Mini review

Mini review

High-Performance Bio-Based Fibers for Sustainable Textile Applications

Feng Liang1, Shuangyang Li1,2*, Jianfei Zhou1,2, and Bi Shi1,2,3

1College of Biomass Science and Engineering, Sichuan University, Chengdu, China

2Key Laboratory of Leather Chemistry and Engineering, Ministry of Education, Sichuan University, Chengdu, China

3Research Center for Biomass Materials, Tianfu Yongxing Laboratory, Chengdu, China

Shuangyang Li, College of Biomass Science and Engineering, Sichuan University, Chengdu, PR China

Received Date: April 24, 2025; Published Date: May 14, 2025

Abstract

The growing global demand for sustainability has spurred intense interest in high-performance bio-based fibers, valued for their renewability, biodegradability, and potential to replace synthetic counterparts. This mini-review presents a concise yet comprehensive overview of recent advances in bio-based fiber materials, emphasizing their relevance to textile applications. We begin by discussing the hierarchical structures of representative fibers such as chitin, Lyocell, and collagen, highlighting how molecular architecture underpins macroscopic properties. Key fabrication techniquesincluding wet spinning, dry spinning, electrospinning, and emerging microfluidic strategies-are compared in terms of their mechanisms, advantages, and limitations. We further explore how reinforcement strategies involving natural polymers, biodegradable synthetic polymers, and inorganic nanomaterials are leveraged to enhance mechanical and functional performance. Finally, the review surveys diverse applications across textiles, biomedicine, and advanced composites, concluding with perspectives on future development directions and challenges. This work aims to provide researchers with a structured reference to guide innovation in sustainable fiber technologies.

Keywords:Bio-based fibers; fiber architecture; spinning technologies; reinforcement strategies; sustainable textiles

Introduction

Escalating concerns over resource depletion and environmental degradation have exposed the limitations of conventional petrochemical-derived fibers, particularly their high energy demand and poor degradability [1]. In response, the efficient use of renewable resources has become a pressing priority. Among the most promising alternatives are bio-based fibers—materials derived from natural polymers such as cellulose, chitin, and collagen [2]. These fibers are not only sourced from abundant and diverse biomass—including agricultural residues, forestry by-products, and marine waste-but also benefit from inherently low-carbon production processes and end-of-life biodegradability [3]. Their emergence aligns closely with global ambitions toward circular economy models and green manufacturing (Figure 1). Market analysts predict that the global bio-based materials sector will exceed USD 70 billion by 2030, with bio-based fibers playing a key role across textiles, biomedicine, and environmental technologies [4,5]. However, compared to their synthetic counterparts, bio-based fibers often fall short in mechanical robustness, thermal stability, and multifunctional integration. Bridging this performance gap demands interdisciplinary strategies spanning molecular design, materials processing, and structural engineering.

From a materials science standpoint, the macroscopic behavior of bio-based fibers is rooted in their microscopic architecturemolecular chain alignment, crystallinity, hydrogen bonding, and cross-linking networks. For example, the rigid β-(1→4)-glycosidic linkages in chitin give rise to high crystallinity and stiffness, while collagen’s triple-helical conformation imparts elasticity and biocompatibility. Understanding this natural design principlesevolved over millions of years-offers insight into mechanisms such as energy dissipation, adaptive stiffening, and self-repair, which inspire bioinspired materials design. Notably, synthetic fibers modeled on the hierarchical architecture of spider silk have recently achieved tensile strengths exceeding that of natural silk by 50%, underscoring the potential of structure-guided innovation. A critical step toward advancing bio-based fibers lies in establishing robust structure–property–function relationships, which are the foundation for rational material design and performance optimization.

This mini-review focuses on high-performance bio-based fibers and systematically overviews their molecular architecture, fabrication technologies, reinforcement strategies, and application frontiers. It first explores the structure-function paradigms of key fibers-chitin, Lyocell, and collagen-at both molecular and supramolecular levels. Then, it compares mainstream spinning technologies, such as wet spinning and electrospinning, and emphasizes how processing conditions influence fiber morphology and properties. The review further highlights how composite strategies involving natural, inorganic, and biodegradable synthetic reinforcements can elevate functional performance. Finally, it examines representative applications in healthcare, textiles, and advanced composites, offering perspectives on the future development of sustainable fiber systems. Together, these insights support the rational design and scalable deployment of nextgeneration bio-based fiber technologies.

Fiber Structures

Chitin Fibers

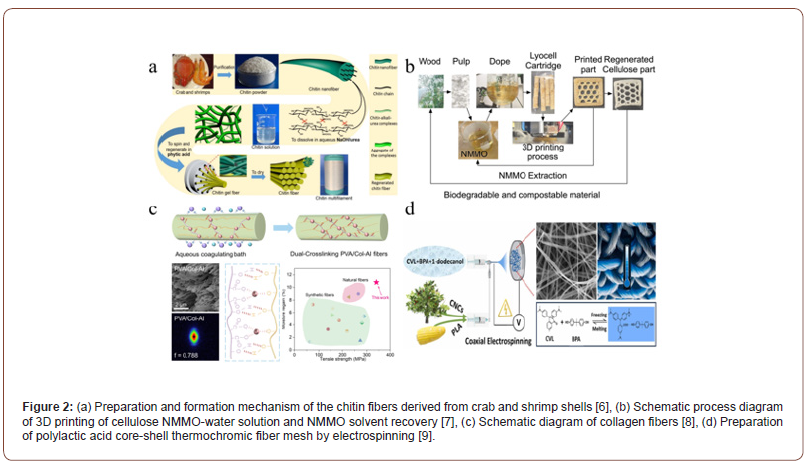

Chitin fibers are constructed from linear polysaccharide chains composed of N-acetyl-D-glucosamine units, stabilized by extensive hydrogen bonding and van der Waals interactions Figure 2a. The abundance of hydroxyl and amide groups along the backbone confers excellent hygroscopicity and biocompatibility. Crystallographically, chitin exists primarily in two polymorphs: α-chitin, the thermodynamically stable and most prevalent form in nature, and β-chitin, which exhibits a looser packing arrangement and can be fabricated under specific conditions to yield higher crystallinity and mechanical strength. Post-treatment processes such as alkali activation and deacetylation can elevate crystallinity levels to 60–70%, resulting in tensile strengths ranging from 500 to 800 MPa-attributes arising from the ordered molecular packing and reinforced hydrogen-bond network [6].

Lyocell Fibers

Lyocell fibers are regenerated cellulose produced via a closedloop solvent-spinning process using N-methyl morpholine N-oxide (NMMO) Figure 2b. The cellulose chains, tightly aligned through intra- and intermolecular hydrogen bonding, self-assemble into microfibrils, imparting the fiber with high tensile strength and resilience. Crystallinity typically falls within 60–70%, reflecting the semi-crystalline nature of the cellulose phase. Combining a smooth fiber surface and a porous internal morphology ensures excellent moisture management and air permeability, rendering Lyocell particularly suitable for high-performance textile applications [7].

Collagen Fibers

Collagen fibers comprise triple-helical protein chains, in which three polypeptide strands intertwine into a stable, right-handed supercoil Figure 2c. This hierarchical assembly imparts collagen with notable elasticity, softness, and intrinsic biocompatibility. Despite a relatively low crystallinity (30–40%), collagen fibers form cross-linked fibrillar networks that offer mechanical compliance and facile processability. Owing to their bioactive surface chemistry and ability to support cellular adhesion and proliferation, collagen fibers are widely utilized in biomedical fields, especially as scaffolds for tissue engineering [8].

Polylactic Acid Fibers

Polylactic acid (PLA) fibers are thermoplastic aliphatic polyester fibers derived from renewable biomass such as corn starch, cassava, or sugar beet (Figure 2d). The production pathway involves microbial fermentation to generate lactic acid, polymerization, and melt spinning. PLA fibers combine moderate tensile strength and elasticity with complete biodegradability and biocompatibility. Their environmental friendliness and functional tunability have enabled applications in eco-conscious textiles and biomedical devices, including absorbable sutures and wound dressings [9].

Fiber Preparation Methods

Wet Spinning

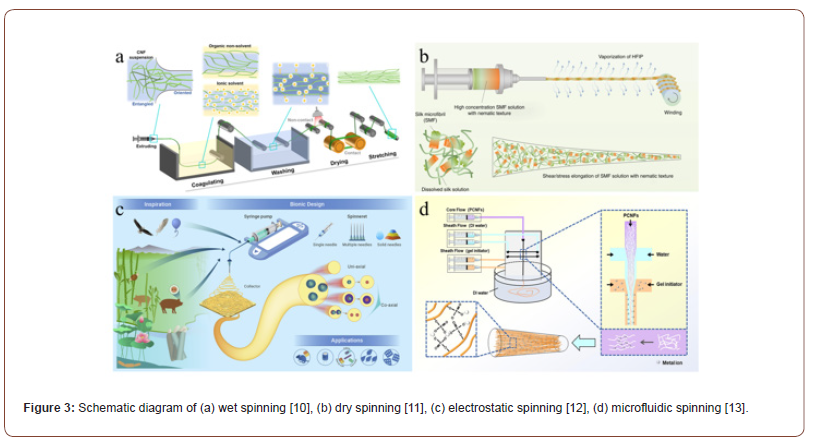

Wet spinning entails extruding a polymer solution through a spinneret into a coagulation bath, where solvent exchange induces phase separation and fiber solidification [10]. For chitin fibers, alkaline coagulation baths are typically employed to facilitate molecular precipitation. This method yields fibers with favorable mechanical integrity and morphology; for instance, wet-spun chitin fibers exhibit tensile strengths of 200–300 MPa and elongations at 10–20% break. However, the multistep bath treatment is chemically intensive and poses environmental challenges due to effluent disposal Figure 3a.

Dry Spinning

Dry spinning involves ejecting the spinning dope into a heated airstream, where solvent evaporation leads to fiber formation [11]. In the case of Lyocell, the cellulose-NMMO solution undergoes rapid solvent volatilization under high-temperature airflow, enabling efficient fiber production with a uniform structure. Dry-spun Lyocell fibers demonstrate tensile strengths of 100–150 MPa and elastic moduli in the 3–5 GPa range. Despite its high throughput, dry spinning demands volatile, thermally stable solvents and a costly solvent recovery system to ensure environmental compliance Figure 3b.

Electrospinning

Electrospinning leverages a high-voltage electric field to generate a fine polymer jet from a spinning solution, which is drawn and deposited as ultrafine fibers onto a collector [12]. This technique enables the fabrication of nanofibers with diameters in the tens of nanometers, high surface area-to-volume ratios, and tunable porosity. Electrospun collagen nanofiber membranes, for example, are extensively used in wound dressings, offering enhanced breathability and promoting tissue regeneration. Electrospinning suffers from low production rates and challenges in achieving uniform fiber deposition at scale Figure 3c.

Microfluidic Spinning

Microfluidic spinning utilizes microscale channels to precisely manipulate fluid flow and polymer phase separation, enabling the controlled assembly of fibers [13]. This emerging technology allows the fabrication of architecturally complex fibers, including coreshell and Janus structures, and facilitates in-fiber encapsulation of bioactive agents. The high structural precision makes it attractive for advanced biomedical and functional textile applications. However, the high capital cost and limited scalability currently restrict its industrial deployment Figure 3d.

Fiber Reinforcement Materials

Natural Polymers

Natural polymers such as cellulose nanofibers and chitosan are promising reinforcement agents due to their intrinsic biocompatibility, biodegradability, and renewability. Cellulose nanofibers, characterized by high tensile strength and stiffness, can significantly enhance the mechanical performance of bio-based fibers. For instance, integrating 5–10 wt% cellulose nanofibers into chitin fiber matrices have increased tensile strength by 20–30%, primarily through load transfer and hydrogen-bond interactions at the fiber-matrix interface.

Inorganic Nanomaterials

Inorganic nanomaterials, including titanium dioxide (TiO2) and silicon dioxide (SiO2), contribute unique functionalities alongside mechanical reinforcement. TiO2 nanoparticles, in particular, offer photocatalytic and antimicrobial properties while improving fiber rigidity. Incorporating 2–3 wt% TiO2 into collagen fibers has been reported to raise tensile strength by 15–20% while delivering >90% antibacterial efficacy against E. coli and S. aureus. Such dualfunction composites hold promise for active medical textiles and safe surfaces.

Synthetic Biodegradable Polymers

Synthetic biodegradable polymers like polylactic acid (PLA) and polycaprolactone (PCL) serve as tunable reinforcements that enhance mechanical robustness and degradability. For example, blending 10–15 wt% PLA with Lyocell fibers yields a composite with improved tensile modulus and controlled degradation kinetics in physiological environments, making it suitable for biomedical scaffolds and absorbable implants.

Fiber Applications

Textile Industry

High-performance bio-based fibers are gaining traction in the textile sector due to their sustainability and functionality [14]. Chitin-based fabrics offer inherent antibacterial activity, moisture regulation, and breathability, making them ideal for intimate apparel and hosiery. Lyocell fibers, renowned for their softness, dimensional stability, and wrinkle resistance, are extensively used in clothing and home textiles. Collagen fibers, due to their proteinaceous nature and processability, are emerging as candidates for high-end leather alternatives and functional textile coatings.

Biomedical Applications

In biomedicine, bio-based fibers enable the design of scaffolds and devices with native-like biocompatibility and tunable degradation [15]. Collagen fibers, with their triple-helical structure and porous architecture, support cell adhesion, proliferation, and differentiation, making them ideal for tissue-engineering constructs. Chitin fibers exhibit intrinsic wound-healing and antimicrobial capabilities, thus serving as effective dressings and hemostatic agents. When functionalized or drug-loaded, Lyocell fibers offer controlled release profiles and biodegradability, providing platforms for sustained therapeutic delivery.

Composite Materials

Bio-based fibers also effectively reinforce polymeric composites for structural and functional applications [16]. Chitin fiber-reinforced epoxy composites exhibit high specific strength and stiffness, making them attractive for aerospace and automotive components where weight reduction is critical. Collagen fiber– polymer composites, leveraging collagen’s flexibility and biological affinity, are being explored as substrates for stretchable electronics and wearable sensors, merging mechanical resilience with skin compatibility Figure 4.

Conclusion and Outlook

High-performance bio-based fiber materials flourish in today’s sustainability-focused era due to their unique structures, versatile preparation methods, and wide-ranging applications. Through in-depth exploration of fiber architectures, integration of diverse fabrication techniques, and strategic use of reinforcement agents, their performance can be continuously enhanced to meet varied application needs. Nevertheless, challenges persist, including environmental impact during production, stability of fiber properties, and the cost and complexity of industrialscale manufacturing. With ongoing technological advances and interdisciplinary research, progress is expected in green processing, precise property control, and new application development, positioning these materials to drive global sustainable materials innovation.

Acknowledgment

This work was financially supported by the National Natural Science Foundation of China Youth Science Foundation (22308232), the Fundamental Research Funds for the Central Universities, and the Tianfu Yongxing Laboratory Organized Research Project Funding (2024KJGG20).

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Antar M, Lyu D, Nazari M, Shah A, Zhou X, et al. (2021) Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization. Renew. Sustain. Energy Rev 139: 110691.

- de Oliveira CRS, da Silva Júnior AH, Molinari J, Immich APS (2021) Textile Re-Engineering: Eco-responsible solutions for a more sustainable industry. Sustain Prod Consum 28: 1232-1248.

- Satyanarayana KG, Arizaga GG, Wypych F (2009) Biodegradable composites based on lignocellulosic fibers-An overview. Prog Polym Sci 34: 982-1021.

- Liu J, Cui T, Xu X, Du Y, Wang L, et al. (2023) Robust alcohol soluble polyurethane/chitosan/silk sericin (APU/CS/SS) nanofiber scaffolds toward artificial skin extracellular matrices via microfluidic blow-spinning. Adv Fiber Mater 5: 349-361.

- Hu J, Li J, Jiang J, Wang L, Roth J, et al. (2022) Design of synthetic collagens that assemble into supramolecular banded fibers as a functional biomaterial testbed. Nat Commun 13(1): 6761.

- Zhu K, Tu H, Yang P, Qiu C, Zhang D, et al. (2019) Mechanically strong chitin fibers with nanofibril structure, biocompatibility, and biodegradability. Chem Mater 31(6): 2078-2087.

- Garces I, Ngo T D, Ayranci C, Boluk Y (2024) Regenerated cellulose in additive manufacturing. Cellulose 31(3): 1773-1785.

- Liang F, Cheng X, Tang Y, Li S, Zhou J, et al. (2025) Robust and durable collagen-based fibers through dual cross-linking for eco-friendly slow fashion. Compos A 193: 108871.

- Shayan M, Koo MS, Abouzeid R, She Y, Gwon J, et al. (2024) Functional electrospun polylactic acid core-shell thermochromic fibers with modified cellulose nanocrystals for enhanced temperature-responsive applications. Ind Crop Prod 222: 119594.

- Zhang Z, Kong Y, Gao J, Han X, Lian Z, et al. (2024) Engineering strong artificial cellulosic fibers: a review of the wet spinning process based on cellulose nanofibrils. Nanoscale 16(13): 6383-6401.

- Ling S, Qin Z, Li C, Huang W, Kaplan D L, et al. (2017) Polymorphic regenerated silk fibers assembled through bioinspired spinning. Nat. Commun 8(1): 1387.

- Song W, Tang Y, Qian C, Kim B J, Liao Y, et al. (2023) Electrospinning spinneret: A bridge between the visible world and the invisible nanostructures. The Innovation 4(2): 100381.

- Ren N, Chen S, Cui M, Huang R, Qi W, et al. (2022) Ultrastrong and flame-retardant microfibers via microfluidic wet spinning of phosphorylated cellulose nanofibrils. Carbohydr Polym 296: 119945.

- Geng Y, Chen G, Cao R, Dai H, Hu Z, et al. (2024) A Skin-Inspired Self-Adaptive System for Temperature Control During Dynamic Wound Healing. Nano-Micro Lett 16(1): 152.

- Rakib Hasan Khan M, Shankar Hazra R, Nair G, Mohammad J, Jiang L, et al. (2022) Cellulose nanofibers as Scaffold-forming materials for thin film drug delivery systems. Int J Pharm 627: 122189.

- Navaratnam S, Selvaranjan K, Jayasooriya D, Rajeev P, Sanjayan J (2023) Applications of natural and synthetic fiber reinforced polymer in infrastructure: a suitability assessment. J Build Eng. 66: 105835.

- Zhou J, Li X, Zhang Z, Hou T, Xu J, et al. (2024) Bio-based and bio-degradable nanofiber materials: A sustainable platform for energy, environmental, and biomedical applications. Chem Eng J 491:152105.

-

Feng Liang, Shuangyang Li*, Jianfei Zhou, and Bi Shi. High-Performance Bio-Based Fibers for Sustainable Textile Applications. J Textile Sci & Fashion Tech 11(3): 2025. JTSFT.MS.ID.000765.

-

Bio-based fibers; fiber architecture; spinning technologies; reinforcement strategies; sustainable textiles, iris publishers; iris publisher’s group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.