Review Article

Review Article

Tactile Rendering of Textile Materials

Thamizhisai Periyaswamy1* and Md Rashedul Islam2

1Department of Fashion, Interior Design and Merchandising, Central Michigan University, USA

2University of Alberta, Canada

Thamizhisai Periyaswamy, Department of Fashion, Interior Design and Merchandising, Central Michigan University, Mount Pleasant, MI USA.

Received Date: December 11, 2021; Published Date: January 18, 2022

Abstract

Tactile rendering attempts to replicate touch stimuli with the aid of haptic devices so that the perception of a material can be stored and transmitted to a remote user. Haptic devices have potential implications on prosthetics, rehabilitation, telemedicine, and virtual reality. Research on haptic interfaces and novel approaches to rendering tactile feedback in virtual and immersive environments has grown recently. We conducted a comprehensive analysis to obtain information on tactile rendering, in general, from scholarly works published between 2009 and 2019. We present a consolidated report on the current techniques on tactile rendering of textile materials. Existing research on tactile rendering focused on three significant areas: surface feature extraction, virtual texture simulation, and assessment by a human observer. We found that in the majority of the cases, the tactile interface system uses a mechatronics framework, where one or more electromechanical transducers converted tiny electrical signals into mechanical forces to generate the necessary haptic stimuli. Furthermore, the paper discusses the prevailing critical challenges in tactile rendering and the directions for future research.

Keywords:Tactile sensation; Surface properties; Virtual texture simulation; Haptics of textile; Soft material haptic

Introduction

The clothing industry is undergoing a digital transformation. Demand for realistic tactile simulations is increasing in the clothing and textiles field due to growing online shopping and virtual prototyping needs. The critical requirement is to incorporate virtual technologies to aid the manufacturers for speed to market, and sustainable and transparent product development. In the future, virtual rendering will replace the actual fabric samples. Digital materials will become a key component in product development and sales. To fully realize this digital transformation, touch rendering is crucial.

Replicating touch-related physical contact experience through tactile interfaces is challenging in haptic technology, especially for flexible fibrous materials. Nevertheless, researchers developed many ways to mimic the surface characteristics of textile materials. The tactile property of textile materials greatly varies by fiber composition, types of yarns, and fabrication processes. The haptic display is generally carried out by extracting material surface features and converting them into artificial tactile stimulation to be perceived through rendering devices [1-6]. The fundamental idea of haptic technology is to communicate somatosensory information virtually or remotely. In a broad sense, haptic technology can be categorized as kinesthetic (force and motion) or tactile (touchrelated) [7,8]. Kinesthetic or force feedback interfaces are purported for a) measuring the forces and movement exerted by human limbs, b) computing the effect of this force on virtual objects and counterforce response, and c) applying the appropriate force feedback to the user. On the other hand, the tactile interfaces reproduce touch-related physical contacts with the environment, i.e., tactile sensations, such as pressure, texture, softness, wetness, thermal properties, and puncture, friction-induced sensations, such as slippage, adhesion, and micro failures, and object features, such as shape, edges, embossing and recessed features [9-16]. The artificial tactile simulation and how closely it imitates reality can vary from device to device, depending on the rendering technique.

The current study provides a comprehensive review of haptic technologies existing for textiles, based on scholarly works from the last ten years. Peer-reviewed work of researchers was collected using Google Scholar, PubMed, ScienceDirect, and IOPScience search engines. The review presents two major sections (sections 3 and 4) that illustrate the haptics and its rendering processes. Section-3 focuses on extracting surface properties from textile substrates and the suitable methods available for this purpose. Section-4 shows how various tactile rendering techniques employ virtual encoding of surface data of substrates to use with rendering devices. Section-5 presents the key challenges in tactile rendering and provides future research directives.

The Sensory Pathways of Touch

Touch is one of the five human sensual abilities. These sensual elements are necessary to identify and interact with objects in the environment. The human touch sensory system comprises various receptors in the skin layer, where every receptor detects different tactile sensory components. For instance, mechanoreceptors can recognize surface property; thermoreceptors can identify the temperature level. In the haptic research study, mechanoreceptors have gained a considerable amount of attention from researchers since these receptors can sense pressure, vibration, and surface roughness. Mechanoreceptors can be (i) fast adapting, (ii) moderate adapting, and (iii) slow adapting. Fast adapting mechanoreceptors (Pacinian) are efficient to sense minute and quick changes, and the response time is less than 0.1 sec. These receptors can perceive the surface roughness property of textiles and other materials. The human skin’s Hypodermis layer (the deep layer) carries the Pacinian cells. Moderate adapting mechanoreceptors (Meissner) can detect surface contact, such as the presence of an insect on the skin, and the response time is near to 1 sec. The Dermis layer contains these receptors. The slow adapting mechanoreceptors (Merkel) identify static pressure and shape of the object, which is close to the skin surface. The response time ranges from 10 to 100 sec [17].

In an actual touch interaction, the skin’s mechanoreceptors generate signals as the object in contact slides and transmit them to the human brain. Subsequently, the brain perceives the object’s surface information and additional properties [18]. In a virtual environment, the contact interface is unreal. Hence, artificial vibrations and interactions are presented to the skin through haptic devices and translated into touch perception in the brain.

Tactile Sensory Perception of Textiles

Traditionally, a human observer assesses the tactile perception of textile materials in a laboratory setup. This perception may vary from person to person depending on the palm prints and the skin type of the observer. Human assessment of the tactile quality of fabrics is a complex multi-dimensional analysis during which the fabric is touched and manipulated with the fingers to sense the properties. Such sensing helps perceive fabric softness, flexibility, compressibility, roughness, elasticity, bulkiness, and thermal characteristics. Artificially emulating the same sensory feel of textiles is the goal that haptic devices hope to achieve. To understand the haptic rendering techniques in reproducing the feeling of touch, knowledge of the physical characteristics of fabrics is necessary. The physical properties can be standalone such as surface roughness and other frictional properties, or a combined measure, such as fabric handle or hand.

Surface characterization

The surface roughness/smoothness of textiles is the most common measure used in determining the tactile properties of fabrics. The sliding friction between the fingertip skin and the fabric surface measures the surface roughness. This friction depends on various contact parameters, sliding speed, surface roughness, and texture [10]. Several measurement techniques exist to measure surface roughness analysis in fabrics (Table 1).

Table 1:Surface roughness characteristics and measurement techniques.

The friction and roughness tester within the Kawabata Evaluation System for fabrics (KES-f) remains a standardized system to test fabric surface characteristics. The tester uses steel fingertip contactors probing the fabric surface for measuring the mean deviation of surface contour, coefficient friction, and mean deviation of the coefficient of friction [19]. A similar and slightly advanced approach, the smart texture sensor, uses flexible fingerlike sensors instead of metallic sensors to mimic the human skin and sliding action while analyzing surface properties [57,58]. The texture sensor was introduced at the beginning of the 21st century. It uses a thin, flexible polymer-based film [57]. The smart texture sensors possess different surface feature extraction mechanisms [59,60]. Some use a rotational mechanism [61], and some have a fixed plane to assess the surface [10]. However, both devices have a finger-shaped probe covered by a texture sensor at the outer layer. Researchers have widely used polyvinylidene fluoride (PVDF) based flexible films as smart sensors because of their excellent piezoelectric property and cost-effectiveness [62]. PVDF is semi crystalline and synthesized from (-CH2-CF2-)n. The difference in electronegativity of carbon and fluorine atoms allows it to generate various electrical potentials during sliding under normal contact forces. The resulting potential difference is converted to a roughness measure [61]. Song, et al. [61] developed a fingertip shape smart sensor covered by PVDF film using a rotation disk for texture classification. The PVDF was connected with a micro- controller to process the raw data. The relative motion between the texture sensor and fabric surface is facilitated during the experiment by adjusting the desired sliding speed and normal contact force. Based on the same principle, Rahmalho, et al. [10] developed a hand-held probe to assess the surface friction of different fabrics at a fixed plane. The probe’s design allowed efficient handling and operation. The tip of the probe has polyvinyl chloride (PVC) covered soft surface, which was mounted on the artificial finger and allowed to slide in a linear or tangential direction to measure the surface friction. The probe cable connects to a computer for further characterization.

TriboTouch is another simplified setup to measure surface roughness, where observers use their right-hand index finger mounted with an accelerometer. The accelerometer can quantify vibration spectra that originated from the sliding rate. The vibration spectra computed as a function of sliding speed provide the surface roughness wavelength [1, 44]. The roughness of the three basic weave structures (plain, twill, and satin) tested by TriboTouch revealed that the resulting vibration due to surface friction increases with the yarn density along the weft direction. On the other hand, the vibration due to surface friction decreases with the yarn fineness along the weft direction. Finally, the frictioninduced vibration increases with the number of interlacements in the weave structure. Satin weave provided less vibrational feeling during the experiment [11].

Computer vision-based analysis of fabric roughness is evolving in recent times. 2D and 3D scanned images of fabrics in combination with advanced digital image processing techniques, and computer algorithms measure the fabric roughness parameters. Wang, et al. [63] developed an algorithm and a novel 3D scanner that could recognize the weave pattern in addition to the roughness of the textile substrate. Silvestre-Blanes, et al. [64] used multiple laser vision cameras to evaluate washed garments’ wrinkled surface and smoothness. The camera position significantly influences the estimated roughness of the fabric, causing inconsistencies. The computer vision technique for texture recognition backed up by artificial intelligence is needed for future textile haptic research. Capturing the surface property of materials using imaging is much more efficient than the previously described surface characterization technique.

Fabric hand

The aggregate physical characteristics of textiles that define the tactile sensory perception is called ‘fabric hand.’ Hand expressions are important fabric properties that experts commonly utilize to communicate the tactile nature of the fabric subjectively. Kawabata et al. identified (i) stiffness (Koshi), (ii) smoothness (Numeri), (iii) fullness (Fukurami), (iv) crispness (Shari), and (v) anti-drape (Hari) as primary hand expressions for suiting fabrics. KES-F instrument allows quantification of fabric hand using a set of objective measures and their correlation with subjective evaluations of tactile comfort. Four different low-stress physical properties of fabrics, (i) tensile and shearing, (ii) rigidity and bending, (iii) compression, and (iv) surface friction/roughness, are analyzed in the experiment. A total of 17 properties are measured for a given fabric, i.e., tensile strain, tensile resilience, linearity in extension, tensile energy, bending stiffness, bending hysteresis, shear rigidity, shear hysteresis, shear hysteresis at 5° shear angle, linearity in compression, compression energy, compression resilience, mean frictional coefficient, frictional roughness, geometrical roughness, fabric thickness, and weight. Translational equations convert the 17 individual properties into a primary and a total hand value. The total hand value defines the overall hand of the fabric estimated from the primary hand values. The total hand value is a numerical expression, ranging between one and five, describing the tactile quality of the fabric, where five means excellent hand and one means poor hand [65, 66].

Fabric Assurance by Simple Testing (FAST) is another fabric hand system that measures the fabric’s compression, bending, extension, and dimensional stability characteristics. The CSIRO Division of wool technology of Australia developed the FAST in 1980. The instrument is digitally enhanced and simple to evaluate the lowstress mechanical properties of lightweight woven substrates [10]. As fabric hand properties match the tactile sensation experienced by human hands, it is a critical element for artificial emulation of the sense of textile touch.

Haptic Rendering Techniques for Textiles

The term “tactile rendering” is associated with the touch sensation of virtual products, where tactile rendering devices artificially simulate the surface properties of a real object. It allows a human observer to feel the surface despite not touching the real object. The study of tactile rendering techniques started long ago with Braille Display made for blind people to perceive the written alphabets on a planar surface. Since then, scientists have invented several methods of tactile rendering. For example, touch screen for navigation [8], endovascular telesurgery [5], gaming interface, and vibrotactile stimuli [11,67,68]. However, to simulate the surface characteristic of textile substrates, the rendering technique should work at a micro-scale since yarn fineness and weave structures contribute to the roughness.

The surface area of the tactile display panel or stimulator is a crucial factor in determining the stimulation type. In local stimulation, a computer program controls a matrix of pins to generate the stimulating surface. The contacting area is somewhat less than or equal to the fingertip shape — for instance, braille display, shape memory alloy (SMA)-based miniature tactile simulator, HAPTEX (24 arrays of pins) [69]. In contrast, global stimulation consists of a large area for tactile sensation. Users are required to slide their fingertips over the examining surface to perceive this type of stimulation. It provides a better idea regarding the object’s surface properties [8]. The magnitude of local and global stimulation depends on the normal and frictional/lateral force originating at the stimulator panel, which causes touch feeling [70]. The normal force acts perpendicularly against the fingertip surface, and the relative motion between the tactile stimulator panel and the human fingertip creates the frictional/lateral force. Moreover, the touch sensation of the human observer depends upon the sliding frequency and the actuated frequency of the stimulator panel. The following sections describe how the measured surface characteristics are artificially generated in various tactile rendering devices.

Electrostatic display

The electrostatic display employs electrostatic force to provide artificial surface roughness stimuli. The two popular electrostatic display types are voltage-driven electrostatic and dielectric-based tactile displays. The voltage-driven electrostatic device consists of electrodes and a thin slider film. The electrodes are stationary and distributed around the surface of the device in a regular pattern. During the fingertip sliding activity, the electrodes cause differential voltages that provide a sense of surface friction. The inner surface of the thin film has a layer of aluminum coating. A linear decoder placed in the slider film spots the finger’s position. These devices can simulate surface textures at micrometer resolution with the electrodes positioned at a 1 mm pitch [12]. In a further development, Ishizuka, et al. [13] introduced Cr-based electrodes with a very high resolution amounted to less than a micrometer. The width of the electrode was 0.95 mm, with a pitch of 0.05 mm [13].

The surface’s insulating layer (alternative to the thin slider film) was of SiO2. In most electrostatic displays, a soft and flexible insulating layer overlaid on rigid touch panels is used [14].

The dielectric layer-based displays consist of actuators separated by dielectric layers [15]. The dielectric layers either contract or expand as a function of a voltage applied to the actuators. As a result, the stimulator tip rises or lowers and offers surface roughness stimuli. Penn Haptic Texture Toolkit HaTT [16], touch screen devices [1,71], and Braille windows [2] are created based on the electrostatic principle.

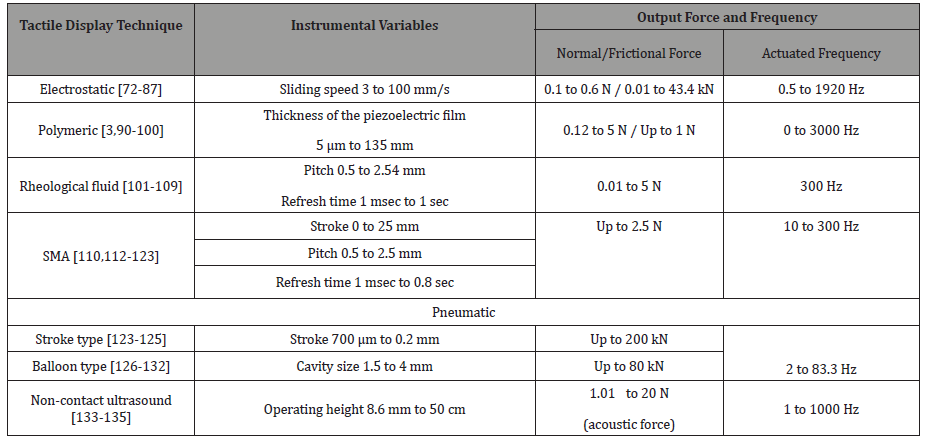

Even though the working principles are somewhat similar for the two display types, there are key differences in the measuring variables. The five most frequently used variables related to electrostatic tactile display are the normal contact force, frictional force, lateral force, sliding speed, and actuated frequency. Table 2 lists the values of these variables.

Table 2:Tactile rendering techniques and instrumental variables.

Polymeric display

Electroactive polymers (EAP) are widely used in actuation, chemical sensation, and physical stimuli. In recent years, EAPs have been employed to create touch panels that deform locally by raising or lowering the array of actuators when an external voltage is applied [88]. EAPs have some exceptional features, for instance, high strain with low modulus value and the ability to change shape. That makes them a perfect candidate for tactile actuation. There are two types of EAP tactile displays; (1) ionic EAPs and (2) electronic EAPs [89].

Ionic EAPs are conductive polymers or polymer-metal composites, generally synthesized from polypyrrole (PPy) and poly(3,4-ethylenedioxythiophene) (PEDOT). The construction of ionic EAP actuators demands an ion tank that facilitates ion migration during surface deformation under current supply. The voltage required for this type of actuator is very low and often less than 5V. On the other hand, electronic EAPs use dielectric elastomers and piezoelectric polymers. They do not need any ion reservoir; instead, they generate ultrasonic waves to produce tactile perception [89].

In piezoelectric polymer-based tactile displays, a propagating ultrasonic wave produces touch stimuli [3,4]. The wave is created by stimulating a pair of interdigital transducers patterned in PVDF piezoelectric polymer film. During a touch event, the ultrasonic wave propagates from one end of the transducer to the other end and returns to the source end. The process is repeated continuously throughout the touch. This reflection mechanism creates a standing wave between the pair of transducers, which gives the perception of surface texture [3]. Some other piezoelectric tactile displays have a moving part down under the probe, which assists in modulating the traveling wave during finger-sliding. This modulating traveling wave helps to provide actual texture perception depending on finger placements [4]. The systematic review found 14 scholarly works on the piezoelectric tactile display. Normal contact force, frictional force, the thickness of the piezoelectric film, and actuated frequency are the control variables in these displays (Table 2).

Rheological fluid display

The rheological fluid is a special carrier fluid capable of changing the form from liquid to pseudo-solid state under electric and magnetic fields. The fluid particles are randomly oriented under normal conditions and with an applied external magnetic field, the fluid viscosity changes due to controlled orientation. The rheological fluid is usually a kind of oil. Electrically active fluids are known as ER, and magnetically active fluids are known as MR. MR fluid-based haptic displays are primarily used in endovascular telesurgery [5,104-109]. The device has two main parts; master and slave. The master site consisted of a rigid catheter embedded with MR fluid container at the user end, which allowed a person to work with the haptic system depending on the applied magnetic field.

The rigid catheter provided a passive haptic sensation concerning the user’s axial and radial motion in the haptic interface. The slave site collected axial and radial motion values from the master site and replicated them in a VR system. However, whenever the rigid catheter moved to the danger zone or vascular wall, the slave site showed a danger signal [5]. The evaluation of this haptic interface using human subjects revealed that a little bit of training of human subjects enhanced the performance. The ER fluid-based tactile interfaces work based on the pressure-driven flow of ER fluid placed between plates. When no voltage is applied, ER fluid remains liquid. In this case, if the human observer slides his fingers over the tactile display, he will not feel any opposing force or vibration. ER fluid turns into a pseudo-solid state when an external voltage is applied, which provides opposing force or vibrational feeling. The device is equipped with a dynamic mechanical analyzer to measure the emerging resistive force concerning different amounts of the applied voltage. The study revealed that the resistive force or vibrational feeling increases with the applied voltage [6]. The advantage of MR/ER fluid display is that it can quickly switch the state from pseudo-solid to fluid or fluid to pseudo-solid. The time taken for changing the state is known as refresh time. If several MR/ER-based tactile actuators are arranged to form an array, they can generate effective feedback. Table 2 lists the most frequently controlled variables and their values in the rheological fluid display.

Shape memory alloy display

A shape memory alloy (SMA) is a smart material that deforms under cold temperature but retains its original shape when subjected to heat. There are two types of SMA display; such as (1) MEMS (Micro-Electro- Mechanical Systems) based display and (2) wire-based display. The MEMS-based tactile display has an SMA- based thick film actuator that deforms its shape under heat to facilitate the raising or lowering of the pins [110]. The device mainly consisted of pins, cap layer (for hiding the pins), springshaped SMA actuator, and micro-heater [110]. When an electrical voltage is applied, the micro-heater heats the actuator. As a result, SMA spring-shaped actuator retains its flat shape and raises the pin. On the other hand, when the actuator is cooled, the spring deforms into a curve shape that pushes the pin down [110]. The pin’s vertical upward and downward movement defines the stroke length. The wire-based tactile display uses SMA wires that shrink under electric pulse. Suppose T2 is the raised temperature after the SMA wire receives a weak current, then the wire shrinks lengthwise. It returns to its previous dimension and temperature T1 when the supply current is withdrawn. The advantage of this SMA wire is that it could rapidly cool down and retain the original form [111]. Commonly, the pulse current creates a micro-vibration effect in SMA wire that generates touch sensation for the human observer. The device could generate up to 300Hz frequency [111]. See table 2 for SMA tactile display, measuring variables, and their numerical parameters.

Pneumatic display

The pneumatic displays are mainly two types, a) stroke display and b) balloon display. The stroke display uses pneumatic pressure to raise or lower the array pins of the contactor for tactile feedback. The air supply is controlled based on the texture value of the textile substrate [8,123]. On the other hand, the balloon displays have cavities on the actuation layer made of silicone material in most cases. Instead of raising the pin, the balloon displays produce airborne layers using the cavities for touch sensation [126-132].

Noncontact ultrasound display

Display techniques discussed thus far are direct contact methods for tactile feedback. The ultrasound technique is a non-contact method for producing an airborne tactile sensation. Takayuki Hoshi and his colleagues invented ultrasound-based non-tactile displays in 2008, and the development of this invention is still going on. The display does not require physical touch by a human observer. Instead, it uses an aerial imaging system to produce airborne layers on the top surface of the display. So, whenever the observer slides a palm over the airborne layer, the roughness can be felt [133]. The ultrasound transducers create three- dimensional forms in space employing acoustic radiation pressure covering a wide range of frequencies with low spatial resolution [134]. Comparing three ultrasound tactile displays with 10 x 10, 10 x 20, and 20 x 20 transducers (single, double, and quad tiles) showed that the tactile feedback sensitivity depended on four parameters. They are the workspace span, resolution of the tactile display, the magnitude of the force feedback created by the airborne layer, and robustness of the simulation. The results showed that the workspace elevation and magnitude of the force feedback were almost similar for the three displays. The workspace increased with the number of transducers along the plane. However, the robustness decreased with the number of tiles [135]. Since the ultrasound tactile display creates an airborne layer instead of a solid surface, it has an operating height from the ultrasound transducers’ basement, which generates acoustic force with the help of a base operating frequency of 40 kHz. Later, modulating this operating frequency generates the actuated frequency for human touch sensation. Table 2 lists the most widely used variables and their values in ultrasound tactile display.

Key Challenges and Future Research Perspectives

Textile materials are complex multi-scale structures. A fabric, for instance, is a 2D plane with indentations due to weave or knit patterns. Within the fabric, yarns are arranged in horizontal and vertical axes. These yarns are, in turn, made of strands of fibers arranged helically. Depending on whether these yarns are filamentbased or staple fiber-based, they can protrude on the surface of the yarn, providing a whiskery surface. When a human observer touches the surface of a fabric, all these structures generate very complex stimuli that are very hard to delineate. In such a scenario, attempting to re-create the same stimuli through tactile rendering is challenging. Nevertheless, researchers are progressing to achieve close-to-real textile stimuli through tactile rendering.

Several rendering techniques discussed here attempt to generate stimuli signals to emulate the sliding touch of textile materials. Both contact and non-contact methods are limited to operating in a rigid framework, i.e., the whole display does not deform like a piece of fabric. This property is essential because when a human observer handles a fabric, the stimuli originate not entirely from surface sliding. Instead, a complex interaction happens where the fabric is deformed, compressed, and strained. The resultant perception about the fabric is possibly a non-linear cumulative phenomenon, which cannot be delineated. There is little or no research addressing this issue.

Since tactile perception is related to human neurophysiology, it may be helpful to study the neural responses of humans as they evaluate a textile material. Comparing those neural responses with those attained with the rendering devices can show how much a device can successfully emulate an actual textile material. Additionally, the physical evaluation varies from person to person due to individual variances in the applied forces, duration and frequency of contact, and whether they use one hand or both. These issues have to be factored into the design of rendering devices so that a closed feedback loop forms between the device and the human observer.

Conclusion

The study presented a review of various technologies available to render tactile stimulation to humans, particularly those that mimic textile materials. Textile industries relied on human observers to evaluate the handle or feel of manufactured fabrics. The evolution of devices such as KES-F and FAST gradually phased in to replace the human observer. The complexity and lack of ability to communicate human perception made these devices unsuitable for digital systems such as online retailing and sampling. The emergence of tactile rendering devices attempts to fill this gap by offering the ability to store and transfer textile stimuli through a digital medium.

Acknowledgement

None.

Conflict of Interest

Authors declare no conflict of interest.

References

- Milburn J (2016) Aussies send 85% of textiles to landfill. Textile Beat: 18.

- Charpail M (2017) What's wrong with the fashion industry?

- Shirvanimoghaddam K, Motamed B, Ramakrishna S, Naebe M (2020) Death by waste: Fashion and textile circular economy case. Science of The Total Environment 718: 137317.

- Karaosman H, Brun A, Morales-Alonso G (2017) Vogue or vague: sustainability performance appraisal in luxury fashion supply chains, in Sustainable management of luxury. Springer: 301-330.

- EPA (2020) Textiles: Material-Specific Data.

- Yalcin-Enis I, Kucukali-Ozturk M, Sezgin H (2019) Risks and management of textile waste, in Nanoscience and Biotechnology for Environmental Applications. Nanoscience and Biotechnology for Environmental Applications: 29-53.

- Hawley JM (2006) Textile recycling: A systems perspective, in Recycling in textiles. Woodhead Publishing Limited, UK.

- Fletcher K (2008) Sustainable fashion and textiles: design journeys, Earthscan. London, Sterling: 13.

- Wang Y (2010) Fiber and textile waste utilization. Waste and biomass valorization 1(1): 135-143.

- Pensupa N, Leu SY, Hu Y, Du C, Liu H, et al (2017) Recent trends in sustainable textile waste recycling methods: Current situation and future prospects. Chemistry and Chemical Technologies in Waste Valorization: 189-228.

- Patti A, Cicala G, Acierno D (2021) Eco-Sustainability of the Textile Production: Waste Recovery and Current Recycling in the Composites World. Polymers 13(1): 134.

- Gardetti MA, Torres AL (2017) Sustainability in fashion and textiles: values, design, production and consumption. Routledge.

- Lu S (2021) State of U.S. Textile and Apparel Manufacturing: Output, Employment, and Trade.

- Altun Ş (2016) Recycling of Textile Production and Usage Wastes, Environmental and Economic Effects; Uşak Chamber of Commerce and Industry Report. Uşak Chamber of Commerce and Industry, Uşak,

- USDA (2021) Cotton Sector at a Glance. Economic Research Service 2020

- Ekström KM (2014) Waste management and sustainable consumption: reflections on consumer waste. Routledge.

- Mui Y (2010) Consumer complaints have companies rethinking how to dispose of unsold inventory. Washington Post A: 8.

- Domina T, Koch K (1997) The textile waste lifecycle. Clothing and Textiles Research Journal 15(2): 96-102.

- Claudio L (2007) Waste couture: Environmental impact of the clothing industry. National Institute of Environmental Health Sciences.

- (2019) Agency UEP Advancing sustainable materials management: 2017 fact sheet. United States Environmental Protection Agency, Office of Land and Emergency.

- Lei M (2021) Wasted Traces/Wasted Spaces: Deploying Pre-Consumer Textile Waste to Activate Vacant Storefronts for Transitional Homeless Housing. Pratt Institute, USA.

- DeVoy JE, Congiusta E, Lundberg DJ, Findeisen S, Bhattacharya S (2021) Post-Consumer textile waste and disposal: Differences by socioeconomic, demographic, and retail factors. Waste Management 136: 303-309.

- Medina M (1997) The effect of income on municipal solid waste generation rates for countries of varying levels of economic development: a model. Journal of Solid Waste Technology and Management 24(3).

- Bartelings H, Sterner T (1999) Household waste management in a Swedish municipality: determinants of waste disposal, recycling and composting. Environmental and resource economics 13(4): 473-491.

- Daneshvary N, Daneshvary R, Schwer RK (1998) Solid-waste recycling behavior and support for curbside textile recycling. Environment and Behavior 30(2): 144-161.

- Stanton A (2021) What Is Fast Fashion, Anyway?

- Morgan LR, Birtwistle G (2009) An investigation of young fashion consumers' disposal habits. International journal of consumer studies 33(2): 190-198.

- Norum PS (2017) Towards sustainable clothing disposition: Exploring the consumer choice to use trash as a disposal option. Sustainability 9(7): 1187.

- Ütebay B, Çelik P, Çay A (2020) Textile wastes: Status and perspectives, in Waste in Textile and Leather Sectors. IntechOpen.

- Stone C, Windsor FM, Munday M, Durance I (2020) Natural or synthetic–how global trends in textile usage threaten freshwater environments. Science of the Total Environment 718: 134689.

- Johnson S, Echeverria D, Venditti R, Jameel H (2020) Supply Chain of Waste Cotton Recycling and Reuse: A Review. AATCC Journal of Research 7(1): 19-31.

- Chapagain AK, Hoekstra AY, Savenije HHG, Gautam R (2006) The water footprint of cotton consumption: An assessment of the impact of worldwide consumption of cotton products on the water resources in the cotton producing countries. Ecological economics 60(1): 186-203.

- Bevilacqua M, Ciarapica FE, Mazzuto G, Paciarotti C (2014) Environmental analysis of a cotton yarn supply chain. Journal of Cleaner Production 82: 154-165.

- Wiedemann SG, Yan MJ, Henry BK, Murphy CM (2016) Resource use and greenhouse gas emissions from three wool production regions in Australia. Journal of Cleaner Production 122: 121-132.

- Ibrahim NA, Abdel Moneim NM, Abdel Halim ES, Hosni MM (2008) Pollution prevention of cotton-cone reactive dyeing. Journal of Cleaner Production 16(12): 1321-1326.

- Wang YL, Lee YH, Chiu IJ, Lin YF, Chiu HW (2020) Potent impact of plastic nanomaterials and micromaterials on the food chain and human health. Int J Mol Sci 21(5): 1727.

- Palamutcu S (2010) Electric energy consumption in the cotton textile processing stages. Energy 35(7): 2945-2952.

- Zhang Y, Xin L, Rufeng X, Zengwei Y (2015) Life cycle assessment of cotton T-shirts in China. The International Journal of Life Cycle Assessment 20(7): 994-1004.

- Bick R, Halsey E, Ekenga CC (2018) The global environmental injustice of fast fashion. Environmental Health 17(1): 1-4.

- Aiama D, Carbone G, Cator D, Challender D (2016) Biodiversity risks and opportunities in the apparel sector. International Union for Conservation of Nature: Gland, Switzerland.

- Kanmani S, Gandhimathi R (2013) Assessment of heavy metal contamination in soil due to leachate migration from an open dumping site. Applied Water Science 3(1): 193-205.

- Salem Z, Hamouri K, Djemaa R, Allia K (2008) Evaluation of landfill leachate pollution and treatment. Desalination 220(1-3): 108-114.

- Udeani N (2017) Textile Waste Recycling: An Innovative Creativity for Entrepreneurial Sustainability in Nigeria. Tropical Built Environment Journal 1(6).

- Nwosu EE, Pepple GT (2016) Site selection and analysis of solid waste dumpsites in Ile-Ife, Nigeria. in FIG Working Week.

- Allwood JM, Laursen SE, Malvido de Rodríguez C, Bocken NMP (2006) Well dressed. The present and future sustainability of clothing and textiles in the United Kingdom.

- Wicker A (2016) Fast Fashion Is Creating an Environmental Crisis, in Newsweek Magazine.

- Hamner B (2006) Effects of green purchasing strategies on supplier behaviour, in Greening the supply chain. Springer: 25-37.

- Meyer A (2001) What's in it for the customers? Successfully marketing green clothes. Business Strategy and the Environment 10(5): 317-330.

- Tisserant A, Pauliuk S, Merciai S, Schmidt J, Fry J, et al. (2017) Solid waste and the circular economy: a global analysis of waste treatment and waste footprints. Journal of Industrial Ecology 21(3): 628-640.

- Sun W, Chen J, Chen L, Wang J, Zhang Y (2016) Coupled electron beam radiation and MBR treatment of textile wastewater containing polyvinyl alcohol. Chemosphere 155: 57-61.

- Ebeling JM, Sibrell PL, Ogden SR, Summerfelt ST (2003) Evaluation of chemical coagulation–flocculation aids for the removal of suspended solids and phosphorus from intensive recirculating aquaculture effluent discharge. Aquacultural Engineering 29(1-2): 23-42.

- Roy R, Fakhruddin ANM, Khatun R, Islam MS (2010) Reduction of COD and pH of textile industrial effluents by aquatic macrophytes and algae. Journal of Bangladesh Academy of Sciences 34(1): 9-14.

- Ciardelli G, Capannelli G, Bottino A (2001) Ozone treatment of textile wastewaters for reuse. Water Sci Technol 44(5): 61-67.

- Lin SH, Peng C (1995) Treatment of textile wastewater by Fenton's reagent. Journal of Environmental Science & Health Part A 30(1): 89-98.

- Przystaś W, Zabłocka-Godlewska E, Grabińska-Sota E (2013) Effectiveness of dyes removal by mixed fungal cultures and toxicity of their metabolites. Water Air Soil Pollut 224(5): 1534.

- Abadulla E, Tzanov T, Costa S, Robra KH, Cavaco-Paulo A, et al. (2000) Decolorization and detoxification of textile dyes with a laccase from Trametes hirsuta. Appl Environ Microbiol 66(8): 3357-3362.

- Tauber MM, Guebitz GM, Rehorek A (2005)Degradation of azo dyes by laccase and ultrasound treatment. Appl Environ Microbiol 71(5): 2600-2607.

- Cardoso JC, Bessegato GG, Zanoni MVB (2016) Efficiency comparison of ozonation, photolysis, photocatalysis and photoelectrocatalysis methods in real textile wastewater decolorization. Water Res 98: 39-46.

- Punrattanasin N, Nakpathom M, Somboon B, Narumol N, Rungruangkitkrai N, et al. (2013) Silk fabric dyeing with natural dye from mangrove bark (Rhizophora apiculata Blume) extract. Industrial Crops and Products 49: 122-129.

- Meksi N, Haddar W, Hammami S, Mhenni MF (2012) Olive mill wastewater: A potential source of natural dyes for textile dyeing. Industrial Crops and Products 40: 103-109.

- Jabasingh SA, Sahu P, Yimam A (2016) Enviro-friendly biofinishing of cotton fibers using Aspergillus nidulans AJSU04 cellulases for enhanced uptake of Myrobalan dye from Terminalia chebula. Dyes and Pigments 129: 129-140.

- Kant R (2011) Textile dyeing industry an environmental hazard.

- Senthilkumar M, Gnanapragasam G, Arutchelvan V, Nagarajan S (2011) Treatment of textile dyeing wastewater using two-phase pilot plant UASB reactor with sago wastewater as co-substrate. Chemical Engineering Journal 166(1): 10-14.

- Wang J, Yan J, Xu W (2015) Treatment of dyeing wastewater by MIC anaerobic reactor. Biochemical Engineering Journal 101: 179-184.

- Gnanapragasam G, Senthilkumar M, Arutchelvan V, Velayutham T, Nagarajan S (2011) Bio-kinetic analysis on treatment of textile dye wastewater using anaerobic batch reactor. Bioresour Technol 102(2): 627-632.

- Kıpçak E, Akgün M (2013) In situ gas fuel production during the treatment of textile wastewater at supercritical conditions. Water Sci Technol 67(5): 1058-1067.

- Morris M, Waldheim L (1998) Energy recovery from solid waste fuels using advanced gasification technology. Waste management 18(6-8): 557-564.

- Bosmans A, Vanderreydt I, Geysen D, Helsen L (2013) The crucial role of Waste-to-Energy technologies in enhanced landfill mining: a technology review. Journal of Cleaner Production 55: 10-23.

- Nishio N, Nakashimada Y (2007) Recent development of anaerobic digestion processes for energy recovery from wastes. J Biosci Bioeng 103(2): 105-112.

- Holm-Nielsen JB, Al Seadi T, Oleskowicz-Popiel P (2009) The future of anaerobic digestion and biogas utilization. Bioresource technology 100(22): 5478-5484.

- Strähle J, Philipsen F (2017) Closed-loop production: a literature review. Green Fashion Retail: 27-47.

- Zonatti WF, J. Baruque-Ramos, Duleba W (2016) Brazilian scope of management and recycling of textile wastes, in Natural Fibres: Advances in Science and Technology Towards Industrial Applications. Springer: 429-439.

- Zamani B (2014) Towards understanding sustainable textile waste management: Environmental impacts and social indicators. Chalmers Tekniska Hogskola (Sweden).

- Haule LV, Carr C, Rigout M (2016) Preparation and physical properties of regenerated cellulose fibres from cotton waste garments. Journal of cleaner production 112: 4445-4451.

- Bhatia D, Sharma A, Malhotra U (2014) Recycled fibers: an overview. International Journal of Fiber and Textile Research 4(4): 77-82.

- Nahil MA, Williams PT (2010) Activated carbons from acrylic textile waste. Journal of analytical and applied pyrolysis 89(1): 51-59.

- Directive E (2008) Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Official Journal of the European Union L 312(3).

- Vats S, Rissanen M (2016) Parameters affecting the upcycling of waste cotton and PES/CO textiles. Recycling 1(1): 166-177.

- Nielsen R, Schmidt A (2014) Changing consumer behavior towards increased prevention of textile waste: background report. Nordisk Ministerrå

- EPA (2021) Textile Mills Effluent Guidelines.

- OFR (1974) Textile Mills Point Source Category in 40. Office of the Federal Register.

- National Pollutant Discharge Elimination System (NPDES).

- Tiseo I (2017) Water and wastewater key figures in the U.S. Statista.

- Wise H (1996) Preliminary Study of the Textile Mills Category. U.S. Environmental Protection Agency.

- EPA (2021) Preliminary Effluent Guidelines Program Plan.

- Chen JY, Polston K, Nicols E, Phung B (2021) A study on textile recycling in college student residence areas. The Journal of The Textile Institute: 1-8.

- Shahbandeh M (2021) U.S. apparel and footwear resale market - statistics & facts. Statista.

- Chua MH, Cheng W, Goh SS, Kong J, Li B, et al, (2020) Face masks in the new COVID-19 normal: materials, testing, and perspectives. Research 2020: 7286735.

- Kane IA, Clare MA (2019) Dispersion, accumulation, and the ultimate fate of microplastics in deep-marine environments: A review and future directions. Frontiers in earth science 7: 80.

- Peng Y, Wu P, Schartup AT, Zhang Y (2021) Plastic waste release caused by COVID-19 and its fate in the global ocean. Proceedings of the National Academy of Sciences 118(47): e2111530118.

-

Tarkan AYDIN, Beste AYDIN, Mehmet Kemal AKIN. Different Pattern Designs with Printing Method on Classic Worsted Wool Fabrics. J Textile Sci & Fashion Tech 9(3): 2022. JTSFT.MS.ID.000714.

-

Tactile sensation, Surface properties, Virtual texture simulation, Haptics of textile, Soft material haptic

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.