Mini Review

Mini Review

Recent Developments in Textile Materials Based on the Piezoelectricity Concept

Gabriela Maestri1, Claudia Merlini2, Leonardo M Rincon1 and Fernanda Steffens1*

1Graduate Program in Textile Engineering (PGETEX), Federal University of Santa Catarina, Brazil

2Special Coordinator of Materials Engineering, Federal University of Santa Catarina, Brazil

Fernanda Steffens, Graduate Program in Textile Engineering (PGETEX), Federal University of Santa Catarina, Brazil.

Received Date: June 07, 2022; Published Date: June 20, 2022

Abstract

Textile materials stand out for presenting various characteristics that allow them to be used in technological solutions in the most diverse areas. In this sense, one may emphasize the growth in studies that cover the piezoelectric technology inserted in the textile area. This study aimed to gather the main and current innovations surrounding piezoelectric textile materials to highlight the various possibilities that this theme offers. For such, a search was carried out with keywords that relate piezoelectricity to textile materials, presenting 132.409 scientific papers published in the last five years. Lastly, this bibliographic review contributed positively to a view of opportunities inserted in the large textile area. Moreover, it was possible to observe some innovations and the ascension of the theme in terms of new developments.

Keywords:Piezoelectricity; Textiles; Technological products

Introduction

Textile materials stand out more and more due to their technological characteristics, and one may evince the piezoelectric technology inserted in the area of textile materials [1]. Piezoelectricity is the ability of a material to generate electrical energy from a mechanical stimulus and vice-versa [2]. This property was first found in natural crystals and later discovered in ceramic and polymeric materials [2,3].

The use of this technology in textile materials is praised, especially due to the flexibility and lightness that the textile products offer, allowing the necessary movement for the piezoelectric textile product to generate electricity in a simple manner [4].

The use of piezoelectric textiles is found in various areas such as the medical and health fields [5], with materials able to generate an intravenous electrical field used for electrotherapies, brain stimulation, and skin tissue regeneration, among others [3].

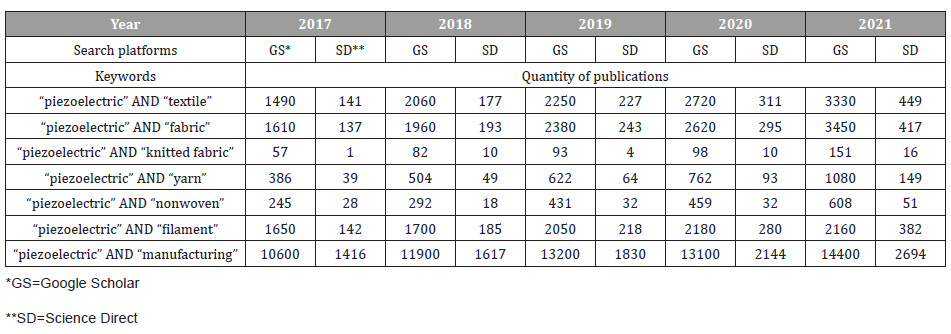

With this, developments concerning the mentioned theme are on the rise, and this may be determined through searches on platforms such as Google Scholar and Science Direct, considering keywords related to the theme. For such, a search on the platforms mentioned before was carried out considering the following terms: piezoelectric AND textile, piezoelectric AND fabric, piezoelectric AND “knitted fabric”, piezoelectric AND yarn, piezoelectric AND nonwoven, piezoelectric AND filament, AND piezoelectric and manufacturing. This search considered only scientific papers, excluding patents and/or books, and the state of the art defined for the search was five years, from 2017 to 2021.

Based on the search results, regardless of the words selected, an increase in publications was noticed since, in total, 132.409 scientific papers were published in the last five years that relate piezoelectricity to textile materials. The data may be observed in Table 1. It is possible to observe that the search keyword covering piezoelectricity and knitted fabric has the lowest number of publications. In this sense, it is verified as a potential area of the textile industry to be explored in terms of products with piezoelectric properties. This ends up being quite interesting since knitting technology provides materials with elastic characteristics, which are important for developing the piezoelectric behavior. Among the words selected, the highest numbers in terms of publications were verified for the term that covers the manufacturing of piezoelectric materials, once again confirming the great potential of this technology.

Table 1:Publications from 2017 to 2021 about the theme of piezoelectric textiles.

From this study, some examples of applications of piezoelectric textile materials were verified in the literature, confirming the various possibilities that this theme offers.

Applications of Piezoelectric Textile Materials

Textile products with piezoelectric characteristics are inserted in the most diverse areas. For example, one may mention the development of piezoelectric and flexible acoustic sensors [6], devices built in layers based on piezoelectricity concepts to capture electrical energy [7], and materials for use in the medical area with the ability to release drugs [3], among others.

Monitoring of human conditions

A study by Naeem et al. [1] evinced the development of a piezoelectric textile device built from polyvinylidene fluoride (PVDF) nanofibers obtained from the electrospinning method incorporated into a knitted fabric with the aid of a sewing technique for use in monitoring the angles of the human body during a given activity. The results confirmed the piezoelectric behavior of the device, given that its electrical response increased as an increase in the curvature (angle variation) of the human body occurred [1].

High-tech piezoelectric products

Yu et al. [8] presented a waterproof piezoelectric textile device with good breathability properties, characteristics still challenging for a piezoelectric material due to the need to incorporate electrodes at the ends. In this study, the authors developed a material built in layers, with the outermost layers being of conductive woven fabric with zinc oxide (ZnO) nanoparticles and a central layer formed of electrospun PVDF nonwoven fabric. The final device presented an average voltage of 1.6 ± 0.08 V and maintained this result even after being submitted to 3600 cycles of a pressure test. Regarding the hydrophobicity test, the material corresponded to a contact angle ranging from 119.87° to 107.41°, thus confirming its waterproof characteristic [8].

Textile machinery components

The so-called “Piezo technology” is present in components for manufacturing textile products. An example is the selection of piezoelectronic needles for use in both weft and warp knitting machines in circular Jacquard and Raschel machines, respectively, developed by Johnson Matthey Piezo Products GmbH®. The set of needles operates electronically and contains piezoelectric technology based on ceramic materials. This technology provides an increase in the productivity of the mentioned machinery since the actuators based on piezoceramics have high quickness in their process compared to the selection of needles. Moreover, it offers a cost reduction, given that it consumes less energy, in addition to not requiring a cooling system because the actuators do not heat up during the operation. Other beneficial characteristics of the technology are the innovative designs, ability to produce different patterns, and long lifespan [9].

Challenges and Perspectives

Piezoelectric materials find challenges regarding their development and the definition of standardized tests to verify the piezoelectric effect, especially when the textile device in question is built in layers, with each layer possibly being formed by a different textile technology, such as weaving, knitting, and nonwoven fabric, among others [2].

However, reinforcing the data presented in Figure 1, in which different textile technologies associated with the term piezoelectricity were selected, one may confirm that the mentioned theme is on the rise and covers various areas within the textile chain.

Conclusions

This work gathered innovations surrounding piezoelectric textile materials, highlighting some areas of application of such products. Through a search on scientific paper platforms, this study evinced the growth in publications regarding the keywords that cover piezoelectricity and the textile area.

Acknowledgement

The authors would like to thank the Brazilian National Council for Scientific and Technological Development (CNPq) and the Coordination for the Improvement of Higher Education Personnel (CAPES) for their assistance in this work.

Conflict of Interest

Authors declare no conflict of interest.

References

- Javed Z, Rafiq L, Anwaar Nazeer M, Siddiqui S, Babar Ramzan M, et al. (2022) Piezoelectric nanogenerator for bio-mechanical strain measurement. Beilstein J Nanotechnol 13: 192-200.

- Scheffler S, Poulin P (2022) Piezoelectric Fibers: Processing and Challenges. ACS Applied Materials & Interfaces 14,15: 16961-16982.

- Yilmaz H (2022) Medical Uses of Synthetic Piezoelectric Polymers; 2020-2021 Overview. J Inno Sci Eng 6(1): 138-159.

- Si S, Sun C, Qiu J, Liu J, Yang J (2022) Knitting integral conformal all-textile strain sensor with commercial apparel characteristics for smart textiles. Applied Materials Today 27: 101-508.

- Yahyapour R, Sorayani Bafqi MS, Latifi M, Bagherzadeh R (2022) Hybrid multilayered piezoelectric energy harvesters with non-piezoelectric layers. Journal of Materials Science: Materials in Electronics 33: 1783-1797.

- Giglio A, Neuwerk K, Haupt M, Maria Conti G, Paoletti I (2022) Textile-Based Sound Sensors (TSS): New Opportunities for Sound Monitoring in Smart Buildings 2(2):296-306.

- Shi J, Beeby SP (2022) The effect of fabric properties on the performance of a textile based ferroelectret generator toward human body energy harvesting. Smart Materials and Structures 31(4): 045015.

- Feng W, Chen Y, Wang W, Yu D (2022) A waterproof and breathable textile pressure sensor with high sensitivity based on PVDF/ZnO hierarchical structure. Colloids and Surfaces A: Physicochemical and Engineering Aspects 633 Part 2: 127-890.

- Piezoproducts (2022) Piezo technology for textile machines. Textile modules with high quality Piezoceramic actuators for single needle selection.

-

Gabriela Maestri, Claudia Merlini, Leonardo M Rincon, Fernanda Steffens. Recent Developments in Textile Materials Based on the Piezoelectricity Concept. J Textile Sci & Fashion Tech 9(5): 2022. JTSFT.MS.ID.000723. DOI: 10.33552/JTSFT.2022.09.000723.

-

Fashion, Eroticism, Branding, Marketing mix, Construct measurement

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.