Review Article

Review Article

A Review on Vortex Yarn Spinning Technology (MVS) in the Global Textile Industry

Ömer Fırat TURŞUCULAR*

R&D Chief, Hatin Textile, and Hatin Tex Weaving Companies, DOSAB, 16245, Bursa Province, Turkey

Ömer Fırat TURŞUCULAR, R&D Chief, Hatin Textile, and Hatin Tex Weaving Companies, DOSAB, 16245, Bursa Province, Turkey

Received Date: June 26, 2024; Published Date: August 05, 2024

Abstract

In this review study included the differences between ring conventional, ring compact, open-end (OE) rotor, and vortex (MVS) yarn spinning technologies. It has also about vortex yarn spinning technology (MVS), its importance, history, technological innovations based on R&D studies over the years, its formation mechanism, structural, physical, and mechanical properties of the yarns to which it can be applied, and the structural, physical and mechanical properties of various textile-based fabrics such as weaving and knitting to which it can be applied were mentioned. Generally, thanks to Vortex yarn spinning technology (MVS), which was a patented yarn spinning system developed and patented by the Japanese company Murata, a manufacturer of yarn spinning machines, MVS production process parameters such as spindle inner diameter, nozzle geometry, air pressure inside the spinneret, distance between the front roller and the spinneret, feed rate by changing the parameters such as draft rate, winding speed, predraft, intermediate draft, main draft, total draft and yarn structural parameters such as yarn type, yarn count and yarn types mixture ratios, for its quantitative determinations can be made for its the structural, physical and mechanical properties. According to the results of various theoretical and experimental studies in the literature, there was a completely positive effect in terms of yarn structural properties, especially for regenerated cellulose-based yarns such as viscose (CV), viscose rayon (CV) and modal (CMD) and synthetic-based yarns such as polyester (PET). That was, as the air pressure inside the nozzle increased and the winding speed decreased, yarn hairiness, CV%, yarn irregularity, and yarn defects decreased Moreover, tensile strength values increased relatively. In synthetic-based yarns such as polyamide 6 (PA 6) and polyamide 6.6 (PA 6.6), the maximum percentage breaking elongation values increased. In addition, as the amount of polyamide (PA) in the yarn increased, there was an increased in the yarn diameter and % CV value of the yarn and a decreased in yarn density (degree of yarn packing). For natural cellulosic-based yarns such as carded-type cotton, a completely negative effect was detected in terms of yarn structural properties. The use of 60% or more carded cotton yarn as blend yarn in MVS was definitely not recommended in terms of yarn quality. It was definitely recommended for use in casual clothing applications where structural, physical, and mechanical properties as well as thermal comfort were at the forefront thanks to the production of viscose (CV) orviscose rayon (CV) yarns with vortex (MVS) yarn technology. In terms of yarn spinning technologies to be used in woven or knitted fabrics; ring compact for maximum tensile strength and maximum breaking force values, open-end (OE) rotor for maximum percent elongation at break and maximum moisture absorption values, vorteks for maximum abrasion and pilling resistance values and minimum yarn hairiness, yarn irregularity, yarn defects, thin places, thick places, and neps. It was concluded that vortex (MVS) spinning technologies should be used in casual clothing applications. Moreover, vortex yarn spinning technology (MVS) extra required qualities such as maximum fiber-fiber friction, fiber distribution, fiber homogeneity, and dimensional stability in its structural, physical, and mechanically properties. It provided tensile strength, maximum breaking force, maximum breaking elongation, minimum yarn hairiness, and minimum yarn unevenness. It was the most effective yarn spinning technology that should be used in woven, or knitted fabrics to be produced for home textile applications such as casual clothes, where thermal comfort will be at the forefront thanks to its unique flexible physical, and mechanical properties.

Keywords:Vorteks Yarn Spinning Technology (MVS); Process Parameters; Yarns; Fabrics; General Properties

Introduction

The purpose of this study is to discuss the differences between ring conventional, ring compact, open-end (OE) rotor, and vortex (MVS) spinning technologies compared to each other, the importance of vortex spinning technology (MVS), its history, and its R&D studies over the years. Their various and specifically determined yarn types, from technological innovations, spinning formation mechanism principles with other spinning technologies, important production process parameters, yarn types and yarn mixtures used, yarn structural, physical, and mechanical properties have previously been published in the literature for both yarn form and woven or knitted fabric forms. As results of the technical summary of various existing theoretical and experimental studies their supported by experimental results, the technical conditions required for maximum yarn structural, physical, and mechanical properties are determined, especially for cotton (CO), polyester (PET), polyamide (PA), modal (CMD), and viscose rayon (CV) yarns. They are widely used in the global textile industry today. Moreover, it has been prepared for the technical optimization of spinning technologies for various structural, physical, and mechanical properties of woven or knitted fabrics to be produced for home textile applications such as casual clothing, where thermal comfort will be at the forefront.

Some Spinning Technologies Including Vortex (MVS); Their Importances, Formation Mechanism Principles, Yarns Used, and General Properties

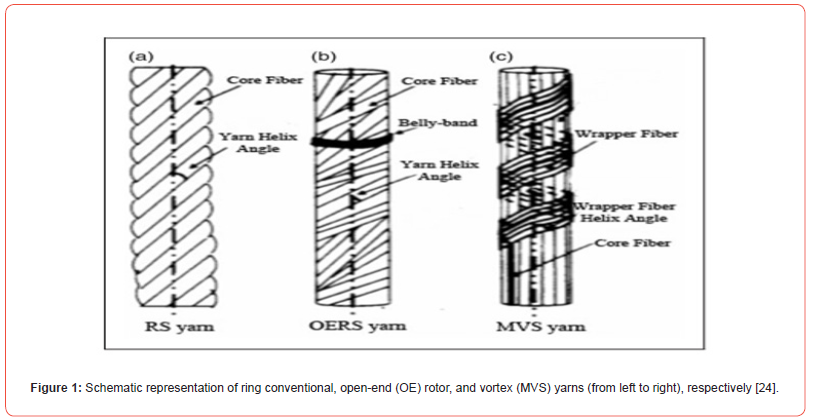

The yarn spinning technologies play an extremely important role in the textile industry. Technological developments in the spinning industry generally involve R&D efforts to ensure that the yarn has high quality, low labor, low cost, and fast production capacity [1,6]. Because high-quality textile products can be produced thanks to high-quality yarns. The method of twisting mostly determines the quality of the yarn, which includes its structural and mechanical properties [1]. When yarn spinning technologies in the textile industry are examined, yarn spinning technologies such as vortex (MVS), open-end (OE) rotor, ring (compact), ring (conventional), air jet (ATY), friction, bi-component (BCY), spot spinning (IMG) are widely used [1-30]. The schematic representation of ring conventional, open-end (OE) rotor, and vortex (MVS) yarns (from left to right), respectively was presented in Figure 1 [24].

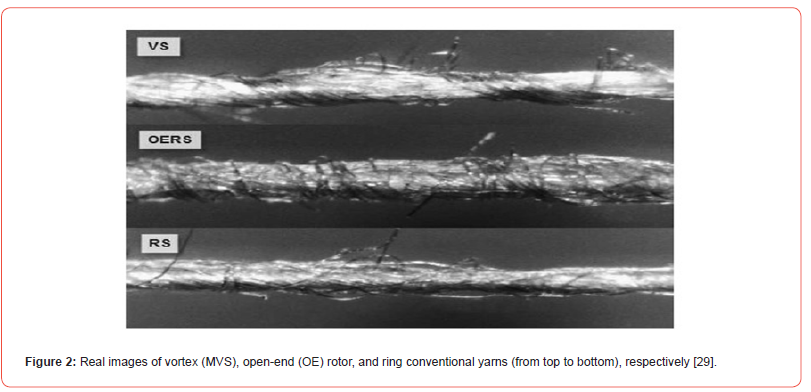

Real images of vortex (MVS), open-end (OE) rotor, and ring conventional yarns (from top to bottom), respectively were presented in Figure 2 [29]. Ring conventional yarn spinning technology is a yarn spinning technology based on the principle of winding empty bobbins of a strip with many filaments depending on the rotation speed of a spindle (spindle) which has yarn traveller (traveller) at the same time giving twist (in S or Z direction) with a circular route [13]. It was discovered in 1965 and the most famous ring conventional spinning machine manufacturers are Zinser and Rieter Companies [23-25,27,29,30]. Ring compact yarn spinning technology is a modified version of ring conventional spinning technology. The difference is that the spinning triangle is eliminated. Thanks to the elimination of the spinning triangle, the tensile strength and production speed of the yarn increase, while yarn hairiness and fiber flyness decrease. Binding of the winding fibers directly to the center fiber without twisting ensures the fiber length of the protruding fibers in the ring compact yarn structure is shorter compared to ring conventional yarns [26].

Open-end (OE) rotor yarn spinning technology is a spinning technology based on the principle that after a strip with many filaments passes through the opening cylinder, the separated fibers are brought to the rotor groove by the air-flow and then combined by twisting in a tube (in S or Z direction). The production speed is on average 200 m/min, and this value means a medium production speed [13]. Open-end (OE) rotor spinning technology is widely used in home textile applications thanks to its high moisture absorbance feature [22]. It was discovered between 1971 and 1975, and the most famous open-end (OE) rotor spinning machine manufacturers are Schlafhorst and Rieter Companies [23,29,30]. Vortex (MVS) yarns have a production speed that is 15-20 times faster than ring yarns and 2-3 times faster than open-end (OE) rotor yarns [18,23]. For 100% cotton (CO) yarns, the parallelization position of the wound fibers to the central fiber is higher in vortex (MVS) and ring conventional spinning technologies compared to open-end (OE) rotor spinning technology, that is, they have more parallel position, but the twist angles are relatively higher. Open-end (OE) rotor yarns have higher volume for the same yarn count compared to ring conventional yarns. For yarn hairiness of 3 mm fiber length, ring conventional spun yarns have much higher yarn hairiness values than vortex (MVS) and open-end (OE) rotor spun yarns [13,14]. Ring conventional yarns have the highest fiber migration compared to open-end (OE) rotor, and vortex (MVS) yarns [14,23]. Moreover, for yarn hairiness values of 3 mm fiber length, vortex (MVS) yarns have the lowest yarn hairiness values compared to ring and openend (OE) rotor yarns [13,14,22].

Open-end (OE) rotor yarn spinning technology is a spinning technology based on the principle that after a strip with many filaments passes through the opening cylinder, the separated fibers are brought to the rotor groove by the air-flow and then combined by twisting in a tube (in S or Z direction). The production speed is on average 200 m/min, and this value means a medium production speed [13]. Open-end (OE) rotor spinning technology is widely used in home textile applications thanks to its high moisture absorbance feature [22]. It was discovered between 1971 and 1975, and the most famous open-end (OE) rotor spinning machine manufacturers are Schlafhorst and Rieter Companies [23,29,30]. Vortex (MVS) yarns have a production speed that is 15-20 times faster than ring yarns and 2-3 times faster than open-end (OE) rotor yarns [18,23]. For 100% cotton (CO) yarns, the parallelization position of the wound fibers to the central fiber is higher in vortex (MVS) and ring conventional spinning technologies compared to open-end (OE) rotor spinning technology, that is, they have more parallel position, but the twist angles are relatively higher. Open-end (OE) rotor yarns have higher volume for the same yarn count compared to ring conventional yarns. For yarn hairiness of 3 mm fiber length, ring conventional spun yarns have much higher yarn hairiness values than vortex (MVS) and open-end (OE) rotor spun yarns [13,14]. Ring conventional yarns have the highest fiber migration compared to open-end (OE) rotor, and vortex (MVS) yarns [14,23]. Moreover, for yarn hairiness values of 3 mm fiber length, vortex (MVS) yarns have the lowest yarn hairiness values compared to ring and openend (OE) rotor yarns [13,14,22].

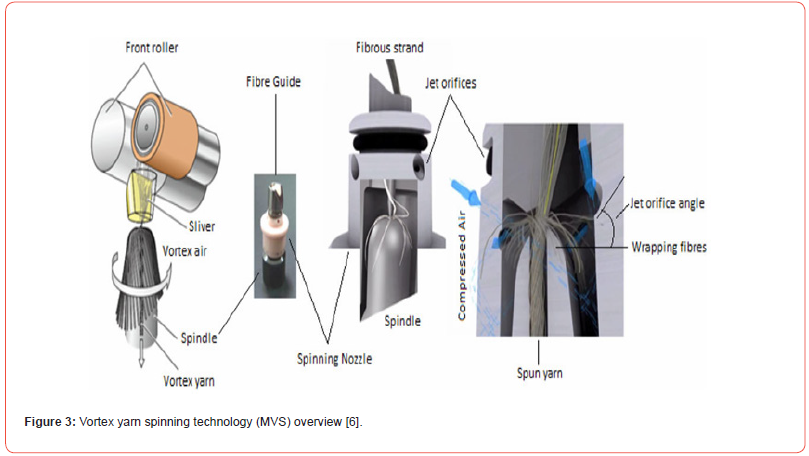

In the following years that Toyoda, Howa, and Toray Companies from Japan and Rieter Companies from Switzerland have also participated in this market, but the world leader in the market is the Japanese Murata Company. The Muratec coded machine is widely used nowadays [1,2,6,8,11,15,19-21,23-27,29,30]. This machine was not suitable for spinning 100% or high ratios of cotton (CO) yarns. It emerged as a spinning technology of various syntheticbased fibers, generally polyester (PET). Over the years, as a solution to this negative and incomplete situation has been eliminated by carrying out various theoretical and experimental R&D studies on nozzle designs, air channels inside the nozzle, air flow regimes within the nozzle, and draft systems (apron zone) [1]. Vortex yarn spinning technology (MVS), a strip with a large number of filaments coming out of a 4-cylinder drafting system (apron zone) is guided by the guidance of the strip feeding hole after coming out of the front rollers, is vacuum sucked into the air jet nozzle, which is a spiral profile opening, is winding as form of twisted yarn on empty bobbins [1]. To explain it more briefly, they are helically twisted yarns produced with wrapping fibers wrapped in a helical profile on the untwisted central fiber in the center of the yarn [1-6,8,9,11- 13,15,16,18,19,23,25-27,29].

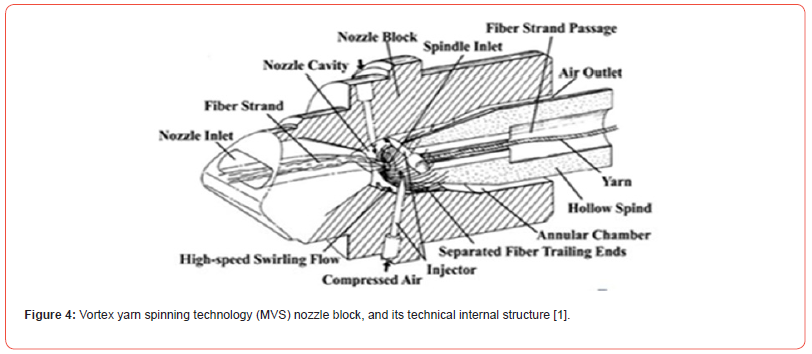

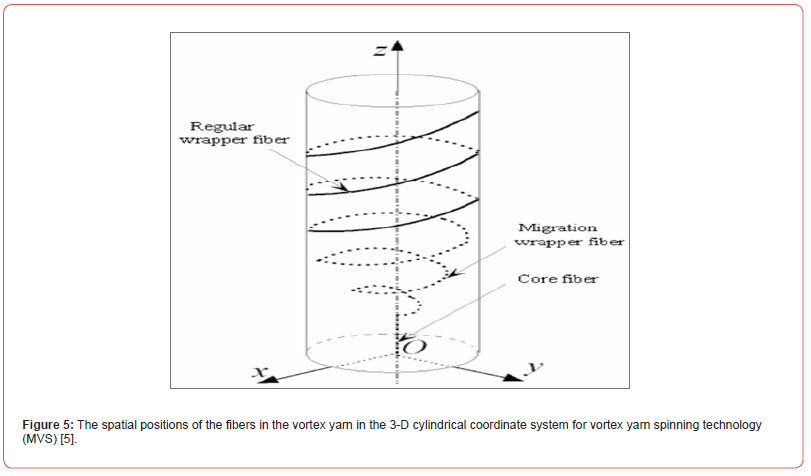

General properties of vortex (MVS) yarns and fabrics are low hairiness, high pilling and abrasion resistance, high color and washing fastness, high thermal comfort, soft touch, low fiber packing density, relatively high elasticity, high moisture absorption, and diffusion properties, fast drying ability and ability to maintain tensile strength values for a long time. (4-9,11,12,15- 17,20,23,25,27-30). Vortex yarn spinning technology (MVS) overview was presented in Figure 3 [6]. Vortex yarn spinning technology (MVS) nozzle block, and its technical internal structure were presented in Figure 4 [1]. The spatial positions of the fibers in the vortex yarn in the 3-D cylindrical coordinate system for vortex yarn spinning technology (MVS) were presented in Figure 5 [5].

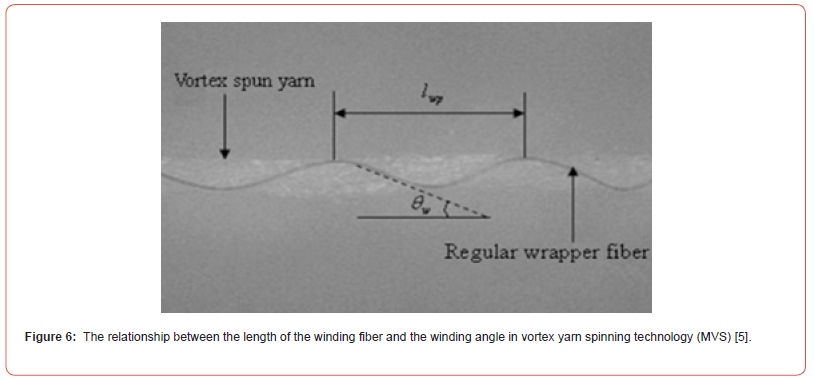

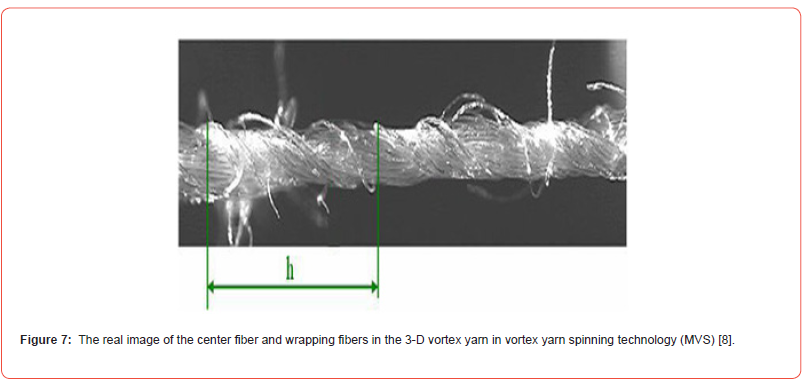

As the fiber length increases or the distance between the front roller and the spinneret decreases, the central fiber length in the vortex (MVS) yarn increases [5,16]. This means that the wound fiber becomes thinner and the winding speed decreases [5]. Moreover, vortex (MVS) increases the tensile strength values of yarns [16]. In order for the reverse of this situation to occur, the yarn count must be thinned and the air pressure inside the spinneret must be reduced. When the winding fiber is thinner and has a lower winding speed, the winding angle of the winding fiber is larger [5]. The relationship between the length of the winding fiber and the winding angle in vortex yarn spinning technology (MVS) was presented in Figure 6 [5]. The real image of the center fiber and wrapping fibers in the 3-D vortex yarn in vortex yarn spinning technology (MVS) was presented in Figure 7 [8].

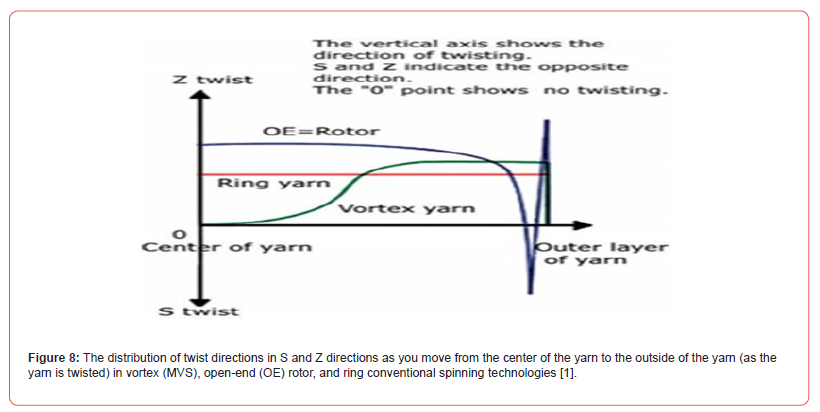

The distribution of twist directions in S and Z directions as you move from the center of the yarn to the outside of the yarn (as the yarn is twisted) in vortex (MVS), open-end (OE) rotor, and ring conventional spinning technologies was presented in Figure 8 [1]. The important production process parameters in vortex spinning technology (MVS) are raw material type or types (yarn type or types), yarn count (Ne (15-60) and Tex (10-39)), fiber length (mm (38-39)), number of slivers (16-96)), winding angle (° (14-20)), spinning speed (m/min (from 65 m/min to 500 m/min but the optimum value is 300 m/min for fine yarn count and 400 m/min for medium and coarse yarn count)) , front (1.5-5), intermediate (1.1-5), main (13.5-80) and total drafts (65-500), feed and winding rates (0.97-1.19), spinneret inner diameter (mm (1-1.4)), air pressure inside the nozzle (kg/cm2 (4-6)), distance between the front cylinder and the nozzle (mm (19-20)) [1-9,11-21,23-30].

These important production process parameters affect the structural, physical and mechanical properties of the yarn, that is, the quality of the yarn. The quality of yarns is structural, physical, and mechanical properties such as tensile strength, maximum breaking force, maximum breaking elongation, hairiness, irregularity, thin places, thick places, and neps. (1-9,11-19,21,23- 25). Cotton (CO), viscose (CV), viscose rayon (CV), modal (CMD), lyocell (LYO) (tencel), elastane (EA) (lycra), polyamide (PA), polyester (PET), linen (LI), wool (WO) are widely used as fibers and rarely copper (Cu) wire can also be used as the center fiber in vortex yarn spinning technology (MVS) [1-21,23-30]. Generally, as the air pressure inside the nozzle and the winding angle increases, the winding speed, the nozzle diameter and the distance between the front cylinder and the nozzle decreases. Moreover, their tensile strength, maximum breaking force, maximum breaking elongation and abrasion resistance of the yarn increase and yarn irregularity, yarn hairiness, and yarn defects decrease [3,6-9,11,13-17,19,26].

When the high air pressure inside the nozzle is within a large inner diameter of the nozzle, the number of fibers winding on the untwisted center fiber will decrease and the winding effect will therefore decrease. Thus, vortex (MVS) will cause a decrease in the tensile strength of the yarn. In order to prevent this situation, 3-D profiled CAD designs of the vortex tube and the nozzle profile, nozzle diameter and air channels inside it is extremely important [12]. Moreover, as the inner diameter of the spinneret decreases and the air pressure inside the spinneret increases, the twisting capacity increases. Because the free-end fibers of the yarn strips will be exposed to a higher radial air flow rate, at the same time the static pressure change will remain at a minimum level. Thus, the winding angle will decrease and they will be wound as twisted wound fibers on the untwisted center fiber. Afterward, the tensile strength value of vortex (MVS) yarn will increase and yarn hairiness, yarn irregularity, and yarn defects will decrease. This means that vortex (MVS) yarns can be produced [9,12]. High winding angle, air pressure inside the spinneret and low winding speed increases the migration of fibers in vortex (MVS) yarns [7]. When high air pressure values are applied inside the spinneret for fine yarn counts, yarn unevenness is higher. All these situations vary depending on the type of yarn [3].

Structural, Physical and Mechanical Properties for Yarn Form

In an experimental study for 100% viscose rayon (CV) yarns included as the air pressure inside the nozzle increased, the yarn tensile strength and hairiness decreased slightly. Yarn evenness was not affected. As the yarn winding speed increased, the yarn hairiness increased but the maximum percent breaking elongation decreased significantly. Moreover, yarn evenness, yarn tensile strength and maximum breaking force were not affected [3]. In an experimental study for 100% carded cotton (CO) yarns included the yarn was completely and negatively affected in terms of their structural properties. Yarn hairiness, yarn irregularity and yarn defects have increased. They have increased diameter, resembled a round cross-section, and had low density. Contrary to all these cases, the yarn for 100% viscose (CV), 100% viscose rayon (CV) and 100% modal (CMD) fibers was completely positively affected in terms of structural properties. Yarn hairiness, yarn irregularity and yarn defects have decreased. Their diameter was reduced and they had a fully round cross-section, and high density. They were determined that 100% polyester (PET) fiber was completely and positively affected in terms of yarn structural properties. A slight negative effect was detected for 100% polyamide 6 (PA) and polyamide 6.6 (PA) yarns.

Although 100% polyamide (PA) yarns generally had similar properties to polyester (PET) yarns, their differences were that they had a higher maximum percentage breaking elongation, and polyamide (PA) fibers with a thicker yarn count cause an increased in yarn diameter, and a decreased in yarn density [4]. For 100% viscose rayon (CV) vortex yarns in various yarn counts included maximum tensile strength values were observed with a spinneret inner diameter of 1.2 mm and a winding speed of 350 m/min. Moreover, as the yarn count increased, the tensile strength also increased. As the yarn count decreased, thin place, thick place, nep, and % CV values increased. As the inner diameter of the spinneret increased, the tensile strength of vortex yarns decreased. Small nozzle inner diameter and low winding speed increased the twist amount. Thus, lower yarn hairiness and higher yarn abrasion resistance values were achieved. As the internal diameter of the spinneret, winding speed, and yarn count increased and the air pressure inside the spinneret decreased, the yarn diameter increased. Moreover, as the spinneret inner diameter and winding speed increased, and the yarn count and air pressure inside the spinneret decreased, yarn hairiness increased [8].

In an experimental study on 100% cotton (CO), cotton (CO)- lyocell (LYO) and cotton (CO)-modal (CMD) ring, open-end (OE) rotor and vortex (MVS) yarns included while yarn diameter and roughness are at their lowest values in cotton (CO)-lyocell (LYO) and cotton (CO)-modal (CMD) yarns, they are highest in compact yarns. For yarn tensile strength values, compact yarns had the highest values, while vortex (MVS) yarns had the lowest values. Moreover, cotton (CO)-lyocell (LYO) and cotton (CO)-modal (CMD) yarns had the lowest values of yarn hairiness, yarn irregularity, and yarn defects. Cotton (CO)-lyocell (LYO) yarns had higher values for yarn strength values compared to cotton (CO)-modal (CMD) yarns, but had lower structural, and physical properties [14]. In an experimental study on vortex (MVS) CVC yarns mixed with 60% cotton (CO) and 40% polyester (PET) included the highest yarn tensile strength, the lowest yarn hairiness, the lowest yarn irregularity, the lowest yarn defect, the lowest thin place, the lowest thick place, and the lowest neps values can be optimized at a winding speed of 350 m/min [15]. In an experimental study on 100% cotton (CO) and 50% cotton (CO)/50% polyester (PET) vortex (MVS) yarns included as the yarn count gets thinner, the wrapping/center fiber ratio increased. Moreover, the wrap/ center fiber ratio, thin places, and neps were higher in 100% cotton (CO) yarns compared to 50% cotton (CO)/50% polyester (PET) yarns, while the thick places were lower. When 300 m/min winding speed was compared to 425 m/min winding speed, 100% cotton (CO) yarns had higher tensile strength, maximum percent breaking elongation, and thin place had lower values compared to 50% cotton (CO)/50% polyester (PET) yarns while % CV, yarn evenness, and yarn hairiness values of PET yarns. Moreover, 50% cotton (CO)/50% polyester (PET) vortex (MVS) yarns were found to have higher tensile strength, yarn hairiness, maximum percent breaking elongation and breaking work compared to 100% cotton (CO) vortex (MVS) yarns [16,17].

In an experimental study conducted for cotton (CO) + elastane (EA) blended vortex (MVS) yarns at 3 different yarn counts, 4 different elastane (EA) ratios and many different draft rates included as the yarn count gets thinner (from Ne 30 to Ne 50) and the elastane (EA) rate (except for the 22 dtex elastane (EA) yarn amount) increased, the % CV, and yarn unevenness values decreased. While the thickest yarn count (Ne 30) had the highest maximum percentage breaking elongation values only for 100% cotton (CO) yarns without elastane (EA), as the elastane (EA) rate increased (from 22 dtex to 44dtex) the maximum percentage breaking elongation values increased. As the yarn count gets smaller (from Ne 30 to Ne 50), the maximum percent elongation at break values increased. While the thickest yarn count (Ne 30) had the highest maximum breaking force values for only 100% cotton (CO) yarns without elastane (EA), as the elastane (EA) rate increased (from 22 dtex to 44dtex) and yarn count gets thinner (from Ne 30 to Ne 50) so the maximum percent elongation at break values varied. For the elastane (EA) yarn blend with 44 dtex yarn count, the highest value in terms of maximum breaking force values was at Ne 50 yarn count, and the lowest value is at Ne 40 yarn count. While the thinnest yarn count (Ne 50) had the lowest yarn hairiness values for only 100% cotton (CO) yarns without elastane (EA), as the elastane (EA) rate increased (from 22 dtex to 44dtex) and the yarn count gets thinner, Yarn hairiness values (from Ne 30 to Ne 50) varied. For the elastane (EA) yarn blend with 44 dtex yarn count, the lowest value in terms of yarn hairiness was at Ne 40 yarn count, while the highest value was at Ne 30 yarn count [18].

In an experimental study on 100% viscose rayon (CV) yarn included various structural, physical, and mechanical properties were examined by changing the winding speeds and intermediate draft ratios. According to the results, as the winding speed and intermediate draft decreased while % CV, yarn evenness, yarn hairiness, thin places, thick places, and neps had lower values, but the tensile strength of the yarn had higher values [20]. In an experimental study conducted by keeping the production process parameters constant for 100% carded cotton (CO) yarn in 3 different yarn counts included the tensile strength values of the yarns increased as the yarn count got thinner, but the maximum breaking force, and breaking work values decreased. The maximum percentage breaking elongation values of the yarn were variable. The yarn had higher maximum percent elongation at break values at relatively fine yarn counts. Moreover, for the maximum percentage breaking elongation values of 100% carded cotton (CO) yarn, respectively; Ne 30, Ne 40, and Ne 20 yarn counts were observed. The reasons for this situation were emphasized that it depends on fiber length, fiber fineness, and fiber number [21].

Structural, Physical and Mechanical Properties for Fabric Forms

Woven Fabric Form

Production process parameters required to produce vortex yarns with various yarn types to be developed for use in woven fabrics are higher feed rate, smaller inner diameter nozzle, and higher internal nozzle air pressure [6]. Ring conventional, open-end (OE) rotor and vortex (MVS) spinning for and weft yarns with 100% cotton (CO) Ne 20/2 as their yarn count Z twist direction cotton (CO) and weft yarn S and Z in woven fabrics woven as SSSS, ZZZZ, SSZZ, and SZSZ Various woven fabrics were produced in 1x1 plain woven fabric construction with densities of 15 warp/cm and 15 weft/cm with various combinations of twist directions. Afterward, the touch properties of these woven fabrics were examined on the Kawabata KESF device. As a result, the SSSS combination had the softest touch, while the ZZZZ combination had the hardest touch [10].

The tensile strength and abrasion resistance values of woven fabrics woven from ring conventional yarns were higher compared to yarns produced from other spinning technologies thanks to the high real twist amount, and high fiber orientation of ring yarns. Various structural, physical, and mechanical properties of woven fabrics produced in 1x1 plain, 3x1 twill and 4x1 satin woven fabric constructions using 50% cotton (CO) / 50% polyester (PET) and carded and combed cotton yarns were experimentally examined. According to the results, combed ring conventional, and carded ring conventional yarns had higher tensile strength, respectively for the tensile strength values of all woven fabrics. Moreover, their maximum percent elongation at break values compared to open-end (OE) rotor yarns had higher values. The reasons for this situation were combed ring conventional yarn had the longest fiber length, the highest fiber homogeneity, low twist angle, and high twist amount. Moreover, the tensile strength values from highest to lowest were determined as 4x1 satin, 3x1 twill, and 1x1 plain, respectively in terms of woven fabric constructions. The reasons for this situation were its maximum yarn-yarn locking, its maximum yarn-yarn friction, and its maximum crimp behavior were effective for 1x1 plain.

The warp direction abrasion resistance values, from highest to lowest, were determined as 4x1 satin, 3x1 twill, and 1x1 plain, respectively, in terms of woven fabric constructions, while the weft direction abrasion resistance values were determined as the opposite. Moreover, combed, carded, and open-end (OE) rotor cotton yarns were determined from highest to lowest, respectively for abrasion resistance values. Combed ring conventional and carded ring conventional cotton (CO) yarns had higher pilling resistance values compared to open-end (OE) rotor cotton (CO) yarns for pilling resistance values. 1x1 plain, 3x1 twill, and 4x1 satin structures were determined from highest to lowest, respectively for pilling resistance in their woven fabric constructions [22]. In an experimental study included ring conventional, ring compact, open-end (OE) rotor, and vortex (MVS) yarns were produced with 50% cotton (CO) / 50% polyester (PET) blends for their yarn counts of 36.7 tex and 24.4 tex, respectively. Then, woven fabrics were produced in 4x1 satin woven fabric construction with S direction and density values of 41.3 warp/cm and 27.6 weft/cm. Ring compact, ring conventional, vortex (MVS), and open-end (OE) rotor yarns were determined from highest to lowest, respectively for their tensile strength values both yarns and fabrics. The maximum percent elongation at break values of the yarns were determined open-end (OE) rotor, ring compact, ring conventional, and vortex (MVS) yarns, respectively.

The maximum percent elongation at break values of the fabrics were determined open-end (OE) rotor, ring conventional, ring compact, and vortex (MVS) yarns, respectively. In addition, as the yarn count gets thicker, the tensile and shear strength values of yarns and fabrics also increased. Moreover, the warp direction had higher tensile strength values compared to the weft direction. The reasons for these situations were the increased in the friction force of the yarns against each other, the increase in the rubbing surface area, and the increased in the orientation of the fibers forming the yarns to stay together, based on the friction coefficient and force. Ring compact, ring conventional, vortex (MVS), and open-end (OE) rotor yarns, respectively were determined for their shear strength values. Vortex (MVS) (5), open-end (OE) rotor, ring compact, ring conventional (1), respectively yarns were determined for their pilling resistance values. Moreover, pilling resistance values for ring compact (1 to 2) and open-end (OE) rotor (2 to 3) yarns increased by 1 point as the yarn count thickens [23].

In another experimental study included ring conventional, open-end (OE) rotor, and vortex (MVS) yarns were produced with cotton (CO), viscose rayon (CV), and polyester (PET) as yarn count of 29.5 tex. Afterward, woven fabrics were produced in a 1x1 plain woven fabric construction at 30 warp/cm and 20 weft/ cm densities for all these yarns. According to the results, viscose rayon (CV), cotton (CO), and polyester (PET), respectively for the tensile strength values were determined for the warp direction in woven fabrics woven from ring conventional yarns. Polyester (PET), viscose rayon (CV), and cotton (CO), respectively for the tensile strength values were determined for the weft direction in woven fabrics woven from ring conventional yarns. Cotton (CO), viscose rayon (CV), and polyester (PET), respectively for the tensile strength values were determined for the warp direction in woven fabrics woven from open-end (OE) yarns. Polyester (PET), viscose rayon (CV), and cotton (CO), respectively for the tensile strength values were determined for the weft direction in woven fabrics woven from open-end (OE) yarns. Polyester (PET), cotton (CO), viscose rayon (CV), and respectively for the tensile strength values were determined for the warp direction in woven fabrics woven from vorteks (MVS) yarns. Polyester (PET), viscose rayon (CV), and cotton (CO), respectively for the tensile strength values were determined for the weft direction in woven fabrics woven from vorteks (MVS) yarns. When crimp behavior was examined, the most uniform, and homogeneous crimp behavior was observed in vortex (MVS) yarn spinning technology, while the most dispersed and non-homogeneous crimp behavior was observed in open-end (OE) rotor yarn spinning technology [24]. In another experimental study included both ring conventional and vortex (MVS) yarns were produced with 67% cotton (CO)/33% polyester (PET), 50% cotton (CO)/50% polyamide (PA) and 100% micromodal viscose rayon (mCV) yarns as yarn count of 16.67 tex.

Afterward, woven fabrics were produced in 1/3 twill woven fabric construction, in Z direction and with density values of 30 warp/cm and 30 weft/cm. According to the results, while relatively higher yarn hairiness was observed in 100% micromodal viscose rayon vortex (MVS) yarn compared to ring conventional yarn, for other yarns, lower yarn hairiness values of vortex (MVS) yarns were observed compared to ring conventional yarns. Polyamide (PA) had higher yarn hairiness and much less yarn irregularity, thin places, thick places, and neps compared to polyester (PET). Tensile strength values were very close to each other, but ring conventional had relatively higher tensile strength and maximum percent elongation at break values compared to conventional vortex yarn spinning technology. In addition, the maximum percent elongation at break values in polyamide (PA) fabrics were significantly higher than other fabrics. As the number of cycles increased, pilling resistance decreased. In addition, the vortex (MVS) yarn spinning technology had a much longer lasting, and higher pilling resistance depending on the number of cycles compared to ring conventional spinning technology. Moreover, depending on the number of cycles, pilling resistance values were 50% cotton (CO) / 50% polyamide (PA), 67% cotton (CO) / 33% polyester PET, and 100% micro modal viscose rayon (mCV), respectively [25].

Knitted Fabric Form

Production process parameters required to produce vortex yarns with various yarn types to be developed for use in knitted fabrics are lower feed rate, larger diameter internal nozzle, and lower internal nozzle air pressure [6]. In an experimental study included 100% cotton (CO) yarns were produced in various yarn counts using combed ring conventional, carded ring conventional, compact, and vortex (MVS) spinning technologies. Then, 1x1 rib knitted fabrics were produced in single bed knitting machine. According to the results, the tensile strength value of compact yarn was determined higher than ring conventional and vortex (MVS) yarns, respectively. As the yarn count gets thickers, tensile strength values increased. Moreover, double-ply yarns had lower tensile strength and maximum percent elongation at break compared to single-ply yarns. As the yarn count thickens, tensile strength values increase. Moreover, double-ply yarns have lower tensile strength and maximum percent elongation at break compared to singleply yarns. Yarn hairiness, % CV, yarn irregularity, thin places, thick places, and neps values were determined higher in ring conventional and ring compact 100% combed cotton (CO) yarns compared to vortex (MVS) yarns. Double-ply ring conventional yarns had higher bursting strength values compared to single- and double-plied ring compact, and vortex (MVS) yarns for their bursting strength.

Double-ply yarns had 1 point higher than single-ply yarns for pilling resistance values. Pilling resistance depended on yarn hairiness. Thus, pilling resistance values were determined as vortex (MVS), ring compact, and ring conventional yarns, from highest to lowest, respectively. Abrasion resistance values were determined as ring conventional, ring compact, and vortex (MVS) yarns, from highest to lowest, respectively [26]. In an experimental study included 100% viscose rayon (CV) were produced as ring conventional and vortex (MVS) yarns. Afterward, 1x1 rib knitted fabrics were produced in single bed knitting machine. According to the results in contrast to the results of cotton (CO) fiber, vortex (MVS) yarns were found to have higher bursting strength, pilling resistance, air permeability, water vapor permeability, and thermal permeability values compared to ring conventional yarns [27].

In an experimental study included 100% viscose rayon (CV) yarns were produced with vortex (MVS) and air-jet (ATY) yarns. Then, they were produced as knitted fabrics with 3 different knitting constructions and density values. According to the results, as knitted fabric density values increased, pilling resistance values increased by 1 point, and abrasion resistance values also increased. In addition, vortex (MVS) yarns had higher pilling resistance, and higher abrasion resistance values compared to air-jet (ATY) yarns. Moreover, as knitted fabric density values decreased, air permeability values increased. Finally, vortex (MVS) yarns had higher air permeability values than air-jet (ATY) yarns [28]. In an experimental study included 100% viscose rayon (CV) yarns were produced with ring conventional, open-end (OE) rotor, and vortex (MVS) yarns for their yarn count as Ne 30/1. Afterward, 1x1 rib knitted fabrics were produced in single-bed knitting machine. Yarn hairiness, % CV, yarn evenness, thin place, thick place, and nep values were determined as rotor (OE) rotor, ring conventional, and vortex (MVS) yarns, from highest to lowest, respectively. According to the results, while the most color change after wear was in the vortex (MVS) yarn, the least color change was detected in the ring conventional yarn. The reasons for this situation depended on the hairiness of the yarn. Vortex (MVS) yarns were the yarn spinning technology that reflected the lightest, the most worn, and the most affected by color change, but they had the lowest yarn hairiness [29].

In an experimental study included polytrimethylenterephthalate (PTT), modal (CMD), and wool (WO) as their blends were double and triple yarn blends yarns were produced as ring conventional, ring compact and vortex yarns (MVS). Afterward, 1x1 rib knitted fabrics were produced in single-bed knitting machine. According to the results, % CV, yarn irregularity, thin place, thick place, and nep values increased, but the maximum breaking force values decreased as the yarn count gets thinner for both yarns and knitted fabrics in terms of all yarn spinning technologies. In terms of maximum breaking force and maximum percent elongation at break values, ring conventional, ring compact, and vortex (MVS) yarns were determined from highest to lowest for both yarns and knitted fabrics, respectively. Vortex (MVS) yarns had the highest air permeability, pilling resistance, thermal comfort, fast drying, moisture, and heat transfer values for both yarns and knitted fabrics. Moreover, vortex (MVS) yarns had a harder touch compared to ring compact and ring conventional yarns, respectively [30].

Conclusion

In this review study included the differences between ring conventional, ring compact, open-end (OE) rotor, and vortex (MVS) yarn spinning technologies. It has also about vortex yarn spinning technology (MVS), its importance, history, technological innovations based on R&D studies over the years, its formation mechanism, structural, physical, and mechanical properties of the yarns to which it can be applied, and the structural, physical and mechanical properties of various textile-based fabrics such as weaving and knitting to which it can be applied were mentioned. Generally, thanks to Vortex yarn spinning technology (MVS), which was a patented yarn spinning system developed and patented by the Japanese company Murata, a manufacturer of yarn spinning machines, MVS production process parameters such as spindle inner diameter, nozzle geometry, air pressure inside the spinneret, distance between the front roller and the spinneret, feed rate by changing the parameters such as draft rate, winding speed, predraft, intermediate draft, main draft, total draft and yarn structural parameters such as yarn type, yarn count and yarn types mixture ratios, for its quantitative determinations can be made for its the structural, physical and mechanical properties. According to the results of various theoretical and experimental studies in the literature, there was a completely positive effect in terms of yarn structural properties, especially for regenerated cellulose-based yarns such as viscose (CV), viscose rayon (CV) and modal (CMD) and synthetic-based yarns such as polyester (PET).

That was, as the air pressure inside the nozzle increased and the winding speed decreased, yarn hairiness, CV%, yarn irregularity, and yarn defects decreased. Moreover, tensile strength values increased relatively. In synthetic-based yarns such as polyamide 6 (PA 6) and polyamide 6.6 (PA 6.6), the maximum percentage breaking elongation values increased. In addition, as the amount of polyamide (PA) in the yarn increased, there was an increased in the yarn diameter and % CV value of the yarn and a decreased in yarn density (degree of yarn packing). For natural cellulosic-based yarns such as carded-type cotton, a completely negative effect was detected in terms of yarn structural properties. The use of 60% or more carded cotton yarn as blend yarn in MVS was definitely not recommended in terms of yarn quality. It was definitely recommended for use in casual clothing applications where structural, physical, and mechanical properties as well as thermal comfort were at the forefront thanks to the production of viscose (CV) or viscose rayon (CV) yarns with vortex (MVS) yarn technology. In terms of yarn spinning technologies to be used in woven or knitted fabrics; ring compact for maximum tensile strength and maximum breaking force values, open-end (OE) rotor for maximum percent elongation at break and maximum moisture absorption values, vorteks for maximum abrasion and pilling resistance values and minimum yarn hairiness, yarn irregularity, yarn defects, thin places, thick places, and neps. It was concluded that vortex (MVS) spinning technologies should be used in casual clothing applications. Moreover, vortex yarn spinning technology (MVS) extra required qualities such as maximum fiber-fiber friction, fiber distribution, fiber homogeneity, and dimensional stability in its structural, physical, and mechanically properties. It provided tensile strength, maximum breaking force, maximum breaking elongation, minimum yarn hairiness, and minimum yarn unevenness. It was the most effective yarn spinning technology that should be used in woven, or knitted fabrics to be produced for home textile applications such as casual clothes, where thermal comfort will be at the forefront thanks to its unique flexible physical, and mechanical properties.

Acknowledgment

None.

Conflict of Interest

The author declares that there is no conflict of interest..

References

- Begum HA, Khan KR, Rahman M (2018) An overview on spinning mechanism, yarn structure and advantageous characteristics of vortex spun yarn and fabric. Advances in Applied Sciences 3(5): 58-64.

- Pei Z, He J (2019) Experimental study on the formation of core-spun yarn manufactured on a modified vortex spinning system. Textile Research Journal 89(21-22): 4383-4397.

- Yalı V, Akdoğanözü R, Kalaycı YE, Göktepe F (2020) An investigation of the effect of delivery speed and nozzle air pressure on viscose yarn properties in Vortex Spinning. Tekstil ve Mühendis 27(117): 2-11.

- Uyanık S, Baykal PD (2018) Effects of fiber types and blend ratios on Murata Vortex yarn properties. The Journal of the Textile Institute 109(8): 1099-1109.

- Zou Z, Cheng L, Xi B, Luo Y, Liu Y (2015) Investigation of fiber trajectory affected by some parameter variables in vortex spun yarn. Textile Research Journal 85(2): 180-187.

- Bhatti MRA, Tausif M, Mir MA, Umar M, Cassidy T (2019) Effect of key process variables on mechanical properties of blended vortex spun yarns. The Journal of the Textile Institute 110(6): 932-940.

- Basal G, Oxenham W (2006) Effects of some process parameters on the structure and properties of vortex spun yarn. Textile Research Journal 76(6): 492-499.

- Moučková E, Mertová I, Jirásková P, Krupincová G, Křemenáková D (2015) Properties of viscose vortex yarns depending on technological parameters of spinning. Autex Research Journal 15(2): 138-147.

- Han C, Xue W, Cheng L (2016) Comparative analysis on yarn mechanism and yarn properties of different jet vortex spinning systems. Textile Research Journal 86(14): 1498-1506.

- Ünal PG (2010) Investigation of some handle properties of fabrics woven with two folded yarns of different spinning systems. Textile Research Journal 80(19): 2007-2015.

- Kremenakova D (2013) Vortex yarn structure Characterization. Beltwide Cotton Conferences, San Antonio, Texas, January 7-10: 1074-1080.

- Li M, Yu C, and Shang S (2014) Effect of vortex tube structure on yarn quality in vortex spinning machine. Fibers and Polymers 15(8): 1786-1791.

- Soe AK, Takahashi M, Nakajima M (2004) Structure and properties of MVS yarns in comparison with ring yarns and open-end rotor spun yarns. Textile research journal 74(9): 819-826.

- Kilic M, Okur A (2011) The properties of cotton-Tencel and cotton-Promodal blended yarns spun in different spinning systems. Textile Research Journal 81(2): 156-172.

- Repon R, Islam T, Rahman M, Malek A, Jalil MA (2021) Characterisation of CVC yarn with different drafting ratios in vortex spinning. Fibres & textiles in Eastern Europe. 29(6(150)): 54-58.

- Erdumlu N, Oxenham W, Ozipek B (2013) The impact of combing and processing parameters on the structure and properties of fine count vortex yarns. Textile Research Journal 83(4): 396-405.

- Kuthalam ES, Senthilkumar P (2017) Optimization of spinning parameters influencing the hairiness properties of polyester/cotton vortex yarn. The Journal of The Textile Institute 108(3): 449-459.

- Ortlek HG, Ulku Ş (2007) Effects of spandex and yarn counts on the properties of elastic core-spun yarns produced on Murata vortex spinner. Textile Research Journal 77(6): 432-436.

- Ortlek HG, Ulku Ş (2005) Effect of some variables on properties of 100% cotton vortex spun yarn. Textile Research Journal 75(6): 458-461.

- Erdumlu N, Ozipek B (2010) Effect of the draft ratio on the properties of vortex spun yarn. Fibres & Textiles in Eastern Europe 18(3): 38-42.

- Gunaydin GK, Özgün C (2017) A research on tensile properties of vortex yarns. DE REDACTIE 68(3): 170-175.

- Azeem M, Ahmad Z, Wiener J, Fraz A, Siddique HF, et al. (2018) Influence of weave design and yarn types on mechanical and surface properties of woven fabric. Fibres & Textiles in Eastern Europe 1(127): 42-45.

- Akhtar KS, Ahmad S, Afzal A, Anam W, Ali Z, et al. (2020) Influence and comparison of emerging techniques of yarn manufacturing on physical–mechanical properties of polyester-/cotton-blended yarns and their woven fabrics. The Journal of the Textile Institute 111(4): 555-564.

- Shanbeh M, Johari MS, Zarrebini M, Barburski M, Komisarczyk A, et al. (2020) Effect of a weft yarn spinning system on the shear characteristics of plain woven fabrics. Textile Research Journal 90(1): 10-23.

- Kostajnšek K, Dimitssrovski K (2016) Comparative study on the properties of vortex and ring spun yarn and the properties of woven fabrics containing those yarns in weft. Fibres & Textiles in Eastern Europe 2(2): 59-65.

- Beceren Y, Nergis BU (2008) Comparison of the effects of cotton yarns produced by new, modified and conventional spinning systems on yarn and knitted fabric performance. Textile Research Journal 78(4): 297-303.

- Thilagavathi G, Muthukumar N, Kumar VK, Sadasivam S, Sidharth PM, et al. (2017) Physical and thermal comfort properties of viscose fabrics made from vortex and ring spun yarns. Journal of The Institution of Engineers (India): Series E 98(1): 65-70.

- Salome K, Wei L, Josphat MI (2013) A study of the effect of stitch density on viscose knitted fabric made from vortex and airjet spun yarns. College of Textiles, Donghua University, Shanghai (CHINA) 4(1): 20-26.

- Ortlek HG, Tutak M, Yolacan G (2010) Assessing colour differences of viscose fabrics knitted from vortex-ring-and open-end rotor-spun yarns after abrasion. The Journal of the Textile Institute 101(4): 310-314.

- Kim HA (2017) Physical properties of ring, compact, and air vortex yarns made of PTT/wool/modal and wearing comfort of their knitted fabrics for high emotional garments. The Journal of The Textile Institute 108(9): 1-10

-

Ömer Fırat TURŞUCULAR*. A Review on Vortex Yarn Spinning Technology (MVS) in the Global Textile Industry. J Textile Sci & Fashion Tech 10(4): 2024. JTSFT.MS.ID.000750.

-

Vorteks Yarn Spinning Technology (MVS); Process Parameters; Yarns; Fabrics; General Properties; Iris Publishers; Iris Publishers Group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.