Mini review

Mini review

Multi-dimensional utilization of cotton and its residues: current status and future directions

Zhenggui Zhang1,2,3*, Xin Wei2, Lei Gao1,2,3, and Zhanbiao Wang1,2,3*

1State Key Laboratory of Cotton Bio-breeding and Integrated Utilization, Institute of Cotton Research, Chinese Academy of Agricultural Sciences, Anyang, China

2Xinjiang Key Laboratory for Crop Gene Editing and Germplasm Innovation, Institute of Western Agricultural of CAAS, Changji, Xinjiang, China

3Institute of Agricultural Economics and Development, Chinese Academy of Agricultural Sciences, Beijing, China

Zhenggui Zhang, State Key Laboratory of Cotton Bio-breeding and Integrated Utilization, Institute of Cotton Research, Chinese Academy of Agricultural Sciences, Anyang 455000, China Zhanbiao Wang, State Key Laboratory of Cotton Bio-breeding and Integrated Utilization, Institute of Cotton Research, Chinese Academy of Agricultural Sciences, Anyang 455000, China

Received Date: June 06, 2025; Published Date: June 13, 2025

Abstract

Cotton is a globally important crop not only for fiber production but also for its valuable by-products, including cottonseed and cotton straw, which offer significant potential for multi-purpose utilization. Comprehensive use of these resources aligns with sustainable development goals and adds value to the cotton industry chain. This review highlights recent advances in the integrated utilization of cotton fiber, straw, and seed. Cotton fiber, beyond its traditional role in textiles, is being engineered into functional materials with flame-retardant, antibacterial, and conductive properties, enabling broader applications in healthcare and environmental fields. Cotton straw, often underutilized, is now explored as a source of organic fertilizer, livestock feed, bioenergy, and construction materials. Processing technologies such as pyrolysis and fermentation have expanded its utilization potential. Cottonseed, rich in oil and protein, is increasingly used in food, feed, and health-related products through advances in detoxification and genetic improvement. Future research should focus on enhancing value-added processing technologies, standardizing industrial applications, and assessing environmental and economic impacts. Promoting circular use and policy support will be essential for fully realizing the potential of cotton and its by-products in a sustainable bioeconomy.

Keywords: Cotton by-products; bio-based materials; resource utilization; sustainable production

Introduction

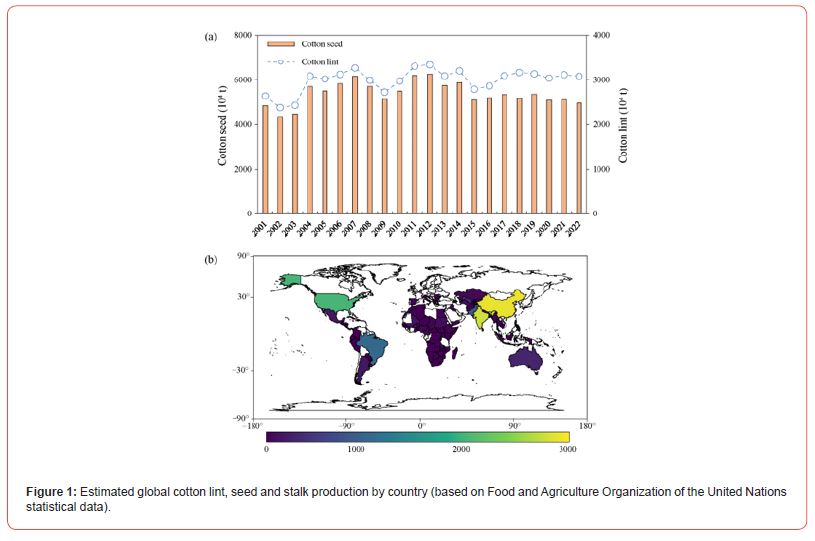

The global consumption of fiber is continuously increasing because of the growth of the population, economy, and fashion cycles [1]. Cotton, the most important fiber crop of the word, it supplies third of the total textile fiber demand [2]. Cotton and auxiliary product (cotton seed, cotton straw and so on) also provides abundant edible oils and protein-rich oil cakes, which contribute nutrients to both human and animal diets. For a long time, the world produces a lot of cotton fiber, seed and straw every year, but only cotton fiber is rationally and sufficient utilized by human (Figure 1). In 2023/2024, global cotton fiber, cotton seed and straw production were 24.12, 49.66 and 153.09 million tonnes, respectively [3]. In all countries, China, the largest cotton mill operator in the world, accounts for 32% of the global cotton consumption, followed by India (21%), Pakistan (9%), Bangladesh (7%) and Turkey (7%) [4]. At present, cotton (fiber) mainly as a raw material for clothing production, but its cotton seed and straw resource is underutilized. For example, cotton stalk can be utilized for livestock feed, fertilizer, and the production of other valuable products, but the most popular methods of disposal are returning the stalk to the field and direct burning. Despite these disposal methods are convenient, they have environmental and economic costs [5]. Therefore, it is necessary that make full use of cotton and its products for global cotton sustainable development.

Cotton Fiber Multi-Purpose Integrated Utilization

Cotton fiber, as one of the world’s top five natural fibers, is the only natural textile fiber produced from seeds, with green, lowcarbon and sustainable characteristics [6]. Its single-cell structure, multi-layer banded centre cavity and natural twist give it excellent physical and physiological properties, so that its products have good moisture absorption, breathability, warmth and wearing comfort [7]. Cotton fiber is widely used in the traditional textile production and is the core raw material for clothes. With the advance of textile technology, its utilization ways to diversify. New high-efficiency spinning equipment has significantly improved the yarn strength and output efficiency; at the same time, physical, chemical and biological methods of cotton fiber modification research continues to advance, so that it has a flame retardant, superhydrophobic, conductive, antibacterial, anti-ultraviolet and photocatalytic and other multi-functional, expanding the potential for its application in the field of electromagnetic protection, medical care, environmental management and other high-value [8-10].

Cotton fiber from the basic textile materials, is gradually to the transformation of functional materials, showing great potential for industrial extension space and sustainable development [11]. Hence, the diversified use of cotton fiber not only reflects the unique advantages of its material properties, but also fits the current trend of green manufacturing and high-performance fiber materials. Although cotton fiber occupies an important position in the textile industry due to its natural, green, and sustainable, its development still faces many challenges in the context of the increasingly fierce competition of modern fiber materials [12]. On the one hand, flax, ramie, bamboo fiber and other representatives of plant fibers due to its high strength, fast-growing and ecological advantages, is partially replacing the cotton fiber market share; on the other hand, wool, silk and other animal fibers by virtue of its excellent warmth and comfort, in the high-end apparel market is still highly competitive [13].

In addition, polyester, polyamide, acrylic and other synthetic fibers with excellent mechanical properties, wear resistance and cost advantages, widely used in the field of functional textiles, constituting a direct replacement of cotton fiber [14]. More noteworthy is that the new bio-based fibers and regenerative cellulose fibers (such as Lysol, modal) with its environmental performance and high processing adaptability, increasingly fevered by the market [15]. At the same time, cotton fiber in the production process still exists in the water consumption, the quality of the natural conditions affected by the obvious, wrinkle antibacterial and other functional deficiencies. Therefore, to improve the functionality, environmental adaptability and processing performance of cotton fibers, and to develop composite materials and high-value application paths, it is urgent to become a key direction for future research, in order to enhance its competitive advantage in the diversified fiber system and the ability of sustainable development of the industry.

Cotton Straw Multi-Purpose Integrated Utilization

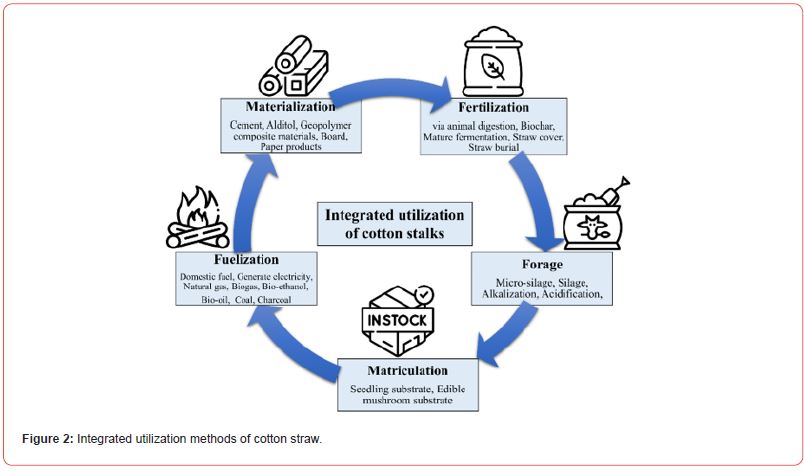

As a plentiful agricultural waste resource, the multifunctional comprehensive utilization of cotton stalks holds significant importance for promoting sustainable agricultural development and efficient resource utilization [16]. At present, there are various ways to comprehensively utilize cotton straw, covering multiple fields such as energy, materials, and feed. In agricultural applications, straw returning stands as the primary utilization method for cotton stalks, which mainly encompasses two approaches: one is mechanical crushing followed by direct turning or mulching for returning; The second is to return to the field after being properly processed to make organic fertilizer, including but not limited to composted straw returning, biochar returning, and livestock-mediated returning (where cotton straw are first fed to animals and then applied as manure) [17,18]. Both returning methods can effectively improve soil structure and increase organic matter content [19,20].

However, direct straw incorporation carries risks of pest and disease transmission and exhibits slow nutrient release. In contrast, processed cotton stalks need to be applied with appropriate amounts of nitrogen fertilizer before incorporation to achieve optimal results [21]. Notably, the stable aromatic carbon structure of biochar derived from cotton stalks can significantly enhance soil carbon sequestration capacity when applied to the soil [22,23]. In livestock production, cotton stalks that undergo pretreatment methods such as physical grinding, chemical treatment, or microbial fermentation exhibit significantly improved palatability and nutritional value. They can serve as an important source of roughage for ruminants and an effective supplement to high-quality feed [24]. Particularly in major pastoral regions such as Xinjiang, processed cotton stalks have been practically implemented in large-scale animal husbandry operations, effectively alleviating local forage shortages.

However, the presence of anti-nutritional factors such as gossypol limits its widespread application. Although agronomic research has successfully developed cotton varieties without gossypol glands through gene-editing technology, these cultivars cannot be cultivated on a large scale due to their low productivity and increased susceptibility to insect pests [25]. Therefore, further research and development of efficient and safe detoxification technologies are required. In terms of energy utilization, cotton stalks possess a calorific value ranging from 14.5 to 19.2 MJ·kg-1, comparable to that of wood (17.4-18.6 MJ·kg-1), making them a highly promising biomass feedstock for energy production. Through gasification technology, cotton stalks can be efficiently converted into combustible gases such as carbon monoxide and hydrogen, achieving a thermal efficiency of up to 70%. This makes them suitable for both power generation and rural cooking applications [26].

Additionally, fast pyrolysis technology can convert cotton stalks into bio-oil, while hydrolysis and fermentation processes enable the production of bioethanol [27]. Anaerobic digestion technology can convert cotton stalks into biogas, further expanding their potential for energy applications [28]. Meanwhile, cotton stalks can also be processed into high-density solid formed fuels (such as pellet fuel) through crushing, drying and compression techniques, facilitating storage and transportation. In the field of industrial applications, cotton stalks have been utilized in the production of particleboard, hardboard, medium-density fiberboard, and corrugated cardboard boxes due to their excellent mechanical properties and high-quality fibers suitable for fabric preparation. Furthermore, cotton stalks are also used in producing polymer composites for construction materials and show potential in pulp and paper production. Converting lignocellulosic components into chemicals is another approach to enhance their value.

Through chemical conversion, cotton stalks can yield highvalue- added products such as furfural, levulinic acid, formic acid, and commercial wood vinegar from their cellulose. These chemicals hold significant application potential in pharmaceuticals, agrochemicals, and other industries. In the development of new materials, cotton stalk-derived products such as activated carbon and cellulose nanomaterials have also demonstrated excellent performance characteristics. In the fields of edible mushroom cultivation and soilless cultivation, the highly lignified nature of cotton stalks endows them with excellent water and nutrient retention properties, making them an effective substitute for conventional substrate materials (e.g., peat moss and vermiculite). Research indicates that the bio-conversion efficiency of cotton waste-coffee grounds composite as a cultivation substrate can reach 79% [29]. Furthermore, mushrooms cultivated on cotton stalk-based substrates demonstrate significantly higher vitamin content compared to those grown on millet straw, wheat straw, or soybean straw substrates [30].

However, the comprehensive utilization of cotton stalks still faces numerous challenges, such as high collection and transportation costs, insufficient standardization of processing technologies, an underdeveloped industrial chain, and limited awareness among farmers regarding its integrated applications. In the future, it will be essential to enhance technological research and development to create efficient and low-cost pretreatment technologies; Improve the collection, storage, and transportation system; establish unified quality standards to promote standardized industry development; and enhance policy support to encourage cotton farmers and enterprises to actively participate in the comprehensive utilization of cotton stalks (Figure 2).

Cotton Seed Multi-Purpose Integrated Utilization

As an important by-product of cotton production, cottonseed is rich in oil and protein resources, and has a very high comprehensive utilization value. Traditional utilization pathways include extraction of edible oil, protein feed and food processing. Cottonseed kernel accounts for about 50% of the total mass of cottonseed, of which the oil content is more than 35% and the protein content reaches 37% to 50%, which is not only an important source of 10% of the global supply of vegetable oil and 6% of the global supply of protein, but is also rich in linoleic acid, oleic acid and other essential fatty acids, as well as vitamin E, sterols and squalene and other physiologically active substances [31]. Refined cottonseed oil has good stability, high temperature resistance and shortening, widely used in frying food and margarine industrial production, part of the cottonseed oil products is also used in skin care products and health food development [32]. Cottonseed protein, on the other hand, can be made into noodles, tofu, bread and other food ingredients through the detoxification process, or used to brew soy sauce and the manufacture of monosodium glutamate (MSG) and other condiments [33].

In recent years, research on the diversified utilization of cottonseed has been advancing. Breakthroughs have been made in effective removal technologies of cotton phenol, such as membrane separation, enzyme catalysis, and adsorption removal, laying the foundation for its safe utilization in the food and feed fields. Some research has also focused on the use of genetic engineering to breed low-phenol or phenol-free cottonseed varieties to enhance their palatability and processing safety from the source. In terms of feed utilization, cottonseed meal can be used as a high-protein feed after detoxification treatment, which is suitable for a variety of livestock and aquaculture, and can effectively replace soybean meal resources. Also, cottonseed hulls are rich in cellulose and lignin, which is an excellent raw material for edible fungus culture medium, widely used in the cultivation of many kinds of mushrooms, such as flat mushroom, enoki mushroom, reishi mushroom and so on.

In the future, with the continuous development of biorefining and green extraction technology, cottonseed will not only be limited to the traditional oilseed use, but also in the functional food, pharmaceutical carriers, bio-energy, biomaterials and other emerging areas to show broader utilization potential. For example, the physiological regulation of cottonseed protein peptides, cottonseed oil-derived phytosterols in lipid-lowering and antihypertensive potential, cotton phenol anti-cancer and male contraceptive development value. In general, as a crucial byproduct in the cotton industry chain, the diversified and high-value development of cottonseed not only helps to enhance the economic benefits of the whole cotton industry chain, but also fits the current concept of green and circular development of agriculture, and has a broad scientific research prospect and industrialization space.

Conclusion

The review summarizes diversified utilization of the three main types of cotton products (cotton fiber, cottonseed and cotton stalks), focusing on their potential for comprehensive development in the fields of textile, food, feed, energy, building materials, biomass materials and agriculture. Also, we review the transformation of cotton fiber in the direction of functional materials, the application of cotton stalks in soil improvement, bioenergy and industrial raw materials in detail, as well as the research progress of cottonseed in the development of oils, proteins, food additives and functional ingredients. Although cotton and its by-products have well resource advantages and broad application prospects, the current utilization process is still facing multiple challenges, such as low utilization efficiency of by-products, processing standards are not uniform, the lack of awareness of the application of farmers, as well as collection and transportation and detoxification treatment technology bottlenecks. In addition, in the fiber market, cotton is also facing competitive pressure from synthetic fibers, bio-based fibers and other alternatives. In the future, research should be strengthened on the fine processing technology of cotton by-products, biological detoxification and quality enhancement paths, multifunctional high-value product development, etc., to improve the industry chain synergistic system, to enhance the overall utilization efficiency of cotton resources, and to provide scientific and technological support for the green and circular development of agriculture and the sustainable upgrading of the cotton industry.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (32401968), Natural Science Foundation of Xinjiang Uygur Autonomous Region (2024D01B91), and the China Postdoctoral Science Foundation (2024T171024, 2024M763621).

References

- Lu L, Fan W, Meng X, Xue L, Ge S, et al. (2023) Current recycling strategies and high-value utilization of waste cotton. Science of the Total Environment 856(Pt 1): 158798.

- Johnson S, Echeverria D, Venditti R, Jameel H, Yao Y (2022) Supply Chain of Waste Cotton Recycling and Reuse: A Review. AATCC Journal of Research 7(1): 19-31.

- Abdullayev R (2022) Trends in the world cotton market condition. Berlin Studies Transnational Journal of Science and Humanities 2(1.1 Economical sciences).

- FAOSTAT Food and Agriculture Data. Crops and Livestock Products. https://www.fao. org/faostat/en/#data/QCL (The 4th International Symposium on Theoretical Innovation and High-quality Development of Cooperative Economy Bengbu).

- Cai C, Wang Z, Ma L, Xu Z, Yu J, et al. (2024) Cotton stalk valorization towards bio-based materials, chemicals, and biofuels: A review. Renewable and Sustainable Energy Reviews 202: 114651.

- Zhang S, Han Y, Wang G, Feng L, Lei Y, et al. (2023) Long-term assessments of cotton fiber quality in response to plant population density: Reconciling fiber quality and its temporal stability. Industrial Crops and Products 198.

- Niu Y, Xie G, Xiao Y, Qin K, Liu J, et al. (2021) Spatial layout of cotton seed production based on hierarchical classification: A case study in Xinjiang, China. Agriculture 11(8): 759.

- Grishanov S (2011) Handbook of textile and industrial dyeing: Elsevier 28-63.

- Abidi N (2018) Chemical properties of cotton fiber and chemical modification. Cotton fiber: physics, chemistry and biology: 95-115.

- Shahriari-Khalaji M, Alassod A, Nozhat Z (2022) Cotton-based health care textile: A mini review. Polymer Bulletin (Berlin) 79(12): 10409-10432.

- Delhom C, Wanjura J, Hequet E (2024) Cotton fibre elongation: a review. The journal of the Textile Institute 115(1): 159-170.

- Attia R, Yousif N, Zohdy M (2022) Electrical conductivity and mechanical properties of conductive cotton fabrics. Journal of Industrial Textiles 51(2_suppl): 3149S-3175S.

- Zhang Z, Huang J, Yao Y, Peters G, Macdonald B, et al. (2023) Environmental impacts of cotton and opportunities for improvement. Nature Reviews Earth & Environment 4: 703-715.

- Gonzalez V, Lou X, Chi T (2023) Evaluating environmental impact of natural and synthetic fibers: a life cycle assessment approach. Sustainability 15(9): 7670.

- Xu Z, Wu M, Ye Q, Chen D, Liu K, et al. (2022) Spinning from nature: Engineered preparation and application of high-performance bio-based fibers. Engineering 14: 100-112.

- Baikeli Y, Xu H, Zhang J, Yue Y, Guo G (2025) Innovations and Challenges in Mechanized Cotton Stalk Harvesting for Environmental Sustainability in the Field: A Review. Journal of the ASABE, 68(3): 365-377.

- Fan W, Wu J, Ahmed S, Hu J, Chen X, et al. (2020). Short-term effects of different straw returning methods on the soil physicochemical properties and quality index in dryland farming in NE China. Sustainability 12(7): 2631.

- Huang T, Wen S, Zhang M, Pan Y, Chen X, et al. (2024) Effect on greenhouse gas emissions (CH4 and N2O) of straw mulching or its incorporation in farmland ecosystems in China. Sustainable Production and Consumption 46: 223-232.

- Jin Z, Shah T, Zhang L, Liu H, Peng S, et al. (2020) Effect of straw returning on soil organic carbon in rice–wheat rotation system: A review. Food and Energy Security 9(2): e200.

- Chen L, Sun S, Zhou Y, Zhang B, Peng Y, et al. (2023) Straw and straw biochar differently affect fractions of soil organic carbon and microorganisms in farmland soil under different water regimes. Environmental Technology & Innovation 32: 103412.

- Zou H, Ye X, Li J, Lu J, Fan Q, et al. (2016) Effects of straw return in deep soils with urea addition on the soil organic carbon fractions in a semi-arid temperate cornfield. PLoS ONE 11(4): e0153214.

- Wang Y, Joseph S, Wang X, Weng Z H, Mitchell D R, et al. (2023) Inducing inorganic carbon accrual in subsoil through biochar application on calcareous topsoil. Environmental Science & Technology 57(4): 1837-1847.

- Chen Y, Sun K, Yang Y, Gao B, Zheng H (2024) Effects of biochar on the accumulation of necromass-derived carbon, the physical protection and microbial mineralization of soil organic carbon. Critical Reviews in Environmental Science and Technology 54(1): 39-67.

- Yu T, Ren Y, Guo Z, Chen X, Chen J, et al. (2018) Progress of research into cotton straw and corn straw cement-based building materials in China. Advances in Cement Research 30(3): 93-102.

- Gadelha I C N, Fonseca N B S, Oloris S C S, Melo M M, Soto-Blanco B (2014) Gossypol toxicity from cottonseed products. The Scientific World Journal 2014(1): 231635.

- Zhang Z, Zhao W, Zhao W (2014) Commercialization development of crop straw gasification technologies in China. Sustainability 6(12): 9159-9178.

- Pandirwar A P, Khadatkar A, Mehta C, Majumdar G, Idapuganti R, et al. (2023) Technological advancement in harvesting of cotton stalks to establish sustainable raw material supply chain for industrial applications: A review. BioEnergy Research 16(2): 741-760.

- Yoruklu H C, Koroglu E O, Ozdemir O K, Demir A, Ozkaya B (2020) Bioenergy production from cotton straws using different pretreatment methods. International Journal of Hydrogen Energy 45(60): 34720-34729.

- Tsegaye Z, Tefera G (2017) Cultivation of Oyster Mushroom (Pleurotusostreatus Kumm, 1871) using Agro-Industrial Residues. J Appl Microb Res Vol: 1: 20.

- Dundar A, Acay H, Yildiz A (2009) Effect of using different lignocellulosic wastes for cultivation of Pleurotus ostreatus (Jacq.) P. Kumm. on mushroom yield, chemical composition and nutritional value. African Journal of Biotechnology 8(4).

- Kumar M, Zhang B, Potkule J, Sharma K, Radha, et al. (2023) Cottonseed oil: extraction, characterization, health benefits, safety profile, and application. Food Analytical Methods 16(2): 266-280.

- Wu M, Pei W, Wedegaertner T, Zhang J, Yu J (2022) Genetics, breeding and genetic engineering to improve cottonseed oil and protein: a review. Frontiers in Plant Science 13: 864850.

- Razzaq L, Abbas M M, Miran S, Asghar S, Nawaz S, et al. (2022) Response surface methodology and artificial neural networks-based yield optimization of biodiesel sourced from mixture of palm and cotton seed oil. Sustainability 14(10): 6130.

-

Zhenggui Zhang*, Xin Wei, Lei Gao, and Zhanbiao Wang*. Multi-dimensional utilization of cotton and its residues: current status and future directions. J Textile Sci & Fashion Tech 11(4): 2025. JTSFT.MS.ID.000769.

-

Cotton by-products; bio-based materials; resource utilization; sustainable production; iris publishers; iris publisher’s group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.