Mini Review

Mini Review

Graphene Reinforced Aluminium Metal Matrix Composite Materials an Alternate Novel Material for Super Lightweight Fuel Tank (SLWT) Structural Application – A State of Art

P Ashwath1*, M Venkatraman3, M Anthony Xavior3, Andre Batako2, P Jeyapandiarajan3, J Joel3, Arivazhagan Anbalagan1 and Jayesh Shanthi Bhavan3

1Faculty of Engineering, Coventry University, UK

2General Engineering Research Institute, UK

3Vellore Institute of Technology, India

P Ashwath, Faculty of Engineering, Environment and computing, Coventry University, UK.

Received Date:February 07, 2023; Published Date:March 16, 2023

Abstract

In recent years, the usage and consideration of aluminium alloy metal matrix composites (AMMCs) in a variety of aerospace and space exploration structural applications has increased. Different microwave susceptor reinforcements, such as Alumina (Al2O3), Silicon Carbide (SiC), and Graphene, have been actively used to build AMMCs for a wide range of aerospace and space exploration structural applications. Microwave processing of the composites, on the other hand, has gained significant interest due to its nature of enhancing composite properties which are beneficial for the aerospace and space exploration structural applications. Overall, an attempt has been made to bring out the current possibility of AMMC’s based materials joinability using a microwave technique alongside for aerospace and space exploration structural application.

Keywords: Aluminium; Metal matrix; Reinforcement; Microwave processing; Mechanical properties; Microstructural properties

Introduction

Recent advances in the study of materials have led to the creation of materials with enhanced mechanical qualities without sacrificing weight, which is quite appealing. It is necessary to examine the new class of advanced materials and its odd combinations without losing the essential qualities because materials have evolved, and different processing techniques have been developed. There is currently a huge demand for replacement materials, particularly in the aerospace, automotive, and military applications industries to enable greater payloads [1]. There is also a significant need for materials with a high strength to weight ratio in modern technical domains like avionics and the industry for light-weight vehicle parts, and thanks to the development of composite materials, such attributes are now easily attainable [1,2]. To produce a material with improved properties for various engineering applications, various blending of new classes of materials with advanced processing methods should be considered. One of the practical technologies that allows for the addition of various novel Reinforcements that are fabricable using novel processing methods. Due to the drawbacks that are compensated for in other metals and alloys, polymers, and ceramics, aluminium alloys are replacing other materials in advanced and modern industrial requirements. In addition, it is anticipated that high performance composite materials with improved properties will be produced using an adequate amount of reinforcement for aluminium alloys [3].

Graphene-Aluminium Composites for SLWT Structural Materials

Aluminium alloy (AA) 2024 is extensively used in the aerospace industry due to its low cost, lightweight and high mechanical strength. In this alloy copper is the primary element. Moreover, it denotes good fatigue resistance as well as high strength to weight ratio. On the conflicting, this alloy is highly allowing to corrosion due to the presence of intermetallic particles, surface treatment is needed for against the corrosion [4,5]. Precipitation hardening process can improve the mechanical properties of AA2024 alloys. The aim of precipitation hardening process is to change an unwanted microstructure where the atoms are accumulated around the grain boundary to a homogenous microstructure [6,7]. The precipitation hardening process consists of solution heat treatment, quenching and natural or artificial ageing. While mechanical properties of some heat-treatable alloys, especially 2XXX series, become stable with natural ageing at room temperature within a few days, some of them are unstable and display important changes in properties even after many years [8]. AA 2024 with silicon carbide (10%) and graphite (5%) by stir casting in his study & he mainly concentrated on the mechanical properties like yield strength, tensile strength, Hardness & dynamic analysis for the crack, he found that there is a increase in the yield strength, tensile strength & the hardness in B scale was 57 & comparatively higher than the conventional Al2024 metal [9]. Graphene exhibits more grain refinement which will improve the micro-hardness of the AA 2024 Graphene composites. X – Ray diffraction analysis shows the presence of carbon related peaks and other compounds. The tensile strength of AA 2024 – Graphene significantly enriched with the lower weight fraction of Graphene (addition of only 0.4 wt. %) [10].

Properties of Reinforcements in Matrix Materials

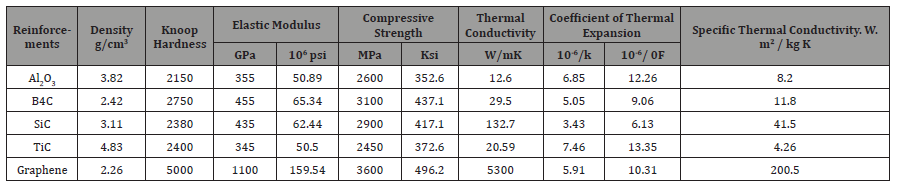

Aluminium oxide particles are inexpensive, they can be used in place of other materials in casting applications. The two most of the frequently used materials in aerospace structural applications are silicon and boron carbides. Table 1, shows the list of various ceramic materials with their respective physical and mechanical properties used in the manufacture of modern discontinuously reinforced MMCs [11].

Table 1:Mechanical and Physical Properties of Various Ceramic Particles Reinforcements [11].

Microstructure and SEM Analysis of Matrix Materials

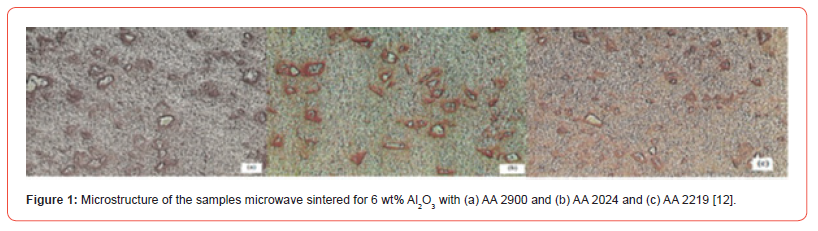

Figure 1 shows the microstructure of the microwave sintered sample for 6 wt% Al2O3 with AA 2900 and AA 2024. Figure 1 (a) and (b) clearly depicts that ball milling has improved the homogeneous dispersion of the reinforcement particulates in the matrix. Very less porosity is being observed in the microstructure and irrespective of the metal matrix used. From Figure 1 (a) and (b), it is evident that reinforcement particles have bonded firmly with the matrix metal during microwave sintering process. From Figure 1 (c), it is observed that very less reinforcement particles are observed on the surface of the 2219 alloy composites. This is attributed that lesser diffusion of the reinforcement particulates into the matrix is obtained because of lack in Si content which leads to reduction in hardness and compressive strength of the composite [12].

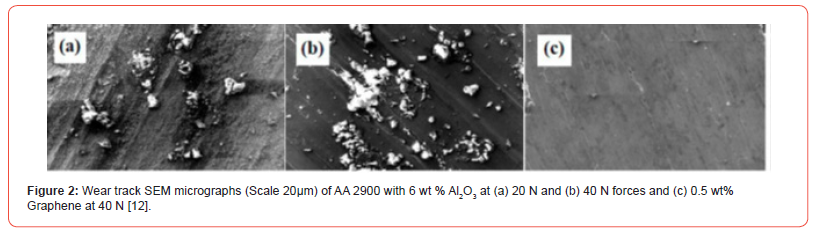

Figure 2 (b) showing the particulate trapped in matrix material even worn at higher load of 40 N confirming the bonding strength of Al2O3 with the aluminium matrix. A frictional mechanism can be understood to explain the relationship between the wear resistance and the material removal of the composites. Enhanced shear strengths of the composites processed by microwave sintering with reinforcements is one of the reasons for the resistance to wear sliding them against the steel disc of 45 HRC. It is also evident that a higher particle weight (wt %) fraction leads to a higher hardness. Similar results have been addressed by zhang et al. [12].

Conclusion

Due to the higher weight percentage of copper alloying percentage and the homogeneous distribution of reinforcement in the aluminium copper alloy system, which is one of the two matrix materials used, mechanical property is observed to be better compared to the parent alloys. Graphene and Al2O3-reinforced MMCs exhibits excellent mechanical properties that has a strong bonding ability when processed with microwave method and can be potentially considered for the SLWT structural applications.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Bastwros Mina, Gap-Yong Kim, Can Zhu, Kun Zhang, Shiren Wang, et al. (2014) Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Composites Part B: Engineering 60: 111-118.

- Ashwath P, Joel J, Prashantha Kumar HG, Xavior MA, Goel A, et al. (2018) Processing and characterization of extruded 2024 series of aluminum alloy. Materials Today: Proceedings 5(5): 12479-12483.

- Kumar HP, Xavior MA, Joel AP, Chakraborty JK (2018) Effect of flake reinforcement on mechanical properties of AA 6061 nano composite with secondary nano platelet-Graphene processed through powder metallurgy. Materials Today: Proceedings 5(2): 6626-6634.

- Ashwath P, Jeyapandiarajan P, Joel J, Prashantha Kumar HG, Xavior MA, Sumanth N, et al. (2018) Flexural studies of graphene reinforced aluminium metal matrix composite. Materials Today: Proceedings 5(5): 13459-13463.

- George E Totten, D Scott MacKenzie (2003) Handbook of Aluminum, Physical Metallurgy and Processes. Marcel Dekker Inc, New York.

- Xavior MA, Ranganathan N, Kumar HP, Joel J, Ashwath P (2018) Mechanical properties evaluation of hot extruded AA 2024–Graphene Nanocomposites. Materials Today: Proceedings 5(5): 12519-12524.

- Anthony Xavior, M Prashantha Kumar HG, Ajith Kumar K (2018) Tribological studies on AA 2024 – Graphene /CNT Nanocomposites processed through Powder Metallurgy” Materials Today: Proceedings 5(2): 6588-6596.

- Marlon Jones Louis (2014) Fabrication, Testing & Analysis of aluminum 2024 metal matrix composite.

- M Anthony Xavior, N Ranganathan, Prashantha Kumar HG, Joel J, Ashwath P (2018) Mechanical properties evaluation of hot extruded AA 2024 –Graphene Nanocomposites. Materials Today: Proceedings 5(5): 12519-12524.

- Karthe M, Prasanna SC (2017) Property Evaluation of Super Hard Alloys. Pakistan Journal of Biotechnology 14: 164- 167.

- Joel J, Anthony Xavior M (2019) Effect of alloying elements on the mechanical behavior of microwave sintered composites. Procedia Manufacturing 30: 208-215.

- ZF Zhang, LC Zhang, YW Mai (1995) Particle effects on friction and wear of aluminium matrix composites. J Mater Sci 30: 5999-6004.

-

P Ashwath*, M Venkatraman, M Anthony Xavior, Andre Batako, P Jeyapandiarajan, J Joel, Arivazhagan Anbalagan and Jayesh Shanthi Bhavan. Graphene Reinforced Aluminium Metal Matrix Composite Materials an Alternate Novel Material for Super Lightweight Fuel Tank (SLWT) Structural Application – A State of Art. Mod Concept Material Sci. 5(2): 2023. MCMS. MS.ID.000607.

-

Aluminium, Metal matrix, Reinforcement, Microwave processing, Mechanical properties, Microstructural properties, Material, Space exploration, Strength, Resistance, Microstructure, Precipitation hardening, Composites

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.