Research Article

Research Article

Optimization Study of Machine-Washed Decontamination Effect of Starch Soil Cloth of Pure Cotton

Anhua Zhong, Professor, Department of Textile Science and Engineering, School of Fashion Design, Wuhan Textile University, China.

Received Date: December 09, 2019; Published Date: December 16, 2019

Abstract

According to the principle of orthogonal experimental, a four-factor and three-level washing experiment has been designed, and the washing of the self-made cotton dirty cloth of starch was carried out for several times. The properties of the washed fabric were analyzed by using the range analysis method. The study found that when the washing time is 20 minutes, the washing temperature is 35 degrees, the washing intensity is medium, and the detergent dosage is 20g, it can make the starch dirty cloth achieve the equilibrium optimal effect of the washing rate, dimensional change rate, strength and fading degree.

Keywords: Machine washing; Decontamination; Orthogonal experiment; Starch soil cloth; Range analysis method

Introduction

The damage for clothing during wearing and washing is extremely great. At present, research at home and abroad mainly focuses on the influence of washing conditions on a certain index[1,2], the physical properties of clothes after washing and their relationships [3]. There are also related studies that explored the optimized process parameters of denim clothes [4]. However, this study is devoted to considering the comprehensive influence of multiple washing conditions on multiple physical properties, so as to arrive at an optimized washing program that can not only achieve the purpose of washing clothes, but also reduce the deformation, discoloration and damage to the material of the garment. Thereby, the good appearance and performance of the garment can be maintained [5]. Relevant data shows that the temperature of water, the amount of detergent, the kind of detergent, and the influence of mechanical forces are important factors affecting the decontamination effect [6,7]. Therefore, these washing conditions can be used as reference data for this experiment to wash stain cloth under different washing conditions. Cotton fabrics have always been loved by people because they are comfortable to wear, soft to the touch, breathable, and moisture permeable, so they have been the subject of this experiment.

Materials and Methods

Under a specific washing condition, the cleaning effect of different stains is different. We made cotton dirty cloth of starch in our own and performs orthogonal washing experiments on the stained cloth. The relevant physical properties of the washed stained cloth have been calculated and measured, and uses the range analysis method to analyze the data to obtain the optimal washing program of the starch cotton stained cloth, while washing the stain cloth, it can also ensure that the strength loss is less, and the condition of fading and deformation are better.

Materials

Experimental equipment: WSB-Ⅱ intelligent digital whiteness meter, YG065H electronic fabric strength machine, precision booster electric mixer, YG (B) 741X shrinkage oven, electronic scale, Midea M880-8100WDQCG fully automatic washing machine.

Experimental materials:Raw materials: cotton twill (width 2.35m, weight 320g / m), Blue Moon laundry detergent (neutral detergent) Homemade ingredients: purple rice flour.

Methods

Experiment preparation: According to the determination of GB / T 13174-2008 detergents for the detergency of laundry detergents and the cyclic washing performance, a homemade starch stain cloth was made, and the size of the stain cloth was 15cm × 15cm.

1. Preparation of dirty cloth of starch

• Materials and equipment: Purple rice flour, cotton cloth, precision booster electric stirrer, microwave oven, beaker, measuring cup, dropper.

• Materials and equipment: Purple rice flour, cotton cloth, precision booster electric stirrer, microwave oven, beaker, measuring cup, dropper.

Experimental scheme design

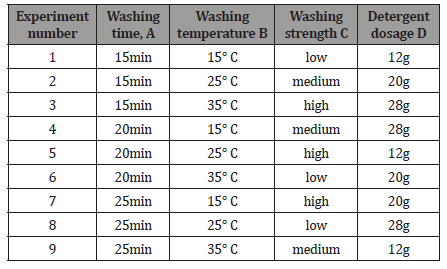

According to the principle of orthogonal experiment, a total of 9 washings were performed in this experiment (Table 1).

Table 1:Four-factor and three-level orthogonal experiment [7].

Testing standards: After washing the cotton stained cloth, we measure and calculate its washing rate, dimensional change rate, tear strength, distinguish its gray level, and measure the same value of the original cloth at the same time to calculate the relevant index parameters. According to related research [8], polyester fabrics are the easiest to rinse, wool nylon fabrics are more difficult to rinse, and cotton fabrics are in between, so we set the rinse times of cotton fabrics twice in the experiment.

1) Washing rate= (RW-RS)/(RO-RS) *100% [9].

RW means the reflectance value after washing of stained cloth, RO means the reflectance value before washing of stained cloth, and RS means the reflectance value of raw fabric. The reflectance value can be measured using WSB-Ⅱ intelligent digital whiteness meter.

2) Dimensional changes rate =(MS-MO)/MO*100%

MS means the size of stained cloth after washing, MO means the size of stained cloth before washing

3) Tear strength

By using the YG065H electronic fabric strength machine, the tear strength of each cloth after washing can be obtained, and the tear strength of the original cloth is 477N.

4) Gray level

The gray value of the fabric before and after washing was evaluated by using the gray sample card for evaluation of discoloration drafted by Shanghai Textile Industry Technical Supervision. This time, a five-level and nine-level gray card is used. The first level represents the largest color difference, and the fifth level represents almost no color difference between the two pieces of fabric.

Principles of range analysis:Orthogonal experiment is a design method to study multi-factors and multi-levels. The experiments are arranged according to the orthogonal table, and the limited number of times of washing experiments is used to reflect the overall washing situation [10]. If the four factors and three levels are combined one by one, it will lead to nearly 100 experiments, which is difficult to implement. Therefore, the orthogonal experiment method is used to select several representative combinations of experimental conditions to reflect the overall washing situation.

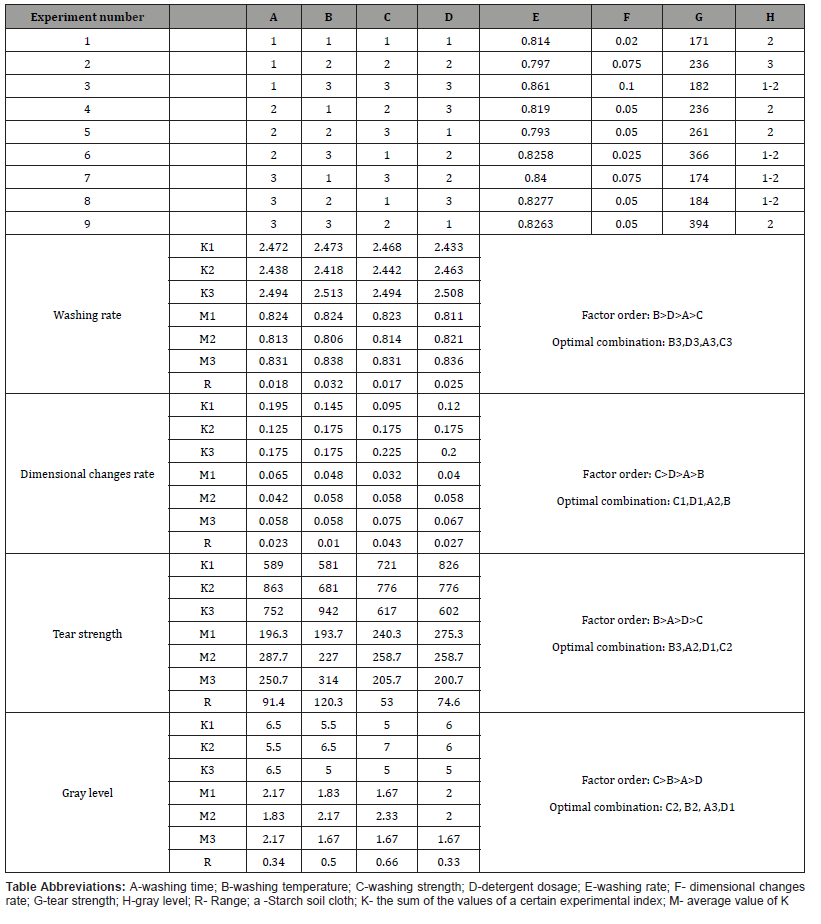

1) Analyze the influence of various factors on experimental indicators one by one. Among them, K1 means the sum of the values of a certain experimental index corresponding to a certain level of “1”, and M2 means the average value of K2 values corresponding to a certain level of “2”. Table 2 for specific values.

2) Sort the major and minor factors. Range R = max (M) -min (M), sort the range R in order of magnitude. The larger the R value, it means that this factor has a great influence on the test index, and the factor is very important. Conversely, the smaller the R value, the smaller the influence of this factor on the indicator, and the less important the factor is.

3) The magnitude of the M value can determine the excellent level of a certain column of factors. The largest M value is the optimal level. Based on the R value, the optimal combination can be obtained.

4) In this experiment, the washing rate, dimensional changes rate after laundering tear strength and gray level are taken as indicators. The larger the value of the washing rate, the cleaner the washing, and the smaller the value of the dimensional change rate, the better the shrinkage and higher value of tear strength means smaller strength loss of the fabric after washing, and larger gray level means smaller color difference.

Results and Discussion

Optimization of washing experiments

After washing the stained cloth, relevant indexes were measured, and the relevant experimental data of the starch stained cloth were sorted out in Table 2.

Table 2:Range analysis results of starch soil cloth test data.

Each wash condition has three levels, namely “level 1, level 2, and level 3.” For example, B2 in the table 2 represents the second level of washing temperature, namely 25 °C.

Optimized analysis of washing conditions for dirty cloth

During the washing process, each experimental index is affected by the washing conditions almost simultaneously. Therefore, while analyzing, we need to analyze the test indicators one by one, comprehensively balance and find the optimal washing program. Sequence, combining the order of influence factors and considering from a comprehensive perspective to get the best washing process.

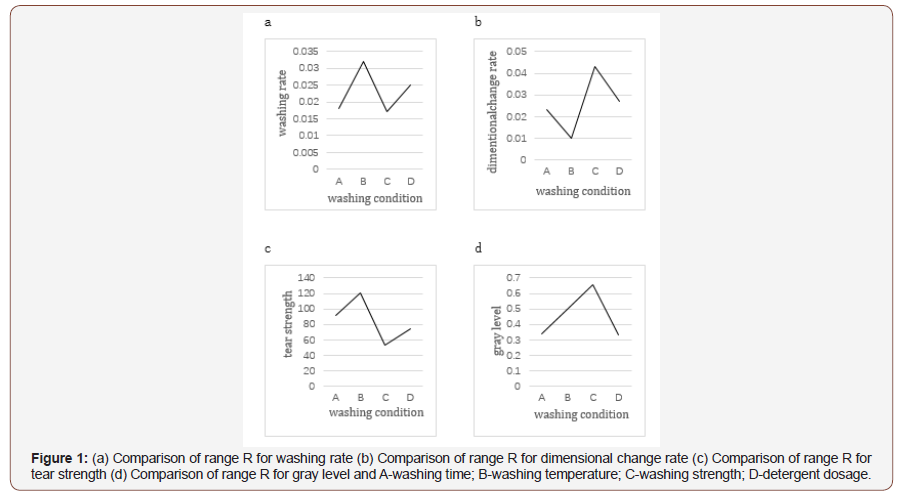

1) Comparison of range R

It can be seen that according to the comparison of the range R, the major and minor order of the influence of different washing conditions on the washing rate of starch soiled cloth is: B> D> A> C

It can be seen from Figure 1 that the influence of different washing conditions on the dimensional change rate of starch stained cloth is as follows: C> D> A> B

It can be seen from Figure 2 that the influence of different washing conditions on the tear strength of starch stained cloth is as follows: B> A> D> C

It can be seen from Figure that the influence of different washing conditions on the gray level of starch stained cloth is mainly: C> B> A> D

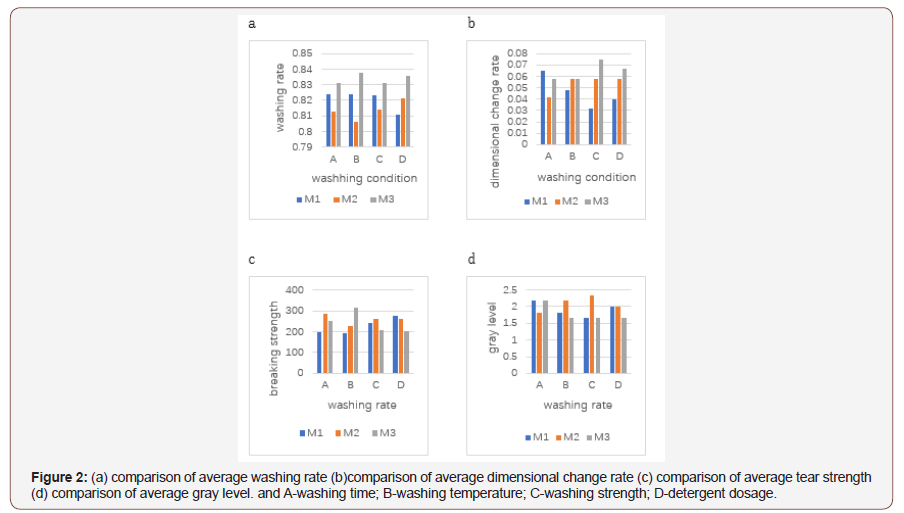

2) Comparison of mean value

With reference to figures it can be known that, for the factor A, its influence on the tear strength ranks second. So, it is the main factor. According to the principle that the larger tear strength means better result. Its effect on the washing rate is ranked third, at this time, taking A1 or A2. Its effect on the gray level is also ranked third, then taking A2. Its impact on dimensional change rate is also ranked third. According to the principle that the smaller the dimensional change rate, the better A is A1 or A3. Comparing these options together, the factor A is taken as A2.

For factor B, its influence on tear strength is ranked first. So, as the main factor, taking B3. Its effect on the washing rate is also ranked first, B takes B3. Its effect on the gray level ranks second, taking B1 or B3. Its effect on dimensional change rate ranks fourth, and as a secondary factor, taking B2 or B3. Comparing several options together, factor B is B3.

For the factor C, its influence on the dimensional change rate is ranked first. As the main factor, it is C1. Its effect on the gray level is also ranked first, taking C2. Factor C’s influence on strength ranks fourth, so C is C3. The effect of C on the washing rate is still fourth, and C is taken as C2. Comparing several options together, so C factor is C2.

For factor D, it has the second largest influence on the washing rate, and D is taken as D1 or D2. Its effect on the dimensional change rate is second, D is D3. It has the third largest impact on tear strength, with D taking D2 or D3. It ranks fourth in the gray level and is a secondary factor. D is D2 or D3. When D is D2, although the washing rate is 1.8% lower than D3, and the dimensional change rate is 13.4% lower than D3, and the tear strength is 28.9% higher than D3 and the gray level is 19.8% higher than D3. Comprehensive comparison, D is D2.

Therefore, when the optimal combination is A2B3C2D2, that is, washing for 20 minutes, and washing temperature is 35 °C, and washing strength is medium, and the detergent dosage is 20g, the starch soiled cloth can achieve the balanced and optimal effect of washing rate, dimensional change rate, and tear strength and the degree of fading to achieve the optimal washing process.

Conclusion

In order to ensure that the performance of the stained cloth is not affected during the washing process, the optimal process of starch stained cloth of pure cotton is studied through orthogonal washing experiments. The research conclusions are as follow:

(1) The washing conditions that have an effect on the washing rate are ranked as follows: B> D> A> C; the washing conditions that have an effect on the dimensional change rate are ranked as: C> D> A> B ;The washing conditions that are affected by the tear strength are ranked as follows: B> A> D> C; the washing conditions that have an effect on the gray level are ranked as: C> B> A> D.

(2) When the starch soil cloth achieves a balanced and optimal washing effect of the washing rate, dimensional change rate, strength loss and fading degree, the washing procedure is as follows: washing time is 20 minutes, washing temperature is 35 °C, and washing strength is medium , When the amount of detergent is 20g.

Acknowledgement

Thanks for the financial support of Wuhan Textile and Clothing Digital Center Platform.

Conflict of Interest

Authors have declared no conflicts of interest.

References

- Shinan Yu, Jing Liu (2005) Fabric size change and washing method. China Fiber Inspection, China 05: 29-30.

- Fengxia Wang, Jingfeng Zeng, Xuemei Ding(2014) Research on Fabric Wear Performance in Home Washing. Appliance Technology, China 12: 86-89.

- Solaiman, Rouf A, Rasel S, Khalil E (2015) Investigation of Different Washing Effects on Physical and Mechanical Properties of Cotton Knitted Garments. Journal of Textile Science and Technology 1(3): 101-109.

- Md Ibrahim H Mondal, Md Mashiur Rahman Khan (2014) Characterization and process optimization of indigo dyed cotton denim garments by enzymatic wash. Fashion and Textiles 1(1): 1-12.

- Jingwei Liu, Songwen Zhu (2015), Science of Gametal Materials (5th edition). China Textile Press, Beijing, China,221.

- Shengfu Dong (1987) Home washing guide. Beijing Press, Beijing, China: 48-49.

- Sijia Peng (2017) Study on the washing of cotton clothing stains. Xi'an Engineering University, Xi'an, China: 24-25.

- Technical Information Group of Beijing No.2 Daily Chemical Factory (1976), The bleaching of fabrics. Daily Chemistry Information, Beijing, China (Z1): 50-51.

- Ling Liu, Zhaowei Su (2018) Research on washing performance of washing machine to different stains. Daily Chemical Science, China 41(1): 48-52.

- Wei Cheng, Yiguo Xu (2019) Research on Optimal Design of Plastic Parts Based on Orthogonal Experiments, Shanghai Automobile, Shanghai, China: 28-31.

-

Xiaomeng Cao, Anhua Zhong, Yuqin Hu. Optimization Study of Machine-Washed Decontamination Effect of Starch Soil Cloth of Pure Cotton. J Textile Sci & Fashion Tech. 4(3): 2019. JTSFT.MS.ID.000588.

-

Machine washing, Decontamination, Orthogonal experiment, Starch soil cloth, Range analysis method

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.