Research Article

Research Article

Multi-Analytical Investigation of Historic Mortars Technology from Water Cisterns at Vryokastro, Kythnos, Greece

Papoutsaki, A1*., Facorellis, Y1, Karatasios, I3., Boyatzis, S1., Stefanis, A2., Mazarakis Ainian, A4

1Laboratory of Study and Conservation of Ancient and Modern Cultural Goods, Department of Conservation of Antiquities and Art Works, School of Applied Arts and Culture, University of Western Attica, Αgiou Spyridonos, 122 43 Aigaleo, Greece.

2Architectural Conservation Laboratory, Department of Conservation of Antiquities and Art Works, School of Applied Arts and Culture, University of Western Attica, Αgiou Spyridonos, 12243 Aigaleo, Greece.

3Institute of Nanoscience and Nanotechnology, National Center for Scientific Research “Demokritos”, Aghia Paraskevi, 15310 Athens, Greece.

4Department of History, Archeology and Social Anthropology, University of Thessaly, Αrgonauton & Filellhnon,38221 Volos, Greece.

Papoutsaki, A, Laboratory of Study and Conservation of Ancient and Modern Cultural Goods, Department of Conservation of Antiquities and Art Works, School of Applied Arts and Culture, University of Western Attica, Αgiou Spyridonos, 122 43 Aigaleo, Greece.

Received Date:May 01, 2023; Published Date:June 13, 2024

Abstract

The present study concerns the technological characterization of mortar samples originating from water supply cisterns at the ancient site of Vryokastro on Kythnos island, Greece, in order to investigate the raw materials that were used for their production and the consequent microstructural and performance characteristics of the mortars. Understanding these characteristics is vital for safeguarding the site’s heritage and guiding conservation strategies. Powdered and freshly fractured samples as well as polished sections were studied to determine the chemical and mineralogical composition of the mortars using various analytical techniques: Optical Microscopy (OM), Scanning Electron Microscopy with microanalyzer (SEM/EDS) and X-ray diffraction (XRD). Furthermore, grain size analysis, Differential Thermal Analysis (TG/DTA), Fourier Transform Infrared Spectroscopy (FTIR) and Mercury Intrusion Porosimetry (MIP) were also conducted. The results of the analyses indicate that the samples from Vryokastro site contain both air-hardening and hydraulic mortars, containing well-graded natural aggregates.

Keywords:Archaeological mortars, Ancient cisterns, Vryokastro archaeological site, Kythnos, Multi-analytical techniques

Abbreviations:O.M: Optical Microscopy, XRD: X-ray Diffraction, FTIR: Fourier-transform infrared spectroscopy, SEM/EDS: Scanning Electron Microscopy/ Energy Dispersive Spectroscopy, TG/DTA: Thermogravimetric analysis/ Differential Thermal analysis, MIP: Mercury Intrusion Porosimetry.

Introduction

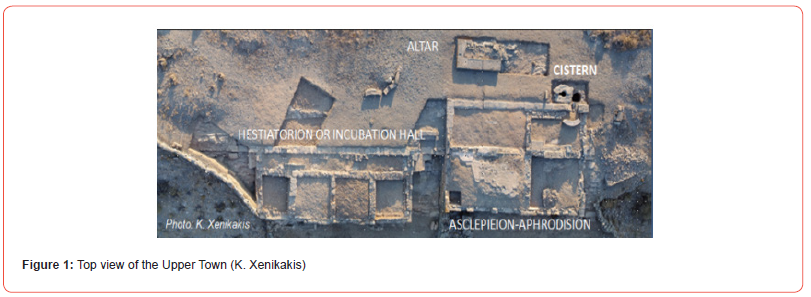

The archaeological site of Vryokastro, the ancient capital of the island of Kythnos, is located on the northwest side of the Cycladic island, between the bay of Merichas and the bay of Apokrousi (37° 24΄ 28΄΄ N, 24° 23΄ 42΄΄Ε). Since 2002 the site has been excavated by the Department of History, Archaeology, and Social Anthropology of the University of Thessaly in collaboration with the Ephorate of Antiquities of the Cyclades (Facorellis et al. [1], Mazarakis Ainian [2]). According to the archaeological finds, the site was inhabited from the 10th century BC till the 7th century AD (Mazarakis Ainian [3], Facorellis et.al, [4]). During these archaeological campaigns cisterns and water supply systems of the ancient town were unearthed. The excavation of the main cistern of the site began in 2016, and it is still ongoing. The cistern is located inside the sanctuary of Asclepios and Aphrodite in the Upper Town and is related to the needs of the cults as it is presented in Figure 1 (Mazarakis Ainian [2]). Based on the archaeological evidence, it has been suggested that the cistern dates back to the Archaic period. However, the absence of written records or definitive dating methods precludes the establishment of an exact date for the construction of the cistern. The cistern is pear-shaped, the orifice diameter of 0.50m, the diameter of the bottom is 7.70m and its depth is 8m. The morphology of the cistern is differentiated in the upper part close to the entrance and at the bottom (Figure 3).

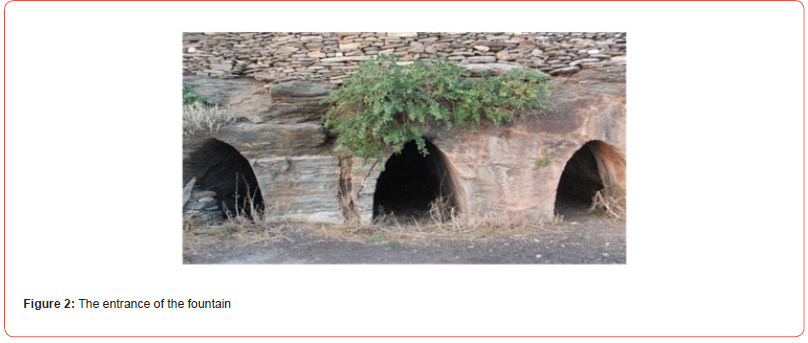

Additionally, an important water supply point of the ancient city was a fountain, located west of the Upper Town (Figure 2). In more detail, the fountain consists of three main entrances that continue for 8m and a fourth one that is 7,5m and intersects the other three (Mazarakis Ainian and Mendoni [5]).

As mortars are vital building materials for every manmade construction from ancient times to today (Palomo et al. [6]), a detailed study of the mortars from the ancient town’s water supply points was undertaken using various analytical techniques. This paper investigates the technological characteristics of the mortars used in the aforementioned sites of interest. The importance of this study rests on the fact that currently there is a lack of analytical studies on mortars originating from water supply points, in the Cyclades during this period. Understanding these materials is crucial for the conservation of water supply points in the Cyclades region and therefore in Kythnos island.

Materials and Methods

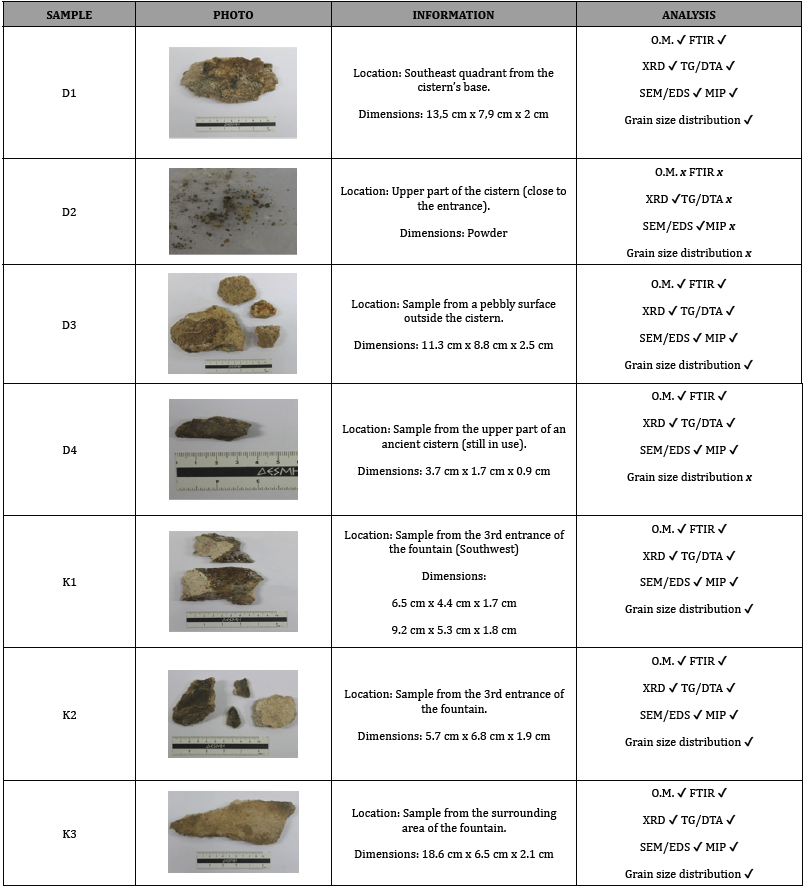

Seven samples in total were selected from several water supply sites of interest (Table 1). In addition, one local rock sample (schist) was also collected for comparison reasons. Sampling was performed at selected positions in order to collect fragments that would provide the most representative results. The sampling procedure was challenging due to the fact that specialized speleological equipment was required and used for the descent in the main cistern.

A top-down method was employed, starting from the surface layer and working downwards towards the core in more specific details. Table 1 presents all the samples details and the analyses performed (Table 1).

Table 1:Main information and investigation techniques employed for the mortar samples from the site of Vryokastro on Kythnos island.

Water is the most effective deteriorating agent for mortars, and it can cause bio-deterioration growth, soluble salts etc., (Sabbioni et al. [7], Stefanidou et al., [8]). Samples D1, D2, D3, D4 and K3 are extensively deteriorated with signs of disaggregation, cracking, and loss of cohesion due to prolonged exposure to moisture, soluble salts, and biological activity. Conversely, samples K1 and K2 display relatively better structural integrity, together with increased evidence of biological activity.

Analytical techniques

The mortar samples were examined using various complementary analytical techniques. First, a stereoscope (Olympus SZ61), with magnifications from x4 to x300 was used to perform an initial examination, providing information about the surface and the morphological features of the sample. The photographic documentation of the samples enabled the determination of points of interest for further analysis.

The stratigraphy of the samples was observed in cross and polished sections with an optical microscope (Leica DFC310 FX) and their microstructure was also photographically documented.

Grain size analysis was performed to determine particle size distribution, after mechanical separation of the binder from the aggregates, in order to compare any differences and determine the requirements of aggregates gradation for future restoration mortars. The analysis was performed according to European Standard EN 933- 1 (European Standard EN 933-1) using sieves in the range of 0,063 to 8mm (IMPACT Laboratory Test sieves BS410 -1 with ISO3310 -1).

The binder fraction obtained from the sieving process (<0,063mm) was further analyzed by X-ray powder diffraction (XRD) to determine the mineralogical composition of the setting products. Additionally, Fourier Transform Ιnfrared spectroscopy (FTIR) analysis was also performed, employing a Perkin Elmer Spectrum GX infrared system with Spectrum v5.3.1 software on the same powdered samples, which were pressed in a KBr disc.

Thereafter, SEM/EDS (model JEOL JSM 6510 LV) coupled with a microanalyzer (Oxford Instruments, Pentafet 6587 EDS, using the INCA software) analysis was performed on both polished sections and freshly fractured surfaces of all the samples, in order to examine their microstructure and determine their elemental composition of individual constituents. Freshly fractured surfaces were examined with Secondary Electron Imaging (SEI), providing images with detailed topographic information. On the other hand, Backscattered Electron Images (BEI) carry elemental information of every region analyzed (Joy [9]). SEI and BEI was used in both polished sections and freshly fractured surfaces.

Thermal/ Thermogravimetric analysis (DTA/TG) was performed on all mortar samples in order to investigate thermal and chemical alterations of the mortars’ binder associated to their composition and typology (air-hardening or hydraulic). The analysis took place in a Perkin Elmer Pyris G2 thermal analyzer, utilizing the binder fraction (<63μm). Furthermore, alumina (Al2O3) was used as reference sample for the comparative change in weight.

Finally, Mercury (Hg) Intrusion Porosimetry (MIP) was used to characterize the pore size characteristics of the mortars (Quantachrome Poremaster 60 Instrument), as porosity is a crucial parameter for the archaeological and historic mortars, associated to the water/moisture transport, durability and mechanical properties (Thomson et al., [10], Mehta and Monteiro [11]).

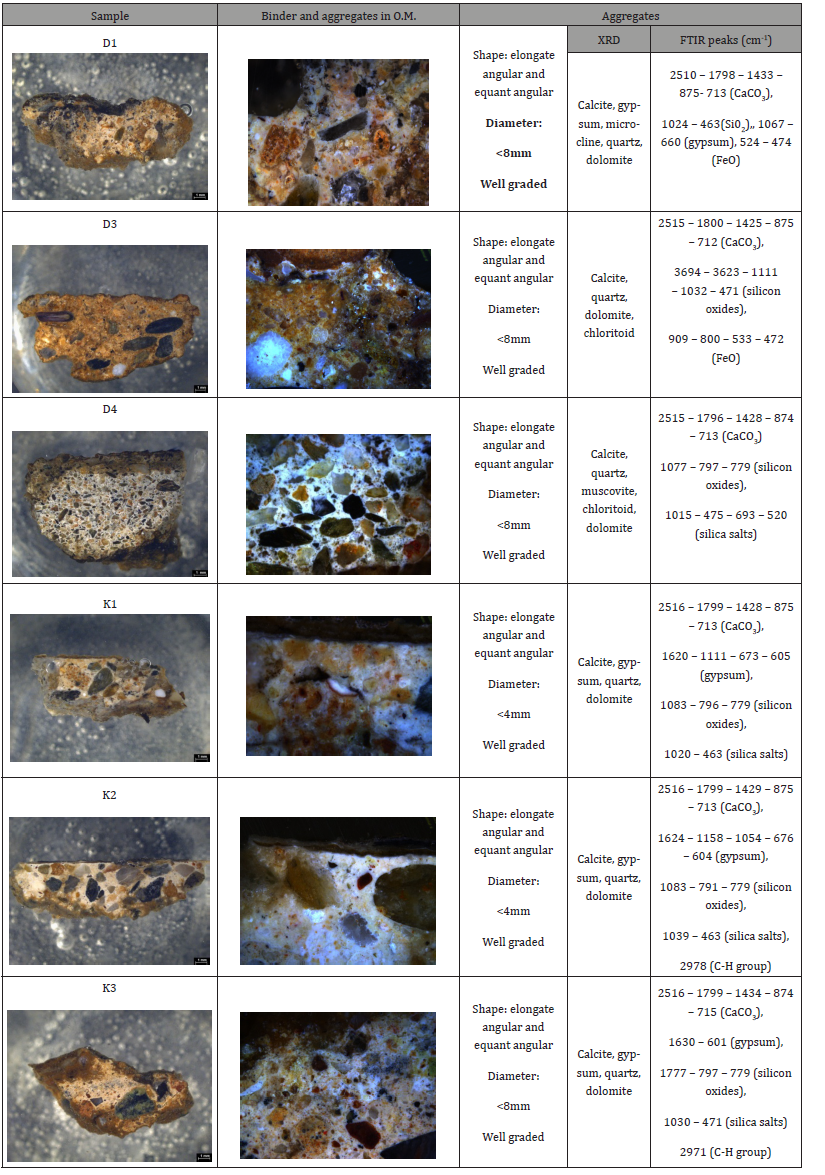

Table 2:Microphotographs showing morphological features of the samples(original magnification: first column x0,67, second column x50). Third and fourth column: description of the aggregates with their physical characteristics and the minerals that are detected in each sample, respectively.

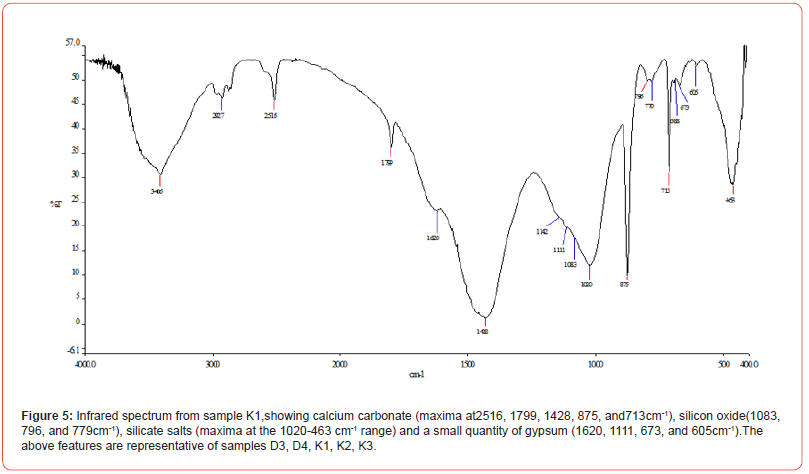

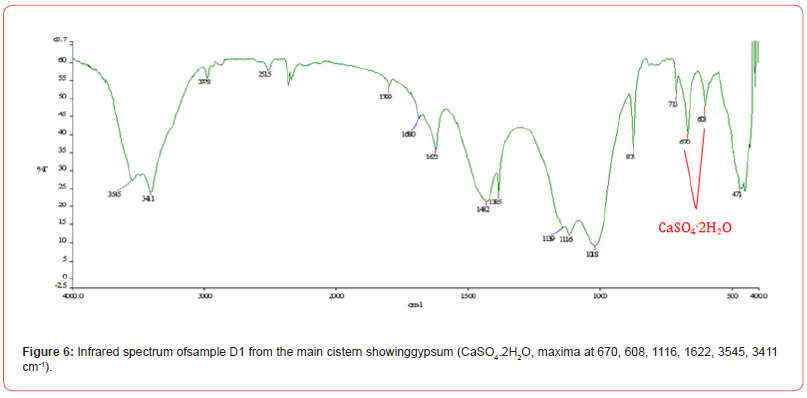

FTIR results indicated besides the existence of carbonate and silicate compounds, the presence of nitrates that would be associated with probably with biodeterioration products (Cutler et al. 2013). All samples showed the presence of silicate salts and samples K1, K2, and K3 revealed the presence of silicon oxides (quartz or flint), and small quantities of gypsum. In Table 2 characteristic peaks are mentioned and Figure 5 is indicative for all samples with the exception of D1, the latter sample originating from the main cistern additionally contains hydrated gypsum (CaSO4.2H2O) with characteristic peaks at 670 and 603 cm-1 as presented in Figure 6 (Mandal and Mandal [14]).

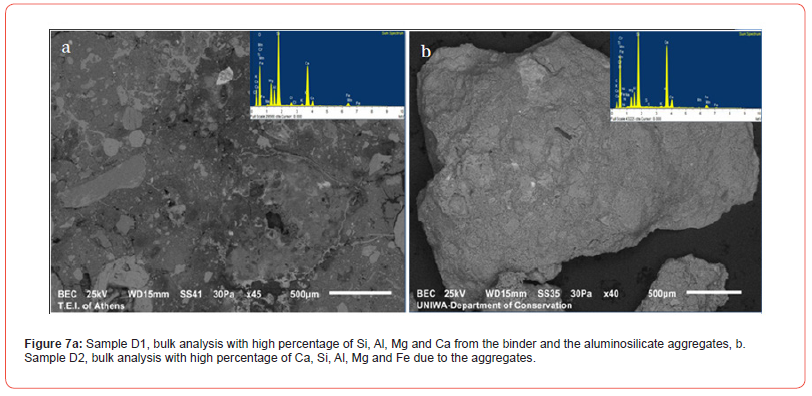

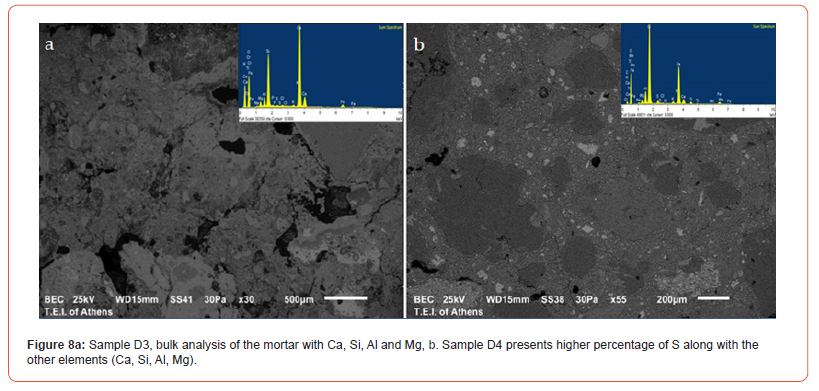

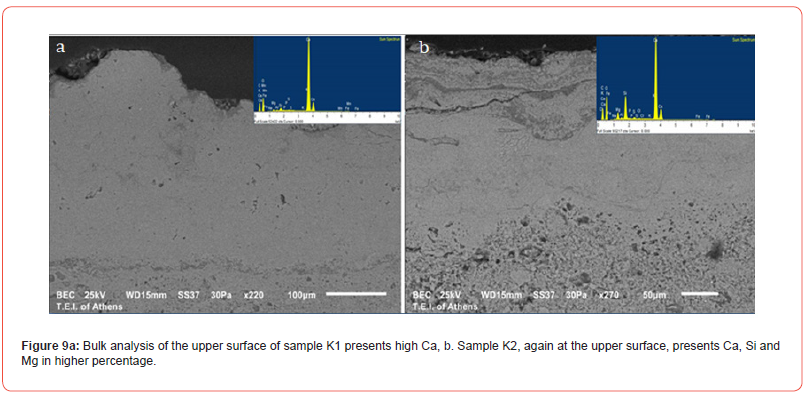

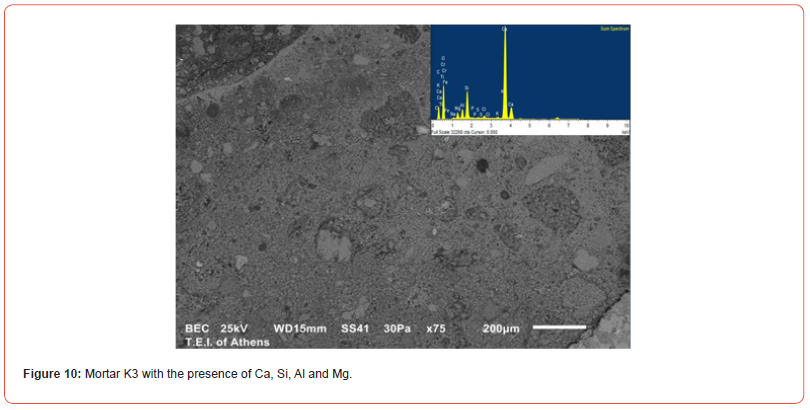

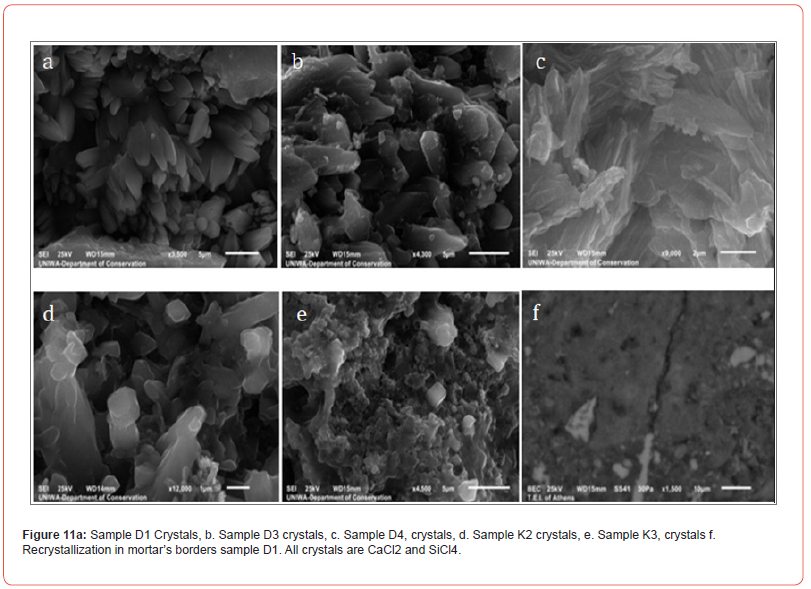

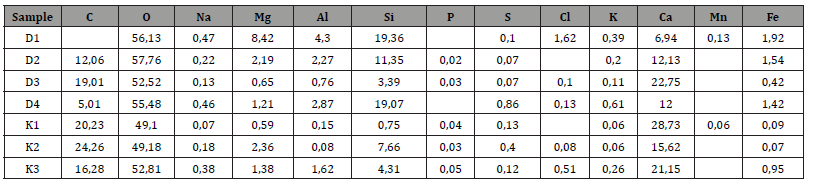

According to their elemental analysis with SEM/EDS, all samples consist of the same elements except for D4, which is the only sample where sulfur (S) was identified corresponding to gypsum. Samples D1, D2, D3, K1, K2, K3 mainly consist of Ca, Si, Al, Mg and Fe. The presence of Si, Al and Fe in samples D1 and D4, each exceeding 20%, indicates the presence of pozzolanic additives (Stefanidou et al. [8]). Samples with less Si, Al and Fe still contain pozzolanic additives in a lower percentage. In Figures 7-10 the bulk analysis of the mortars is presented and in Table 3 the elemental composition. Additionally, freshly fractured surfaces from the mortars were analyzed and calcite crystals were detected (Figure 11) (Maravelaki-Kalaitzaki et al. [15], Zamba et al., [16]). The crystals are CaCl2 and SiCl4.

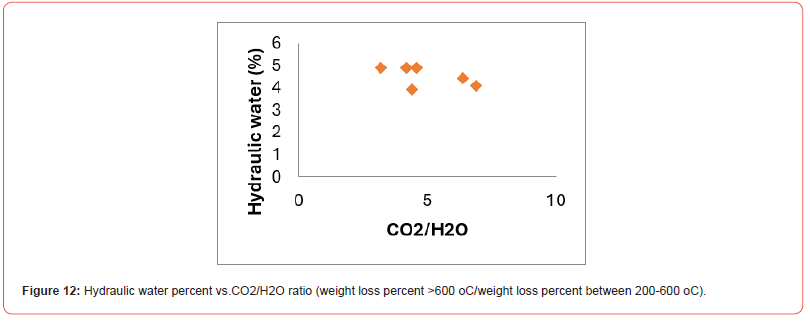

Thermal analysis (TG/DTA) provides information about the chemical transformations that take place during controlled heating of the samples. Physically absorbed water evaporates at temperatures up to 90oC, while chemically bound water of hydraulic compounds evaporates at temperatures between 90 and 400oC, followed by the dehydroxylation of clay minerals and lime (calcium hydroxide) (Karatasios et al. [17]). According to Moropoulou et al. [18], if the weight loss between 400-600oC is 3-5 % then the mortar is considered hydraulic, whereas if the weight loss is up to 10% then the mortar is considered highly hydraulic. Using these data, all samples are hydraulic, as shown in Table 4. The ratio of CO2/loss of H2O varies between 3,2 and 6,9%. The presence of CO2 along with the loss of water supports the idea of hydraulic mortars, as they often contain carbonate phases along with hydrated compounds (Stefanidou et al. 2014). According to Table 4 and Figure 4 a loss of chemical bound water between 3,9 - 4,9 % occurred between 400- 600 oC.

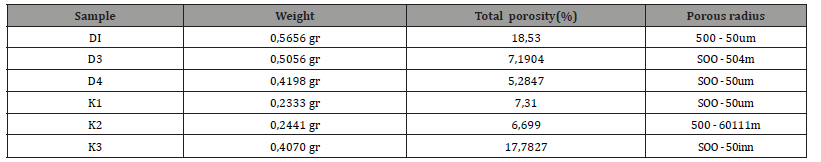

The samples present similar total porosity, except for samples D1 and K3, which have much higher porosity. The low porosity is attributed to the excellent choice of the aggregate grading and the binding material, leading in excellent durability behavior of the mortar (Koui and Ftikos [19]). In Table 5 the results of MIP indicates that sample D4 has a lower total porosity due to its later application and presents different natural characteristics due to the fact that is gypsum. All samples are characterized as macroporous with pores radius >50nm according to I.U.P.A.C (I.U.P.A.C., 20]) [21].

Table 3:EDS results from mortar analysis are presented in weight percentage (%).

Table 4:TG/DTA analysis and the weight loss of the samples in different temperatures.

Table 5:Total porosity and the porous radius are presented.

Conclusion

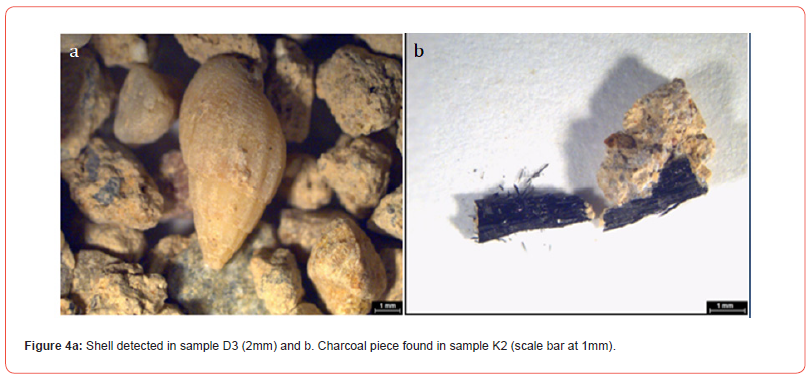

The mortar analysis provided an insight into the materials and the applied manufacturing technology. According to SEM/EDS and FTIR analysis the binder is identified as lime. The size of aggregates was found to be <8 mm in all samples except for two, which measure <4mm. These samples were obtained from the interior of the fountain, and their rounded shape and the presence of seashells suggest that sand from a local beach was added to the mortars. Specifically, FTIR results indicates the existence of calcium carbonates, silicates, quartz and nitrates (biodeterioration products). One sample from the main cistern also presents gypsum (CaSO4.2H2O). Salts in the edge of aggregates were detected which are due to secondary phases that increase the hydraulicity of the mortars. Calcium chloride and silicon chloride crystals were detected in the samples, and their presence may be due to the site’s proximity to the sea.

TG/DTA analysis shows that a loss of chemical bound water between 3,9-4,9 % occurred between 400-600 oC (endothermic peaks) and the ratio CO2/loss of H2O fluctuates between 3,2-6,9 %.

In conclusion, the mortars of the present study are characterized as hydraulic lime mortars (which means that they are suitable for their use), containing calcitic (pure and dolomitic), quartz, feldspars (KAlSi3O8), Fe oxides and in some samples seashells and charcoal aggregates. The presence of pozzolanic additives strengthens the hydraulic properties of the samples. As the mortars demonstrated satisfactory performance, it can be inferred that the aggregates also functioned effectively. The Sample D4 is identified as gypsum mortar, and it manufactured in a later period than the rest. This differentiation is shown in the elemental composition (the existence of sulfate) and the CO2/loss of H2O (%), which is lower.

Future Research

Suggested future studies are the sampling and examination of the upper plaster of the cistern. Another vital question is the absolute dating of the sample. Due to the fact that organic residues were found in the samples e.g seashells and charcoal pieces, it is feasible to be dated with the 14C with the AMS technique (Facorellis et al., [1], Facorellis et al., [4]).

Acknowledgement

This research could not have been done without the aid of Papadopoulou Zacharoula and Vaxevanopoulos Markos for their contribution on the samples collection, Tziamourani Eleni and Koukouli Anna for their aid to the preparation of the samples for Optical Microscopy and Grain size distribution. Finally, SPELEO (Hellenic Caving Club) for the provision of equipment for the descent in the cisterns if necessary.

Conflict of Interest

No financial interest or conflict of interest exists for both authors.

References

- Facorellis Y, Damiata BN, Vardala Theodorou E, Ntinou M, Southon J (2010) AMS Radiocarbon Dating of the Mesolithic site Maroulas on Kythnos and Calculation of the Regional Marine Reservoir Effect.

- Mazarakis Ainian A (2017) Land and underwater excavations, Archaeological work in Aegean islands, Rhodes, November-December 2013, International Scientific Conference II: 305.

- Mazarakis Ainian A (2013) Τhe sanctuaries of ancient Kythnos, Presses Universitaires de Rennes.

- Facorellis Y, Damiata B N, Vardala-Theodorou E, Ntinou M, Southon J (2017) Calculation on the regional Marine reservoir effect (CA. 8th, 1st century BC) based on the samples from the Vryokastro site on Kythnos, Les sanctuaries archaïques des Cyclades, Presses Universitaires de Rennes, pp. 275-285.

- Mazarakis Ainian A, Ancient Kythnos. Historiography and Archaeological research.In Mendoni L and Mazarakis Ainian A (eds) (1998), Kea- Kythnos: History and Archaeology, Acts of an International Symposium, Athens, pp. 49-63.

- Palomo A, Blanco-Varela MT, Martinez-Ramirez, S, Puertas F, Fortes C (2002) Historic Mortars: Characterization and Durability. New Tendencies for Research, Spain.

- Sabbioni C, Zappia G, Riontino C, Blanco-Varela MT, Aguilera J, et.al (2001) Atmospheric deterioration of ancient and modern hydraulic mortars”, Atmos Environ 35-3: 539-548.

- Stefanidou M, Pachta V, Konopissi S, Karkadelidou F, Papayianni I (2013) Analysis and characterization of hydraulic mortars from ancient cisterns and baths in Greece, Greece.

- Joy DC (1987) A model for calculating secondary and backscattered electron yields, Journal of Microscopy.

- Thomson M, Lindqvist JE, Elsen J, Groot, CJWP (2004) Porosity of mortars. In Characterisation of Old Mortars with Respect to their Repair. RILEM.

- Mehta PK, Monteiro PJM (2001) CONCRETE Microstructure, Properties and Materials.

- Geo Engineer, Step –by –step Guide for Grain Size Analysis.

- Groot CJWP (2000) A study of the effects of charcoal on hydraulic lime mortar properties, Proceedings of the 9th International Congress on Deterioration and Conservation of Stone 1: 517-526.

- Mandal PK, Mandal TK (2002) Anion water in gypsum (CaSO4 x 2H2O) and hemihydrate (CaSO4 x 1/2H2O) Cement and Concrete Research 32(2):313-316.

- Maravelaki-Kalaitzaki P, Bakolas A, Moropoulou A (2003) Physico-chemical study of Cretan ancient mortars, Cement and Concrete Research 33(5): 651-661.

- Zamba IC, Stamatakis MG, Cooper FA, Themelis PGZambas CG (2007) Characterization of mortars used for the construction of Saithidai Heroon Podium (1st century AD) in ancient Messene, Peloponnesus, Greece”, Materials Characterization, ELSEVIER 58(11-12): 1229-1239.

- Karatasios I, Alexiou K, Müller NS, Day PM, Kilikoglou V, (2014) The second life of ceramics: a new home in a lime environment”, In MMartinón-Torres (Eds.), Craft and science: International perspectives on archaeological ceramics, Doha, Qatar: Bloomsbury Qatar Foundation.

- Moropoulou A, Bakolas A, Bisbikou K (1995) Characterization of ancient, byzantine and later historic mortars by thermal and X- ray diffraction techniques, Athens and Venezia 269-270: 779-795.

- Koui M, Ftikos Ch (1998) The ancient Kamirian water storage tank: A proof of concrete technology and durability for three millenniums, Materials and Structures 31: 623-627.

- IUPAC (1972) Manual of Symbols and Terminology, Appendix 2, Pt. 1, Colloid and Surface Chemistry, Pure Appl. Chem 31: 578.

- Froberg L Thermal Analysis TGA/DTA, Process Chemistry Center.

-

Papoutsaki, A., Facorellis, Y, Karatasios, I., Boyatzis, S1., Stefanis, A., Mazarakis Ainian, A. Multi-Analytical Investigation of Historic Mortars Technology from Water Cisterns at Vryokastro, Kythnos, Greece. Open Access J Arch & Anthropol. 5(4): 2024. OAJAA.MS.ID.000618..

-

Morphology, Speleological equipment, Stereoscope, Thermogravimetric analysis

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.