Research Article

Research Article

Influence of Temperature on the Consolidation Behavior of Structural Spool Components Made of Hybrid Yarns with a Shrinking Reinforcing Component and a Matrix Component

Susanne Schanz*, Dr. -Ing. Kathrin Haigis, Christoph Riethmüller, Viola Finckh and Prof. Dr. -Ing. Götz T Gresser

German Institutes for Textile and Fiber Research (DITF), Denkendorf, Germany

Susanne Schanz, Smart Living Textiles Technology Center, German Institutes for Textile and Fiber Research (DITF), Denkendorf, Germany.

Received Date:December 04, 2024; Published Date:December 19, 2024

Abstract

Hybrid yarns, consisting of a thermoplastic matrix and a shrinking reinforcing component, enable the production of textile structural-windingcomponents with an innovative thermal consolidation behavior. The German Institutes for Textile and Fiber Research (DITF Denkendorf) have shown in their research that the consolidation and the mechanical properties can be varied over a wide range by specifically adapting the material properties and process conditions. With these hybrid yarns, flexible and porous structural components, as well as those with few pores and high strength, can be specifically produced in a free consolidation without external pressure.

Keywords:Free thermal consolidation; Structure winding; Shrinking reinforcing component; Adjustable consolidation; Hybrid yarn

Introduction

The development of highly functional structural components with reinforcing components has become increasingly important in recent years. They are used in the aviation and automotive industries. The advantages of these structural components can be found in an optimal combination of low weight and high strength.

The DITF Denkendorf has also been working on the development of textile structural components for many years [1]. A particular focus here is on structural components, as these make it possible to produce established and new structures quickly, economically, and flexibly. In numerous research projects on the topics of structuralwinding and structural-balling technology, the techniques were advanced [2-6].

The development of new hybrid yarns using twisting and wrapping technologies is a central field in this context.

Hybrid yarns are special yarns that consist of a combination of different materials or fiber types, which make it possible to combine different properties. To develop structural-winding components for thermal consolidation, a hybrid yarn is needed that consists of a high-melting-force-absorbing component and a low-melting matrix component.

Another important aspect of the research work on structuralwinding components is the thermal consolidation possibilities of the winded structure.

For this purpose, two thermal consolidation processes have been used at the DITF so far.

One method is free thermal consolidation, in which the winded structures are heated freely, i.e., without external pressure, in an oven. This leads to an uneven bond between the matrix and the reinforcing fibers in many hybrid yarns used, which usually consist of continuous filaments as the high-melting component. The lowmelting matrix material flows together and collects in drops at discrete points on the high-melting reinforcing component. In between, there are areas where the reinforcing fibers are not completely connected by the matrix. Moss-like fragile structures arise with a large surface.

To obtain a more uniform embedding of the reinforcing fibers compared to free thermal consolidation, forced thermal consolidation is often used. In this process, the winded structure is heated in the oven while applying a mechanical pressure (i.e., by creating a vacuum). This can reduce the formation of droplets and air inclusions, but the applied pressure can cause the winding layers to shift.

At the DITF, special hybrid yarns have now been developed based on the described experience, in which the high-melting forceabsorbing component consists of a thermally shrinking polyester yarn and the matrix component of a low-melting polypropylene. This is to ensure that the contact pressure of the hybrid yarn is applied by the yarn itself during free consolidation.

In the present work, the influence of different process temperatures on the consolidation of structural components made of hybrid yarns was investigated. These yarns contain a high-melting polyester (PES) reinforcement component and a lowmelting polypropylene (PP) matrix component. This combination aims to use the shrink effect of the PES yarn to compact the wounded structure and to homogenize the matrix without the need for external mechanical pressure.

Polypropylene has a melting temperature of 160-175 °C. Its selfignition temperature is 430-450 °C. Thus, a process temperature of 160° to 210 °C could be selected in the investigations.

This represents the set temperature in the oven. The actual temperature directly at the filament could not be measured.

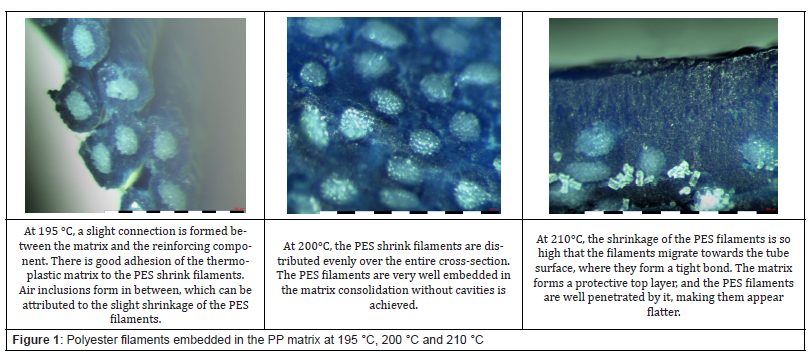

During the melting process of the thermoplastic matrix, the reinforcing filament, the polyester, shrunk, creating an internal contact pressure that pressed the filament bandage onto the tube. It is important here that the core is a winding form, in which the contracting filament can be wrapped more tightly around the core, thus avoiding the spaces between the PES filaments that result from the melting, since each individual yarn layer exerts a certain pressure on the layers below it due to the shrinkage-related length reduction and the resulting radial contact force (Figure 1).

Results at Different Temperatures

A characteristic temperature window was identified by investigating process temperatures of 195 °C, 200 °C and 210 °C.

At a furnace temperature of 195 °C, slight shrinkage effects were observed, the PES filaments (white) were very well encapsulated by the matrix (blue) with incipient penetration. However, air inclusions remained, and individual yarn layers were visible. The result was structured spool parts with a structured large surface with a textile character, which had good strength.

At oven temperatures of 200 °C, the PES filaments were integrated even better into the matrix. The individual yarn layers were fused and consolidated very well. The PES filaments were evenly distributed over the entire cross-section, air pockets disappeared and compact structural components with very good strength were achieved.

At process temperatures of 210 °C and above, the PES filaments shrank so much that they compressed in the direction of the winding core axis. The strong compression of the PES filaments resulted in a change from a round filament cross-section to an elongated filament cross-section. The PES filaments were completely encapsulated and penetrated by the PP matrix. This resulted in a high-quality bond between the matrix and the reinforcing filaments, as well as a non-porous structure. The PES yarn layers gathered tightly around the tube surface, with the PP matrix forming a protective outer layer over the PES filaments due to this modified distribution of the filaments over the cross-section. This further improved the mechanical properties.

Conclusion

The results of the investigation show that the processing temperature has a decisive influence on the consolidation behavior of the investigated hybrid yarns. In particular, the combination of a low-melting matrix component and a shrinking reinforcing component makes it possible, through precise temperature control, to develop structural components with a character ranging from a rather loose textile to a very stable, pore-free component. These findings expand the range of applications for textilebased lightweight components and provide a basis for future developments in textile technology and lightweight construction.

Acknowledgement

This research work is sponsored by DITF Denkendorf.

Conflict of Interest

Authors declare no conflict of interest.

References

- Christoph Riethmüller, Bastian Baesch, Heinrich Planck (2011) Matrix components – new process for the production of intelligent components, Technical Textiles 1.

- Haigis K (2022) Fundamental investigation of structure-property relationships in the structure-tangle process for technical applications, dissertation Stuttgart, Germany.

- Christoph Riethmüller (2018) Development of lightweight, textile pressure vessel reinforcement for construction applications using the example of pneumatic line actuators (lightweight, textile pressure vessel reinforcement) AIF research report no,18587.

- Christoph Riethmüller (2014) Light grids using structural coils, final report for IGF- project 17382.

- Viola Finckh, Kathrin Haigis, Christoph Riethmüller, et al. (2023) Development of basic elements for a modular system for paper yarn-based exhibition and presentation systems with a holistic utilization concept, Final report for DBU- project 37234.

- Finckh Viola, Haigis Kathrin, Christoph Riethmüller, et al. (2020) Development of recyclable luminaires made of paper yarn composites, Final report for DBU-project 35166.

-

Susanne Schanz*, Dr. -Ing. Kathrin Haigis, Christoph Riethmüller, Viola Finckh and Prof. Dr. -Ing. Götz T Gresser. Influence of Temperature on the Consolidation Behavior of Structural Spool Components Made of Hybrid Yarns with a Shrinking Reinforcing Component and a Matrix Component. J Textile Sci & Fashion Tech 11(2): 2024. JTSFT.MS.ID.000758.

-

Free thermal consolidation, Structure winding, Shrinking reinforcing component, Adjustable consolidation, Hybrid yarn

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.