Short Communication

Short Communication

Structured Ways to Improve the Design of Mechanical Product Such as Drawer Based on Life-Stress and Sample Size

Seongwoo Woo1*, Dennis L O’Neal2, Yimer Mohammed Hassen1 and Gezae Mebrahtu1

1Manufacturing Technology, Mechanical Technology, Ethiopian Technical University, Ethiopia

2Engineering and Computer Science, Baylor University, USA

Seongwoo Woo, Manufacturing Technology, Mechanical Technology, Ethiopian Technical University, Addis Ababa, Ethiopia.

Received Date:July 05, 2023; Published Date:July 26, 2023

Abstract

To make better the lifetime of system, parametric Accelerated Life Testing (ALT) as structured method presents to judge the mechanical life exerted by repetitive food loads, entrenched on life–stress type and sample size formation. This method enables a designer to find the system flaws that make a crucial effect on reliability. Finally, companies can prevent recalls from the marketplace. As an example, the refrigerator drawer was investigated.

Keywords:Mechanical product; Refrigerator drawer; Parametric ALT; Fatigue; Design flaws

Introduction

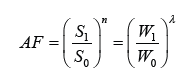

The mechanical system transmits power to attain a function which requires forces & displacement and makes mechanical advantages by adopting mechanisms. Employing the vapor-compression refrigeration cycle, a refrigerator furnishes cooled air from the heat exchanger such as evaporator to the freezer and refrigerator section. Especially, a refrigerator drawer stores food freshly. It comprises the box, two rails, and the support. The drawer could be devised to support the operating situations exerted by the end-user. If there are design flaws where the food loads are applied, drawer will immediately terminate in its lifetime. After finding the defects, an engineer could design in the most favourable way [1]. Parametric ALT consists of: (1) an ALT plan, (2) load scrutiny, (3) a taylored ALTs with the alternations, and (4) a calculation of whether the product achieves the BX life. As a sample study, the new drawer in a refrigerator will be examined.

Parametric ALT in Mechanical System

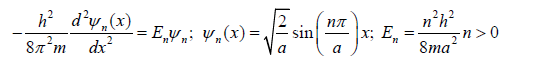

The solution of Schrodinger’s governing formulation can be defined:

Linear transport is defined:

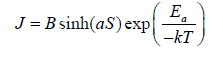

For example, solid-state diffusion for silicon, J, can be defined as:

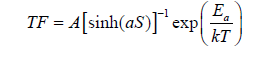

If Equation (3) takes the reverse, the life-stress (LS) expression could be defined as:

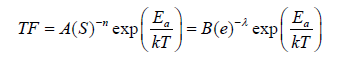

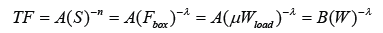

The [sinh(aS)]−1 term for Equation (4) has attributes: 1) (S)−1 in the start has somewhat linear influence, 2) (S)−n is established as a central influence, and 3) (eaS )−1 in the termination is tall. In the middle span, as an ALT is usually performed, because the stress come from effort, Equation (4) can be defined as:

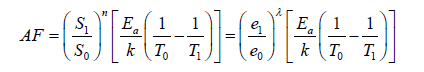

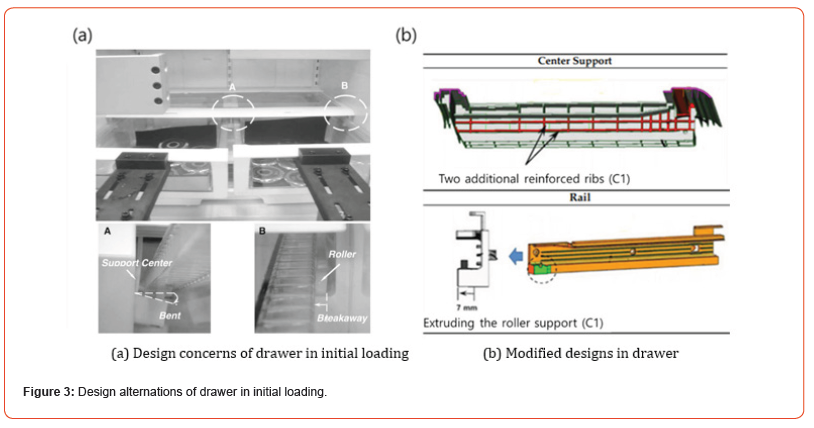

To fulfil the acceleration factor (AF), defined as the quantitative relation between the raised stress and normal stress situations, it might be changed to unite with the concept:

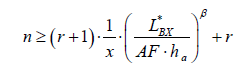

To achieve the assigned cycle for an ALT, sample size expression with Equation (6) could be expressed as [2]:

Case Investigation: Increasing the Fatigue Lifetime of a Refrigerator Drawer

Customer employs the refrigerator to stock food freshly for some period. To satisfy this motivation, the drawer in the refrigerator is devised. Stocking food in a domestic refrigerator involves: (1) the refrigerator drawer is open, (2) stored food is placed in it, and (3) drawer is closed. The drawer thus should be devised to secure the operating circumstances applied to it by the end-user (Figure 1).

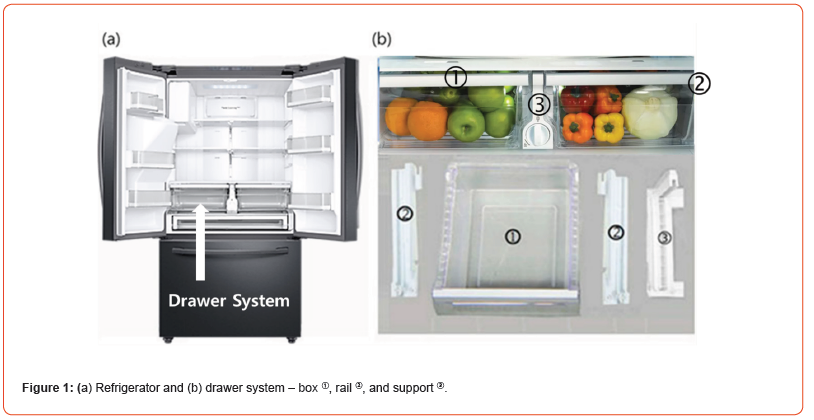

From the marketplace, as repetitively opening/closing with loading are applied, drawer returned from the field had been failing due to design defects, causing customers to ask for replacement. To properly function the drawer system for expected lifetime, stress raiser such as sharp corner, etc. in drawer assembly should be found and modified by parametric ALT (Figure 2).

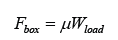

From the free-body diagram (Figure 2b), the applied load on the refrigerator drawer originated from the food weight. That is,

Because the drawer stress relies on the food loading, Equation (5) might be defined:

Thus, based on Equation (6), the AF can be formulated:

For the refrigerator drawer, the working (or environmental) circumstances are 0-43 ℃ with 0.2-0.24 g’s acceleration, and a humidity spanning from 0 to 95%. The operating cycles of drawers a day were from five to ten cycles. Based on the design of a system life for ten years, the drawer system was exerted to 36,500 usage cycles. For the most severe situation, the maximum force subjected to the end-user in stocking food, W1, was 0.059 kN (6 kgf). For ALT, the applied force, W2, took double to 0.117 kN (12 kgf). With an accumulative exponent, λ, of 2, AF from Equation (10) was 4.0. To keep the life target – B1 life for ten years, if the shape parameter was supposed to be 2.0, the assigned cycles for six samples calculated in Equation (7) were 37,000 cycles. The problematic designs of drawers thus can be modified after recognizing them.

Results and Conclusions

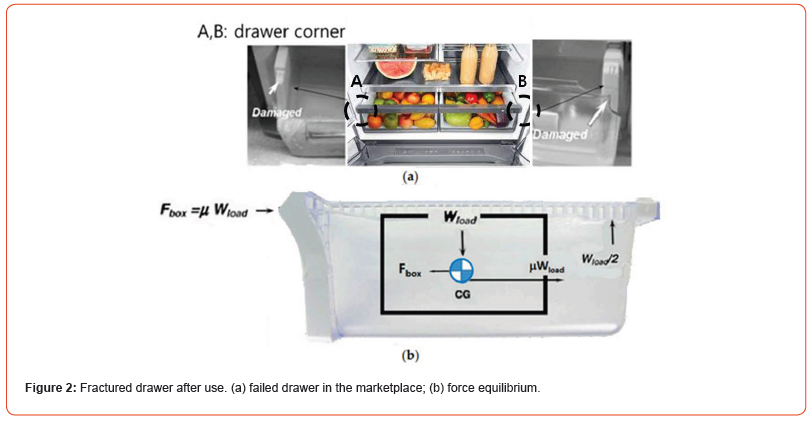

Initially, as 1.17 kN (12 kgf), the raised food load, was applied in drawer, the rollers in the left/right rail were left away and the support rail was disfigured. As a result, the drawer system did not slide. The draw design thus was changed by expanding the roller support to 7 mm (C2) in the guide rail, and in addition attaching enforced ribs in the rail of center support (C1) (Figure 3).

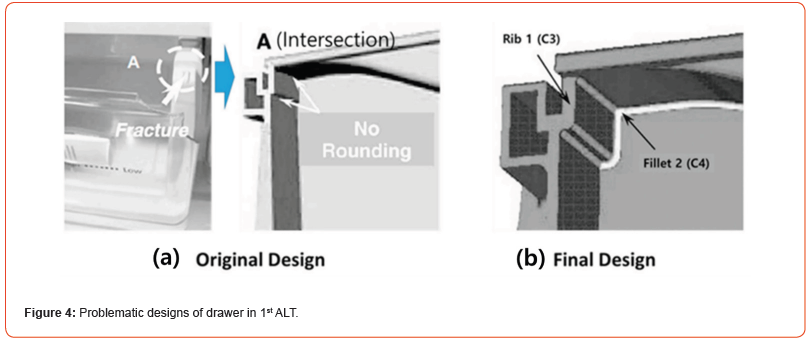

In 1st ALT, drawer failed at 3800 cycles and 4800 cycles. As cautiously looking at the fractured drawer systems from the first ALT and the marketplace, failure sites were found uncovered in the joints of the drawer cover and its hull. Due to stress raisers such as no corners in the intersection regions (A), the drawers can have been failing the drawer cover. These designs were modified by: (1) enlarging enforced ribs thick, Rib1, C3, from T2.0 mm to T3.0 mm; (2) attaching the fillets, Fillet1, C4, from R0.0 mm to R1.0 mm (Figure 4).

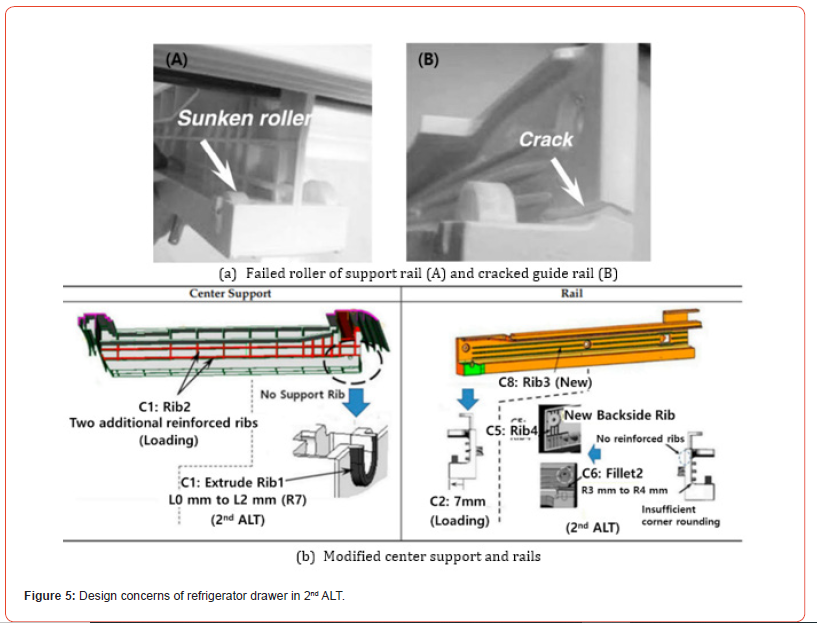

In the 2nd ALT, the roller was sunken and guide rail in center support was cracked at 6000 cycles. As cautiously checking the failure sites, the drawer guide rail in the structure had no enforced rib and not sufficient corner rounding to hold out against the loading. To enhance the lifetime of the guide rail, it was changed by (1) fastening reinforced ribs, C5; (2) expanding the rounding, C6, from R3 mm to R4 mm. The drawer center support in the structure was modified by (1) enlarging the roller rib, C7, from L0.0mm to L2.0mm (Figure 5).

With the design alternations, the refrigerator drawer might properly function to achieve the life objective – B1 life 10.0 years – because there were no complications until 19,000 assigned mission cycles.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Woo S, O’Neal D, Pecht M (2023) Improving the lifetime of mechanical systems during transit established on quantum/transport life-stress prototype and sample size. Mechanical Systems and Signal Processing 193: 110222.

- Woo S, Pecht M, O’Neal D (2020) Reliability design and case study of the domestic compressor subjected to repetitive internal stresses. Reliability Engineering and System Safety 193: 106604.

-

Seongwoo Woo*, Dennis L O’Neal, Yimer Mohammed Hassen and Gezae Mebrahtu. Structured Ways to Improve the Design of Mechanical Product Such as Drawer Based on Life-Stress and Sample Size. Mod Concept Material Sci. 5(2): 2023. MCMS. MS.ID.000610.

-

Mechanical product, Refrigerator drawer, Parametric ALT, Fatigue, Design flaws, Sample size, Life-stress, Reliability, Lifetime, Structure, Center support, Enforced rib, Design alternations

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.