Mini Review

Mini Review

A Review: Sustainable Material Selection for Children’s Wear

Francesca Burks1, Jiangning Che1* and Wei Cao2

1Apparel Merchandising and Management Department, Huntley College of Agriculture, California State Polytechnic University, Pomona, USA

2Apparel Design and Merchandising program, Department of Family and Consumer Sciences, California State University Northridge, USA

Dr. Jiangning Che, Apparel Merchandising and Management Department, Huntley College of Agriculture, California State Polytechnic University, Pomona, USA.

Received Date: September 16, 2021; Published Date: October 18, 2021

Abstract

In this mini-review article, the health and safety concerns of textiles used for children’s wear were discussed including topics such as the adverse impacts of inappropriate clothing materials, fabric dyestuffs, and common textile wet processing. In the selection of fiber materials to use in children’s wear, usually it is best to use natural fibers to best prevent skin irritation or potential damage to children’s bodies through the dermal absorption of toxic chemicals. Rather than synthetic fibers, there are a few safer alternatives such as organic cotton, hemp, or lyocell fibers. Fabrics selected for children’s wear should be lightweight, breathable, soft, and gentle on the skin, and have some stretch to accommodate the children’s growth and playing activities. Moreover, applying natural and low-impact dyes to children’s clothing would be a sustainable practice to minimize the adverse impacts caused by conventional textile dyeing throughout the product life cycle of a garment.

Keywords:Children’s wear; Plant dyestuffs; Sustainable dyeing

Introduction

Consumers with children may be the most sensitive to health and safety risks such as pesticide or toxic chemical residue in textiles, which suggests that having children can motivate parents to be ecologically responsible. Wearing inappropriate clothing may constitute a potential threat to a child’s health. Because many types of children’s clothing are worn next to the skin, any chemical substances present on the surface can be absorbed. Chemicals used in textile dyeing, printing, and finishing processes can also have negative health influences, and the use of toxic substances and manmade or unecological materials poses health and environmental risks, especially to vulnerable children. In addition, children tend to be more physically active than adults. Excessive sweat during play and activities can cause adverse reactions between the skin and dyes and chemicals, and the excess humidity results in higher absorption of chemicals through the skin, which can create a myriad of health problems.

There are limited studies that give attention to the enormous variety of materials and chemicals being used for children’s clothes. Previous studies mainly focused on the discussion of aesthetics, comfort, and functionality of children’s clothing. Therefore, additional studies are needed to investigate sustainable practices used in developing children’s wear. The emphasis should be put on the selection of sustainable materials, application of both ecofriendly dyes and auxiliaries, the practices of textile wet application, and performance evaluation of these practices in improving the safety of children’s clothing. This review also intends to provide a more reliable perspective to manufacturers and retailers who are endeavoring in or are ready to develop green campaigns to be better position themselves in the competitive global market.

Health and Safety Concerns of Textiles

The textile industry complex uses a variety of raw and processed materials, which are assembled into textile products. There are non-chemical materials such as yarns, fabrics, thread, and fibers among others. Dyes, auxiliaries, and other chemicals are also to be considered. In addition to product design and function, materials also play a critical role in the industry, as incorrect apparel and material selection may establish possible risks to a child’s health that could cause serious body injury and/or death. O’Sullivan reported that only 38.8% of 183 school children’s outerwear met the safety recommendation established by the Consumer Product Safety Commission [1]. Minimizing sun exposure via sun-protective clothing among children is also particularly important [2,3], since childhood sunburns may be an antecedent to melanoma [4,5]. Several studies [6-8] have revealed the correlation of common skin eczema, infectious skin diseases, contact dermatitis, and other skin lesions with inappropriate clothing.

Even though synthetic fibers and conventionally grown cotton are still widely used in apparel production, there has been a shift in the apparel industry towards using more recyclable and biodegradable materials for apparel, such as organic cotton, to minimize the negative environmental impacts of production since the millennium. However, little research has been done on reducing health risks to children [9] via suitable fiber and fabric selection and improvement of processing technology.

Fiber - Cotton

In children’s wear, fabrics are usually constructed from cotton or polyester because both materials are more affordable and easier to produce. In recent years, a noticeable shift has occurred in the children’s wear market towards using organic cotton over regular cotton due to the health and environmental concerns arising from the use of harsh chemicals and pesticides to treat regular cotton. Apparel retailers and manufacturers, such as H&M, Levi Strauss & Co, Marks and Spencer, and Nike have made some efforts to use organic cotton [10]. On the other hand, many apparel products have been developed using other environmentally friendly fibers. Patagonia has been offering outdoor apparel products made from recycled polyethylene terephthalate bottles [11], and Jimtex, a division of Martex Fiber Corp., has produced regenerated fibers from recycling cut and sew clippings from apparel manufacturing [12].

In addition, more natural fiber alternatives are gaining favor over synthetic materials. Ola’s [7] study indicated a strong effect of textile materials on dermatitis in children, and they recommended using cotton and other natural materials for uniforms instead of wool and synthetic fibers because cotton has better absorbency and a more suitable permeability, which aid the transference of sweat and keep skin dry. Patchett K, et al. [8] study confirmed that children’s clothing made with cotton had a lower level of cat allergen than clothing constructed of wool and polyester [13].

Fiber– Organic cotton

Organic cotton is grown without pesticides which can have negative impacts on the health of farmers and children and promotes farming practices that are healthier for the environment. It is also comfortable for children to wear close to their skin [14] (“4 Benefits of Buying Organic Baby Clothes,” n.d.). Because consumers have become more aware of the potential dangers to children that could arise from materials and clothing produced using synthetic chemicals, attention has shifted to using organic cotton. While children’s wear made with organic cotton is available, it is not as cheap and easy to source as that made using conventionally grown cotton. Despite the higher price of organic cotton clothing compared with conventional cotton clothing, parents have shown higher interest in organic fabric clothing if it is beneficial to their children [15].

Fiber– Hemp

Another natural cellulosic fiber with great potential to be used in children’s clothing is hemp. Its rigid structure and overall lack of elasticity generally make it rough and uncomfortable to be worn against the skin. However, modern industrial modification processes have improved the hand of the fiber and used it in blends with other fibers. Studies have proven that industrial hemp has better performance than cotton in moisture absorption/desorption and inhibition of fungi [16,17]. Industrial hemp is naturally resistant to mold and mildew and possesses anti-microbial and UV protection functions [18,16]. Clothing made with cotton and hemp could help reduce the risk of skin disease for children, and its porous nature also allows it to have higher heat absorption and retain dyes more easily [19]. These inherent qualities would add benefits to children’s wear. Furthermore, the growth of hemp benefits the environment due to it has bioremediation abilities that help remove toxins from the soil, as well as “lower impact in respect to energy, water, and ecology,” and lack of need for pesticides or fertilizers, making it an attractive crop to grow [20]. While it can be used for a wide range of different products, hemp is usually blended with synthetic fibers, and little research has been done on blending hemp with other natural fibers.

Fiber– Lyocell

In addition to organic cotton and hemp, Lyocell fiber has been widely used in children’s wear. Lyocell is an environmentally friendly regenerated cellulosic fiber by using N-methyl morpholine- N-oxide (NMMO) that does not produce hazardous byproducts and can be almost completely recovered and reused. Moreover, Lyocell fiber also has great tenacity, absorbency, breathability, and a soft hand that makes it comfortable to wear against the skin [21]. The manufacturing process of Lyocell is a closed-loop and uses nontoxic chemicals that would not pose any danger to children, and the properties of lyocell fibers are suitable for children’s wear, making it a great alternative to synthetic fibers and conventional cotton.

Fabric choices

Fabrics made of natural fibers that have softly twisted yarns and medium to high thread counts are suitable because they are breathable, have some stretch, and are soft against the skin, which will help prevent irritation. Usually, fabrics with knit structures, such as jersey knits provide comfort, breathability, and can stretch to fit children’s forms as they develop and grow, making them appropriate for sleepwear, T-shirts, or sweaters [22]. Fabrics with lightweight, plain weave structures, such as gauze have less elasticity, but are also breathable and have good absorbency, and can be used in button-up shirts or dresses.

Traditional Textile Wet Processing

Textile dyeing, printing, and finishing are the most chemicalconsuming processes since they involve the use of different dyes, auxiliaries and agents, metal ions, and surfactants. A large amount of natural and synthetic fibers (i.e. cotton, polyester) are treated with these chemicals to achieve multifunctional properties such as self-cleaning, antimicrobial, insect repellence, wrinkle resistance, antioxidant, UV-protective, waterproof, mothproof, flame retardant, and stain-resistant properties for various hygienic applications. The properties of the fibers and chemicals used during textile processing might also cause irritation or allergic reaction among wearers, which can be explained as either textile contact dermatitis or chemical allergy [23,24]. Textile allergies usually occur when peoples’ skin comes into direct contact with these fabrics.

For children, chemicals used in dyeing and finishing processes present in their clothing can cause developmental issues, heighten future reproductive risks, and create hormone imbalances through dermal or oral absorption [25]. Many studies indicated that allergic contact dermatitis in children can appear in symptoms such as red cheeks and ears, hyperactivity, and behavior or learning problems [26-29]. The potential causations of these incidents include an improper selection of clothing materials, excess sweat creating reactions between the skin and dyes in the materials, and excess humidity leading to more absorption of chemicals through the skin. Skin disease can cause severe disability and handicaps in children [30]. In these studies, chemicals left on the fabrics during manufacturing were transferred from fabrics to the skin, absorbed by the skin, and reacted to cause a wide variety of health problems such as nausea, diarrhea as well as muscle and joint pain. Other studies have reported that incidents such as the high prevalence of common skin eczema, infectious skin diseases, contact dermatitis, and other skin lesions in children were caused by a lack of appropriate and safe clothing [6-8,31].

In addition, children have a tendency to chew and gnaw on their clothes, which increases the chance of the intake of dyes and other chemical residuals in textiles. Giusti F, et al. [32] found that disperse dyes (one of the conventional synthetic dyes) should be regarded as a potential allergen to children with suspected contact sensitization. A clinic finding reported 5 patients suffering from allergic contact dermatitis due to Disperse dyes in their diapers [33]. The absorption of these chemicals into the skin for newborns and infants is practically unavoidable, especially when babies tend to chew and gnaw on their clothes. Because their skin is thinner, covered by a sort of down that increases the absorbent surface and there is a high ratio between skin surface area and body weight ratio [34], the effect of hazardous chemicals from dyes and auxiliaries are particularly serious and can impact their growth. Bacteria (such as Staphylococcus species, Streptococcus pneumonia, and Pseudomonas aeuroginosa) and fungi are two predominant microorganisms for (non-viral) microbial keratitis in children [35].

Chemicals used in dyeing and finishing can remain on clothes after laundering, presenting many potentially dangerous health problems for kids [36]. Luckily, it has been found that many other popular chemicals, such as formaldehyde reactants in wrinkle-free finishes for cotton, brominated FRs in flame-resistant finishes for household fabrics, and fluorochemicals for soil-repellent finishes in outdoor wear, are rarely used in children’s wear. Nonylphenols, phthalates, per fluorinated chemicals, and formaldehyde used in apparel to impart properties such as flame retardants, wrinkle resistance, and mildew resistance can hinder mental and physical development, hormone function, and immune function, which poses risks to young children when used in infant wear [37]. Additionally, benzotriazoles and benzothiazoles- chemicals that can be used as biocides, in household detergents, and antifreeze solutions- have also been found in clothing and textiles and could potentially be absorbed by children through dermal and oral exposure [24]. Chemicals used in textile wet processes also raise health and safety issues, which is even more critical in the case of children, since their skin is thinner and more permeable than that of an adult’s and can absorb harsh chemicals from their clothes more easily [38]. Phthalates, which are chemicals that act as plasticizers, surfactants, and detergents, have been detected in preschool children’s clothing from different Asian countries and present possible reproductive risks [39].

Natural Dyeing and Mordanting

Synthetic dyeing

Synthetic dyes and chemicals have been widely used to produce a wide range of colors with high tinctorial strength and colorfastness properties to satisfy customers in the textile industry. It has been reported that textile industries all over the globe produce and use approximately 1.3 million tons of dyes, pigments, and dye precursors that cost around $23 billion [40]. In recent years, there has been a drop in the usage of such chemicals; however, it is estimated that over 10,000 different dyes and pigments are used industrially, and over 7x 105 tons of synthetic dyes are produced annually worldwide [41].

While synthetic dyes have given rise to brightness and long-lasting colors, they have also created an array of health and environmental problems, since their excessive production inevitably leads to excessive waste and contamination [42]. Millions of tons of textile dyeing, printing, and finishing wastewater are discharged into the ecosystem annually. The dumping of toxic dye effluent into rivers and lakes harms aquatic life, puts the health of people at risk, and can cause allergic reactions to consumers who wear products colored with synthetic dyes [22]. It is essential to identify the relevant chemical restrictions in textiles (and other materials) that are fundamental to the retail and manufacture of consumer products, such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to substances and articles manufactured and sold. In a recent restriction within REACH, more than thirty-three textile chemicals have been added to Annex XVII of REACH under a major new amendment, which came into effect on 1st November 2020. Brands, retailers, and manufacturers of textiles and products containing textiles need to be aware of this major change in REACH regulation and ensure that finished articles are compliant with the new amendment [43].

So far as textile dyeing, printing, and finishing are concerned, conventional synthetic dyes (including benzene and organochlorides) and auxiliaries, which cannot be washed out in the laundry, might induce skin allergies or sensitivities. Chemicals present in these dyes can cause adverse health effects among consumers, and a study found thirty-one dyes have caused allergic contact dermatitis [24]. Hatch KL, et al. [24] summarized the textile-dye prevalence studies and indicated a lower prevalence of non-dispersed than to disperse dyes. Even though the majority of synthetic dyes are safe to use for adults, minimizing the adverse impacts caused by conventional synthetic dyeing for children and babies is crucial. The chemicals present in synthetic dyes and materials can be very harmful to young children and infants since they are especially vulnerable to outside elements due to their thinner, more permeable skin [38]. However, the issue of applying sustainable dyes for children’s clothing has not been adequately investigated at the present [44].

Natural dyeing

Textile dyeing and finishing in a green way can be achieved by using chemical-free dyes and environmentally conscious processes. Using natural dyes made from plants, marine invertebrates (like sea urchins and starfish), algae, bacteria, and fungi are not just biodegradable but also possess medicinal properties. Plants, fruits, barks, stems, minerals, and herbs are used to make fabrics with anti-bacterial, anti-inflammatory, and anti-allergenic properties. Historically, natural dyes from plants, fruits, and insects, such as those derived from madder, cochineal, kermes, indigo, and algae, have been used by civilizations around the world to color clothing and other textiles [45-47]. They are comparatively less dangerous and toxic to human health and recent experiments using them in clothing dye have concluded they cause no or less skin dermatitis [48]. However, developing methods to produce natural dyes in the quantities required, with high colorfastness, and at reasonable costs is the primary challenge in the textile dyeing field.

Currently, dyeing application using natural colorants is regaining interest and can be a promising technology that has the potential to minimize environmental pollution due to the excessive use of synthetic dyes and chemical agents. More research is being focused on using different methods and sources of natural dyes to increase color payoff and colorfastness properties, as well as to explore other important attributes of certain natural ingredients that can provide added benefits to materials. There are many different types of natural resources that have been studied in an effort to find substitutes for synthetic dyes. One of those typically used in experiments is black rice extract, which was found to have poor lightfastness and moderate colorfastness as a dye yet provided excellent antibacterial properties that could be used to substitute chemicals employed for antibacterial resistance [49]. In addition to this, blackcurrant applied to cotton and silk was discovered to provide good colorfastness, strong antibacterial properties, and UV resistance [50], whereas henna used as a natural dye produced excellent fastness properties and increased color intensity [50].

Natural colorants have produced delicate and subdued shades, and many of them can exhibit novel functional agents in the achievement of highly active textile surfaces having deodorizing, antioxidant, antimicrobial, antifeedant, and UV protection properties [51]. Most of the current perspective is largely intended to outline the functional finishing of different textile substrates with colorants and functional agents exploited from natural, renewable sources. To find an alternative colorant for the current synthetic dyestuffs used in the textile industry, colorants from nature have been suggested as a candidate with its better biodegradability, renewability, and environmental compatibility [52]. Natural dyes have historically been used to dye natural fibers only, but recent research shows that they could also be used to color some synthetic fibers. The coloration process with natural colorants on various synthetic textile materials was developed in the presence of dopamine, which in-situ self-polymerization could produce rich polyphenolic coloration anchors [53]. Some additional alternatives include colorants from black carrot, prickly pear peel, cochineal, pomegranate juice, and annatto seeds [54-57].

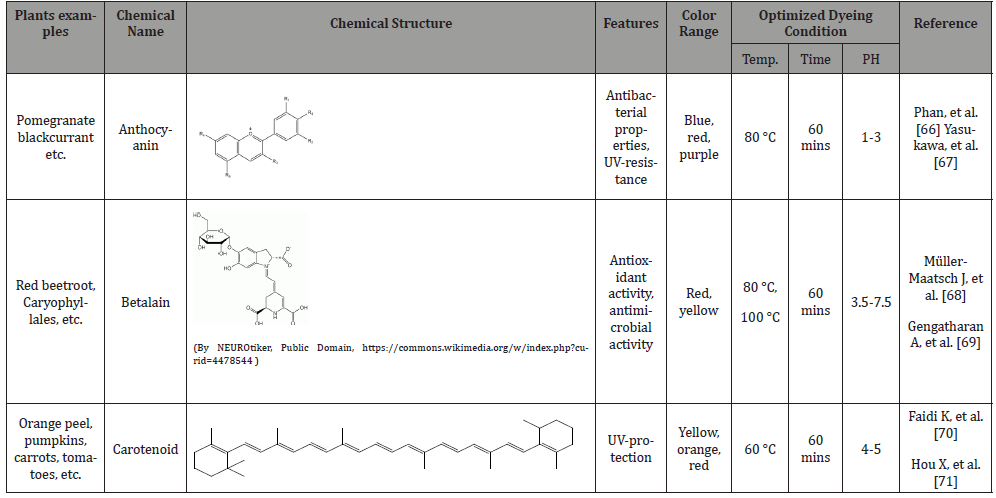

Natural resources rich in coloring compounds are typically anthocyanins, carotenoids, and betalains, which are the most popular to be used in food coloring and could also be used in textile dyeing applications [58]. Anthocyanins mainly produce reds, purples, and blues, and can be extracted successfully from fruits such as pomegranate, which has been found to provide antibacterial properties, though more research is needed in terms of improving colorfastness properties [57]. Carotenoids are yellow, orange, and red organic pigments produced by plants and algae as well as several bacteria and fungi. Carotenoids give the characteristic color to pumpkins, carrots, corn, tomatoes, canaries, flamingos, salmon, lobster, shrimp, and daffodils. Betalains are a class of red and yellow pigments found in plants of the Caryophyllales and some higher-order fungi. They are most often noticeable in the petals of flowers but may color the fruits, leaves, stems, and roots of plants that contain them. They include pigments such as those found in beets. The specification and dyeing profiles of these typical natural colorants with the structure are summarized in Table 1.

Table 1:Characteristic of the patients with AED withdrawal (n=162).

Applying natural and low-impact dyes on children’s clothing could be one of the many practices to minimize the adverse impacts caused by conventional textile dyeing throughout the product life cycle of a garment. In apparel products, and especially in children’s wear, it is crucial to avoid harmful dyes and toxic chemicals to prevent them from being absorbed into their skin. Because of this, dyes that are obtained from natural resources are advantageous as an alternative way of coloring children’s wear.

Mordanting – chemical vs. bio

Natural dye application has been seen as hazardous since the chemical binding agents (mordant) needed during dyeing contain heavy metals like compounds of iron, alum, chrome, and potassium. Mordants are used in the textile dyeing industry to fix colors to fabrics and give an increased depth of shade. However, they are usually composed of heavy metals that linger in dye effluent, such as “Cupric sulfate, potassium dichromate, stannous chloride, and stannic chloride,” which are widely used “despite being toxic in nature,” [59]. Contact with metals such as chrome and nickel increase exponentially allergic contact disease for kids during school age and adolescence [60].

While natural dyes are eco-friendlier to use, they are often treated with mordants containing heavy metals including iron, chromium, and copper compounds because they are cheap and provide excellent color exhibition and colorfastness. Though they are generally low to medium in toxicity, they do not fully exhaust in dyeing solutions and pollute areas where wastewater is dumped, which may linger on clothing, thus, causing allergic reactions or other health problems via dermal absorption. To reap the full benefits of using natural dyes to reduce or eliminate the number of toxic chemicals present in children’s wear, the auxiliaries used in the mordanting process must also be free of or contain minimal amounts of harsh chemicals. To promote more sustainable color that can be achieved with less pollution and hazards to both factory workers and children who wear the finished products, biological mordants should be used to fix natural dyes to fibers.

The substitution of metal mordants by enzymes complexed with tannic acid to improve the dye adsorption was proved [61]. In conjunction with natural dyestuffs, the use of biological mordants has been studied due to environmental standards limiting chemicals present in metal mordants and to prevent health concerns and contamination that arise from the use of metal mordants. In one study, the use of chitosan, a sugar from shellfish skeletons, as a biological mordant combination with a dye extracted from seaweed provided great uniformity and color strength when applied to cotton. In addition to chitosan, tannic acid is another type of natural mordant that can be used to impart better colorfastness to laundering and depth of shade by forming a complex with the dye molecule that gives an “increase in its molecular size and a decrease in water solubility” [64]. Tannic acid has been used and studied in a wide range of fields due to its unique antibacterial, antioxidation, and anti-carcinogenic properties, and, in small amounts, tannic acid mordant is considered safe for wearers when applied to fabric meant to be worn close to the skin [62]. Myrobalan, pomegranate rinds, tartaric acid, and ash from banana and guava leaves have also been successfully used as biological mordants, and an experiment by Rather, et al. [63] reported that using gallnut as a biological mordant in conjunction with Adhatoda vasica as a natural dye applied to wool gave better wash fastness properties and depth of shade compared to samples mordanted with alum and stannous chloride. Lotus leaf or pot extract has also been successfully used as a fabric treatment to improve the color intensity and provide an antibacterial finish [57]. In another study, the effect of various UV absorbers and antioxidants on the light fastness of madder, weld, and wood natural dyes were determined. After treatment with UV absorbers and antioxidants, an increase in the light fastness of dyed cotton was observed.

Conclusion and Perspective

Based on the information reviewed, minimizing skin diseases, allergies, and injures caused by the adverse impacts of inappropriate clothing materials, fabric dyes, and unsafe clothing design in children’s clothing are pertinent and critical in improving children’s quality of life [64]. Overall, in the selection of fibers and materials to use in children’s wear, usually it is best to use natural fibers to best prevent skin irritation or potential damage to children’s bodies through the dermal absorption of toxic chemicals. Fabrics selected for children’s wear should be lightweight, breathable, soft to wear against the skin, and have some stretch to accommodate them as they grow and play. There are many safer alternatives to manmade, synthetic fibers, such as organic cotton, hemp, and lyocell or other cellulosic fibers subjected to the lyocell process.

While improvements still need to be made as far as increasing colorfastness to light and laundering for most natural colorants, many research projects are being conducted into a wide variety of natural sources for dyestuff and attempt to optimize natural dyeing processes without employing harmful chemicals. It is one of the possible alternatives to replacing synthetic dyes, but not enough is known to make natural dyes commercially viable around the world [65]. However, the lower negative impact they have on the health of the environment, consumers, and workers makes them worth studying further to improve their qualities. Therefore, for the future study of natural dyeing, the potential toxicity and safety concerns related to natural dyes and application must be investigated, since there are needs for the standardization of techniques, practices, and processes related to natural dyeing. For industry practices, applying natural and low-impact dyes on children swear as safer alternatives to synthetic dyestuffs could help minimize the adverse impacts caused by conventional textile dyeing.

Acknowledgement

None.

Conflict of Interest

Authors declare no conflict of interest.

References

- O’Sullivan J, Ryan CA (1999) No strings attached: preventing deaths from children’s clothing. Arch Dis Child 81(3): 278.

- Harrison SL, Buettner PG, Maclennan R (2005) The North Queensland ‘’Sun-safe clothing’’ study: design and baseline results of a randomized trial to determine the effectiveness of sun-protective clothing in preventing melanocytic nevi. Am J Epidemiol 161(6): 536-545.

- Stern RS (1995) Sunscreens for cancer prevention. Arch Dermatol 131(2): 220-221.

- Stern RS, Weinstein MC, Baker SG (1986) Risk reduction for nonmelanoma skin cancer with childhood sunscreen use. Arch Dermatol 122(5): 537-545.

- Katasambas A, Nicolaidous E (1996) Cutaneous malignant melanoma and sun exposure: recent developments in epidemiology. Arch Dermatol 132(4): 444-450.

- Fung WK (2000) Prevalence of Skin Disease Among School Children and Adolescents in a Student Health Service Center in Hong Kong. Pediatric Dermatology 17(6): 440-446.

- Ola AE, Barakat G, Huda GMA (2008) Association between materials used in children’s clothes and contact dermatitis. Journal of Applied Sciences Research 4(10): 1155-1165.

- Patchett K, Lewis S, Crane J, Fitzharris P (1997) Cat allergen (Fel d 1) levels on school children’s clothing and in primary school classrooms in Wellington, New Zealand. J Allergy Clin immunol100(6 Pt 1): 755-759.

- Beattie PE, Lewis-Jones M (2006) A comparative study of impairment of quality of life in children with skin disease and children with other chronic childhood diseases. British Journal of Dermatology 155(1): 145-151.

- Organic Exchange (2007) Organic Cotton Market Report highlights.

- Rupp J (2008) Ecology and economy in textile finishing. Textile World 158: 38-41.

- Marks J (2007) Eco-friendly merchandising on the rise. Home Textiles Today 28: 1-12

- Beegum MR (2005) Speaking of Child Care and Nutrition. New Dawn Press Group, Sterling Publishing.

- 4 Benefits of buying organic baby clothes.

- Nolan K (2006) Wal-Mart first mass retailer to offer organic clothing. DSN Retailing Today 45: 20.

- Zhang JC (2009) Structure and properties of China hemp fibers. Chemistry Industry Ed. Beijing, China.

- Gam HJ, Cao H, Farr C, Kang M (2010) Quest for the eco-apparel market: a study of mothers’ willingness to purchase organic cotton clothing for their children. International Journal of Consumer Studies 34(6): 648-656.

- Nissen L, Zatta A, Stefanini I, Grandi S, Sgorbati B (2010) Characterization and antimicrobial activity of essential oils of industrial hemp varieties (Cannabis sativa). Fitoterapia 81(5): 413-419.

- Muzyczek M (2020) The use of flax and hemp for textile applications. Kozłowski R, Mackiewicz-Talarczyk M (edts), Handbook of natural fibres (2nd edn), Woodhead Publishing, UK, pp. 147-167.

- Novaković M, Popović DM, Mladenović N, Poparić GB, Stanković SB (2020) Development of comfortable and eco- friendly cellulose based textiles with improved sustainability. Journal of Cleaner Production 267: 122154.

- Zhang S, Chen C, Duan C, Hu H, Li H, et al. (2018) Regenerated cellulose by the lyocell process, a brief review of the process and properties. BioResources 13(2): 1-16.

- Sita RM (1977) Fire Resistant Sleepwear for Young Hospital Patients. Hospital Topics 55(4): 40–41.

- Ngan V (2013) Textile dye allergy.

- Hatch KL, Maibach HL (2000) Textile dye allergic contact dermatitis prevalence. Contact Dermatitis 42(4): 187-195.

- Liu W, Xue J, Kannan K (2017) Occurrence of and exposure to benzothiazoles and benzotriazoles from textiles and infant clothing. Science of The Total Environment 592: 91-96.

- Roul S, Ducombs G, Taieb A (1999) Usefulness of the European standard series for patch testing in children. A 3-year single- centre study of 337 patients. Contact Dermatitis 40(5): 232-235.

- Giordano-Labadie F, Rance F, Pellegrin F, Bazex J, Dutau G, et al. (1999) Frequency of contact allergy in children with atopic dermatitis: results of a prospective study of 137 cases. Contact Dermatitis 40(4): 192-195.

- Mortz CG, Andersen KE (1999) Allergic contact dermatitis in children and adolescents. Contact Dermatitis 41(3): 121-130.

- Weston WL, Bruckner A (2000) Allergic contact dermatitis. Pediatr Clin N Am 47(4): 897-907.

- Levis-Jones MS, Finlay AY (1995) The children’s dermatology life quality index (CDLQI): initial validation and practical use. Br J Dermatol 132(6): 942-949.

- Qashqary KQ (1994) The effect of materials’ quality of the internal clothes in causing dermatitis. Alexandria Agricultural Research Journal.

- Giusti F, Massone F, Bertoni L, Pellacani G, Seidenari S (2003) Contact sensitization to disperse dyes in children. Pediatr Dermatol 20(5): 393-397.

- Alberta L, Sweeney S, Wiss K (2005) Diaper Dye Dermatitis. Pediatrics 116(3): 450-452.

- Pigatto P, Martelli A, Marsili C, Fiocchi A (2010) Contact dermatitis in children. Ital J Pediatr 36(2): 1-6.

- Al-Otaibi AG (2012) Non-viral microbial keratitis in children. Saudi Journal of Ophthalmology.

- Katesurfs (2014) The toxic truth about what’s in your child’s clothing (and easy things you can do about it).

- Luo I (2015) Made-in-China clothing for kids could contain toxic chemicals.

- Caceres A (2018) Why organic clothes matter for your baby.

- Tang Z, Chai M, Wang Y, Cheng J (2020) Phthalates in preschool children’s clothing manufactured in seven Asian countries: occurrence, profiles and potential health risks. J Hazard Mater 387: 121681.

- Sengupta S, Singh BR (2006) Natural, ‘‘Green’’ Dyes for the Textile Industry. Technical Report No.57, Toxics Use Reduction Institute University Research in Sustainable Technologies Program.

- Drumond Chequer FMD, De Oliveira GA, Anastacio Ferraz ER, Carvalho J, Boldrin Zanoni MV, et al. (2013) Textile dyes: Dyeing process and environmental impact. Eco-Friendly Textile Dyeing and Finishing.

- Kumbhar S, Hankare P, Sabale S. Kumbhar R (2019) Eco- friendly dyeing of cotton with brown natural dye extracted from Ficus amplissima smith leaves. Environmental Chemistry Letters 17(2): 1161-1166.

- (2019) New chemical restrictions in textiles: Are you ready?

- Begala K (1994) Child’s death spurs effort to release guidelines for drawstrings on children’s jackets and sweatshirts.

- Ali N (2018) Colourants made from aphids and ivy gum. Heritage Science 6(1): 1-14.

- Petroviciu I, Teodorescu I, Albu F, Virgolici M, Nagoda E, et al. (2019) Dyes and biological sources in nineteenth to twentieth century ethnographic textiles from Transylvania, Romania. Heritage Science 7(1): 1-15.

- Yusuf M, Shabbir M, Mohammad F (2017) Natural colorants: historical, processing and sustainable prospects. Nat Prod Bioprospect 7(1): 123-145.

- Kherallah A (2003) Information updates in textile industries.

- Hong KH (2015) Preparation and properties of cotton and wool fabrics dyed by black rice extract. Textile Research Journal 85(18): 1875-1883.

- Bhuiyan MR, Islam A, Ali A, Islam M (2017) Color and chemical constitution of natural dye henna (Lawsonia inermis L) and its application in the coloration of textiles. Journal of Cleaner Production 167: 14-22.

- Shahid-ul-Islam, Sun G (2017) Thermodynamics, Kinetics, and Multifunctional Finishing of Textile Materials with Colorants Extracted from Natural Renewable Sources. ACS Sustainable Chemistry & Engineering 5(9): 7451-7466.

- Bulut MO, Akar E (2012) Ecological dyeing with some plant pulps on woolen yarn and cationized cotton fabric. J Clean Prod 32: 1-9.

- He L, So VLL, Fan S, Xin JH (2018) Polyphenol-Assisted Natural Coloration on Various Synthetic Textile Materials. Fibers and Polymers 19(7): 1411-1419.

- Batool F, Adeel S, Azeem M, Ahmad Khan A, Ahmad Bhatti I, et al. (2013) Gamma radiations induced improvement in dyeing properties and colorfastness of cotton fabrics dyed with chicken gizzard leaves extracts. Radiat Phys Chem 89: 33-37.

- Scarano P, Naviglio D, Prigioniero A, Tartaglia M, Postiglione A, et al. (2020) Sustainability: Obtaining Natural Dyes from Waste Matrices Using the Prickly Pear Peels of Opuntia ficus-indica (L.) Miller. Agronomy 10(4): 528.

- Elshemy NS (2011) Unconventional Natural Dyeing Using Microwave Heating with Cochineal as Natural Dyes. Research Journal of Textile and Apparel 15(4): 26-36.

- Naz S, Siddiqi R, Ahmad S, Rasool S, Sayeed S (2007) Antibacterial Activity Directed Isolation of Compounds from Punica granatum. Journal of Food Science 72(9): M341-M345.

- Azeredo HM (2009) Betalains: properties, sources, applications, and stability – a review. International Journal of Food & Science Technology 44(12): 2365-2376.

- Teli MD (2015) Advances in the dyeing and printing of silk. Advances in Silk Science and Technology: 55-79.

- Pigatto P, Martelli A, Marsili C, Fiocchi A (2010) Contact dermatitis in children. Italian Journal of Pediatrics 36(1): 2-2.

- Vankar P, Shanker R, Verma A (2007) Enzymatic natural dyeing of cotton and silk fabrics without metal mordants. Journal of Cleaner Production 15(15): 1441-1450.

- Lou W, Li B, Dubova Н (2019) Recent advances in studying tannic acid and its interaction with proteins and polysaccharides. Food Science & Technology 13(3): 63-69.

- Rather LJ, Islam S, Shabbir M, Bukhari MN, Shahid M, et al. (2016) Ecological dyeing of woolen yarn with Adhatoda vasica natural dye in the presence of biomordants as an alternative copartner to metal mordants. Journal of Environmental Chemical Engineering 4(3): 3041-3049.

- Joseph P (2015) Fabric Science (Chapter 16 - Guide to Fabric Selection), 11th Ed, Fairchild.

- M Ángeles B, Eva B, Ignacio M, Pablo D (2015) Dyeing cotton with Eisenia bicycles as natural dye using different biomordants. Annals of the University of Oradea: Fascicle of Textiles, Leatherwork 16(2): 9-12.

- Phan K, Van Den Broeck E, Van Speybroeck V, De Clerck K, Raes K, et al. (2020) The potential of anthocyanins from blueberries as a natural dye for cotton: A combined experimental and theoretical study. Dyes and Pigments 176: 108180.

- Yasukawa A, Chida A, Kato Y, Kasai M (2017) Dyeing silk and cotton fabrics using natural blackcurrants. Textile Research Journal 87(19): 2379-2387.

- Müller-Maatsch J, Schweiggert RM, Carle R (2016). Adulteration of anthocyanin- and betalain-based coloring foodstuffs with the textile dye “Reactive Red 195” and its detection by spectrophotometric, chromatic and HPLC-PDA-MS/MS analyses. Food Control 70: 333-338.

- Gengatharan A, Dykes GA, Choo WS (2016) Stability of betacyanin from red pitahaya (Hylocereus polyrhizus) and its potential application as a natural colourant in milk. International Journal of Food Science & Technology 51(2): 427-434.

- Faidi K, Baaka N, Hammami S, Mokni RE, Mighri Z, et al. (2016) Extraction of carotenoids from Lycium ferocissimum fruits for cotton dyeing: Optimization survey based on a central composite design method. Fibers and Polymers 17(1): 36-43.

- Hou X, Chen X, Cheng Y, Xu H, Chen L, et al. (2013) Dyeing and UV-protection properties of water extracts from orange peel. Journal of Cleaner Production 52: 410-419.

-

Francesca Burks, Jiangning Che, Wei Cao. A Review: Sustainable Material Selection for Children’s Wear. J Textile Sci & Fashion Tech 9(2): 2021. JTSFT.MS.ID.000708.

-

Children’s wear, Plant dyestuffs, Sustainable dyeing

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.