Research Article

Research Article

Thermal Comfort Analysis of Moisture Management Treated Cotton Fabrics for Sportwear

Su Kyoung An1*, Seung Bong Ko2 and Shuvo Kumar Kundu2

1Department of Fashion, Interior Design, & Merchandising, Central Michigan University, USA

2Independnent Researcher, USA

Su Kyoung An, Department of Fashion, Interior Design, & Merchandising, Central Michigan University, 2033 Cobblestone Ct., Mount Pleasant, MI 48858, USA,

Received Date: June 03, 2021; Published Date: June 23, 2021

Abstract

Currently, health concern continues to increase in importance and leads people to exercise more. It also increases people’s interest in purchasing athletic performance apparel that is promoted as superior apparel due to performance in moisture and heat transfer during exercising. This trend encourages more apparel companies to develop moisture management fabric. The aim of this study was to examine whether moisture management treated fabrics provide significant heat, moisture, and air transfers. Significant differences were found in air permeability among three different moisture management conditioned fabrics. There was no significant difference in heat and moisture transfers among them. However, statistically significant differences in heat, moisture, air transfers were found between two different fabric structures.

Keywords:Sportwear; Moisture management technology; Thermal comfort; Cotton; Knitted fabric

Introduction

With increased attention to living a healthy lifestyle, people tend to allocate more time to exercise and participate in sport and leisure activities [1]. Athletic people are interested in purchasing the most comfortable sportswear that must dry quickly, be most comfortable, and provide a wide range of motion to enhance athletic performance [2,3].

To satisfy the needs of athletic people, many apparel companies have invested a lot of time and effort to develop athletic performance apparel, which is referred to as moisture management apparel [4]. Moisture management apparel provides a greater degree of thermal comfort to the wearer especially during physical activity and performance since the moisture management property is effective to decide the comfort level of apparel [5,6].

The most important aspect of athletic apparel is how to transfer the heat, moisture, air from the body effectively [7-9]. This aspect assists in providing a comfortable environment for the wearers during exercising [10-12]. It also helps to maximize the wearer’s performance by reducing discomfort and fatigue from the presence of heat and sweat on the microclimate of the body [13-15].

As shown in recent trends for athletic apparel, an important characteristic is the moisture management capacity of the fabric/apparel to improve the thermal functionality and comfort performance during exercise [16-20]. Moisture management technology has been applied to athletic apparel to provide effective moisture absorption and quicker drying theoretically [16, 21].

Several companies have patented moisture management treated fabrics designed to be the most comfortable athletic apparel that keeps human skin dry and comfortable [21]. Each manufacturer has produced a variety of different names or trademarks for athletic performance apparel to emphasize their own values such as quick moisture absorption and quick dry [22]. Nike used many high technology-based materials and developed “Dri-fit” as a trademark of moisture management apparel, which emphasizes premium handling with reduced cling when wet [23]. It maximizes sweat to dry faster than regular fabric and increases the wearer’s comfort level during their performance [24,25]. Champion also created “Double Dry,” which employs a moisture management technology, “Wicking Windows” technology established by Cotton Incorporated, to speed up the moisture movement and the evaporation rate. It modifies the angles that contact the liquid surface and the fabric surface to transfer moisture quickly from the body to the environment through the fabric. Reebok (PlayDry), Adidas (ClimaCool), and Under Armour (CoolGear) have also developed similar textile technologies to compete in the athletic apparel industry.

Despite these trends, the amount of research related to the effectiveness of treatments on the thermal comfort of moisture management apparels is insufficient and lacking. These gaps have created many opportunities for research and development. Therefore, this study aims to examine if athletic apparel made with moisture management fabric provides significant heat, sweat, and air transfer from the body to the environment as promoted by popular athletic brands. Additionally, a comparison of dry thermal resistance, water-vapor resistance, and air permeability among three different moisture management conditions was conducted to verify effectiveness on the structure of fabric for thermal comfort. Dry thermal resistance (Rct) for thermal resistance, water-vapor resistance (Ret) for thermal absorptivity, and air permeability for air transfer were employed as variables to determine the effects of moisture management technology and fabric structures with athletic apparel. Two hypotheses follow:

H1a,b,c: There are significant differences in (H1a) dry thermal resistance (Rct), (H1b) water-vapor resistance (Ret), and (H1c) air permeability among three different moisture management conditions on cotton fabric for athletic apparels.

H2a,b,c: There are significant differences in (H2a) dry thermal resistance (Rct), (H2b) water-vapor resistance (Ret), and (H2c) air permeability between two different fabric structures on cotton fabric for athletic apparels.

Experimental

Testing fabrics

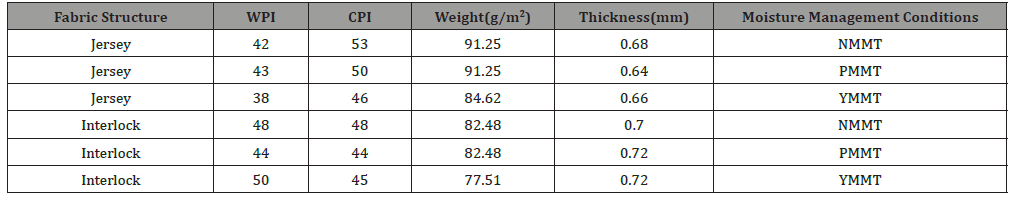

100% knitted cotton fabrics with two different fabric structures, jersey and interlock, were chosen for the experiment. To test the effects of different moisture management technology with cotton fabrics, three moisture management applications were chosen for this study: None Moisture Management Technology (NMMT), Print Moisture Management Technology (PMMT), and Yarn Moisture Management Technology (YMMT). NMMT fabrics were not applied with any moisture management treatments. PMMT fabrics were treated with water repellent finishes through print application onto the skin side of cotton fabrics. Finally, YMMT fabrics used cotton yarns treated through a special process to make them water repellent before knitting. Thus, six fabric samples with two different fabric structures and three different levels of moisture management treatments were tested. The conditions of six fabric samples were provided with specific details such as weight and thickness (Table 1).

Table 1:Testing fabrics.

Equipment

Three specimens of each fabric, a total of 18 specimens, were cut 12 inches in length by 12 inches in width and pre-conditioned in the environmental chamber for 24 hours before testing. Each fabric specimen was tested by using the Sweating Guarded Hot-Plate (SGHP) (Figure 1) manufactured by Measurement Technology Northwest to conduct both dry thermal resistance (Rct) and water-vapor resistance (Ret). According to the ASTM F1868- 09, environmental chamber was pre-conditioned at the specific temperature and humidity for Rct and Ret. Three repetitions of each test were collected. The collected Rct and Ret values were calculated as the mean values with 5% of the standard deviation for the reliability of the study.

To measure the air permeability, the TEXTEST Air Permeability Tester (model: FX 3300 LabAir IV) was utilized. Ten specimens of each fabric, a total of 60 specimens, were cut according to the ASTM D737-04. The specimen was placed under the test head with no wrinkle. All measurements were repeated ten times for each specimen. ANOVA comparison of air permeability among three different moisture management conditions was run.

Results and Discussion

H1a,b,c: There are significant differences in (H1a) dry thermal resistance (Rct), (H1b) water-vapor resistance (Ret), and (H1c) air permeability among three different moisture management conditions on cotton fabric for athletic apparels.

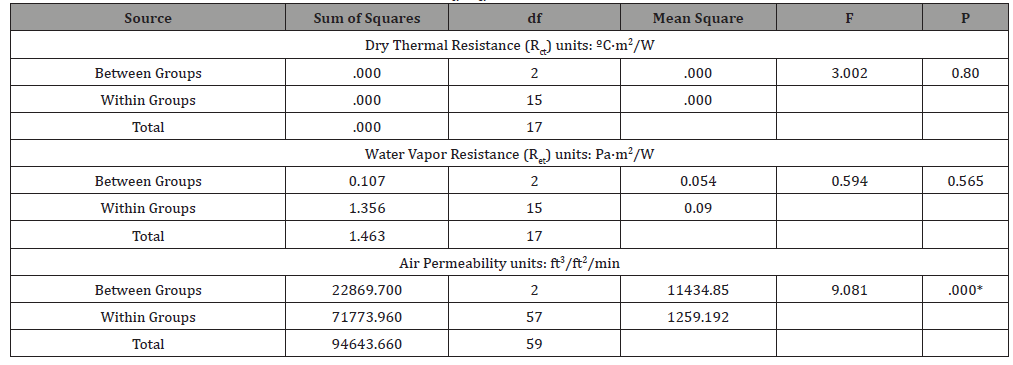

No significant differences were found in both Rct (F (2, 17) = 3.002, p = .080) and Ret (F (2, 17) = .594, p = .565) according to three different moisture management conditions. However, a statistically significant difference in air permeability (F (2, 59) = 9.081, p = .000) was found (Table 2). It indicates that no differences exist among three different moisture treatment technology in transporting heat and sweat. However, a significant difference in air transfer among three different moisture treated fabrics was found from the body to the environment.

Table 2:ANOVA Table by Moisture Management Conditions on Rct, Ret, & Air Permeability.

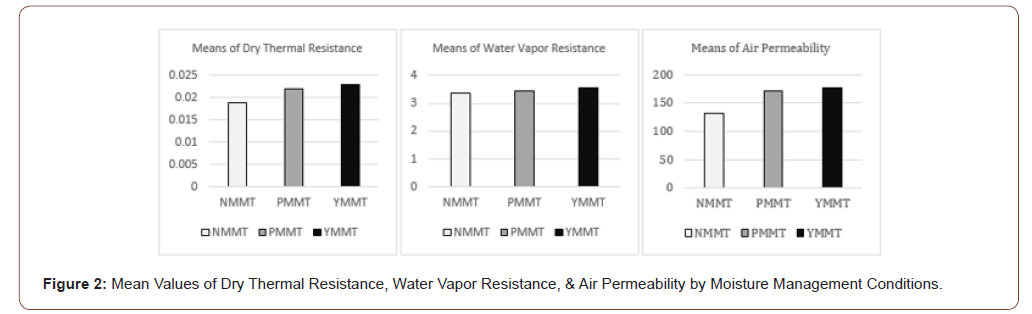

Although no significant differences were found in Rct, the mean value of NMMT (Mean = .019, SD = .004) for Rct is higher than the mean values of PMMT (Mean = .022, SD = .001) and YMMT (Mean = .023, SD = .001) (Table 3). It means more heat remains between body and NMMT fabrics than other fabrics. However, for Ret, the mean values of all three different fabrics (NMMT: Mean = 3.361, SD = .424, PMMT: Mean = 3.452, SD = .265, & YMMT: Mean = 3.550, SD = .144) have the similar amount of moistures between garment and body under no significant difference on Ret (Table 3 & Figure 2).

Table 3:Means and Standard Deviations by Moisture Management Conditions on Rct, Ret, & Air Permeability.

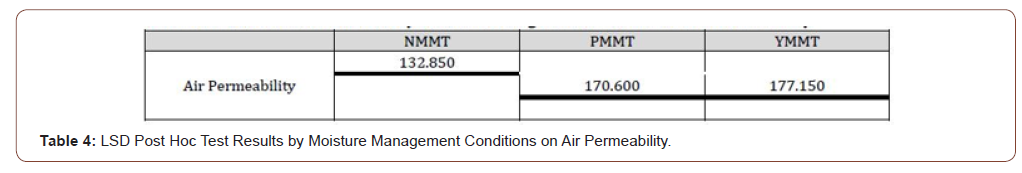

To see the group difference of air permeability, the LSD Post Hoc test was used (Table 4 & Figure 1). PMMT (Mean = 170.600, SD = 36.453) and YMMT (Mean = 177.150, SD = 27.494) were grouped together while NMMT (Mean = 132.850, SD = 41.143) were grouped together while NMMT (Mean = 132.850) remained in its own group. It indicated that no significant difference in moisture treated fabrics exits regardless to the moisture management treatment. However, a significant difference in air permeability between non-treated moisture management fabric and treated moisture management fabrics was found. PMMT and YMMT, which treated the moisture management on yarn and the top of the fabric, have higher air transfer than NMMT, which did not apply any moisture management technology.

H2a,b,c: There are significant differences in (H2a) dry thermal resistance (Rct), (H2b) water-vapor resistance (Ret), and (H2c) air permeability between two different fabric structures on cotton fabric for athletic apparels.

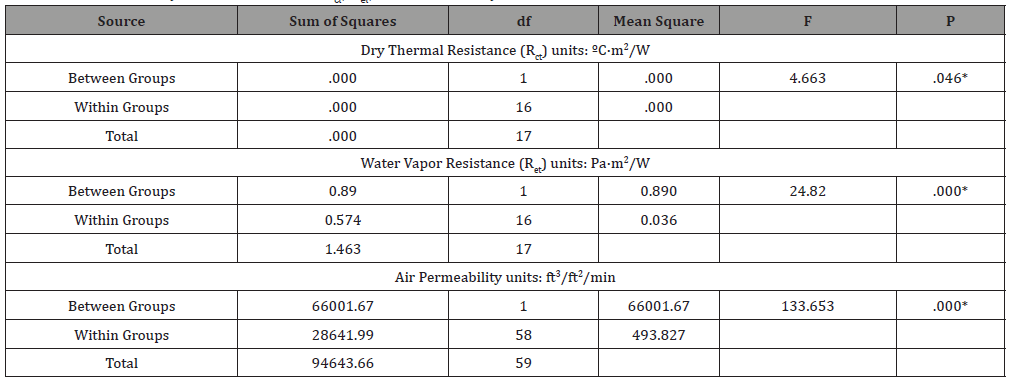

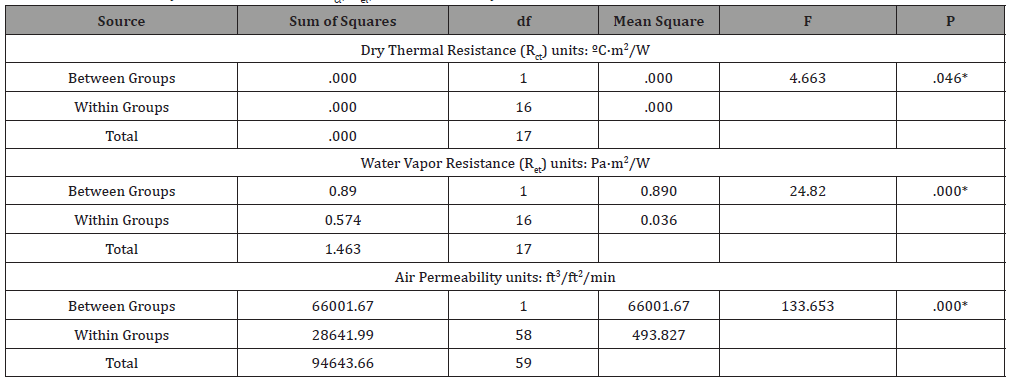

As presented in Table 5, statistically significant differences were found in all of Rct (F (1, 17) = 4.663, p = .046), Ret (F (1, 17) = 24.820, p = .000), and air permeability (F (1,59) = 133.653, p = .000) between two different fabric structures. It indicates that there are significant differences in dry thermal resistance, water-vapor resistance, and air permeability between two fabric structures, jersey and interlock.

Table 4:ANOVA Table by Fabric Structures on Rct, Ret, & Air Permeability.

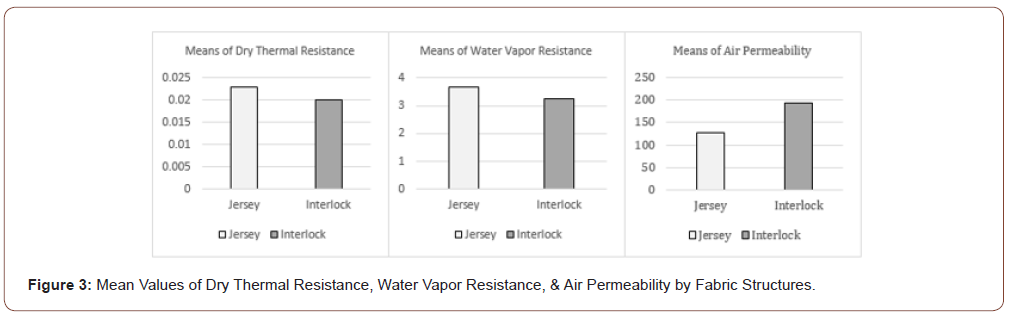

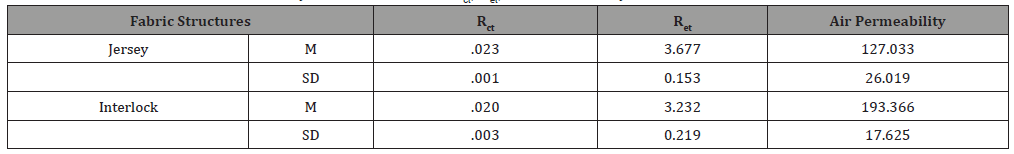

To see more detail in these differences, the means and standard deviations were conducted (Table 6 & Figure 3). For both Rct and Ret, the mean values of jersey fabrics (Rct: Mean = .023, SD = .001 & Ret: Mean = 3.677, SD = .153) is greater than the mean values of interlock fabrics (Rct: Mean = .020, SD = .003 & Ret: Mean = 3.232, SD = .219). It indicates that more heat and moisture remain in jersey structured fabrics between body and garment than in interlock fabrics. Lastly, air permeability in interlock fabric structure (Mean = 193.366, SD = 17.625) has higher mean value than in jersey fabric structure (Mean = 127.033, SD = 26.019). It means that better air transfer in interlock fabrics occurred than in jersey fabrics.

Table 5:Means and Standard Deviations by Fabric Structures on Rct, Ret, & Air Permeability

Conclusion

Many manufacturers and retailers promote to consumers that moisture management apparel has greater heat and sweat transfer properties than conventional sportswear, but this study has shown that the beneficial properties of moisture management fabrics are only seen in air transfer, not in heat and sweat transfer. Especially, two types of fabrics, PMMT and YMMT, which were differently treated for moisture management treatment, did not show a significantly differences of heat and sweat transfer than NMMT fabrics. However, although no significance showed in Rct among three different fabrics, the descriptive analysis presented that PMMT and YMMT fabrics contained lower heat values which mean better heat transfer from the body to the outer portion of a T-shirt than NMMT fabrics. On the other hand, the Ret values of PMMT and YMMT fabrics are lower than NMMT fabrics, which means more sweat between body and T-shirt in NMMT fabrics remains than in PMMT and YMMT fabrics. It means that sweat in PMMT and YMMT fabrics is easily transferred from the body to the outer layers of the T-shirt and NMMT fabrics follow.

However, significant difference was found in air permeability test. NMMT has a significantly lower air permeability value than PMMT and YMMT which indicates moisture treated fabrics for athletic have better air transfer from the body to the environment than non-moisture treated fabrics. Thus, the athletic t-shirts made of both PMMT and YMMT fabrics provide better air transfer and ventilation than the athletic T-shirts made of NMMT fabrics.

Another major finding of this study is that there are statistically significant differences in dry thermal resistance, water-vapor resistance, and air permeability depending on types of fabric. These results support that fabric structures influence the thermal property of fabric such as heat, sweat, and air transfer. Two knitting structured fabrics, jersey and interlock, which are popularly used for athletic t-shirts, were employed for this research. According to the finding, the interlock structure has more effective heat, sweat, and air transfers than the jersey structure. It indicates heat, sweat, and air remain in jersey structures more than in interlock structures. It might be related to the weight of fabric that produces these different results.

Adding moisture management technology in athletic apparel has been widely promoted by many sportswear companies to provide quick heat, sweat, and air transfer effectively. Consumers tend to trust what popular companies promote and purchase their apparel by paying the premium price. However, as shown through this study, the effectiveness of moisture management technology on heat and sweat transfers is inadequate. The moisture management technology on air permeability only shows the significantly different air transfer on fabrics. A clearer description of effects on moisture management technology is relatively suggested and it will help to reduce consumers’ misunderstanding and misguided purchase decisions. Also, using a certification mark after completing the appropriate tests should help consumers to understand more clearly about moisture management technology and build a positive image of a company promoting such athletic apparel.

Acknowledgment

I would like to acknowledge the support of Cotton Inc. and the Center for Merchandising & Design Technology (CMDT) at Central Michigan University.

Conflicts of interest

The authors declare that there are no conflicts of interest.

References

- Sharpe (2014) Vermont No. 1 in Frequent Exercise, Produce Consumption.

- Davis JK, Bishop PA (2013) Impact of clothing on exercise in the heat. Sports Medicine 43(8): 695-706.

- Kundu SK, An SK (2018) Exploring thermal comfort of sports shirts from the price difference perspective. International Journal of Polymer and Textile Engineering. 5(3): 26-32.

- Herek M (2003) Never let ‘em see you sweat. Sporting Goods Business 36: 70-71.

- Sampath MB, Senthilkumar M (2009) Effect of moisture management finish on comfort characteristics of microdenier polyester knitted fabrics. Journal of Industrial Textiles 39(2): 163-173.

- Völker C, Hoffmann S, Kornadt O, Arens E, Zhang H, et al, (2009) Heat and moisture transfer through clothing, UC Berkeley: Center for the built Environment.

- Lee H, An S (2018) A comparative analysis of thermal comfort properties for nurse scrub jackets. AATCC Journal of Research 5 (2): 35-39.

- Oğlakcioğlu N, Marmarali A (2007) Thermal comfort properties of some knitted structures. Fibres and Textiles in Eastern Europe 5-6(64-65): 94-96.

- Kar F, Fan J, Yu W, Wang X (2007) Effects of thermal and moisture transport properties of T-shirts on wearer’s comfort sensations. Fibers and Polymers 8(5): 537-542.

- Dai XQ, Imamura R, Liu GL, Zhou FP (2004) Effect of moisture transport on microclimate under T-shirts. Eur J Appl Physiol 104(2): 337-340.

- Shishoo R (2005) Textiles in sport.

- Bivainyte A, Mikučioniene D, Kerpauskas P (2012) Investigation on thermal properties of double-layered weft knitted fabrics. Materials Science 18(2): 167-171.

- Adams BB (2008) Skin infections in athletes. Dermatology Nursing 20(1): 39-44.

- Mecheels JH, Demeler RM, Kachel E (1966) Moisture transfer through chemically treated cotton fabrics. Textile Research Journal 36(4): 375-384.

- Abreu MJ, Catarino A, Cardoso C, Martin E (2011) Effects of Sportswear design on thermal comfort, Innovation and Research in Textile Science: 50-55.

- Midha V, Kumar SS, Kumar MN (2017) Investigation on permeability and moisture management properties of different denim fabrics after repeated laundering. The Journal of the Textile Institute 108(1): 71-77.

- Wang SX, Li Y, Tokura H, Hu JY, Han YX, et al. (2007) Effect of moisture management of functional performance of cold protective clothing. Textile Research Journal 77(12): 968-980.

- Onofrei E, Rocha AM, Catarino A (2011) The influence of knitted fabrics’ structure on the thermal and moisture management properties. Journal of Engineered Fibers and Fabrics 6(4): 10-22.

- Fan F, Tsang HWK (2008) Effect of clothing thermal properties on the thermal comfort sensation during active sports. Textile Research Journal 78(2): 111-118.

- Supuren G, Oglakcioglu N, Ozdil N, Marmarali A (2011) Moisture management and thermal absorptivity properties of double-face knitted fabrics. Textile Research Journal 81(13): 1320-1330.

- Wang F, Zhou X, Wang S (2009) Development processes and property measurements of moisture absorption and quick dry fabrics. Fibers & Textiles in Eastern Europe 17(2): 46-49.

- Dai H (2011) Study on thermal comfort property of moisture absorption and quick drying apparel. Advanced Materials Research 332-334: 416-419.

- Lee EJ, Paik CE (2008) A study on the fabric trend in sportswear. J Korea Fashion and Costume 10(3): 47-59.

- Motlogelwa S (2018) Comfort and durability in high-performance clothing, High-Performance Apparel: Materials, Development, and Applications: 209-219.

- (2017) PR Newswire.

-

Su Kyoung An, Seung Bong Ko, Shuvo Kumar Kundu. Thermal Comfort Analysis of Moisture Management Treated Cotton Page 6 of 6 Fabrics for Sportwear. 8(4): 2021. JTSFT.MS.ID.000692.

-

Sportwear, Moisture management technology, Thermal comfort, Cotton, Knitted fabric

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.