‘one-dimensional’ smelting-at-the-mine paradigm which has been the guiding model for Classical/Hellenistic Northern Greece metals exploration and exploitation, so far.

Acknowledgments

The authors wish to thank the excavator Dr S. Papadopoulos for the opportunity to work on the Pistyros metallurgical waste. One of us (NN) has spent considerable time on site attempting to quantify/ inventory/categorize the vast quantities of slag revealed in the early years and to excavate particular features, which are still waiting full publication. EPJ first published on the ancient metallurgical waste of the Lekani mountains about thirty-five years ago! She is grateful for the opportunity to reevaluate past observations.

We wish to thank Dr Paul Edwards of University of Strathclyde, Department of Physics, for the EPMA analysis undertaken in the midst of the pandemic and remotely! NN acknowledges funding for this project from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 840894 – Metals Technology in North Aegean Societies (ME.Tech.NAS). Additional funding was granted to NN within the scope of project ARISTEAS (Prof N. Zacharias, PI) cofinanced by Greece and the European Union under the auspices of the program “Competitiveness, Entrepreneurship and Innovation” NSRF 2014-2020.

Conflict of Interest

The authors declare no competing interests.

References

- Koukouli-Chrysanthaki Ch (1973) News from the Thasian ‘continent’. 6: 230-240.

- Koukouli-Chrysanthaki Ch (1980) The colonies of Thasos in the North Aegean, some new finds. In Kavala and its region. Proceedings of the 1st Local Symposium, Kavala, Thessaloniki, pp. 309-325.

- Papadopoulos S, Zannis A (2022) c. AEMTh 30, pp. 553-564.

- Myteletsis M (in press) Ancient Pistyros, the numismatic evidence, In: S. Papadopoulos and N. Nerantzis (Eds.). Pistyros of the Aegean, Athens (in Greek).

- Zannis A.G (2014) Le pays entre le Strymon et le Nestos: géographie et histoire (VIIe-IVe siècle avant J.-C.), Meletemata 71, Athè

- Spathi K, Kouvelos C, Perdikatsis V (1982) The Manganese-Iron Mineralisation in the area of Palaia Kavala. Mineralogical and Petrological Research, 3. Institute of Geological and Mining Exploration. Athens. (English summary).

- Fornadel A P, Spry PG, Melfos V, Vavelidis M, Voudouris P (2011) Is the Palea Kavala Bi‑Te‑Pb‑Sb±Au district, northeastern Greece, an intrusion‑related system?. Ore Geology Reviews 39 119‑133: 39(3).

- Vavelidis M, Christofidis G, Melfos V (1997) Ancient mining activity in the wider region of Kavala-Philippoi, in Ancient Greek Technology, Proceedings of the 1st International Conference. Thessaloniki, pp. 95-101.

- Koukouli-Chrysanthaki Ch (1990) The ‘metals’ of Thasian Peraia. In Memoriam of D. Lazaridis. Polis and Chora in Ancient Macedonia and Thrace: Proceedings of Archaeological Conference, Greco-French Research, Kavala 1986, Thessaloniki pp. 493-514.

- Photos E (1987) Early Extractive Iron Metallurgy in N. Greece. A Unified Approach to Regional Archaeometallurgy, PhD Dissertation, University of London.

- Photos E, Koukouli-Chrysanthaki Ch, Tylecote R.F, Gialoglou G (1989) Precious Metals Extraction in Palaia Kavala, NE Greece, An Archaeometallurgical Attempt to Locate Skapte Hyle. In International Old World Archaeometallurgy Conference, Der Anschnitt. Heidelberg, Max-Plank-Institut fur Kern Physik, pp. 179-190.

- Vavelidis M, Gialoglou G, Wagner G.A, Melfos V (1996) Skapte Hyle: a gold mine at the locality of Mandra Kari, Palaia Kavala, Proceedings of the 2nd Symposium of the Hellenic Archaeometric Society. Thessaloniki, pp. 23-35.

- Picard O (2006) Mines, monnaies et impérialisme. conflits autour du Pangée (478‑413 av. ‑C), In: A.M. Guimier‑Sorbets, M.B. Hatzopoulos and Y. Morizot (Eds.) Rois, cités, nécropoles: institutions, rites et monuments en Macédoine, Meletemata 45, Paris: de Boccard, pp. 269‑283.

- Bode M, Hanel N, Rothenhöfer P (2021) Roman lead ingots from Macedonia-the Augustan shipwreck of Comacchio (prov. Ferrara, Italy) and the reinterpretation of its lead ingots’ provenance deduced from lead isotope analysis. Archaeological and Anthropological Sciences 13: 163.

- Beck L. Y (trans.) (2005) De materia medica by Pedanius Dioscorides, Hildesheim, Olms-Weidmann.

- Photos-Jones E, Bots P, Oikonomou E, Hamilton A, Knapp C.W (2020) On metal and ‘spoiled’ wine: analysing psimythion (synthetic cerussite) pellets (5th-3rd centuries BCE) and hypothesising gas-metal reactions over a fermenting liquid within a Greek pot. Archaeological and Anthropological Sciences 12(10): 243.

- Nerantzis Nand, Photos-Jones E (in press) Lead and the city: a methodological approach to the study of large-scale Pb-based metallurgy at Hellenistic Pistyros. N. Greece, in S. Papadopoulos and N. Nerantzis (Eds.) Pistyros of the Aegean, Athens

- Photos-Jones E, Edwards P, Nerantzis N, forthcoming.

-

Nerantzis Nerantzis*, Effie Photos-Jones*. The Presence of Au and Ag in Pb-Rich Slags from Hellenistic Pistyros, N. Greece: Some Observations. Open Access J Arch & Anthropol. 5(2): 2024. OAJAA.MS.ID.000610.

-

Demokritos, Archaeometry, lyophilizer, Radiocarbon, Carbohydrates, Neolithic

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.