Mini Review

Mini Review

Interaction of Mobile Dislocation with Additives in Ionic Crystals

Yohichi Kohzuki*

Science of Advanced Materials, Central Michigan University, Mt. Pleasant, MI 48859-0001, USA

Department of Mechanical Engineering, Saitama Institute of Technology, 1690 Fusaiji, Fukaya, Saitama 369-0293, Japan.

Received Date: September 26, 2021; Published Date: October 04, 2021

Abstract

The mechanical properties of materials are affected by the interaction of mobile dislocation with additive ions. Although this has been widely investigated by various methods (yield and proof stress measurements, microscopy observations of dislocation, internal friction measurements, stress relaxation tests and so on), it is difficult to obtain the information on mobile dislocation-additives interaction during plastic deformation of bulk. While, the strain-rate cycling tests between two strain-rates of 1.1×10−5 s−1 and 5.5×10−5 s−1 with ultrasonic oscillations (original method) would overcome the weak points of them. The original method is considered to give the information of dislocation mobility on the slip plane contained mainly with two kinds of obstacles: forest dislocations and additive ions. Some results will be presented here.

Keywords: Dislocation; Point defects; Plastic deformation; Ultrasonic oscillation; Strain rates

Strain-Rate Cycling Tests Combined with Ultrasonic Oscillations

Study on the strength of materials has been often conducted

with simple ionic crystals so far [1-3]. The reason is that the crystals

are readily available and have a slight number of glide systems,

comparing with metals. On account of it, the crystals contained

additives are excellent, when the mechanical properties of materials

are investigated. It is well known that the solution hardening due

to the additives are caused by the result that mobile dislocations

are obstructed by the point defects around them in the crystal at

low temperature. The plasticity of crystal varies with dislocation

motions in a microscopic observation and the dislocation-additive

ions interaction affects the hardening. Dislocation motion on

a slip plane has been extensively studied by many different

methods: measurements of yield and proof stress (e.g., [4-8]),

micro-hardness tests (e.g., [9,10]), microscopy observations (e.g.,

[11,12]), measurements of internal friction (e.g., [13,14]), or stress

relaxation (e.g., [15,16]), but it is difficult to obtain the results on

the movement of the dislocation which glides forward breakingaway

from the forest dislocations and the point defects such as

additives on the slip plane in bulk. On the other hand, the original

strain-rate cycling test combined with ultrasonic oscillations is

different from the well-known methods. The original tests would

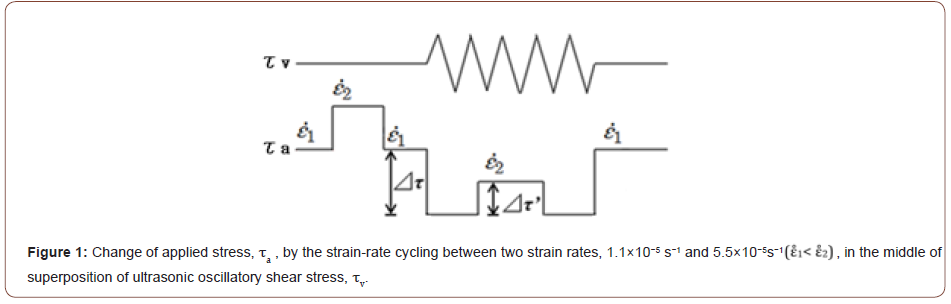

be possible to clear up it. Figure 1 shows the illustration of the

original tests. The results on the movement of dislocation breakingaway

from impediments such as the additives [17,18] and also the

defects due to X-ray irradiation [19,20] with the oscillatory stress

has been reported by the strain-rate cycling tests combined with

ultrasonic oscillations. Applying ultrasonic oscillatory stress to

a plastic deforming crystal, a stress decreases and Δτ appears as

illustrated in Figure 1. When the strain-rate cycling between the

strain rates was conducted keeping the stress amplitude constant,

τv, the stress change due to the strain-rate cycling is Δτ’. The Δτ’/

has been made an estimate as the strain-rate sensitivity of

flow stress, which is termed λ here.

has been made an estimate as the strain-rate sensitivity of

flow stress, which is termed λ here.

Relation of Strain-Rate Sensitivity to Stress Decrement

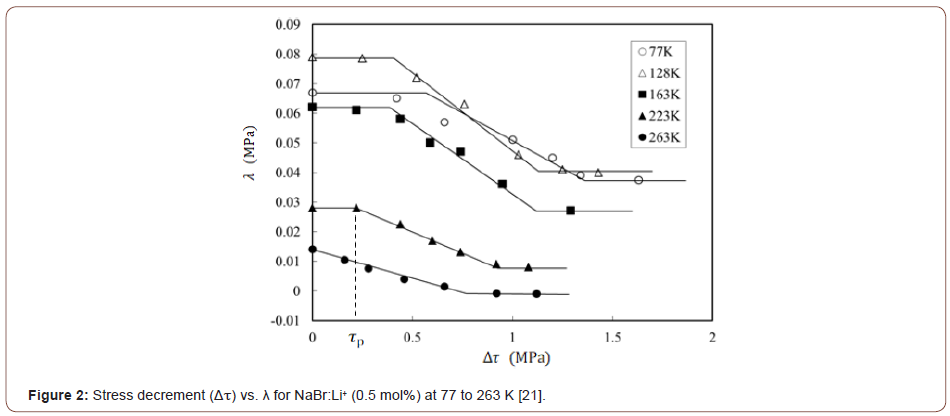

Δτ vs. λ curve looks like a flight of stairs, which has two bending points and two plateau places. Figure 2 shows the Δτ vs. λ curve at 77 to 263 K for NaBr:Li+ (0.5 mol%) [21]. The value of Δτ at first bending point (τp denoted in Figure 2) refers to the additive ions in the crystals, since first bending point does not exist on the Δτ vs. λ curves for nominally pure NaBr crystal within the same low temperatures and strains [21]. The value of τp tends to be lower at the higher temperature and disappears near atmospheric temperature such as 263 K, as shown in Figure 2. τp depends on temperature, also the density and the type of impediments such as point defects [22,23].

The Δτ vs. λ aspect is considered to represent the oscillation effect on the free flight motion of the dislocation on a slip plane during plastic deformation [18]. Additive ions and a few forest dislocations are regarded as main impedimenta to the slip motion of dislocation here. Applying oscillation with high stress amplitude to the crystal, the λ value begins to decrease with increasing Δτ. Some point defects stop acting as obstacles in the region at Δτ beyond τp. Second plateau place appears on Δτ vs. λ curve by the oscillation with still higher stress amplitude. At this place, only forest dislocations are expected to act as obstacles to the dislocation slip. Furthermore, the activation energy for the break-away of a dislocation from additive ion has been obtained by analyzing the data on the basis of Δτ vs. λ curve [21].

Conclusion

The original strain-rate cycling tests combined with ultrasonic oscillations clear up the weak point of many different methods. The aspect of the Δτ vs. λ curve obtained from the original method is considered to represent the movement of the dislocation which glides forward breaking-away from the forest dislocations and additive ions on the slip plane in ionic crystal.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Kataoka T, Ohji H, Kishida K, Azuma K, Yamada T (1990) Direct Observation of Glide Dislocations in a KCl Crystal by the Light Scattering Method. Appl Phys Lett 56(14): 1317-1319.

- Sprackling MT (1976) The Plastic Deformation of Simple Ionic Crystals. Academic Press, London.

- Zakrevskii VA, Shul’diner AV (2000) Dislocation Interaction with Radiation Defects in Alkali-Halide Crystals. Physics of the Solid State 42(2): 270-273.

- Boyarskaya YS, Zhitaru RP, Palistrant NA (1990) The anomalous behaviour of the doped NaCl crystals compressed at low temperatures. Crystal Research and Technology 25(12): 1469-1473.

- Okazaki K (1996) Solid-solution hardening and softening in binary iron alloys. Journal of Materials Science 31: 1087-1099.

- Tabachnikova ED, Podolskiy AV, Smirnov SN, Psaruk IA, Liao PK (2014) Temperature dependent mechanical properties and thermal activation plasticity of nanocrystalline and coarse grained Ni-18.75 at. % Fe alloy. IOP Conference Series: Materials Science and Engineering 63(1): 012105.

- Pratt PL, Harrison RP, Newey CWA (1964) Dislocation mobility in ionic crystals. Discussions of the Faraday Society 38: 211-217.

- Newey CWA, Harrison RP, Pratt PL (1966) Precipitation hardening and dislocation locking in doped NaCl. Proceedings of the British Ceramic Society 6: 305-316.

- Buravleva MG, Rozenberg GK, Soifer LM, Chaikovskii EF (1980) Changes in the flow stress of LiF:Mg2+ and LiF:Co2+ crystals during precipitation of solid solutions. Soviet Physics. Solid State 22: 150-152.

- Narasimha Reddy K, Subba Rao UV (1984) Influence of gadolinium impurity on microhardness of host alkali halide crystal. Crystal Research and Technology 19(7): K73-K76.

- Kataoka T, Ohji H, Kishida K, Azuma K, Yamada T (1990) Direct observation of glide dislocations in a KCl crystal by the light scattering method. Applied Physics Letters 56(14): 1317-1319.

- Messerschmidt U (2010) Dislocation Dynamics During Plastic Deformation. Berlin Heidelberg: Springer.

- Kosugi T (2001) Temperature dependence of amplitudedependent internal friction due to simultaneous breakaway of a dislocation from several pinning points. Materials Science and Engineering A 309-310: 203-206.

- Gremaud G (2001) Dislocation-point defect interactions. Materials Science Forum 366-368: 178-246.

- Dotsenko VI (1979) Stress relaxation in crystals. Physica Status Solidi (b) 93(1): 11-43.

- Urusovskaya AA, Petchenko AM, Mozgovoi VI (1991) The influence of strain rate on stress relaxation. Physica Status Solidi (a) 125(1): 155-160.

- Kohzuki Y (2009) Study on the interaction between a dislocation and impurities in KCl:Sr2+ single crystals by the Blaha effect-Part IV influence of heat treatment on dislocation density. Journal of Materials Science 44: 379-384.

- Kohzuki Y (2010) Bending angle of dislocation pinned by an obstacle and the Friedel relation. Philosophical Magazine 90(16): 2273-2287.

- Ohgaku T, Migiuma S, Nagahira D (2011) Interaction between dislocation and defects induced by X-irradiation in alkali halide crystals. Radiation Measurements 46: 1385-1388.

- Kohzuki Y, Ohgaku T (2017) X-ray-induced defects as obstacles to dislocation motion in alkali halide crystals. Journal of Materials Science 52(7): 3959–3966.

- Kohzuki Y, Ohgaku T (2017) Study on influence of additive and host ions on deformation characteristics of alkali halide crystals by strainrate cycling tests during the Blaha effect. Crystal Research and Technology 52(3): 1600290.

- Ohgaku T, Teraji H (2001) Investigation of interaction between a dislocation and a Br− ion in NaCl:Br− single crystals. Physica Status Solidi (a) 187(2): 407-413.

- Ohgaku T, Matsunaga T (2009) Interaction between dislocation and divalent impurity in KBr single crystals. IOP Conference Series: Materials Science and Engineering 3: 012021.

-

Yohichi Kohzuki. Interaction of Mobile Dislocation with Additives in Ionic Crystals. Mod Concept Material Sci. 4(4): 2021. MCMS. MS.ID.000588. DOI: 10.33552/MCMS.2021.04.000588.

-

Dislocation, Point defects, Plastic deformation, Ultrasonic oscillation, Strain rates, Crystals, Additive ions, Materials, Stress, Sensitivity, Slip, Temperature

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.