Short Communication

Short Communication

The Airless Tire: Will this Revolutionary Concept be the Tire of the Future?

Ulf Sandberg*

Swedish National Road and Transport Research Institute (VTI), Sweden

Ulf Sandberg, Swedish National Road and Transport Research Institute (VTI), Sweden.

Received Date: September 09, 2020; Published Date: September 21, 2020

Abstract

Conventional pneumatic (air-inflated) tires have dominated the tire market for over a century. However, several tire manufacturers have presented concepts or prototypes for airless tires which use rubber only in the treads, while the load-carrying structure is made of composite materials such as polyurethane, thermoplastics, fiberglass and epoxy laminates, but also eco-friendlier and bio-degradable materials have been proposed.

First, some early projects (1989-2008) are described in which a Swedish innovative airless tire concept was tested, resulting in so-called Composite Wheel prototypes. This reduced noise emission and rolling resistance substantially and had excellent wet skid resistance properties while also providing acceptable vehicle handling. However, in full-scale testing, it did not endure an extreme test on a “pot-hole” test track due to a design lapse.

Then, a number of concept or prototype airless tires suggested by tire manufacturers in the last 15 years are reviewed. In general, very sparse information have been provided, but they all promise (without scientific proof) significant improvements over pneumatic tires. Advantages are foreseen especially in terms of dramatic reduction in global use of raw materials, use of more eco-friendly materials and much less complicated production. Even 3D-printing can be used in some cases. One of the prototypes is currently tested for use on an electric vehicle in service, with a possible market introduction targeted in 2024.

It is concluded that airless tires have substantial potential for initiating a revolution in terms of use of raw materials of which many may be eco-friendly, in addition to significant advantages over pneumatic tires in the environmental footprint during operation. However, a wide use of airless tires will have dramatic consequences for the tire manufacturing plants, and significantly influence the vehicle industry, with a risk of recent investments not being fully paid-off. Therefore, a wide introduction of airless tires on the market might take a longer time than what is technically needed, regardless of all benefits.

The Pneumatic Tire, A Most Sophisticated Product

The pneumatic (or air-inflated) tire as a concept was invented in the 19th century and was conquering the market for tires in the first decades of the 20th century. Since then, this concept has completely dominated the tire market and is currently stronger than ever. The basic idea is to use compressed air contained in a toroid or torus as a cushion between the vehicle and the road pavement and to let the solid materials in the outer part of this toroid or torus transfer the forces in both transverse and longitudinal directions between the axle and the pavement. To this end a rubber tread is added around the torus. However, the most essential material in the tires is air which, in case of punctures, will make the tire non-useable. Trials have been made with inflation by other gases, primarily nitrogen, but air is used in almost all road vehicle tires.

The product we call tire and is used on all rolling vehicles, is thus pneumatic in its principle and relies on a proper inflation. From its invention until today, the main principle is the same, but today’s product has been improved continually and in several relatively small steps over the more than 100 years since it entered the market. It is now an incredibly sophisticated product; an average tire today contains well over 100 separate components of various materials. It is often claimed by experts that the tires are the most important and sophisticated part of a road vehicle. Rubber is the main raw material used in manufacturing tires, and both natural and synthetic rubber are used, where synthetic rubber constitutes 60-70% of the total rubber amount. Other materials include carbon black, various oils, sulfur, silica, textile and steel reinforcements, to name a few.

Manufacturing such a product is very complicated. This means that manufacturing plants and the materials chains get complicated too, which has led to very substantial investments by the manufacturers that must be paid off during decades of production. Thus, when the radial tire was invented by Michelin in the 1940’s, despite it soon was found to be technically much better than its predecessors (i.e., the diagonal or bias ply tires), it took until the 1960’s until the radial tire became dominant on the European market. However, in USA, the tire and vehicle manufacturers hesitated to accept the radial tires. It was not until about 20 years after Europe when radial tires started to dominate the market in USA. This was partly due to US cars with very soft suspension not being adapted to the new tires, partly due to the refusal to rebuild their tire plants, as radial tires required very costly retooling.

Other major concepts that have been tried including building air inflated tires with essentially only a plastic torus fitted with a rubber tread, or to replace the air with solid material, such as polyurethane. None of them have been developed further than into prototypes.

The Airless Tire - First Trials

In 1982, Goodyear was granted a patent for an Integral Wheel- Tire (IWT) for passenger cars, based on a single-sided wheel rim with an asymmetrical deformation behavior [1]. The IWT was made of composite materials, having a circumferential part covered with a rubber tread. An extensive report dealing with this IWT was presented in 1989 [2], indicating very good characteristics. Yet, nothing more happened, at least not publicly reported.

Without being aware of the Goodyear concept, another airless tire (with dimensions suited for cars) was designed by the Swedish inventor Mr. Hans-Erik Hansson [3]. The patent was granted in Sweden and applications were filed in the major industrial countries. This wheel, like the Goodyear IWT, was a non-pneumatic, highly flexible construction in composite materials giving unique characteristics. Relative to the Goodyear design it used a more sophisticated shape, potentially giving much more flexibility in the design.

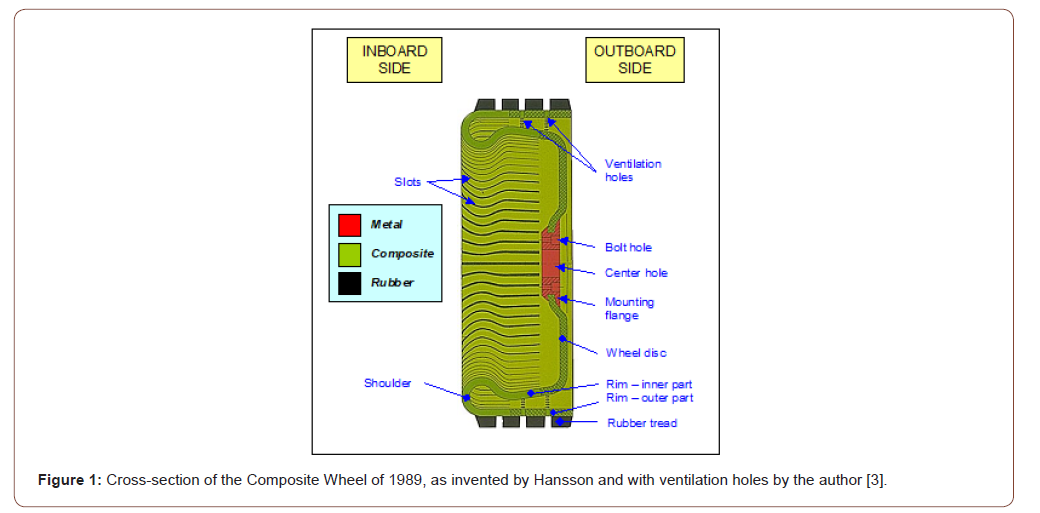

This product was named the “Composite Wheel (CW)” due to its integration of rim with tire, using a composite material of glass-fiber/ polyester laminate. To avoid confusion, it should be noted that, in principle, a normal air-inflated tire is also made of composite materials, although many more and totally different ones. Figure 1 shows a cross-section through the first version of the Composite Wheel (Figure 1).

In a project run at Swedish National Road and Transport Research Institute (VTI), the tread and underlying “belt” of this CW design was perforated with holes that let air and water flow through the tread and structure. With this design a noise reduction of up to 10 dB (A-weighted) was measured compared to one of the most popular quality tires of the time (a Goodyear Eagle NCT70) [4]. A problem was that after some driving with normal loads at highway speeds some cracks appeared in the “belt” area. The design was apparently not durable enough, which had not been the purpose with this particular design. The purpose had been to study the potential for noise reduction of the concept and not to build a fully durable tire. Nevertheless, as intended, the noise reduction potential had been demonstrated. It should be noted that in today’s traffic, the noise emission of tires constitutes the major part of traffic noise, so a 10 dB reduction would mean a revolution to traffic noise mitigation.

The reasons for the noise reduction were identified to be essentially two-fold [5]:

For low frequencies, the torus of a normal air-inflated tire can be compared to a closed loudspeaker cabinet. The latter separates the sound waves from the rear of a loudspeaker and the sound waves from the front of the loudspeaker, in order to avoid that these waves will cancel each other (which happens if there is no loudspeaker cabinet or large baffle). In loudspeaker technology this is known as “the baffle effect”. In the CW design, the sound waves from the rubber tread and the sidewall are not separated from the waves of the rear side of the same; therefore, creating a case where these low-frequency waves are partly or fully cancelling each other.

For high frequencies, the so-called air pumping sound which is created by trapping the air in the interface between rubber tread (with its open or closed grooves) and pavement surface, results in high air pressure gradients, when air is “pumped” in and out of the interface. In the CW design, this mechanism is eliminated by holes constructed or drilled through the tread and belt where air in tread grooves or trapped in cavities in the pavement can easily escape from the traps. Further, the so-called “horn effect” (the shape of the front and rear of the tire circumference curved over the flat pavement surface technically resembles an acoustic horn which may amplify sound created in the throat of the horn) is eliminated as the tire tread is perforated.

In reality, the two noise-reducing mechanisms are partly overlapping between low and high frequencies and in combination they constitute an efficient “killer” of noise.

Later Trials with the Composite Wheel

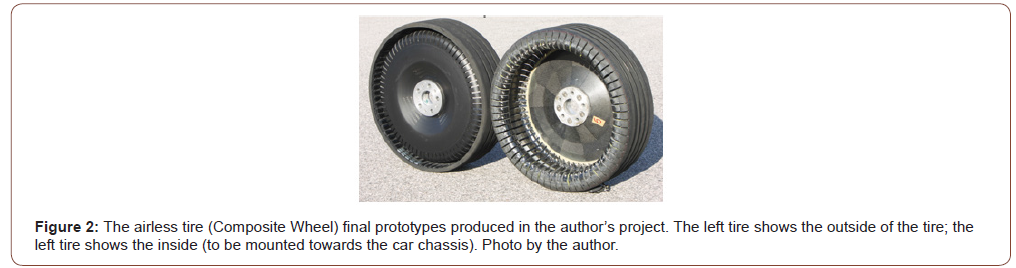

Tires are required to meet several very important requirements, of which noise would be one, but other performances should not be impaired when noise is reduced. Consequently, later projects should aim at studying the CW concept from a holistic point of view, considering primarily safety, wear, durability, vehicle handling, energy consumption and CO2 emission (the latter two depending on rolling resistance). In a later international project [6], utilizing carbon- fiber and epoxy laminate as materials but retaining the basic principle shown in Figure 1, focus was on noise, rolling resistance, durability, and vehicle handling. With regard to safety, it was obvious that skid resistance or hydroplaning on wet roads would be improved by the CW design as long as the tread was “ventilated” by holes, so no measurements were needed to confirm it. In order to improve durability, some of the noise properties had to be sacrificed. Figures 2 and 3 show the prototype samples during the final testing session.

The result was a CW tire resulting in about 5 dB noise reduction (A-weighted) and up to 30 % reduction in rolling resistance compared to regular air-inflated tires such as the Michelin Energy Saver brand. The latter result is extremely valuable, and it was our experience that the crucial issue for lowering rolling resistance was the way to connect the spokes with the belt. It appeared obvious that there is a potential to improve it further by optimized design and choice of material. Vehicle handling and tire dynamics on a Volvo car were judged to be satisfactory by a Volvo professional test driver and a development manager of Nokian Tires. However, when the car was driven over a “pot-hole” test lane, the deflection of the CW tire/road contact patch exceeded the available space between the belt and a part of the sidewall (see the left part of Figure 2). This resulted in mechanical contact between the two and highly non-linear behavior, which created some minor cracks in a critical part of the structure; albeit not destructive. Had this space been designed a few mm greater, it is expected that driving on the pot-hole track would not have caused a problem. Attempts to get funds for a new project to correct the problem failed.

Tire Manufacturers’ Present Airless Tire Concepts or Prototypes

The tire manufacturers have not been sleeping since the Goodyear invention in 1982. Of course, most of the attempts have not been publicly presented, and those that have been presented have only been concepts or prototypes with no technical performance data released. Over the last 10 years it has been very popular to present such concepts at automotive shows, and a search on the web will show hundreds if not thousands of news reports. Those that seem to be somewhat more promising and interesting are the following:

Uptis (Unique Puncture-Proof Tire System), by Michelin North America. In 2019 it was announced that GM will try this airless tire on their Bolt electric car and that a market introduction may happen already in 2024; see Figure 4. This trial is ongoing at the time of writing, but no results have been revealed. However, Michelin claims (without data) that there will be advantages such as longer lifetime, less wear, while the rolling resistance target of Uptis is on par with a pneumatic ZP tire. The material of the spokes is said in unconfirmed blogs to be “composite rubber and proprietary innovative high-strength resin embedded fiberglass” while it seems that the treads are essentially similar to conventional rubber treads. It is claimed that part of the tire can be 3D-printed [7] (Figure 4).

Tweel (acronym for Tire-WHEEL), by Michelin, was presented already in 2005 at a motor show [8]; see Figure 5. Tweel consists of a composite reinforced tread band, connected to a flexible (deformable) wheel via rectangular, polyurethane spokes. The resulting mechanical structure provides weight-carrying ability, shock absorption, ride comfort, rolling resistance and mass similar to pneumatic tires while adding suspension-like characteristics that greatly improve handling [8]. However, this never made it to the road vehicle market, instead it is now used on industrial trucks and some other off-road vehicles. The author believes that the main problem with the Tweel is that the spokes generate severe noise, which may be the reasons why it is not implemented on road vehicles (Figure 5).

Vision (concept), by Michelin North America, was presented in 2017 as a visionary concept, claimed to be an “organic tire”. The materials used will be both bio-sourced and biodegradable to minimize the tire’s environmental footprint. It will also rely greatly on 3D-printing [7].

Bridgestone airless tire for trucks and bicycles (no name known) was presented in 2019 and is claimed to be presented for bicycles at the Tokyo Olympics. A version for trucks will be presented later. The design replaces the pressurized air in normal tires with a recycled thermoplastic ‘web’ that holds up to 2,270 kg (5,000 pounds) of tire load. Bridgestone presented earlier versions of airless tires in 2011 and 2014, which resemble the newest version. They were claimed to be made of renewable materials [9].

Goodyear Aero (concept), by Goodyear, is a futuristic concept airless tire intended to be used on future “flying cars”, as it can work both as an airless tire and as a propeller [10]. The concept’s spokes would provide support to carry the weight of the vehicle and also act as fan blades to provide lift when the tire is tilted. It may sound as a joke to some, but it is serious.

iFlex, by Hankook Tire in South Korea, is the 5th generation of airless concepts developed by Hankook (Figure 6). In 2015, an article based on a press release suggested that “Hankook’s airless car tires should hit the market very, very soon” [11]. However, this has not yet happened. Construction of the iFlex is said to be centered on a new type of uni-material designed to maximize the tire’s eco-friendly potential. Several tests (durability, hardness, stability, slalom (zigzag), and speed) have been done and results are positive according to the manufacturer, but no data have been released.

Barez Tires, in Iran, has started to manufacture airless tires due to the political sanctions imposed on Iran. Barez wrote in 2019 that 150 raw materials are needed to produce pneumatic tires, of which 45% are imported, and the latter has become a serious challenge due to the sanctions. Therefore, in 2019, three versions of airless tires had been produced [12]. A picture found on the web shows hundreds of such tires in a store, so this seems to be a serious approach for Iran under the circumstances, although there is no information indicating what the airless tires should be used for.

The tires presented above, of which only some have reached the prototype stage which has allowed technical testing, are not the only ones. Similar concepts have been suggested by at least Sumitomo and Kumho. Common to all seems to be that puncture-free operation is the most prominent feature, supplemented by the potential of using eco-friendly and renewable materials, as well as less complicated production. The airless tires suggested most recently seem to be aimed mostly at electric car usage and 3D-printing is indicated as a possibility.

At a roundtable discussion at the conference of the 2020 Tire Technology Expo, including representatives of Michelin, Goodyear and Continental plus two experts from the scientific community, the moderator asked the question whether airless tires will be the tires of the future. Despite all the concepts by the tire industries described above, the answers from Goodyear and Continental were skeptical while the other experts were more uncertain. It was only the Michelin expert who seemed to believe in this concept. He also held a presentation at the conference but did not reveal any technical data.

Pros and Cons of Airless Versus Pneumatic Tires

• The advantages and disadvantages with airless tires versus pneumatic tires for similar operation, of course depend on the construction, but in rather general terms the following is expected:

• The materials can be eco-friendlier and especially the need for rubber (both natural and synthetic) will be much less, as sidewalls of rubber will not be needed.

• The production can be much less complicated; potentially by means of 3D-printing.

• Pneumatic tires require grooves in the tread surface to transport water away from the contact patch to provide grip in wet conditions. Some airless tire designs can transport this water through the tread and do not require such complicated groove patterns. Wet grip will be improved.

• Given that no air container is needed, some airless tire designs allow more space on the inside of the tire, which potentially gives more space for brakes or even for electric motors.

• The air cavity in a pneumatic tire acts as a resonator, as well as acoustically corresponding to a “loudspeaker cabinet”, although in airless tires this is not an issue.

• Exterior noise emission and rolling resistance can be substantially reduced compared to pneumatic tires – at least for the CW version. The lower rolling resistance leads to less energy consumption of road vehicles, thereby less consumption of fossil fuels, or of electricity; the latter can be utilized as increased operating range.

• Rolling resistance of pneumatic tires increase when the tire is not enough inflated, but airless tires do not depend on any air pressure.

• Under- and over-inflation leads to tire irregular wear patterns that increase tire noise. These wear patterns do should not occur on airless tires.

• Durability at high speeds of airless tires is not yet proved to be sufficient. It may be necessary in the beginning to limit the maximum operating speed.

• Interior noise in road vehicles may become a challenge for airless tires, since they would be stiffer than flexible sidewalls of pneumatic tires; although the trend is that the sidewalls get lower and lower for modern high-performance tires. Further, it may be difficult to avoid the spokes generating audible noise.

• On the other hand, airless tires may give vehicle designers new tools to optimize steering and other handling performance.

• Vehicle designers would probably like airless tires since they may give the vehicle a “sporty” and/or futuristic look.

• On today’s road vehicles, new tires may be fitted 5-10 times during a vehicle’s lifetime, which obviously requires enormous volumes of raw material, even when implementing limited recycling. Airless tires made of more recyclable material and constructed to serve as long as the vehicle they sit on (apart from the rubber treads), will mean substantial global savings for material resources and thus give a more sustainable future.

The Future Prospects - The Author’s Vision

The author believes that the airless tires may be successfully implemented especially in the design of electric road vehicles. This is for three main reasons:

• Rolling resistance may become substantially lower, increasing the operating range of such vehicles; while also reducing global energy production needs for the transportation sector

• In at least the CW design, there is space for integrating electric motors and brakes on the inside of the tires (see Figure 1), which may be used for example to increase traction

• Noise emission from airless tires will be reduced; thus, making electric vehicles quieter also at higher speeds.

An international research consortium in Europe has recently suggested producing airless prototypes related to the CW design for trucks and buses (further details are confidential). If this will be a success, it may boost further development of airless tires to a final market introduction. However, before that, the Uptis tire may find a practical use on certain electric road vehicles. As suggested above, Bridgestone and Hankook may not want to be left behind, given the expanding electric vehicle production in Japan and South Korea. Therefore, the next 5-10 years will be very exciting for the tire and vehicle industries and all other stakeholders as well as engineers and researchers.

Even if airless tires will give very favorable performance, one may expect that market introduction will be delayed, for the same (and amplified) reasons as the radial tires introduction was delayed in North America due to restructuring of manufacturing plants combined with vehicles needing some redesign. When airless tires, apart from the treads, may last as long as the vehicle, the tire replacement market will die in favor of a heavily expanded retreading market. The normal lifetime of tire manufacturing plants lasts for decades, so everybody in the tire and vehicle industries will not be happy with too rapid developments. Consequently, and unfortunately, an anticipated airless tire revolution will likely take a long time.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- US Patent (1982) Non-pneumatic structurally resilient integrated wheel-tire. United States Patent 4,350,196, Sep 21, 1982.

- Su JH (1989) Design and analysis of a Composite Integral Wheel-Tire. Tire Science and Technology 17(2): 138-156.

- Hansson, Hans-Erik (1990) Design of a Composite Wheel. Proceedings of the International Tire/Road Noise Conference 8-10 August 1990 Gothenburg, Sweden. STU-information No. 794-1990, NUTEK, Stockholm, Sweden.

- Sandberg Ulf, Ejsmont Jerzy A (1990) Tire/Road Noise from an Experimental Composite Wheel. Proceedings of the International Tire/Road Noise Conference 8-10 August 1990 Gothenburg, Sweden. STU-information No. 794-1990, NUTEK, Stockholm, Sweden.

- Sandberg Ulf, Ejsmont Jerzy A (2002) Tyre/Road Noise Reference Book. Informex HB, Kisa, Sweden.

- Sandberg Ulf (2009) The Composite Wheel - An innovation featuring low tire/road noise and low rolling resistance simultaneously. 38th International Congress and Exposition on Noise Control Engineering, Ottawa, Canada, pp. 423-434.

- Michelin (2019) Michelin, GM take the air out of tires for passenger vehicles. Michelin Press Information.

- Michelin (2005) Tweel/Audi8488. Press release from Michelin North America.

- DailyMail (2020) Bridgestone unveils airless tires that can hold up to 5,000 pounds and never loses pressure - but will only be used on commercial trucks and bicycles.

- Goodyear (2019) The Goodyear AERO - A Concept Tire for Autonomous, Flying Cars.

- Medlock Katie (2015) Hankook’s airless car tires should hit the market very, very soon.

- Parviz Akhavan (2020) Iran joins the Airless Tire production countries.

-

Ulf Sandberg. The Airless Tire: Will this Revolutionary Concept be the Tire of the Future?. Mod Concept Material Sci. 3(3): 2020. MCMS. MS.ID.000563.

-

Airless tire, Prototypes, Materials, Composite wheel, 3D-printing, Manufacturers, Rolling resistance, Design, Emission

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

- Abstract

- The Pneumatic Tire, A Most Sophisticated Product

- The Airless Tire - First Trials

- Later Trials with the Composite Wheel

- Tire Manufacturers’ Present Airless Tire Concepts or Prototypes

- Pros and Cons of Airless Versus Pneumatic Tires

- The Future Prospects - The Author’s Vision

- Acknowledgements

- Conflict of Interest

- References