Research Article

Research Article

Analysis the Physical Properties of Twill Derivatives: A Case Study

Nasrin Akter1, Md. Nura Alam Shiddique2, Tarikul Islam3* and Md. Abdullah4

1Department of Textile Engineering, Ahsanullah University of Science and Technology, Bangladesh

2Department of Textile Engineering, Khwaja Yunus Ali University, Bangladesh

3Department of Textile Engineering, Jashore University of Science and Technology, Bangladesh

4Department of Textile Engineering, Mawlana Bhashani Science and Technology University, Bangladesh

Tarikul Islam, Department of Textile Engineering, Jashore University of Science and Technology, Jashore-7408, Bangladesh.

Received Date: November 26, 2019; Published Date: December 03, 2019

Abstract

Predict on physical properties of some derivatives of plain and twill weave is very crucial in textile areas. The main approach of this study is to produce plain and twill weave derivatives in rapier loom and estimate the physical properties by comparing with the quality of same yarn count, EPI, PPI and cover factor for different weave designs. From this study, it is found that the physical properties of Brighton honeycomb structure are better than other twill as well as plain derivatives of our test samples. According to test it is clear that the weave structures influence the fabric quality like Tensile strength, Drape Co-efficient, Air permeability and Fabric thickness. These tests help to control of process, quality of product and in the development of the process.

Keywords: Twill Derivatives; Tensile strength; Drape co-efficient; Air permeability; Fabric thickness

Introduction

Introduction

Woven fabric is mostly used among all other fabrics because of its versatile application for clothing, industrial, commercial and other technical purposes [1]. Though Bangladesh is an auspicious land of textile production, the demand of woven cloth is comparatively less than the knitted one [2].

A woven cloth is formed by the interlacement of two sets of yarns, namely, warp and weft yarns. These yarns are interlaced with one another according to the type of weave or design. The warp yarns are those that run longitudinally along the length of the fabric and the weft yarns are those that run transversely across the fabric. For the sake of the convenience, the warp yarns are termed as ends and the weft as picks or fillings [3]. Large numbers of weave structures are applied in weaving industries like plain, twill, satin etc. with a great variety of derivatives to serve different purposes [4]. Twill weave is one of the main elementary weaves (along with plain, sateen and satin). Characteristically, it produces diagonal lines on the face of the fabric. The weft yarn is passed over one or more warp yarns and then under two or more warp yarns and so on [5]. In rapier loom, an updated weft insertion system is being used. The gripper heads are attached to rapiers which are flexible tapes or rigid rods. Insertion of weft by rapier is a mechanically modern and refined version of the primitive method of fabric production in which the weft was secured in a slot of stick [6]. The void volume in woven textile fabrics causes air permeability. The air permeability of a textile fabric is determined by the rate of air flow through a material under differential pressure between two fabric surfaces. It is generally expressed in SI unit as cm3/cm2/sec. The prescribe pressure differential is 10mm of water [7].

Tensile strength is used to determine the behavior of a sample while under and axial stretching load. From this, the breaking load and elongation can be obtained. The principle of the tensile strength test is simple where the test piece is held in two or more places and extended until it breaks [8]. The drape is the term used to describe the way a fabric hangs under its own weight. It has an important bearing on how good a garment looks in use. The draping qualities required from a piece of fabric will differ completely depending on its end use, therefore a given value for drape cannot be classified as either good or bad. Woven fabrics are relatively stiff when compared with knitted fabrics so that they are used in tailored clothing where the fabric hangs away from the body and disguises its contours. Measurement of a fabric drape is meant to assess its ability to do this and also its ability to hang in graceful curves [8]. The air permeability of a fabric is influenced by several factors: the type of fabric structure, the design of a woven, the number of warp and weft yarns per cm or inch, the amount of twist in the yarns and type of yarn structures [9]. Fabric thickness is one of the most important factors determining thermal comfort. It was found that fabric thickness had a direct effect on thermal transmittance, where the thicker material, the lower the thermal transmittance [10].

In this study, Different types weave structures (Plain and Twill) by using same fabric parameters have been constructed for this study purpose. Then physical behavior of plain and twill weave derivatives such as air permeability, tensile strength, drape-ability, fabric thickness had been evaluated using different techniques. After obtaining the result, it has been showed the comparison of the physical properties of different weave structures.

Materials and Methods

Materials

Fabric: For this experiment, six samples of woven fabrics (Matt, Diaper, Diamond, Brighton honeycomb, Twill, and Vertical Zig-Zag) were produced with different weave design by using respective pattern card in Rapier loom of Ahsanullah University of Science and Technology (AUST) weaving lab, Dhaka, Bangladesh. During the production same EPI (72), PPI (42) and width (63.5″) of the fabrics was maintained. In making the fabrics same count yarn (warp count-30Ne, weft count-22Ne) was used. After taking every sample out of the loom they were laid on a table in lay form for 48 hours to get relaxed (Dry Relaxation). Finally, the fabrics were ready for the test.

Machine

The following machinery have been used to develop and analysis the sample from the AUST Lab, Dhaka, Bangladesh.

Rapier loom (Dobby, Capacity: 20 Heald frames-2 for Selvedge)

•Air permeability tester (Textest)

• Drape Tester (Cusick)

• Universal Strength Tester (Titan)

• Thickness Gauge (Dial Type)

• Electronic Balance

• Wet and Dry Bulb Hygrometer

• Counting Glass

• Scissor

• GSM Cutter

• Iron Machine

• Stationery items (Scale, Marker pen)

Methods

The sample was developed and tested in AUST lab, Dhaka, Bangladesh and analyzed the samples by the following testing standards:

• Tensile strength: Tensile strength is determined by ASTM D5035-11 (2015) (20s)

• Drape Co-efficient: Drape Co-efficient is determined by BS 5058

• Air permeability: Air permeability is determined by ASTM D737

• Fabric thickness: Fabric thickness is determined with the help of MITUTOYO thickness gauge

Results and Discussion

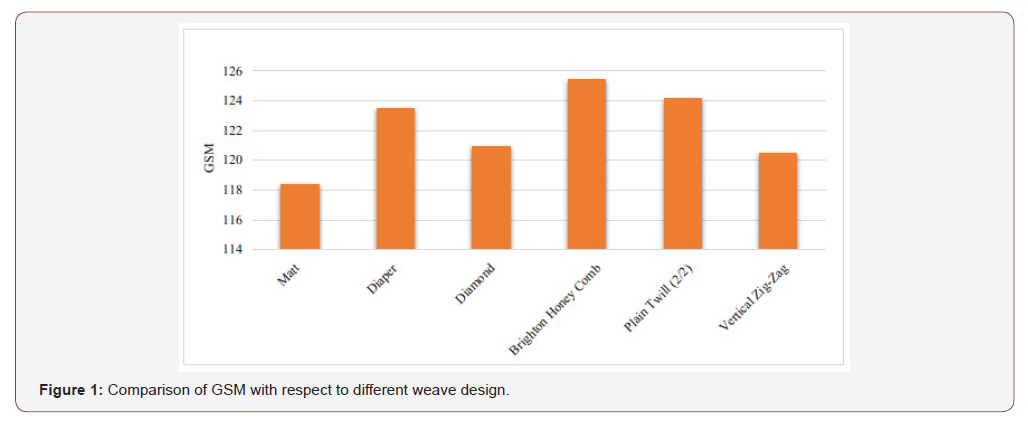

Determination of GSM value of different fabric design

From the above Figure 1, it is obvious that Brighton honeycomb design has the highest GSM value for having highest number of alternate floats in the fabric. Twill and Diaper design have almost the same GSM. Vertical Zigzag and Diamond have almost same GSM. In case of Matt design, GSM is lower because of higher number of floats in both warp and weft direction.

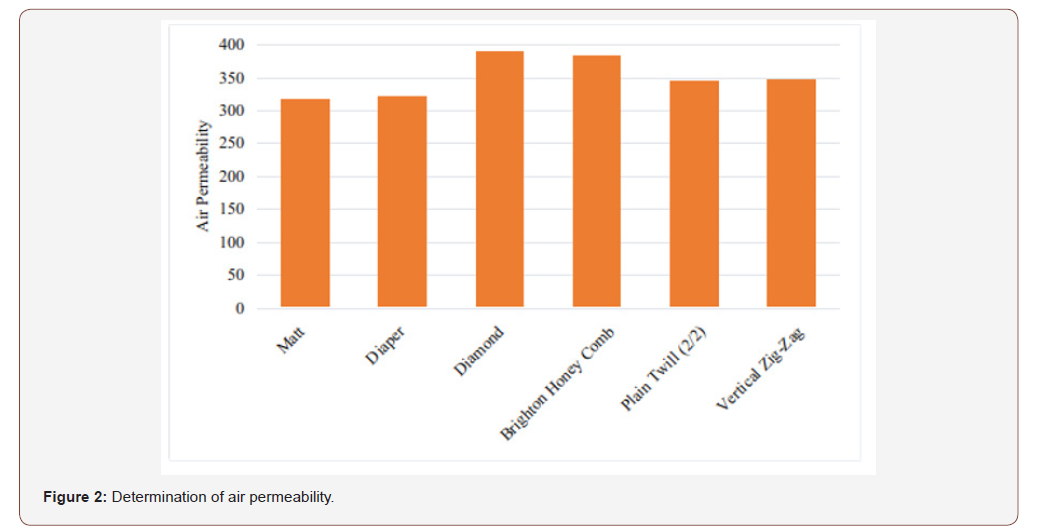

From the above Figure 2, it is observed that all the designs have Air Permeability between the range of 300 – 400 cm3/cm2/sec (which is ideal for machine setting at 6) as all of them has the same cover factor but variation in the values arises because of irregular floating of different designs and also for having different amount of free space between warp yarns in the fabrics.

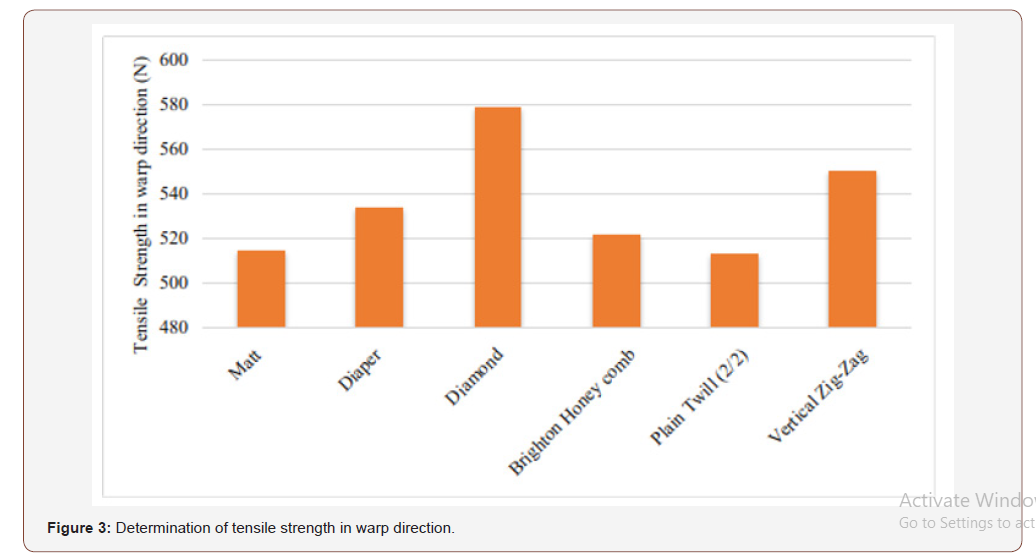

Determination of tensile strength in warp direction

From the above Figure 3, it is clearly observed that Diamond structure have the higher tensile strength in the warp direction because of almost equal ratio of float in both directions. From the designs, Vertical Zigzag, Diaper, Brighton honeycomb, Matt, Twill have variation in tensile strength in descending order.

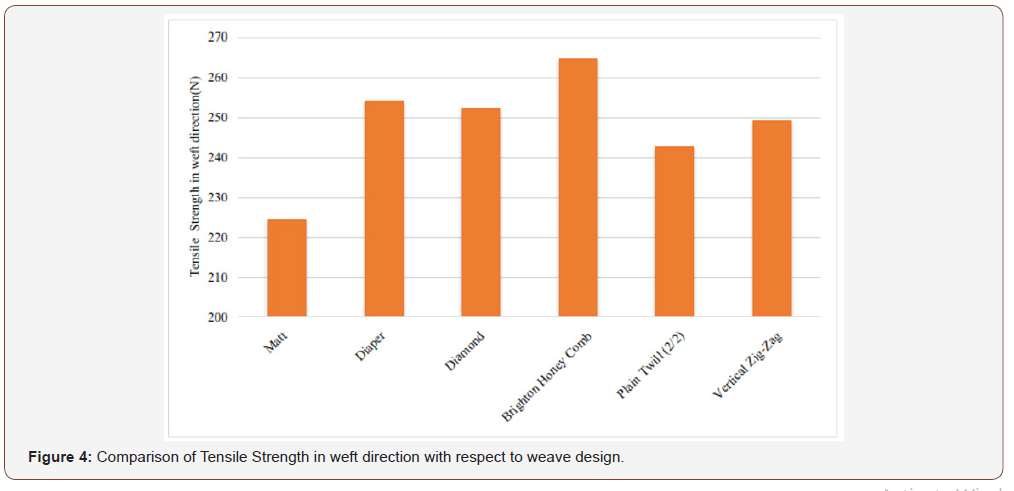

Determination of tensile strength in weft direction

From the above Figure 4, it is clearly observed that Brighton honeycomb has the highest tensile strength in weft direction due to higher number of interlacement in weft direction. From the designs, Diaper, Diamond, Vertical Zigzag, Twill, Matt have variations in tensile strength in descending order.

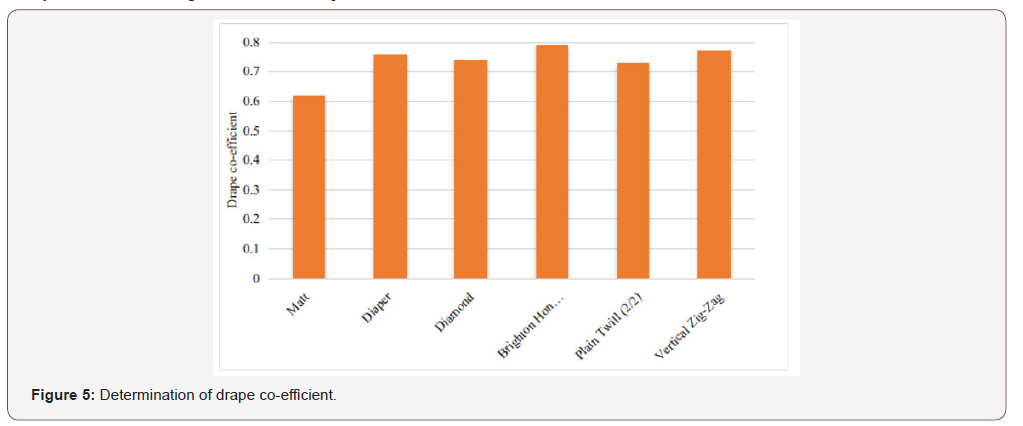

Determination of drape co-efficient

From the above Figure 5, it is clearly observed that Brighton honeycomb has the higher value of drape co-efficient. From the designs, Vertical Zigzag, Diaper, Diamond, Twill, Matt have variations in value of drape co-efficient in descending order

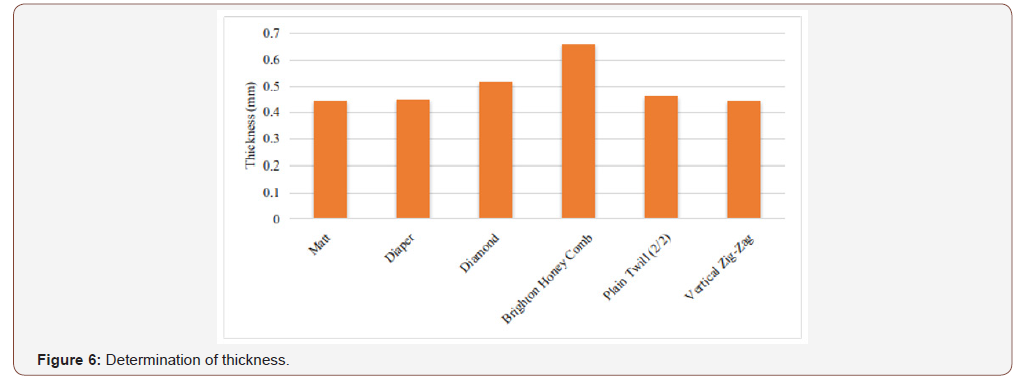

Determination of thickness

Having examined fabric thickness mentioned Figure 6, we observed like previous that Brighton honeycomb has also higher thickness where the following designs, Diamond, Twill, Diaper, Matt, Vertical Zigzag have variations in the value of drape coefficient in descending order.

Discussion

What we have studied about the derivatives of twill based on their different physical properties it has been pellucid and the outcome can be concluded according to their test results. The result was disclosed that brighton honeycomb structure showed better physical properties on an average than other structure whereas matt structure showed lower value in case of physical properties. All the values of physical properties for different weave designed fabrics differs because of irregular float in the designs and free space between adjacent warp yarns and also weft yarns while having same EPI, PPI, warp count, weft count, cover factor as well as fabric width.

Conclusion

In textile fabric weave structure has an important role on the fabric quality. Yielding fabric with different weave structure whether it is plain or twill derivatives the physical properties varies according to their weave structure. Here, we had examined with same specification, but the outcome was different due to nuance of their fabric structure. According to test it is clear that weave structures influence the fabric quality. These tests help to control of process, quality of product and in the development of the process.

Acknowledgement

The authors acknowledge the AUST lab, Dhaka, Bangladesh for conducting this project work.

Author Contributions

This project work was done under the supervision of NA The sample development, experimental design, testing, and the presentation part was done by MNAS and TI with the help of MA. Finally, all authors revised the manuscript carefully.

Conflicts of Interest

Authors have declared no conflicts of interest.

References

- Jeon HY (2012) Woven Fabrics, InTech, pp. 1-304.

- (2016) Bangladesh Garments Manufacturers and Exporters Association, Woven and Knit.

- Adanur S (2001) Handbook of Weaving, CRC News, 2001, Library of Congress Catalog Card No.00-107625.

- Rahman M, Asif AA, Siddiquee MA, Rokonuzzaman M (2014) Effect of shade percentage on various properties of cotton knitted fabric dyed with reactive dyes. International Journal of Research in Engineering and Technology 2(3): 339-343.

- Gokarneshan N (2004) Fabric Structure and Design, New Age International (P) Ltd., Publishers, New Delhi, India.

- Talukdar MK, Sriramulu PK (1998) Weaving, Mahajon Publishers Private Ltd., India, India.

- Ogulata RT (2006) Air Permeability of woven Fabric. Journal of Textile and Apparel, Technology and Management 5(2): 1-10.

- HU (2008) Fabric Testing, Woodhead Publishing Ltd., UK.

- (2012) Characteristics of diamond design diaper design.

- Mao N, Russell SJ (2015) Fabric thickness, Textiles and Fashion. Woodhead Publishing Series in Textiles: 307-335.

-

Tarikul Islam, Nasrin Akter, Md. Nura Alam Shiddique, Md. Abdullah. Analysis the Physical Properties of Twill Derivatives: A Case Study. J Textile Sci & Fashion Tech. 4(2): 2019. JTSFT.MS.ID.000585.

-

Twill derivatives, Tensile strength, Drape co-efficient, Air permeability, Fabric thickness

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.