Research Article

Research Article

The Design and Development of Photochromic Jacquard Woven Fabric

Jingjing Zhan1,2, Kaiqiang Lei1,2, Gaoyang Xu3 and Chunhong Lu1,2*

1Key Laboratory of Textile Science & Technology, Ministry of Education, Donghua University, China

2College of Textiles, Donghua University, China

2Jiangsu Danmao Textile Co., Ltd, China

Chunhong Lu, Department of Textiles Engineering, College of Textiles, Donghua University, China.

Received Date: November 08, 2021; Published Date: November 16, 2021

Abstract

The jacquard woven fabric is often composed of dyed yarns to demonstrate brilliant colors and ever-changing patterns. Currently, the innovation of most jacquard woven fabrics focuses on pattern design, complicated weave structure and weaving process. To endow traditional jacquard woven fabric with functionality for value-added applications, it is necessary to combine artistic jacquard woven fabrics with functional yarns. To achieve this goal, the photochromic jacquard woven fabric has been developed by using photochromic yarn as weft yarn for reversible color change effect under sunlight or ultraviolet (UV) light. The design of photochromic jacquard woven fabric includes fabric pattern design and process design. Three jacquard woven fabric samples have been developed by changing two process parameters including weft density and weave structure. The effect of weft density and weft-float length on the photochromic performance of the jacquard woven fabrics has been investigated by comparing the coloration time and the color recovery time of fabricated samples with various weft densities and different weave structures under natural sunlight. The results show that as the jacquard woven fabric’s weft density increases, the coloration and color recovery time of jacquard woven fabric is prolonged. Similarly, with longer weft-float in the fabric weave structure of the same pattern, the color recovery time of jacquard woven fabric is prolonged. The design and development of the photochromic jacquard woven fabric not only indicate the fabric’s aesthetic value, but also provide practical reference for the design of smart fabrics.

Keywords:Jacquard woven fabric; Weave design; Photochromic behavior

Introduction

Jacquard woven fabrics often demonstrate exquisite and artistic pattern with ever-changing colors and texture by interweaving colored warp and weft yarns. They are the combination of art and weaving technology, which can be innovated in terms of artistic color, style, and weave structure, etc. Jacquard woven fabrics are widely used in the fields of apparel, home textile and decoration, which have a large number of consumers and a growing market.

In recent years, the design and development of jacquard woven fabrics mainly focus on diversified raw materials selection, modern style of pattern design, complicated weave structure and fabrication process. For instance, innovated pleated jacquard woven fabrics with pleat length up to 23.7 mm can be achieved by modern manufacturing equipment of air jet loom [1]. Also, embossed wool jacquard woven fabrics can be obtained by retraction method [2]. However, the integration of functionality into jacquard woven fabrics are not widely investigated to meet the diverse needs of the market. Currently, a few researchers have successfully developed functional jacquard woven fabrics. For example, antimicrobial jacquard woven fabric has been obtained by blending antimicrobial viscose fibers with cotton fibers at a 3:7 ratio [3]. A jacquard woven fabric with complex functions of UV resistance, flame retardancy and odor absorption, has been fabricated with flame retardant polyester warp yarns and blended weft yarns with UV resistant polyester and cellular photocatalytic polyester fibers [4]. Among the functional textiles, smart textiles with functions such as health monitoring, temperature control, data collection and color changing, etc., can better meet the needs of consumers in the age of information and intelligence. As one type of these smart textiles, photochromic fabrics change color when they are exposed to sunlight or UV light [5]. This is mainly because the photochromic compounds in the fibers/yarns cause structural changes and further color changes in the absorption spectrum. When the fabric is no longer exposed to sunlight or UV light, the color changes back to previous state, therefore this color change process is often reversible.

In general, the photochromic function of fabrics is mainly achieved by photochromic fibers/yarn or by fabric finishing [6,7]. The photochromic fibers/yarns can be directly woven into fabrics, which provide a facile way to achieve functional textiles. Typically, photochromic fibers/yarns are obtained by the following methods: (a) Graft photochromic monomer onto the main or side chain of polymer by graft polymerization followed by fiber spinning; (b) Incorporate photochromic compounds into spinning dopes before fiber spinning; (c) Fill the gap between fibers with microcapsules containing photochromic compounds. Finishing is also a simple way to endow the fabrics with photochromic behavior by the following methods: (a) Dye the fabric with photochromic dyes; (b) Chemically crosslink the adhesives containing photochromic dyes with fabric by impregnation. Currently, research and development regarding the use of photochromic materials in fabrics are not very mature, they are still at an exploration stage. For instance, Fan, et al. [8] treated cotton fabrics with double-shell polyurethane-chitosan photochromic microcapsules using the coating method. Lee, et al. [9] treated a polyamide fabric with a photochromic material in a dye bath and then soaked the fabric in a polymer solution to form a polymer film for durable photochromic performance, which showed a decrease of 30-50% in discoloration rate. Cheng, et al. [10] introduced epoxy into the silica matrix of silica/photochromic compound dye to improve the durability of photochromic dye in finished fabrics and the resulting fabric had a wash resistance up to 1000 times. However, these photochromic fabrics aforementioned can only change color as a whole piece, therefore demonstrating a tedious photochromic effect.

To demonstrate photochromic behavior of fabrics with exquisite patterns and ever-changing effect, it is necessary to develop photochromic jacquard woven fabrics. In this work, photochromic jacquard woven fabric is designed and developed by using the photochromic yarn as the weft yarn system. The photochromic yarn containing photochromic microcapsules on the surface or in between the fibers shows substantial effect of color-changing. The photochromic jacquard woven fabrics have been fabricated to investigate the effect of weave structure and weft density on the photochromic performance of the jacquard woven fabrics. The fabric’s interaction with the environment [11] will bring a new intelligent experience and artistic interest to the user or wearer.

Design and Development of Photochromic Jacquard Woven Fabric

The design of the functional jacquard fabric included two parts, which were pattern design and weaving design. Pattern design was completed by Corel Draw software. Computer Aided Design (CAD) (ZDJW Ltd. Co., China) software was used for plan of weave, which included the design of the weave repeat, the designation of warp and weft densities, color separation, the determination of picking order, the design of weave structure and the generation of electronic jacquard card for weaving [12]. The following sections will introduce the details of fabric design.

Pattern design of jacquard woven fabric

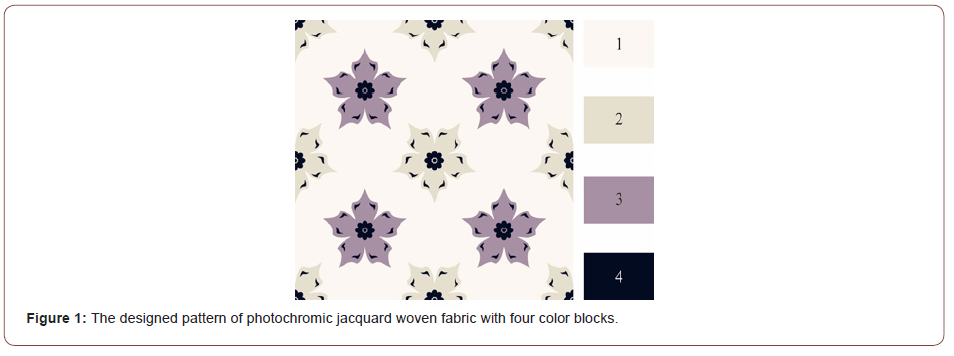

As shown in Figure 1, the designed pattern for the photochromic jacquard woven fabric in this work is simple and elegant. There are totally four colors in the designed pattern with each color block representing a designated weave structure. The pattern design adopts abstract flower graphic as the main theme, which indicates beautiful thing in life. With the large flower patterns, it is more convenient to observe the color change process when the fabric is exposed to natural sunlight. It should be noted that the flower pattern has two different color blocks corresponding to two weave structures with different weft-float lengths. Thus, it is much easier to indicate the effect of the weave structure on the photochromic performance of the fabric with same surface area.

Fabrication of photochromic jacquard woven fabric

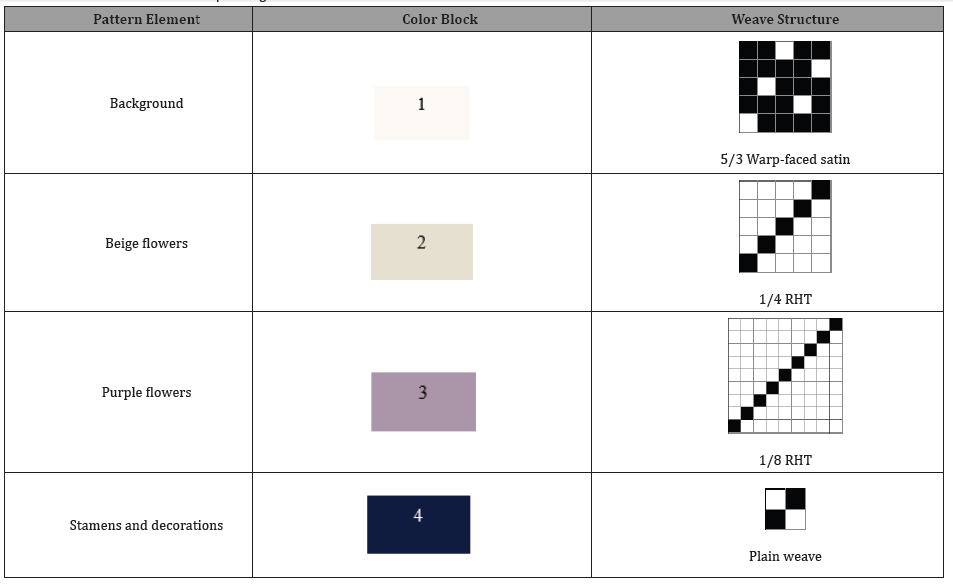

To obtain photochromic jacquard woven fabric, one type of weft yarn and one type of warp yarn are used for the formation of weave structure, demonstration of the pattern design and photoinduced coloration effect. A total of four weaves structures are used, and their relationship with corresponding pattern elements and color blocks from Figure 1 is summarized in Table 1. No.1 color block is 5/3 warp-faced satin weave structure. In this structure, warpfloats on fabric surface form the background part of the fabric pattern. No. 2 color block represents a 1/4 right hand twill (RHT) with weft-floats on the fabric surface for the demonstration of the beige flowers in the fabric pattern. No. 3 color block has a 1/8 RHT weave structure. In this part, weft-floats form the purple flowers pattern on fabric surface and the length of weft-floats are twice that of weft-floats in the weave structure of No. 2 color block. No. 4 color block consists of a tight plain weave structure that corresponds to the stamens and petal decorations in the designed fabric pattern.

Table 1:Pattern elements’ corresponding color blocks and weave structures.

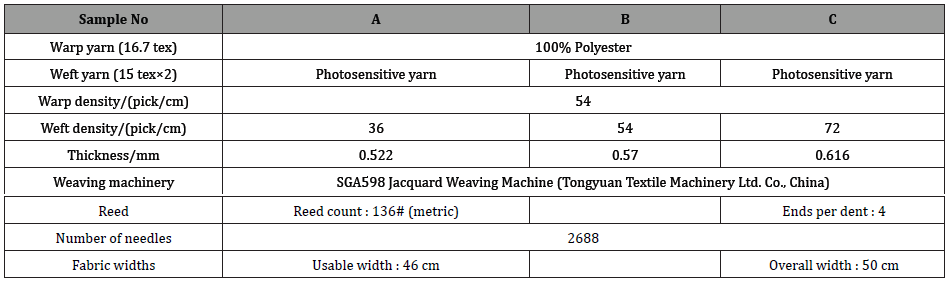

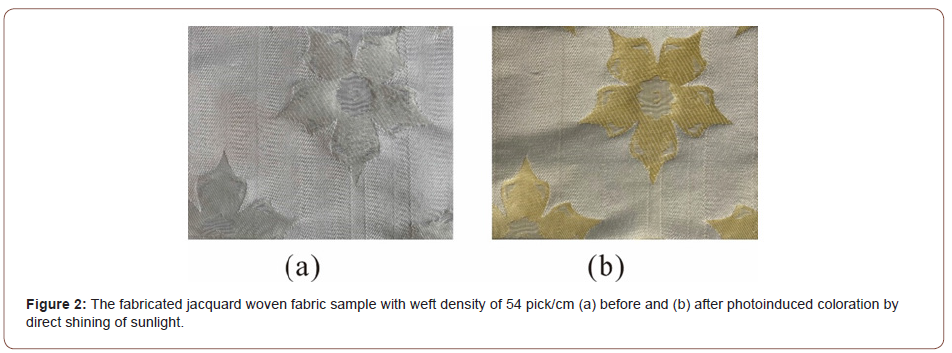

In this work, three types of photochromic jacquard woven fabric samples were woven. Their weft densities are 36, 54 and 72 pick/cm, respectively. The warp yarn is a 16.7 tex polyester yarn. The weft yarn is a 15 tex×2 photochromic yarn (purchased from Yiyuan Co., China), which changes color from white to yellow under sunlight. The photochromic yarn changes color mainly due to the photochromic microcapsules. This smart yarn has significant photoinduced coloration effect, good thermal stability and launderability. The specifications of sample fabrics are shown in Table 2, in which the fabric thickness has been measured according to the standard GB/T 3820-1997 Determination of Thickness of Textiles and Textile Products. The digital photographs of sample fabrics before and after photoinduced coloration are shown in Figure 2. It is observed that flower pattern in the sample fabric clearly shows white warp and weft yarns with no sunlight. After direct shining of sunlight, the white flower pattern with photochromic weft yarn floats on fabric surface clearly turns into yellow color.

Table 2:The specifications of all jacquard woven fabrics.

Evaluation of Photochromic Behavior of Jacquard Woven Fabrics

Up to date, there are few test methods to evaluate photochromic behavior of jacquard woven fabrics. In this work, the influence of weft density on the photochromic performance of jacquard woven fabrics is indicated by recording the coloration time under direct natural sunlight and color recovery time in the absence of sunlight of fabric samples with different weft densities. Moreover, the influence of weft-float length on the photochromic performance of jacquard woven fabric is studied by recording the coloration/color recovery time of flower patterns with different weave structures of the same fabric.

The test procedure is as follows: fabric sample was placed under natural sunlight (UV index 2000 μW/cm), timing was immediately started to observe the process of the fabric pattern turning from white to yellow. Timing was stopped till the fabric sample no longer changed color. This time duration was defined as coloration time. When the fabric was blocked from direct sunlight, the time was recorded again till the fabric changed to complete white color. The time duration that the fabric sample fully restored its original color was recorded as the color recovery time.

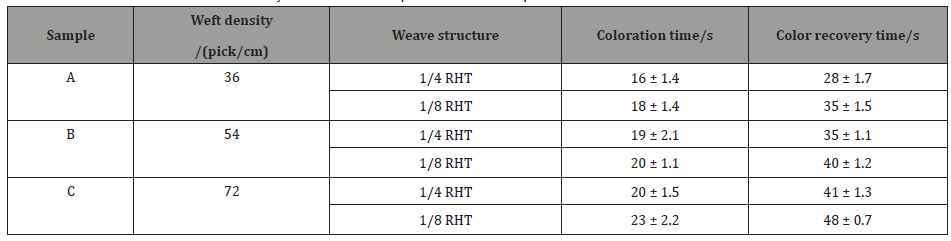

Table 3:Coloration time and color recovery time of fabric samples with different specifications.

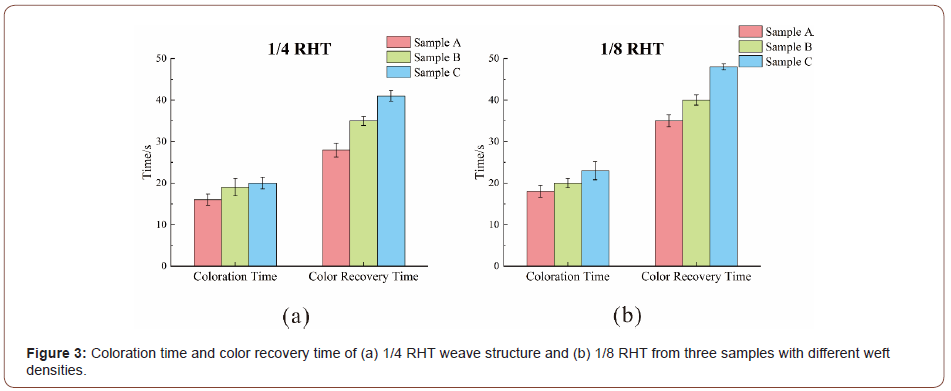

To better visualize the testing results, a comparison of the coloration time and color recovery time of 1/4 RHT weave structure and 1/8 RHT weave structure within three types of fabric samples is shown in Figure 3. In Figure 3a, the average coloration time of fabric pattern with 1/4 RHT is 16, 19 and 20 s, respectively for sample A, B and C. The average color recovery time of fabric pattern with 1/4 RHT is 28, 35 and 41s, respectively for three fabric samples. It is concluded that with increased weft density of the fabric sample, the coloration and color recovery time of fabric pattern with 1/4 RHT weave structure is prolonged. The same trend is shown in fabric pattern with 1/8 RHT weave structure as fabric weft intensity is increased (Figure 3b): the average coloration time of fabric pattern with 1/8 RHT is 18, 20 and 23s, respectively and the average color recovery time of fabric pattern with 1/8 RHT is 35, 40 and 48s, respectively for sample A, B and C. The jacquard woven fabrics with larger weft density have a larger number of photochromic weft yarns per unit area, indicating that the weft yarns are arranged more closely to each other and the fabric surface area exposed to the sunlight is smaller. Therefore, the absorption rate of UV energy for fabrics with higher weft density is slower, which corresponds to longer coloration time. Overall, with the same pattern area, fabric with higher weft density absorbs more UV energy and it takes more time to fully release the UV energy, resulting in longer color recovery time. On the contrary, fabric with smaller weft density has a looser structure with more photochromic weft yarns exposed to sunlight. Therefore, it absorbs UV energy more quickly and takes less time to fully discolor.

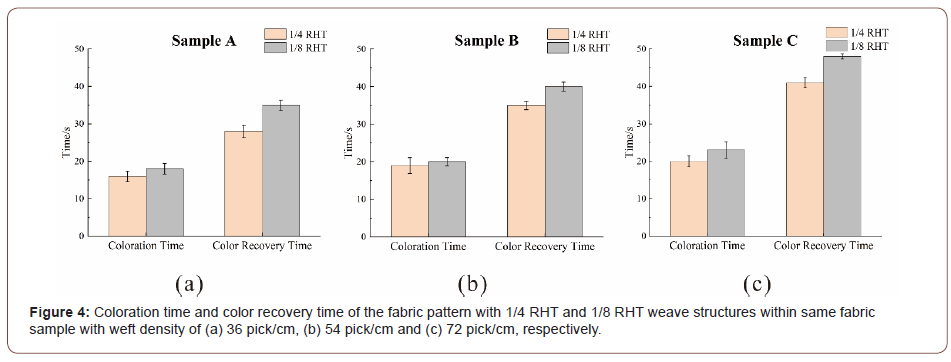

A comparison of coloration time and color recovery time for the two weave structures of each sample is shown in Figure 4. The coloration time of patterns with 1/4 RHT and 1/8 RHT structures within each type of fabric sample is not significantly different. However, the color recovery time of fabric pattern with 1/8 RHT weave structure is longer than that of pattern with 1/4 RHT weave structure in each fabric sample of A, B and C. The weft-floats of the 1/8 RHT weave structure are twice as long as the weft-floats of the 1/4 RHT weave structure. And longer weft-float in the same area of fabric pattern often suggests that more UV energy is absorbed by the photochromic weft yarns, therefore it takes more time to release UV energy and return to its original color. This is why the color recovery time of same pattern area with 1/8 RHT weave structure is longer.

Conclusion

The most distinctive features of jacquard woven fabrics are their brilliant colors and delicate patterns. This work combines jacquard woven fabrics with photochromic functionality to enable the color change of fabric pattern in varying environment and enrich the visual effect of artistic fabric. The combination of art and technology allows photochromic jacquard fabrics to be used in the fields of decoration, fashion clothing, etc. In addition, the influence of weft density and length of weft-floats on the photochromic performance of the fabrics was investigated. The results have practical implications for the innovation of highquality photochromic smart textiles with artistic value.

Acknowledgement

This work is sponsored by “Chenguang Program” (Grant number: 19CG79) supported by Shanghai Education Development Foundation and Shanghai Municipal Education Commission, China.

Conflict of Interest

Authors declare no conflict of interest.

References

- Wang F , Li J , Yang NS (2017) Break out of the big pleats and come up with new patterns. Textile Science Reserch 6: 56-58.

- Tao HY, Wang GH, Zha SA (2018) Development of jacquard woolen fabric based on lace texture effect. Wool Textile Journal 46(1): 6-58.

- Sun C, Wang JK , Liu T (2020) Development of antibacterial viscose jacquard fabric. Journal of Dyeing and Finishing Technology 42(3): 47-50.

- Wang Q (2017) Curtain fabric composite functional studies and product development. Zhejiang University, China.

- Liu XH, Chen HH (2012) The preparation and application of photochromic functional fabrics. Advanced Textile Technology 20(6): 58-60.

- Fan F (2016) Application of photochromic material in textiles. Cotton Textile Technology 44(12):80-84.

- Ba Dulescu R, Vivod V, Jausovec D, et al (2008) Grafting of ethylcellulose microcapsules onto cotton fibers. Carbohydrate Polymers 71(1): 85-91.

- Fan F, Zhang W, Wang C (2015) Covalent bonding and photochromic properties of double-shell polyurethane-chitosan microcapsules crosslinked onto cotton fabric. Cellulose 22(2): 1427-1438.

- Lee SJ, Son YA, Suh HJ, Lee DN, Kim SH (2006) Preliminary exhaustion studies of spiroxazine dyes on polyamide fibers and their photochromic properties. Dyes & Pigments 69(1-2): 18-21.

- Cheng T, Lin T, Brady R, Wang X (2008) Photochromic fabrics with improved durability and photochromic performance. Fibers and Polymers 9(5): 521-526.

- Zang FR (2021) Application of Photochromic Materials in Product Design. Art Research 1: 170-172.

- Zhan JJ, Lei KJ, Xu GY, Zhang P, Lu C (2021) The Application of Chinese Song Brocade Concepts in Developing Jacquard Woven Design and Fabrics. Journal of Textile Science & Fashion Technology 9(2): 1-8.

-

Jingjing Zhan, Kaiqiang Lei, Gaoyang Xu, Chunhong Lu. The Design and Development of Photochromic Jacquard Woven Fabric. J Textile Sci & Fashion Tech 9(3): 2021. JTSFT.MS.ID.000712. DOI: 10.33552/JTSFT.2021.09.000712.

-

Jacquard woven fabric, Weave design, Photochromic behavior

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.