Research Article

Research Article

Creation of Illuminated Sofa Cloth with Innovative Jacquard Woven Structures: A Practice-based Approach

Gloria WU1, Joe AU2* and Jin LAM3

1Practitioner, School of Fashion and Textiles, The Hong Kong Polytechnic University, Hong Kong

2Associate Professor, School of Fashion and Textiles, The Hong Kong Polytechnic University, Hong Kong

3Assistant Professor, School of Fashion and Textiles, The Hong Kong Polytechnic University, Hong Kong

Joe AU, School of Fashion and Textiles, The Hong Kong Polytechnic University, Hunghom, Kowloon, Hong Kong

Received Date: June 01, 2024; Published Date: June 28, 2024

Author Bio

This paper describes a practice-based approach to creating an illuminated sofa cloth. By integrating innovative weaving structures, glow-inthe- dark photonic yarn, and a pressure sensor, an illuminated sofa cloth was developed and tailored for comfortable seats with an enjoyable lighting atmosphere and relaxing music for people who had a busy lifestyle. Initial prototypes were created and assessed by the performances of their abrasions test and lux tests. A detailed design specification for illuminated sofa cloth was finalised and a textile prototype was then developed. The final prototype has promising theoretical and practical implications for textile design. Both fashion and textile design education can also benefit from an expanded knowledge of illuminated home textiles from aesthetic and functional perspectives. The illuminated sofa cloth produced can also be applied in other textile products to satisfy consumers with diverse lifestyles and preferences. Both textile design practitioners including textile design students can benefit from the theoretical and practical contributions generated from this study

Keywords: Illuminated sofa cloth; Jacquard woven structure; design specification; practice-based research

Introduction

To meet the challenging needs of future lifestyle and consumer

requirements, high-tech fabrics must continue to cross the

boundary into everyday fashion apparel as well as into home

interior furnishings. Products have always engendered some

kinds of sensorial qualities such as our senses of sight, touch,

sound, taste and smell. Those stimuli form our experiences from

our environment. Intelligent materials will provide a new array

of sensorial qualities, that will impact how we experience and

interact with our surroundings. This practice-based research

study combined the theories of illumination and Jacquard weaving

technologies, and practical concept development in creating a

high-value interior home textile design. An illuminated sofa cloth

that can absorb and store light and heat energy in the daytime and

illuminate in the dark was developed. The specific objectives of this

study were as follows:

a. To identify the optimal weaving structure, and illuminated

material to develop the sofa cloth,

b. To finalise a detailed design specification for the

illuminated soft cloth, and

c. To create high-end illuminated sofa cloth for the home

textiles market.

The resulting prototype demonstrates the integration of artistic creativity and intuition with scientific rationales and principles, and engineering technical know-how to design high-value illuminated home textiles. This study will increase awareness of the aesthetic and functional aspects of illuminated home textiles and promote more novel designs in the modern textile industry.

Products of Smart Home Textiles

There are examples of current smart home textile products adopting illuminated materials. The current smart home textile products include pillows, cushions, curtains, carpets and decorations [1-6]. There has been an increasing demand for illuminated products in the market. Specific applications can be categorised as positively advantageous and valuable [7]. For example, the use of smart textiles to provide thermal control, including air conditioning and the control of solar radiation by the use of curtains would be beneficial in a variety of indoor environments. Furthermore, as smart materials like photochromic can control light and colour, they have shown positive benefits in energy efficiency and mood control [7].

History of Photochromic

The first photochromic lenses were made of glass and developed by scientists in the U.S. at Corning. The plastic photochromic lenses as we know them today are the process of quite a history, the first photochromic lenses were introduced in 1966. It became popular and started taking over the market, back in the 1960s. They were made of glass and contained light-sensitive silver halide crystals that were mixed in while the glass was still in its molten state. Like today’s lenses, they are activated by ultraviolet light from the sun. The lens material, which supports a layer of photochromic dyes, also affects how fast the lens darkens and fades [8]. Since photochromic dyes do not work well in common plastic lens materials, companies have developed special, but proprietary monomers that are compatible with the dyes. Companies are continuing to design new dyes by adding various substituents that absorb more into the visible region to get more activity behind auto windshields [9].

For painting and screen printing, Long-lasting Glow-in-thedark materials are recommended to use neutral or weak alkaline clear resin. To avoid precipitates of glow powder occurring in glow paint, it is needed to use high-viscosity resin and ant-precipitation agent to the paint and make sure stirred well before use. Also, it is recommended not to add any heavy metal compounds. For the best result, use white or light colour as a background as any colour other than white will diminish glow. For the best result, an 80-120 mesh screen is suggested for screen printing, the photochromic dye cannot be injected and moulded at temperatures over 250c due to its low decomposition temperature, and aqueous-based ink or paint with 5% to 60% recommended [10].

Illuminated Principles of Photochromic Materials

Photochromics change colour in response to ultraviolet light, usually from the sun or black light. Photochromic behaviour can be either reversible or irreversible. Technically, all photochromism is defined as reversible, but for simplicity, the term irreversible photochromic is used to describe the irreversible photochemical reaction that yields a visible colour change. Reversible photochromics transform from clear to colour by changing their chemical structure after absorbing ultraviolet light, usually from the sun. The ultraviolet light causes the photochromics to absorb colour (like a dye), and then change back to clear when the ultraviolet source is removed. They can cycle thousands of times depending upon the application. They can also change from one colour to a different colour by combination with a permanent pigment. Standard photochromic ink will change from clear to colour when activated by ultraviolet light.

The most famous reversible photochromic application is colour-changing lenses for glasses, as found in transition eyeglasses. Reversible photochromic is also found in novelty applications such as T-shirts, toys, cosmetics, and industrial applications [11].

Long-lasting Glow-in-the-dark material can absorb and store light/heat energy, then it can glow in the dark. It can be recharged and provide unlimited glowing. Also, it can be charged faster by exposure to sunlight/UV light. The long-lasting glow powder is a pigment which is suitable for plastic injection and solvent-based ink or paint. Its benefits are having good weather resistance, applicable both indoors and outdoors [10].

Technologies and Application of Sound Sensor

Elements that stimulate our senses, sight, touch, sound, taste and smell from our experiences of our environment. Products that arouse human sensorial are always acting as an important activity as both correspond to each other. “Intelligent material will provide a new array of sensorial qualities, which will impact both on how we experience our surroundings and how we interact with them [12]. A smart textile should be able to feel the changes in the environmental condition. A sensor is defined as a device providing information mostly in the form of an electrical signal. It senses the measured object or medium and emits a signal related to the variations of the measured quantity [13].

Pressure sensor

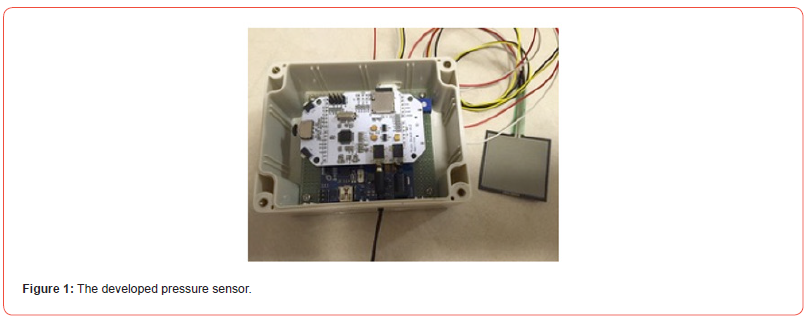

A pressure sensor also known as a pressure transducer, is used to measure pressure typically of gases or liquids. A pressure sensor converts pressure into an analogue electrical signal such as a voltage output or current output which can easily be measured. There are different types of pressure measurement, those are as follows: a) Absolute pressure sensor measuring the pressure relative to perfect vacuum; b) Gauge pressure sensor measuring the pressure relative to atmospheric pressure; c) Vacuum pressure sensor measuring pressure that is less than 0 PSI; d) Differential pressure sensor measuring the difference between two pressures points; e) Sealed pressure sensor measuring the pressure relative to some fixed pressures [14].

Methodology

A practice-based research methodology was adopted in this study. Art and technology expert Linda Candy characterised practice-based research as an original investigation undertaken to gain new knowledge partly employing practice and the outcomes of that practice [15]. The definition of practice-based research is similar to that of any research not exclusively concerned with theoretical analysis. The research process is complete when the understandings reached are considered transferrable. Original contributions to knowledge may include artefacts such as images, music, designs, models, digital elements, media, performances and exhibitions with creative outcomes. The advantage of using a practice-based research method is the articulation of design processes in such a way as to bring clarity to the skills, orientation and processes that shape the development of design outcomes [16].

The initial design of the illuminated sofa cloth

The sofa cloth was designed and developed by using a Jacquard loom machine. It was divided into two main groups, and each group was woven with different compositions of yarn types, but with the same weaving structures, plain weave, satin and twill weaving effect structures for experiments and testing afterwards. The first group was woven with Glow-in-the-dark photonics yarn with 100% polyester yarn and the second group was woven with Glow-in-thedark photonics yarn with 100% cotton yarn. This design aimed to make the sofa cloth illuminated both in daytime and nighttime. Also, it was embedded with medicated music for relaxing while seated on this sofa. The specific pressure sensor was also integrated into the finished woven fabric. The pre-selected soundtrack was automatically turned on when a person was sitting or lying on the sofa. The target was to design an illuminated woven sofa cloth for comfortable seats with an enjoyable lighting atmosphere and relaxing music for people with a busy lifestyle.

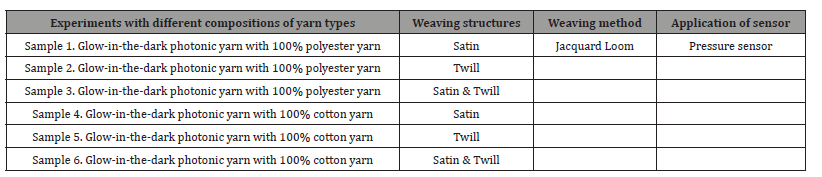

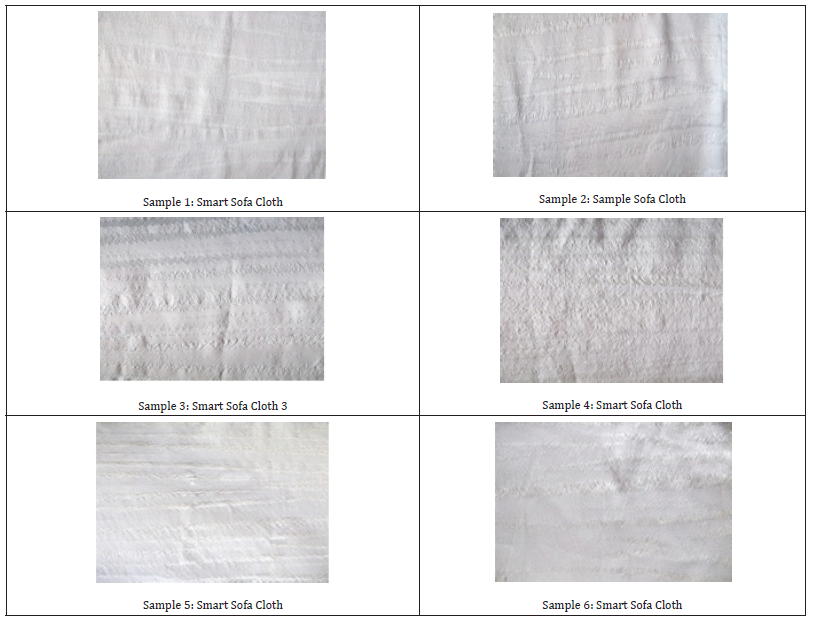

As a Jacquard loom machine was used to weave a bigger size of fabrics, that was suitable to produce the sofa cloth. Besides, a Jacquard loom machine was able to allow designers to create a more complicated weaving structure design compared to a handloom machine. Table 1 shows the combinations of various materials for producing the prototypes and Table 2 presents the initial illuminated prototypes. Figure 1 shows the developed pressure sensor and Figure 2 presents the loudspeakers with integrated amplifiers which were connected with the pressure sensor to play music when sensing a pressure signal

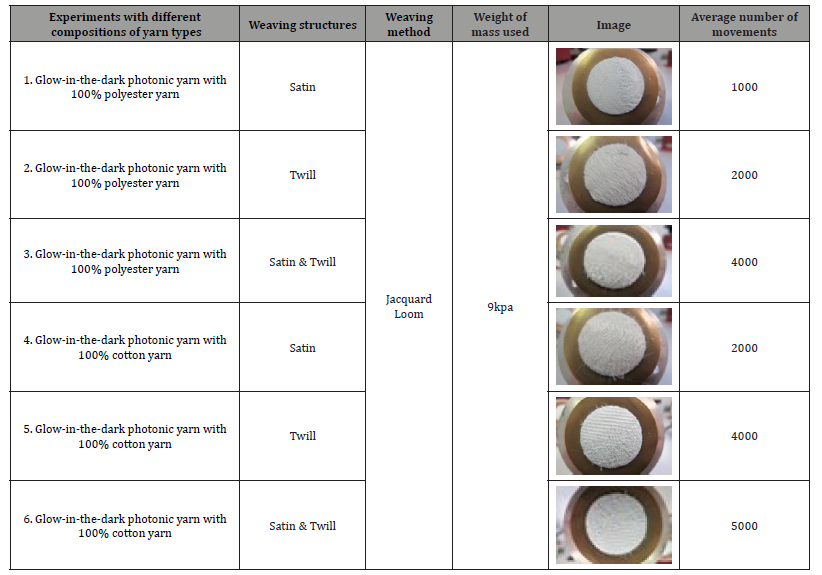

Table 1:Combinations of various materials for prototyping illuminated sofa cloth.

Table 2:Illuminated sofa cloth prototypes.

Findings and Discussion

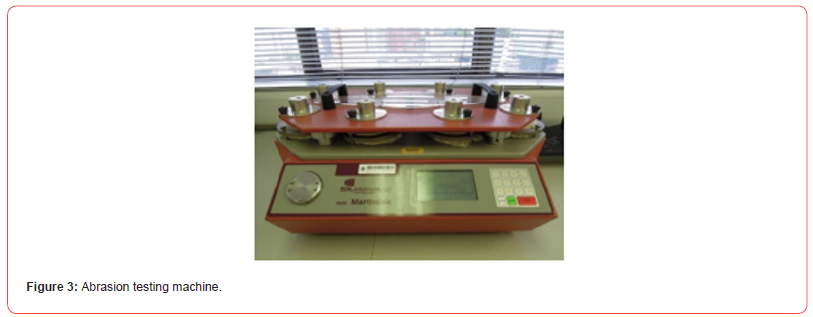

Assessment of illuminated materials and weaving structures The Abrasion Test Machine (D4966)

The abrasion test was to ensure the durability of woven samples as experienced in the actual use of the material. The abrasion test was used to predict the durability of each fabric related to abrasion resistance and durability (see Figure 3).

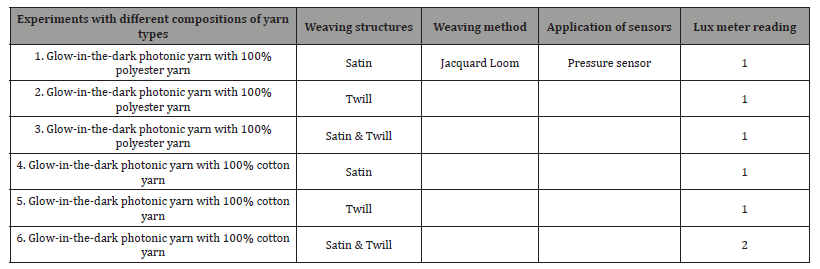

The Digital Lux Meter (LX1010B)

The lux test was to help test the intensity of illumination by a lux meter and a common lux meter consisted of the measuring device itself and a sensor. The sensor was made of selenium or silicon photocells. It was very accurate in measuring as it permitted a wide range of light measurements (Figure 4).

Abrasion Test on initial illuminated sofa cloth prototypes

The abrasion test result with the highest average number of movements was the combination of ‘Glow in the dark photonics yarn with 100% cotton yarn, woven with satin and twill pattern’ (Table 3).

Lux test on initial illuminated sofa cloth prototypes

The best result was the fabric made of ‘Glow-in-the-dark photonics yarn with 100% polyester yarn woven with satin and twill pattern’, the reading of the lux meter was 2 and it had the highest reading of the lux meter compared with the others. All of the other sample fabrics were tested in the dark and had the same reading ‘1’ of lux meter (Table 4).

Detail design with specifications of illuminated sofa cloth

a. Colouration The colour of the illuminated sofa cloth’ was inspired by the pale green colour of Arctic light and it was able to illuminate both in daytime and nighttime. The pale green colour showed up and illuminated very well when it absorbed the light and it looked similar to the colour of Arctic light in the sky. The Arctic light showed better when the sky was dark. Both concepts were similar as the illuminated sofa cloth appeared at nighttime and showed up the best in the dark.

Table 3:Abrasion test of initial prototypes.

Table 4:Lux test of initial prototypes.

b. Illuminated material Glow-in-the-dark photonic yarn was the effective illuminated material used. This colour-changing material changed colour when exposed to the light and was able to absorb and store light/heat energy, then was able to glow in the dark. It could be recharged and glowed. This fabric became intensely coloured after 15 seconds in direct sunshine or light and returned to clear after about 5 minutes indoors. Its characteristic helped to produce this illuminated sofa cloth into a relaxation product for the interior market as well as to let the consumer enjoy the illuminated effect of the sofa.

c. Yarn Type The yarn type was 100% cotton yarn and Glow-in-the-dark photonic yarn as the mixture of the yarn fulfilled both the abrasion test and lux test resulting in the highest average number of movements in the abrasion test and highest reading of lux meter in the lux test.

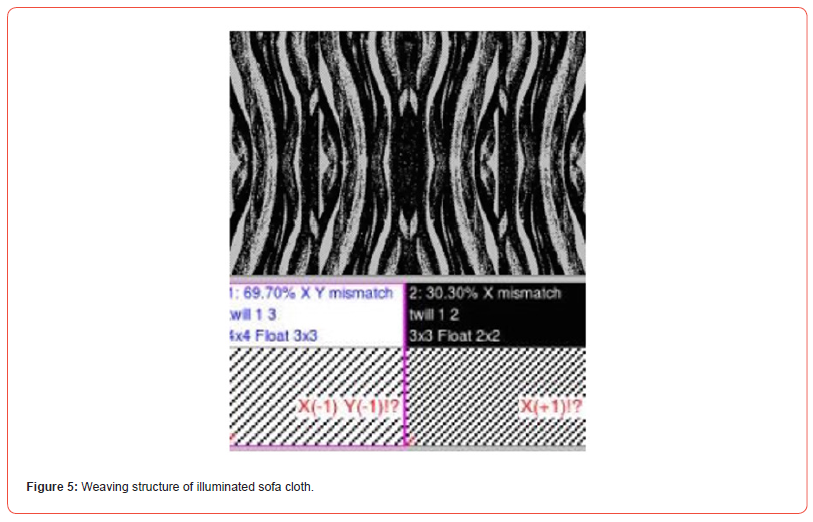

d. Weaving structure Satin and twill were the main weaving structures as they passed the abrasion test and provided the best performance for the fabric, and these structures helped to show the best design on the weaving software (Figure 5). The main characteristic of the twill weave is its improved drapability as compared to plain weave, being at the same time prone to snagging when the harness is large and/or the diagonal ribs are thin. Besides, twill weaves were often used for producing durable upholstery as soils and stains are less noticeable on the twill weaves.

e. Graphic pattern Figure 6 shows the graphic pattern of the illuminated sofa cloth and the inspiration has come from the movements of water flowing. This graphic pattern combined with the colours as well as the music, brings a relaxed mood for the consumer while sitting on the illuminated sofa cloth

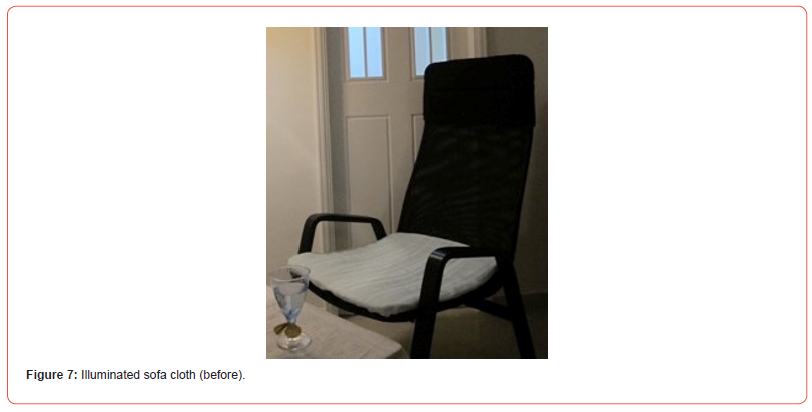

f. Sensor The specific pressure sensor was integrated with the woven fabric and the pre-selected music turned on when a person was sitting on it automatically. When the pressure sensor sensed a pressure greater than 30lbs, it then sent a specific signal to the amplifier which was then activated to start playing the music. The aim was to design an illuminated woven sofa cloth for comfortable seats with an enjoyable lighting atmosphere and relaxing music for busy people. The final illuminated sofa cloth is presented in Figures 7 and 8.

This practice-based study combined weaving technology, practical concept development and prototyping of the illuminated home textiles. The final prototype has promising theoretical and practical implications for textile design. Both fashion and textile design education can also benefit from an expanded knowledge of illuminated home textiles from aesthetic and functional perspectives. Furthermore, the prototypes developed can be applied to diverse textile products and promote novelty in the textile industry. In conclusion, home textiles play a crucial role in the interior environment of a home by affecting the home interior not governed by architecture, such as texture, colour, character and scale. Further research into smart fabrics is highly recommended to enhance the textile field and stimulate the creation of additional smart products for the fashion and textile markets.

Acknowledgement

The authors would like to thank the research funding provided by the Hong Kong Polytechnic University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Seung, J.J. (2010). Pillow alarm. Retrieved from http://www.coroflot.com/Design-jay/Alarm-Pillow

- Hilhorst, D., & Zambetti, N. (2007). Pillow remote control. Retrieved from http://studio.droog.com/studio/all/smart-deco-2/cushion-control-by-didier-hilhorst---nicholas-zambetti

- Sjardijn, D. (2010). The magical illumination of a carpet. Retrieved from http://prettysmarttextiles.com/exhibition2010/

- Findmeagift Ltd, (2010). Colour-changing moonlight cushion. Retrieved from http://www.findmeagift.co.uk/gifts/colour-changing-moonlight-cushion.html

- Schicker, K. (2009). IntertechPira smart fabrics conference. Retrieved from http://www.intertechpira.com

- Ernevi, A., Jacobs, M., Mazé, R., Müller, C., Redström, J., & Worbin, L. (2012). Solar energy curtain. Retrieved from http://www.tii.se

- Schwarz, A, van Langenhove, L., Guermonprez, P., Deguillemont, D. (2010). A roadmap on smart textiles. Text Prog 42(2): 163.

- Baldy, C. (2008). Making photochromic history: The next generation of technology 2012. Retrieved from http://www.bretoncom.com/vision/2002/03/09.asp

- Erickson, B. (2009). Self-darkening eyeglasses: The science behind dual-purpose lenses. American Chemical Society Journal of Science and Society, Science & Technology, 87(15), p.54.

- New Prismatic Co., LTD. (2008). Long lasting glow-in-the-dark material. Retrieved 2012 from http://www.colorchange.com.tw/english/index.php/long-lasting-glow-in-the-dark-material.html

- LCR Hallcrest. (2006). Photochromic Retrieved from http://www.colorchange.com/photochromic

- Baurley, S. (2004). Interactive and experiential design in smart textile products and applications. Cambridge, UK: Pourdeyhimi.

- Schwarz, A., van Langenhove, L., Guermonprez, P., & Deguillemont, D (2010). Smart textile system. Journal of Textile Progress, 42(2), p.107.

- Reebals, C. (Ed.). (2008). WAKA Handbook: Pressure & temperature measurement U.S. edition. Cumming, GA: Corporate Printers.

- Candy, L. (2006). Practice-based research: A guide. CCS report. 1(2):1-9.

- McLaughlin, S.M. (2006). Valuing insight and judgement: A hermeneutic perspective on the development of validating contexts for practice-based research in design. Speculation and Innovation: Applying practice-led research in the creative industries.

-

Gloria WU, Joe AU* and Jin LAM. Creation of Illuminated Sofa Cloth with Innovative Jacquard Woven Structures: A Practice-based Approach. J Textile Sci & Fashion Tech 10(4): 2024. JTSFT.MS.ID.000747.

-

Illuminated sofa cloth; Jacquard woven structure; design specification; practice-based research; Iris Publishers; Iris Publishers Group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.