Review Article

Review Article

Dehairing trial of Patagonian Cashmere-Bearing goat fleeces: Yields and Quality of Textile Products

Diego Sacchero1*, Julia Maurino1 and Leandro De Vitta2

1Laboratorio de Fibras Textiles, Instituto Nacional de Tecnología Agropecuaria (INTA), Estación Experimental Agropecuaria (EEA) Bariloche, Río Negro, Argentina.

2Sacro Grido Tecnológico, Buenos Aires, Argentina.

Diego Sacchero, Laboratorio de Fibras Textiles, Instituto Nacional de Tecnología Agropecuaria (INTA), Estación Experimental Agropecuaria (EEA) Bariloche, Río Negro, Argentina.

Received Date: July 25, 2025; Published Date: August 13, 2025

Keywords: Animal fibres; Double layer fleeces; Textile transformation; Cashmere

Introduction

The textile transformation of cashmere fibres includes several steps, among which fibre dehairing is a key process. This process is the mechanical separation of the coarse and usually longer guard hairs, from the fine short fibres (down fibres), which are those of high textile value. In northern Argentine Patagonia, there are currently about 410,000 cashmere-bearing goats identified as the creole Neuquén (CN) breed [1,2]. A previous study has shown that the fibre diameter of this goat is similar to that of Iranian cashmere and that fibre length is similar to that of Chinese and Mongolian cashmere [3]. Since Argentina could potentially produce 15 tons of Patagonian cashmere fibre per year [4], dehairing technology is imperative for the subsequent use of this fibre in the local textile industry. This study aimed to evaluate the performance of the CN goat fleeces at the dehairing stage and to estimate dehairing yields and record the effects of the dehairing process on fibre quality.

Materials and Methods

The raw material consisted of batches of cashmere and cashgora fleeces from the shearing of CN goats. Fleeces were processed using a Cormatex® dehairing machine [5]. The process consisted in first passing the fibre through the dehairing machine (P1), the by-product obtained was reprocessed to obtain the second dehaired product (P2). The P1 and P2 products were then unified (IP, Intermediate Product) and reprocessed to obtain the final dehaired product (FP). The weights of each product and byproducts were recorded. Three samples were taken from each of the products at fixed times every 30 minutes. Quality of the raw material and dehaired products (fibre lengths, fibre average diameter, and distribution and percentage of fine fibres and coarse fibres) were analysed by means of OFDA2000 and Almeter. The yield was calculated as weight-by-weight ratio of fine fibres to initial weight. For fibre quality analysis, reported values are means of three samples taken at each stage (P1, P2 and FP).

Results and Discussion

Dehairing Yield

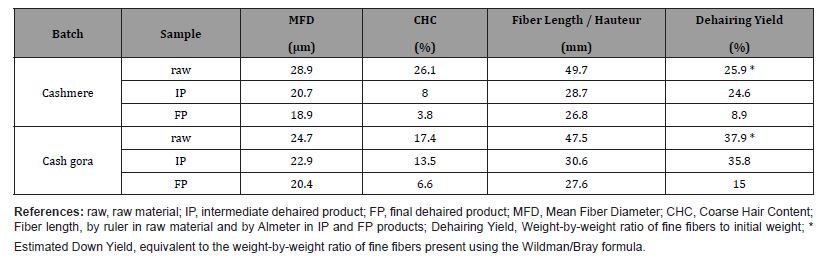

The content of fine fibre presents in the raw material (maximum potentially extractable by dehairing) and effectiveyield obtained are summarizes in Table 1. At all stages, dehairing yields were consistently lower for the cashmere batch than for the cashgora batch. The dehairing yield of cashmere fleeces was 8.9 %, whereas that of cashgora fleeces was 15.0 %. Despite processing a significant fraction of down fibre ended up in the discards and vice versa (hairs remaining in the dehaired product), this type of “cross-contamination” was of magnitude. Ulterior recovery of cashmere by reprocessing the waste is not economically feasible, while the reduction of hair content in a yarn is achieved at a later stage by blending with wool or other textile fibres. Previous works processing cashmere fleeces resulted in yields between 10.9 % and 17.9 % [6,7]. In Australian cashmere goats, [8] obtained yields of 33.9 % in greasy fleeces, whereas obtained yields of 36.0 % in scoured fleeces.

The dehaired cashmere length achieving hauteur means of 26.8 mm in cashmere and 27.6 mm in cashgora (Table 1). These values do not differ from those found for Australian dehaired cashmere (28.8 mm in first-grade cashmere and 23.4 mm in second-grade cashmere; [9,10]. Dehairing resulted in significant reductions in cashmere length. The reduction in the initial staple length, measured as fibre shortening in the FP (i.e. percentage of the initial length lost by fibre breakage during dehairing) was 46 % in cashmere and 42 % in cashgora. McGregor [11,12] reported fibre length shortening between 55.5 % and 67.4 % on cashmere processing. The fibre length is of great importance since it definitively conditions the subsequent performance at the spinning stage.

Fiber Diameter and Reduction in the Coarse Hair Content

Cashmere dehairing allowed a significant reduction in the mean fiber diameter (10 μm) and coarse hair content, while in cashgora the reduction in both mean fibre diameter (4.3 μm) and coarse hair content was smaller. The proportion of coarse fibres present in the CN fleeces is high [13,14]. The dehairing allowed reducing the CHC to 3.8 % in the cashmere and to 6.6 % in cashgora (Table 1).

Table 1:Quality of cashmere and cash gora fibre before and after mechanical dehairing.

Conclusion

The low yield of cashmere obtained from dehaired fleeces significantly limits its commercial viability and suggesting that dehairing should be performed close to the origin, to minimize the impact of the transport cost on the value added chain. The variability observed between fleece types suggests that industrial approaches should shift from standardization toward flexible processing strategies that can adjust to heterogeneous raw material. Economically, low yields and residual coarse fibers reduce product quality and market value. Beyond technical improvements, a systemic approach is essential—linking science, technology, public policy, and local knowledge- to build a sustainable value chain. Establishing a distinct identity for “Patagonian cashmere” could position it competitively in luxury fiber markets and help transform a marginal activity into a driving force for rural development in northern Patagonia.

References

- Lanari MR (2004) “Variación y diferenciación genética y fenotípica de la Cabra Criolla Neuquina en relación con su sistema rural campesino”. Tesis doctoral. Universidad Nacional del Comahue.

- Servicio Nacional de Sanidad y Calidad Agroalimentaria (Senasa). Anuario Estadístico 2023-Centro Regional Patagonia Norte.

- Maurino J, Monacci L, Lanari MR, Pérez Centeno MJ, Sacchero D, et al. (2008) Caracterización de la fibra Cashmere del norte neuquino. Memorias del IX Simposio Iberoamericano de Recursos Genéticos, Mar del Plata, 10 al 12 de diciembre, PP. 457-460.

- Lanari MR, Pérez Centeno MJ, Arrigo J, Debenedetti S, Abad M (2009) Razas locales y fibras caprinas, bases para un desarrollo rural del norte de la Patagonia Argentina. Boletín de información sobre recursos genéticos animales, FAO 45: 55-59.

- Sacchero D, Lamas H, Maurino J, Galfione L (2024) A study on dehairing of vicuña fiber: evaluation of yields and quality characteristics that impact on its transformation and textile added value, The Journal of The Textile Institute 116(4): 1-7.

- Sacchero D (2018) Informe técnico sobre descerdado de vellones de cashmere patagónico obtenido mediante esquila de cabras criollas de Neuquén.

- Maurino MJ (2020) Cosecha y agregado de valor en fibra cashmere de cabras Criollas Neuquinas. Tesis de maestrí Universidad Nacional del Comahue.

- Wang L, Singh A, Wang X (2008) A study on dehairing greasy cashmere. Fibers and polymers 9 (4): 509-514.

- McGregor BA (2002) Australian Cashmere – attributes and processing. RIRDC. Research Paper No. 02/112. RIRDC Barton ACT Australia.

- McGregor BA, Postle R (2004) Processing and quality of cashmere tops for ultrafine wool worsted blend fabrics. International Journal of Clothing Science and Technology 16(1): 119-131.

- McGregor BA, Butler KL (2008) The effects of cashmere attributes on the efficiency of dehairing and dehaired cashmere length. Textile Research Journal 78(6): 486-496.

- McGregor BA (2018) Scouring and dehairing Australian cashmere. Agrifutures Australia Publication No 18/001.

- Wildman AB (1954) The microscopy of animal textile fibres. Wool Industries Research Association.

- Maurino J, Sacchero D, Lanari MR (2022) Cashmere en cabras Criollas Neuquinas: influencia del momento de la esquila sobre la cantidad y calidad de la fibra. Archivos Latinoamericanos de Producción Animal 30(4): 321-329.

-

Diego Sacchero*, Julia Maurino and Leandro De Vitta. Dehairing trial of Patagonian Cashmere-Bearing goat fleeces: Yields and Quality of Textile Products. J Textile Sci & Fashion Tech 12(1): 2025. JTSFT.MS.ID.000776.

-

Animal fibres; double layer fleeces; textile transformation; cashmere; iris publishers; iris publisher’s group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.