Research Article

Research Article

A Study on Thermal Comfort Feeling Properties of 60%/40% and 80%/20% Cotton/Polyester and 100% Cotton Fleece

Pran Krisna Saha1, Md. Anamul Haque2, Tarikul Islam3*, Debasree Paul4 and Joy Krishna Saha4

1Department of Textile Science and Engineering, Wuhan Textile University, China

2Deartment of Chemistry and Chemical Engineering, Wuhan Textile University, China

3Department of Textile Engineering, Jashore University of Science and Technology, Bangladesh

4Department of Textile Engineering, Mawlana Bhashani Science and Technology University, Bangladesh

Tarikul Islam, Department of Textile Engineering, Jashore University of Science and Technology, Jashore-7408, Bangladesh.

Received Date: November 27, 2019; Published Date: December 04, 2019

Abstract

In this study, thermal properties of 60%/40% & 80%/20% Cotton/Polyester and 100% Cotton fleece fabrics were investigated. It is known that Cotton fiber has good comfort properties and Polyester fiber is especially known for its strength, anti-wrinkle, anti-mildew, whiteness. The aim of this study was to determine the most thermally comfortable combination of these two fibres among the three most used common blend ratios of these two. First, cotton and Polyester fibers spun with different blend ratios standard spinning systems. Then, three thread fleece fabrics were produced with these yarns having 60%/40% and 80%/20% Cotton/Polyester and 100% Cotton and the thermal comfort parameters of fabrics were measured on Standard devices. The three-fleece fabric only varied in yarn composition. And all other parameters were the same for all three. The results indicated that the 80%/20% Cotton/Polyester has the most desired thermal comfort properties.

Keywords: Air Permeability; Cotton fabric; Thermal conductivity; Thermal resistance; Water vapor Permeability

Introduction

In recent years there has been a very fast growth in the knitting section of the textile industry. A demand for weft knitted garments has increased many folds over the years in the domestic and export markets. Knit fabrics have found its wider use in time since they can be produced more easily for a lower cost, and they are more flexible. The ever-increasing demand of knitted apparels has attracted attention in global niche market. In comparison to woven garment, around 50% of the clothing needs are met by the knitted goods [1-3].

Consumers of textile and clothing products are becoming increasingly aware of the importance of the comfort. In addition to aesthetic appearance, the comfort is one of the main properties of clothing, which affects the choice of product. The term comfort is a subjective concept which is only recognized by the person experiencing it. It can be defined as “the absence of displeasure or discomfort or a neutral state compared to the more active state of pleasure“. A state of comfort can only be achieved when the most complex interactions between a range of psychological and physical factors have taken place in a satisfactory manner [3-5]. However, knit fabrics are less stable than weave fabrics since they are produced with low twist yarn and have a slack construction, as a result of which they have a low dimensional stability and pilling performance. Especially in garments produced from knit fabric and garments approaching a state of disuse does the pilling problem play an important rule [6,7].

When garments are worn, the heat and moisture diffused from skin, get exchanged by several transfer mechanisms. These mechanisms are simply thermo-physiological regulators that include heat and mass transport through the textile layers to keep the energetic balance between the human body and environment. These two concepts are considered to characterize the thermophysiological comfort [4]. The mass transport concerns the moisture vapor, air permeability and heat transfer concerns with thermal resistance and thermal conductivity. In this project we are going to emphasize on the thermal comfort of 60/40, 80/20 cottonpolyester blend and 100% cotton [8,9].

In this project we took the 3 most used fleeces 60%/40% & 80%-20% Cotton-Polyester and 100% Cotton Fleece and we put our efforts to determine which of these three would be most comfortable to wear in winter season. The thermal comfortness of these fleeces largely depends on some properties like air permeability, thermal conductivity, thermal resistance, moisture vapor permeability etc. [5,7].

So, in this project work, we have tried to measure the air permeability of these fleece and the thermal conductivity and thermal resistance of fleece fabrics of these 3 specifications. Also measures the moisture vapor permeability and identified the fleece which are most suitable to wear during the winter season.

Materials and Methods

Materials

Fabric

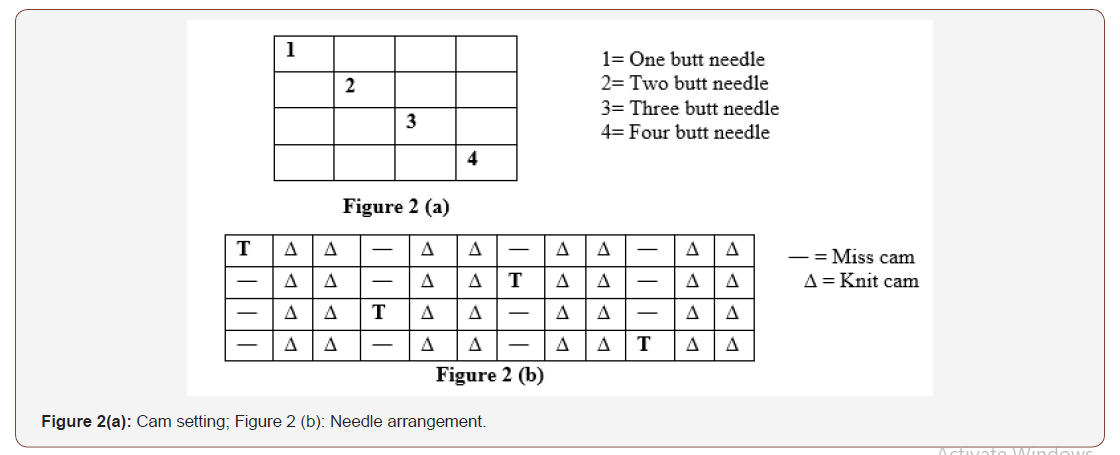

• M/c GG: 30˝ × 20 GG

• Fabric : Fleece

• S. length : Base/4.65 + Binding/3.65 + Loop/1.65

• F.G.S.M : 270

• Yarn : 30s /1 cotton/polyester blend (Figures 1&2)

Yarn: Only two types of yarns used for producing fabric. These three yarns were used:

• 100% cotton

• 80% cotton / 20% polyester

• 60% cotton / 40% polyester

Sample: Three fabric samples were made by using the abovementioned yarns. The three-sample varied in yarn composition. One having 100% cotton, another having 80% cotton- 20 % polyester and the other having 60% cotton- 40 % polyester. Other specifications of the fabric are given below (Table 1).

Methods

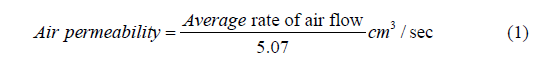

Air permeability test

In this research, air permeability tests of the knits investigated were conducted according to EN ISO 9237:1995. The air permeability was measured using an GT-N44 Air Permeability Tester with a head area of 20 cm2. There is no required any formula for air permeability test result. Just clamp the specimen in the specimen holder of air permeability tester than the press start button and automatically get the air permeability result from the machine display.

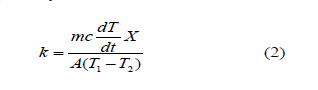

Thermal conductivity test

To determine the coefficient of thermal conductivity of a bad conductor using Lee’s disc apparatus. Lee’s disc apparatus consists of a metallic disc resting on a 5 cm deep hollow cylinder (steam chamber ) of same diameter. It has inlet and outlet tubes for steam. In addition, it has radial holes to insert thermometers. Thermal conductivity is the property of a material . It indicates the ability of a material to conduct heat. When steam is passed through the cylindrical vessel a steady state is reached soon. At the steady state, heat conducted through the bad conductor is equal to heat radiated from the Lees disc. At the steady state, rate of heat transfer (H) by conduction is given by:

Where, k - Thermal conductivity of the sample, A- Cross sectional area, T2 - T1 -Temperature difference across the sample, x-Thickness of the bad conductor.

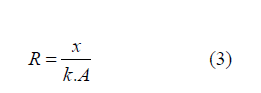

Thermal resistance test

The thermal resistance is calculated by the following relationship:

Where, x = the wall thickness (m), k = the thermal conductivity of the material (W/(m·K)), A = the total area of the heat exchanger (m2)

Measurement of water vapor permeability

The water vapor permeability index is calculated by expressing the water vapor permeability (WVP) of the fabric as a percentage of the WVP of a reference fabric which is tested alongside the test specimen. Each dish is filled with sufficient distilled water to give a 10mm air gap between the water surface and the fabric. A wire sample support is placed on each dish to keep the fabric level. Contact adhesive is applied to the rim of the dish and the specimen, which is 96mm in diameter, is carefully placed on top with its outside surface uppermost. After a suitable time for example overnight the dishes are reweighed, and the time noted again. The water vapor permeability is calculated by the following relationship:

Where: M = loss in mass (g), t = time between weighing (h), A = internal area of dish (m2).

Results and Discussion

Air permeability

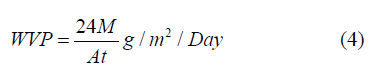

From Figure 3, It shows that the Air permeability of 100% cotton, 80%/20% cotton-polyester and 60%/40% cotton polyester were 76mm/s, 58.4 and 72.7mm/s respectively. Here we can see that air permeability of the 80%/20% cotton-polyester is lowest so we can say it is most preferable to use in the winter season. And 100% cotton will be most preferable to use in the summer season.

Water vapor permeability

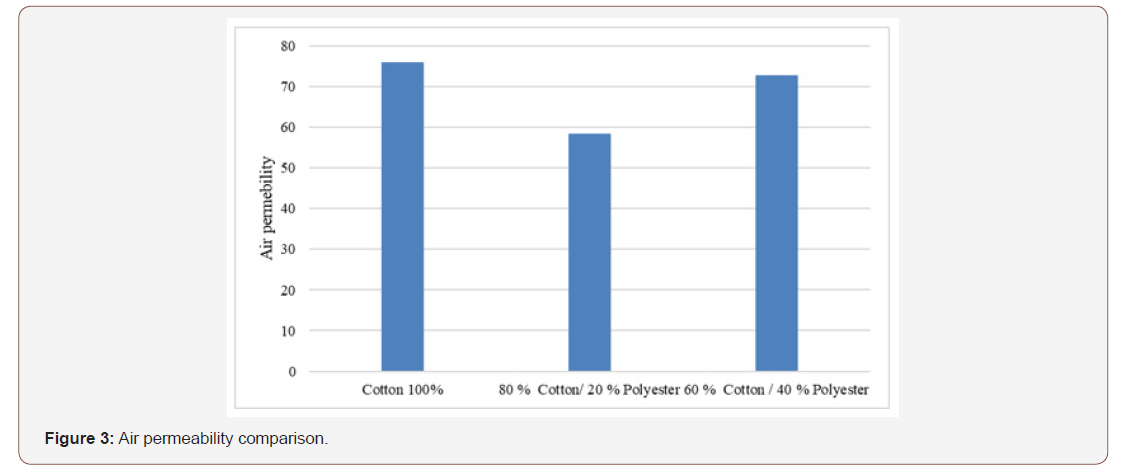

The water vapor permeability measurement results of samples are given below-From Figure 4, It shows that the water vapor permeability of 100% cotton, 80%/20% cotton-polyester and 60%/40% cotton polyester were 1390 g/m2/day, 1176 g/m2/day and 1303 g/m2/ day respectively. Here we can see that water vapor permeability of the 80%/20% cotton-polyester is lowest so we can say it is most preferable to use in the winter season. And 100% cotton will be most preferable to use in the summer season.

Thermal Conductivity

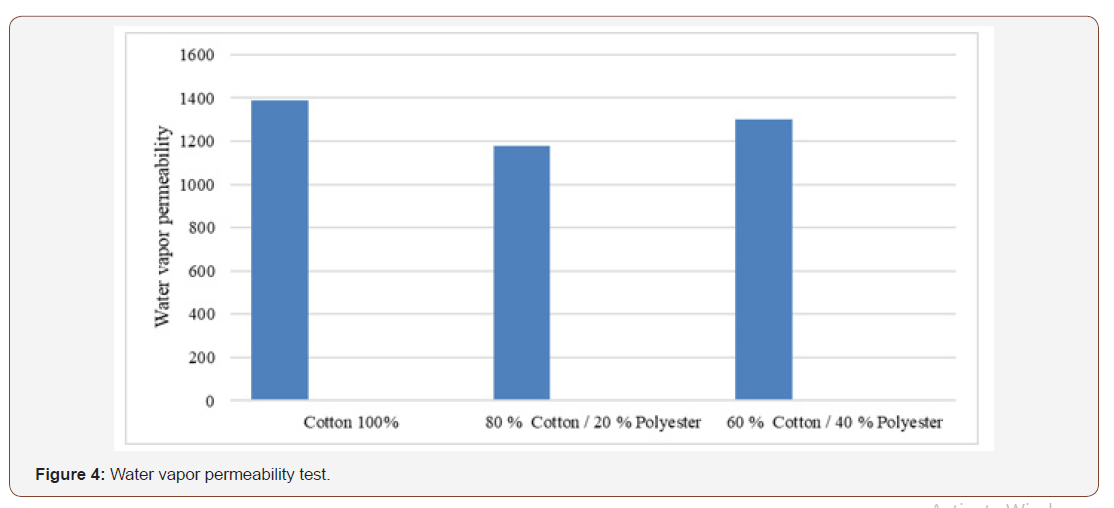

From Figure 5, It shows that the Thermal Conductivity of 100% cotton, 80%/20% cotton/polyester and 60%/40% cotton/ polyester were 0.003627 calories per cm per centigrade per sec, 0.000178 calories per cm per centigrade per sec and 0.002870069 calories per cm per centigrade per sec respectively. Here we can see that Thermal Conductivity of the 80%/20% cotton/polyester is lowest so we can say it is most preferable to use in the winter season and 100% cotton will be most preferable to use in the summer season.

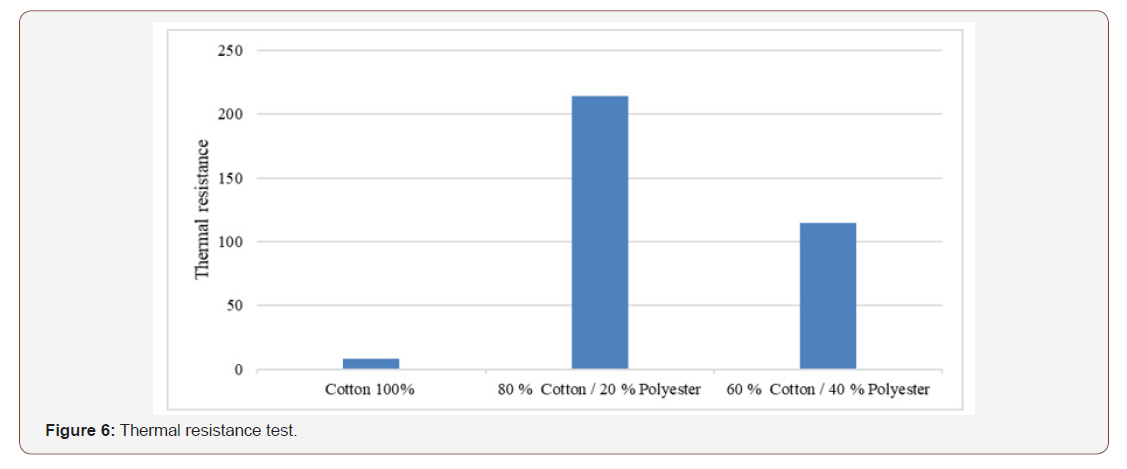

Thermal resistance

From Figure 6, It shows that the Thermal resistance of 100% cotton, 80%/20% cotton/polyester and 60%/40% cotton/ polyester were 8.21 (m2K/W), 214.29 (m2K/W) and 114.385 (m2K/W) respectively. Here we can see that thermal resistance of the 80%/20% cotton/polyester is highest so we can say it is most preferable to use in the winter season. And 100% cotton will be most preferable to use in the summer season.

Conclusion

Thermal comfort is a very important property of a fabric as a result of which a human can feel comfort or discomfort in various activities and environmental conditions. This feeling could be achieved by using different types of yarns. While comparing air permeability of the fabrics we observed that fabric with 100% cotton was most permeable to air. And the fabric made with 80%/20% cotton/polyester showed the lowest air permeability. While comparing thermal conductivity of the fabrics we observed that 100% cotton was highest, and the fabric made with 80%/20% cotton/polyester showed the lowest thermal conductivity. However, the difference between 60%/40% cotton/polyester and 80%/20% cotton polyester were much less compared to their difference with 100% cotton. Thermal resistance is inversely proportional to thermal conductivity. So higher thermal conductivity means lower thermal resistance. While comparing water vapor permeability we saw observed that 100% cotton has the highest water vapor permeability and the and the fabric made with 80%/20% cotton/ polyester showed the lowest water vapor permeability.

So, evaluating the values we can see that the 100% cotton will show most thermal comfort during summer season. And 80%/20% cotton/polyester will show most thermal comfort during winter season. Due budget and technological difficulties and unavailability of suitable testing facilities we faced a lot of problems, so we suggest using more advanced equipment and testing facility for more accurate results.

Author Contributions

This project work was done under the supervision of JKS. The sample development, experimental design, testing, and the presentation part was done by PKS, TI and MAH with the help of DP. Finally, all authors revised the manuscript carefully.

Acknowledgement

None.

Conflicts of Interest

Authors have declared no conflicts of interest.

References

- Sakthivel JC, Anbumani N (2012) Dimensional properties of single jersey knitted fabrics made from new and regenerated cellulosic fiber. Journal of Textile and Apparel, Management and Technology 7(3): 1-10.

- Gokarneshan N, Viswanath SR, Nagarajan VB, Veeraprabhakar J (2015) Dimensional characteristics of cotton and viscose weft knits. International Journal of Innovative Research Review 3(3): 84-105.

- Farha FI, Akter N (2015) Visitation of Yarn Twist on Divers Properties of Cotton Knitted Single Jersey Fabric. International Journal of Current Engineering and Technology 5(6): 3862-3865.

- Tyagi GK, Dhirendra S (2005) Thermal Comfort Characteristics of Polyester-Cotton MVS Yarn Fabrics. Indian Journal of Fibre & Textile Research 30(4): 363-370.

- Rosato Dominick V, Rosato Donald V, Rosato Matthew V (2004). Plastic product material and process selection handbook. Elsevier. p. 85.

- Gunesoglu S, Meric B, Gunesoglu C (2005) Thermal Contact Properties of 2Yarn Fleece Knitted Fabrics. Fibres & Textiles in Eastern Europe 13(2): 50.

- Gupta D, Kothari VK, Jhanji Y (2014) Heat and moisture transport in single jersey plated fabrics. Indian Journal of Fiber and Textile Research 39(2): 115-121.

- Parthiban M, Kumar R (2007) Effect of fabric softener on thermal comfort of cotton and polyester fabrics. Indian Journal of Fiber and Textile Research 32(4): 446-452.

- Nida O, Arzu M (2007) Thermal comfort properties of some knitted structures. Fibres & Textiles in Eastern Europe 5-6(64-65): 94-96.

-

Tarikul Islam, Pran Krisna Saha, Md. Anamul Haque, Debasree Paul, Joy Krishna Saha. A Study on Thermal Comfort Feeling Properties of 60%/40% and 80%/20% Cotton/Polyester and 100% Cotton Fleece. J Textile Sci & Fashion Tech. 4(3): 2019. JTSFT.MS.ID.000586.

-

Air permeability, Cotton fabric, Thermal conductivity, Thermal resistance, Water vapor, Permeability

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.