Research article

Research article

Mechanical Study of the Valorisation of Concrete Waste from Construction Waste in Bituminous Concrete

Lassaâd Ajam2,3 Noredine Abriak4* and Mohamed Belgaied1

1Higher Institute of Technological Studies of Rades, Tunis

2National School of Engineers of Tunis, Civil Engineering Laboratory (LGC), Tunis

3Higher Institute of Environment, Urban Planning and Building Technologies, Tunis

4University Professor, Mines Telecom North Europe Institute, France

Noredine Abriak, University Professor, Mines Telecom North Europe Institute, France.

Received Date:February 06, 2023; Published Date:March 07, 2023

Abstract

Given the increase in construction waste in Tunisia and the lack of waste management, the economic and environmental impact is very strongly felt inducing huge problems [1]. This work presents the first results of the valorisation of the concrete waste in bituminous concrete BC 0/14. This study with aggregates of Djebel El Oust allowed the analysis of the effects of the partial substitution of quarry aggregates by concrete waste from the recycling of construction wastes on Marshall Compactness and stability related to the classic formula used in CETEC. The results of the study, namely Duriez and Marshall have led to an experimental formulation of a bituminous concrete Meeting the necessary requirements with a slight improvement in the water holding r/R (≥ 0,89), of stability (≥ 5,3 kN), of creep (≤ 4mm) and the Marshall quotient (≥ 1,47).

Keywords:Bituminous concrete; Concrete waste; Resistance; Stability marshall; Compactness; Water holding

Literature Review

In the Face of continuous growth in construction waste In Tunisia and mainly with the important expansion of the urban regions, notably the greater Tunis, Sousse and Sfax, it becomes necessary to find solutions to put a fraction of the waste into use and solve a part of this problem.

To study bituminous mixtures, there are no Specific methods for the formulation of a mixture of aggregates, filler and bitumen, experimentation is the only Possibility to achieve this and the tests carried out (Measurement of crushing resistance, water holding, compactness, percentage of vacuum, stability and creep) must check certain characteristics for bituminous concrete BC 0/14.

This research involves studying the influence of concrete waste from the recycling of construction waste on the properties of bituminous concrete BC 0/14 carried out in accordance with the formulation adopted by the CETEC in Tunisia. The study was conducted by defining in the first place the characteristics of the natural aggregates of Djebel El Oust quarry and the recycled aggregates from the concrete waste. A formulation of a reference BC 0/14 Mixture was made with aggregates from the Djebel El Oust quarry (42% Sand 0/4, 28% gravel 4/8 and 30% gravel 8/14). A second carried out with proportions of aggregates from the Djebel El Oust quarry and concrete waste from the recycling of construction waste. (Optimum Composition: 48% Sand 0/4, 17% gravel 3/9 (Concrete waste) and 35% gravel 8/14).

A mechanical and identification tests were carried out on the formulated bituminous concretes and validated the idea of upgrading recycled aggregates from concrete waste in bituminous concrete. A Study [2] demonstrates the beneficial effect incorporating concrete waste on its fatigue cracking.

The valuation of waste from concrete has been the subject of several Studies [3-5]. Their use in the development of new concrete has proved possible. Laboratory tests and experimental sites have proved this.

In Chaponost for example, the construction of an 18 cm thick paving for a parking lot of 2,100 m2 for light vehicles tested several types of concrete manufactured with different levels of recycled aggregates (from 0 to 100%). Apart from the use of recycled concrete, the usual site practices have not been altered and no pathology has been found [6].

Characterization of the Materials Used

The aggregates

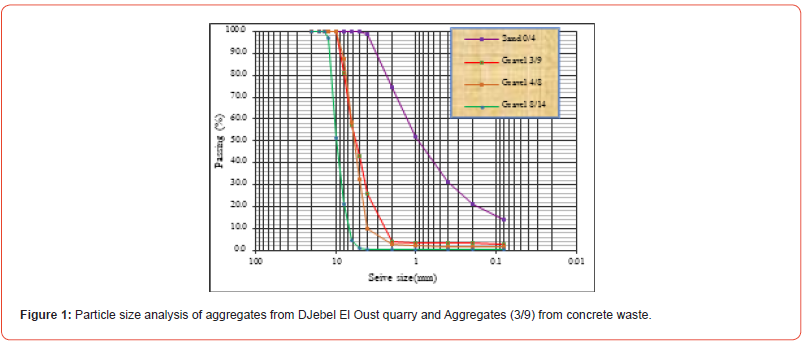

The aggregates used in this study are from the quarry of Djebel El Oust and concrete waste (Gravel 3/9) Figure 1 shows the curves of Particle size analysis [7] of the four fractions Sand 0/4, Gravel 4/8, Gravel 3/9 (Concrete waste) and gravel 8/14.

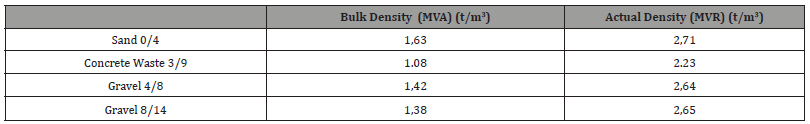

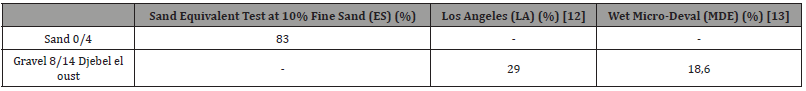

The Actual and apparent density of aggregates [8,9] and resistance to fragmentation [10], wear and polish [11], are shown in the tables below (Table 1&2).

The aggregates used must comply with the following specification: LA ≤ 25, MDE ≤ 20, PS ≥ 60.

Table 1:Aggregate characteristics.

Table 2:Aggregate characteristics.

The values found by the sand equivalent test and Micro-Deval test meet the values required for the bituminous concretes on the other hand the value LA % is approaching but still insufficient.

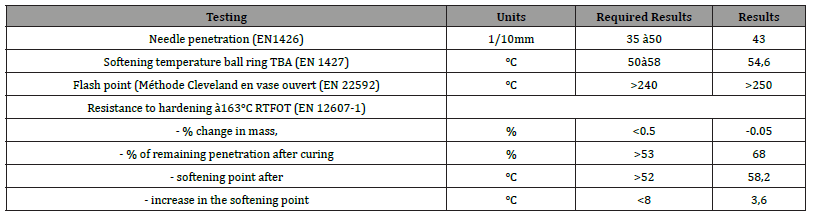

Bitumen

Bitumen is a hydrocarbon binder which is used to bind the aggregates to each other by developing in the mixture of cohesion forces ensuring rigidity, resistance to tensile deformation resistance to compression and shear strength [12]. The bitumen used in our study is a 35/50 grade bitumen, whose Characteristics are summarized in Table 3.

Table 3:Characterization of bitumen 35/50 used.

Study of the Formulation

The formulation of the BC 0/14 is based on particle size analysis of aggregates. This method is adopted by the CETEC to determine the formulations throughout the Tunisian territory.

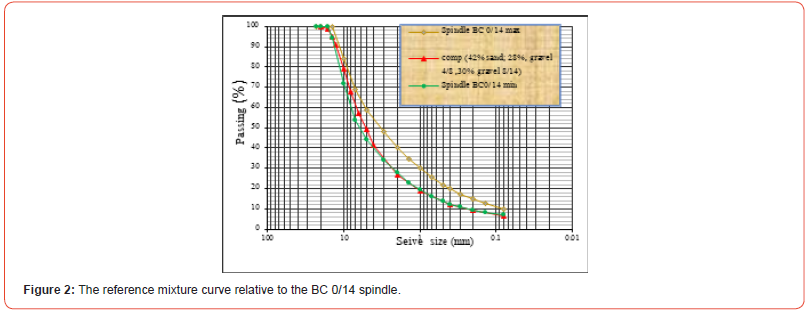

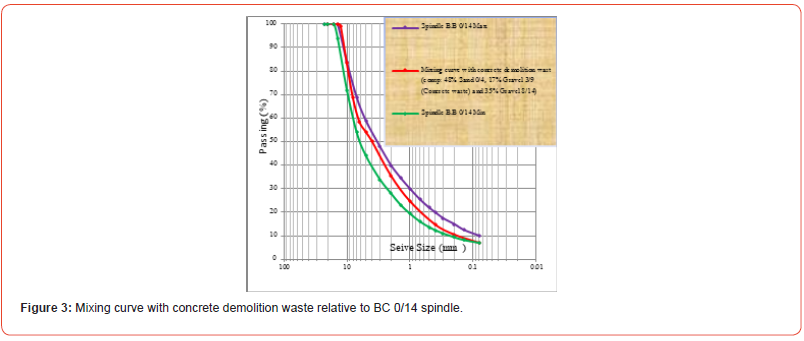

The Figures 2 and 3 respectively present the Curves of analysis Sizes obtained with a composition of 42% Sand 0/4, 28% Gravel 4/8 and 30% Gravel 8/14 (Reference mix from the DJebel El Oust Quarry). The curve obtained with a composition of 48% Sand 0/4, 17% Gravel 3/9 (Concrete waste) and 35% Gravel 8/14 (Mix made with aggregates from the DJebel Oust quarry and concrete demolition waste). The mixtures of the two formulations as well determined integrate into the BC 0/14 Optimum.

Results and Interpretations

Measuring crushing resistance and the holding at water of the test specimens (Duriez)

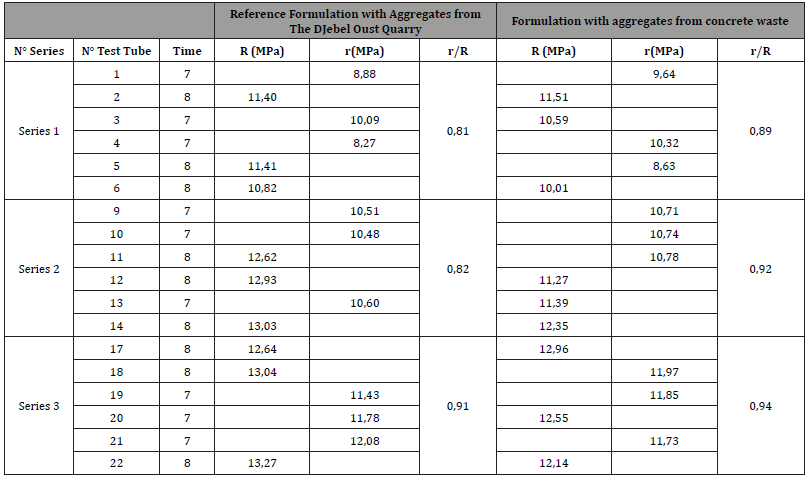

Table 4:Evaluation of R, r and water resistance r/R.

The resistance of the test specimens to the crushing Duriez and the outfits at the water [13] for the two formulations quoted above with three different contents of binders: 4.7%, 5% and 5.3% are shown in Table 4.

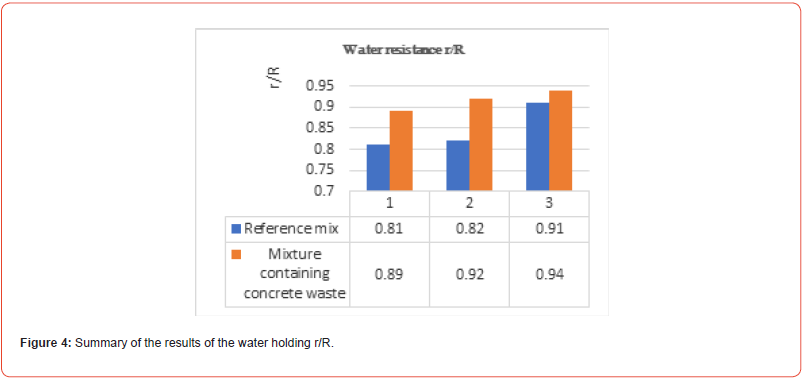

It is well noted that the r/R ratio, for the 3 series, exceeds 0.75, and the R resistance value is greater than 7MPa, which corresponds to the minimum value required for a BC 0/14 so the results are considered acceptable and both formulations are reliable with regard to the holding in the water.

Measurement of the compactness and the percentage of vacuum

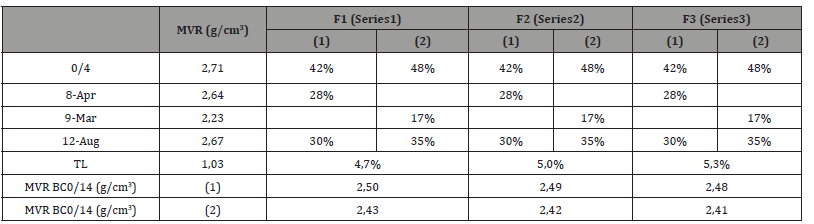

Two additional test specimens for every series are retained for the determination of the percentage of vacuum and the compactness.

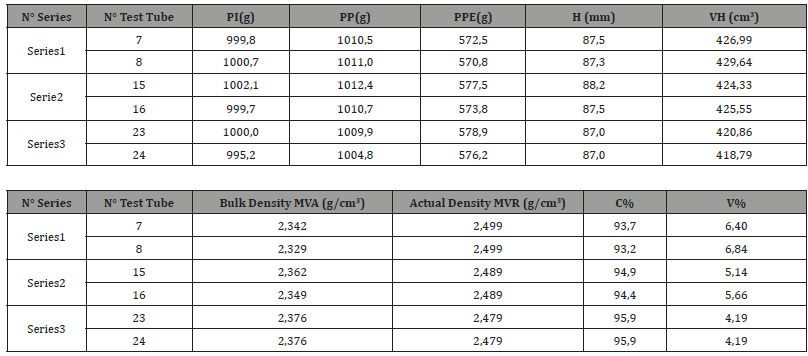

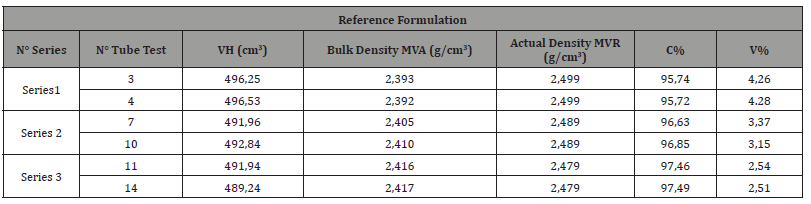

The compactness and the percentage of vacuum are determined from the measurements of the actual density MVR and the apparent density MVA of the test specimens. The measures are represented on Tables 5, 6 and 7.

Table 5:Determination of the actual density of the test specimens.

(i) Reference formulation with aggregates from Djebel Oust quarry. (ii) Formulation with aggregates from concrete waste.

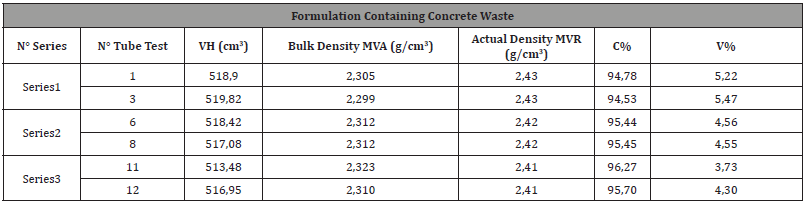

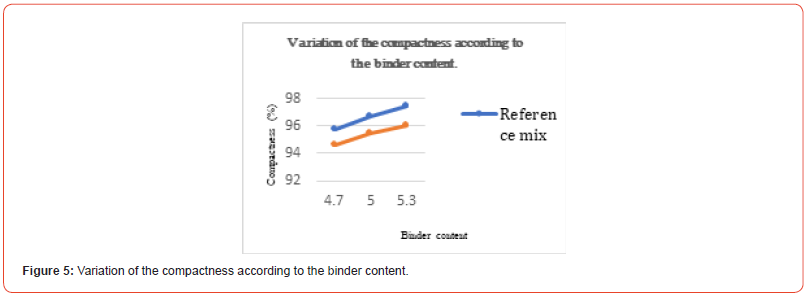

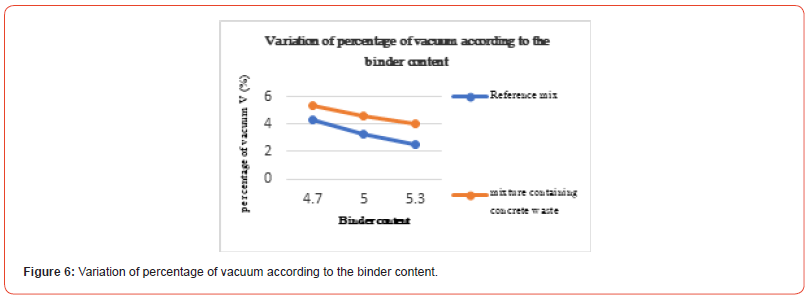

The Compactness and the percentage of vacuum in both formulations BC 0/14 reference and the one containing concrete waste according to the binder content introduced in each series are shown in tables 6 and 8 (Table 6).

Table 6:Compactness and et percentage of vacuum “Reference formulation”.

The aggregates used must comply with the requirement

specifications for BC 0/14:

• Compactness: 92% ≤ C% ≤ 97%

• Percentage of vacuum: 3% ≤ V% ≤ 8%

It is noted that he compactness and the percentage of vacuum for the case of the three series meet the required values for bituminous concrete BC 0/14 (Table 7).

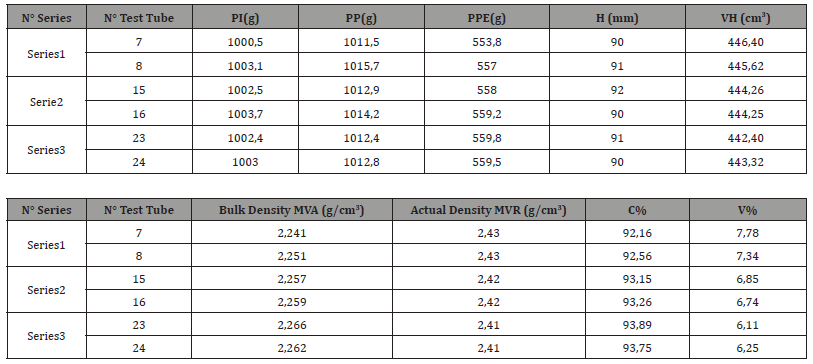

Table 7:Compactness and Percentage of vacuum “Formulation containing concrete waste”.

The formulation containing concrete waste respects the

specifications relating to BC 0/14 for the three series:

• Compactness: 92% ≤ C% ≤ 97%

• Percentage of vacuum: 3% ≤ V% ≤ 8%

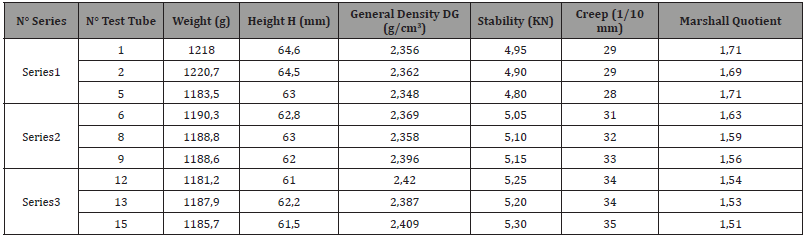

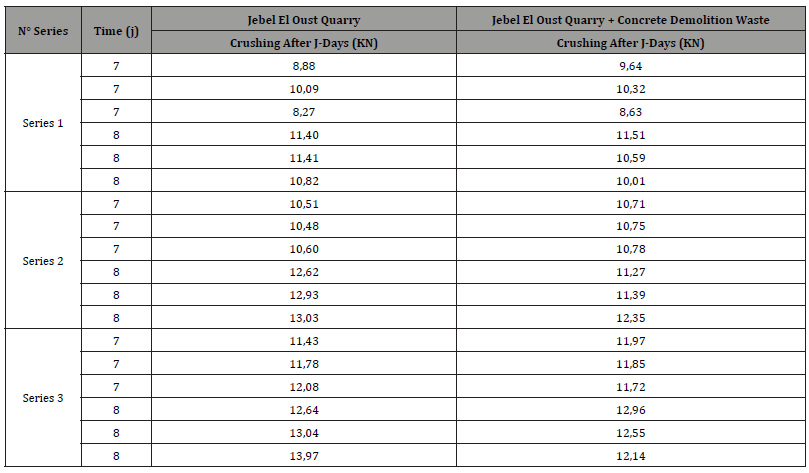

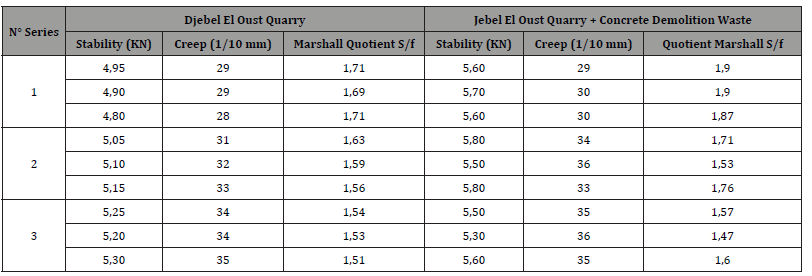

Marshall test (Standard NF P 98-251-2)

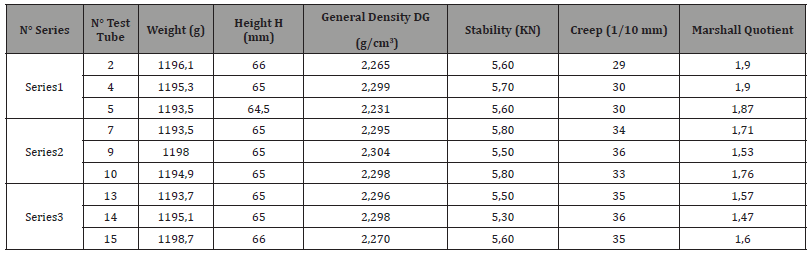

The Marshall test [14] allowed to measure stability, creep and Marshall quotient made on both formulations, reference, table 8 and that containing concrete waste, table 9. The Results are divided into 3 series according to the Binding content (4.7%; 5% and 5.3%).

The specifications for BC 0/14 are:

Stability: S ≥ 10.5 KN

Creep: f ≤ 4 mm

Marshall Quotient: 2, 5 ≤ S/f ≤ 4, 5

Measurement of the compactness and the percentage of vacuum of the Marshal Test

The tests performed (Marshal, Duriez), shows good behavior of the materials for both formulations (Jebel El Oust aggregates and concrete waste). They are conform to the standard that sets the specifications for Concrete Bituminous BC 0/14 (Table 10&11).

Table 8:Measurement of the Stability and Marshall creep. (Reference formulation).

Table 9:Measurement of the Stability and Marshall creep (Formulation containing concrete waste).

Table 10:Determination of the compactness and percentage of the vacuum of the Marshall test specimens.

Table 11:Determination of the compactness and Percentage of vacuum in Marshall test specimens.

Table 12:Summary table of the crush resistance Duriez.

The aggregates used must comply with the specifications

relating to BC 0/14:

• Compactness: 92% ≤ C% ≤ 97%

• Percentage of vacuum: 3% ≤ V% ≤ 8%

Comparative Study of the Two Formulations and Interpretations

The Crush Resistance R of test specimens containing the aggregates of the waste of concrete is greater than 7MPa and Shows a Comparable behavior to those made with quarry aggregates (Table 12).

The Results of the r/R water holding for both formulations is presented on Figure 4. A slight improvement of the r/R report and exceeding 0.75 is found for test specimens containing aggregates from demolition wastes.

A Slight improvement “Also Stability [15,16] of the creep and the Marshall quotient” is found for the formulation using concrete demolition waste (Table 13).

Table 13:Summary table of stability and creep results.

Based on the Results shown in table 14 and figures 5 and 6, we note that the compactness and the percentage of vacuum in the two compositions meet the specifications for BC 0/14. The regression of compactness (increase in percentages of vacuum) of Marshall test Specimens for the mixture containing concrete waste could be explained by the form of aggregates of waste (3/9) after crushing which are presented in the form of platelets.

Conclusions and Perspectives

Waste recovery is becoming increasingly important for several developed countries in view of the economic, environmental and technical interests and benefits it presents. In particular the building and demolition wastes have a significant impact on the environment, reaching aesthetic and image of the city.

This research Processes the study of a new formulation of bituminous concrete with concrete waste that aims to highlight the impact of this incorporation of point of view, resistance, creep and compactness.

A comprehensive approach to comparing the characteristics obtained between bituminous mixtures shows that concrete aggregate formulations from demolition waste have good characteristics, some of which are better than the reference bituminous mixture as the result of the remarkable increase in r/R ratio and stability.

The current research requires further testing to see the rheological behaviour, the resistance to permanent strains in order to avoid the risk of high-temperature service rutting (LPC rutting test), resistance to a low temperature cracking and fatigue test to predict pavement durability.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Oyeshola Femi, Kofoworola, Shabbir H Gheewala (2009) Estimation of construction waste generation and management in Thailand. Waste Manag 29(2): 731-738.

- AR Pasandín, I Pérez (2017) Fatigue performance of bituminous mixtures made with recycled concrete aggregates and waste tire rubber. Construction and Building Materials 157: 26-33.

- Shahidan S, Azmi MAM, Kupusamy K, Zuki SSM, Ali N (2017) Utilizing Construction and Demolition (C&D) Waste as Recycled Aggregates (RA) in Concrete. Procedia Engineering 174: 1028-1035.

- Puthussery JV, Kumar R, Garg A (2017) Evaluation of recycled concrete aggregates for their suitability in construction activities: An experimental study. Waste Management 60: 270-276.

- Yang S, Lee H (2017) Mechanical properties of recycled aggregate concrete proportioned with modified equivalent mortar volume method for paving applications. Construction and Building Materials 136: 9-17.

- P Collet Actu Environnement [Online] Available: https://www.actuenvironnement.com/ae/news/recybeton-recycler-beton-normes-granulats-deconstruction-elasticite-retrait-24806.

- (1996) AFNOR - Particle size analysis by sieving. Standard (NF EN 933–1 and NF EN 933-2).

- (2014) AFNOR - Tests to determine the mechanical and physical characteristics of aggregates - Part 6: determination of the true density and the water absorption coefficient. Standard (NF EN 1097-6).

- (2010) AFNOR - Tests to determine the mechanical and physical characteristics of aggregates - Part 3: method for determining bulk density and intergranular porosity Standard (NF EN 1097-3).

- (1990) AFNOR - Los Angeles trial. Standard NF EN 1097-2.

- (2011) AFNOR - Micro Deval wear test. Standard NF EN 1097-1.

- OLGA SOLOMAT NIKOUA (1998) Rheological behavior and cohesive and adhesive properties of bituminous binders. Department of Chemical Engineering: Faculty of Science and Engineering, Laval University, Canada.

- (2002) AFNOR DURIEZ test on hot hydrocarbon mixtures - Tests relating to pavements, Static tests on hydrocarbon mixtures, Part 1, Standard NF P 98-251-1.

- (2002) AFNORAFNOR DURIEZ test on hot hydrocarbon mixtures - Tests relating to pavements, Static tests on hydrocarbon mixtures, Part 1, Standard NF P 98-251-1.

- Wong YD, Sun DD, Lai D (2007) Value-added utilisation of recycled concrete in hotmix asphalt. Waste Management 27(2): 294-301.

- Zulkati Anggraini, Wong Yiik Diew, Sun Darren Delai (2013) Mechanistic performance of asphalt-concrete mixture incorporating coarse recycled concrete aggregate. J Mater Civ Eng 25(9): 1299-1305.

-

Lassaâd Ajam, Noredine Abriak* and Mohamed Belgaied. Mechanical Study of the Valorisation of Concrete Waste from Construction Waste in Bituminous Concrete. Mod Concept Material Sci. 5(2): 2023. MCMS. MS.ID.000606.

-

Bituminous concrete, Concrete waste, Resistance, Stability marshall, Compactness, Water holding, Particle size, Density, Binder, Stability, Creep, Percentage of vacuum, Demolition waste, Specimens, Specifications

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.