Research Article

Research Article

Strategic Supply Chain Management Impact on Profitability of Manufacturing Companies in Plateau State. A Case Study of Swan Paint Nigeria Limited Jos South).

Ruth Agwom Panle1 and Arinzechukwu Jude Okpara2*

1Department of Business Administration, Faculty of Management Sciences, University of Jos, Jos, Nigeria

2Department of Marketing Faculty of Management Sciences, University of Jos, Jos, Nigeria

Arinzechukwu Jude Okpara, Department of Marketing Faculty of Management Sciences, University of Jos, Jos, Nigeria.

Received Date:July 10, 2024; Published Date:October 09, 2024

Abstract

The Benefit of Strategic deliver chain management is the truth the strategic supply chain plays a massive role within the profitability sustainability of manufacturing firms. Supply Chain Management integrates capabilities with number one responsibility of linking important commercial enterprise capabilities and processes within and across organizations right into a cohesive and high acting commercial enterprise model. The look at examines the impact of strategic supply chain management at the profitability of Manufacturing Companies, Plateau State the usage of 4(four) practices of supply chain that cowl the upstream, downstream and inner practices which can be strategic providers partnership, customer relationship, level and exceptional of facts sharing and postponement. Data were amassed via questionnaire, approximately one hundred questionnaires become disbursed the various top, middle and occasional stage managers inside the company which had been anticipated to have the first-class expertise approximately their deliver chain operations and its effect on the general profitability of the employer, eighty of them answered definitely. The records have been analyzed the usage of SPSS model 23 The end result confirmed that there is a high-quality dating between deliver chain practices and profitability and it changed into recommended that to improve both strategic providers partnership and client relationship and adoption of top and less effort must be placed on postponement as it has a bad and insignificant impact on profitability of an business enterprise even as level and great of information sharing ought to be practice at minimally because it has a negative although insignificant effect on profitability.

Keywords: Supply Chain Management; Strategic; Profitability; Partnership; Quality and Customers

Introduction

Strategic Supply chain control ought to really be efficient and effective. In this case efficiency approach to decrease resource use to accomplish particular outcomes; and be effective, in phrases of designing distribution channels. Efficiency is measured through transport overall performance, product great, again orders and inventory stage, whereas effectiveness is measured by means of carrier exceptional, level of customer delight and the provider need (Domenica, 2002). Strategic Supply chain management (SCM) has grown into a fascinating and exciting discipline global-huge, given the present reality of growing uncertainty and instability brought about with the aid of globalization, competition and speedy development in generation. Managing upstream price added drift of substances, very last items and associated information among providers, company, resellers, final client is delivering chain control (Jobber, 2004).

The council of supply chain control professionals (CSCMP) defined Supply chain Management to encompasses the making plans and management of all activities concerned in sourcing and procurement, conversion and all logistics management sports. Importantly, it is also coordination and collaboration with channel companions, which may be providers, intermediaries, third-birthday party carrier providers and customers. SCM draws closely from the areas of operations control, logistics, procurement, and information era, and strives for an incorporated approach (Bartsch,2013).

In essence, the Benefit of Strategic supply chain management is the reality the strategic supply chain performs a substantial role inside the profitability sustainability of production firms. Supply Chain Management integrates functions with number one duty of linking predominant commercial enterprise functions and methods inside and throughout corporations right into a cohesive and high appearing enterprise version. It consists of all the logistics management activities mentioned above, as well as manufacturing operations. It drives coordination of methods and activities inside and across advertising sales, product design, finance and facts generation. Supply chain management is a first-rate issue in lots of industries as corporations recognize the significance of creating an integrated courting with their suppliers and consumers. Managing the deliver chain has come to be a manner of improving competitiveness by way of decreasing uncertainty and enhancing customer service (Palmer, 2000).

Nigeria is the most populated and also is most of the developing economy in the global. Supply chain occurs where two or greater parties are linked through a waft of sources. The parties concerned in a deliver chain do now not want to be one-of-a-kind companies; they can be exclusive departments, divisions or maybe key people inside an organization. The concept of deliver chain is set coping with coordinated statistics and material flows, plant operations and logistics. It presents flexibility and agility in responding to consumer call for shift without price overlay in aid utilization. The essential premise of this philosophy is; Synchronization among multiple self-sufficient commercial enterprise entities represented in it. That is, progressed coordination inside and between diverse deliver chain participants. Increased coordination can cause reduction in lead time and costs, alignment of interdependent decision-making approaches and improvement inside the typical performance of every member as well as the supply chain (Jobber, 2004).

The Challenges going through Supply Chain Management these days is the fact that, Nigeria may also have the largest home market in Africa and may be attracting more Foreign Direct Investment (FDI) than ever earlier than, but its manufacturing region has been experiencing downturn. Government of the day had instructed whoever cared to pay attention that industrialization became important for monetary growth. Unfortunately, over the years, a combination of power troubles, terrible infrastructure, and terrible know-how of Supply chain management, importation of cheap however every now and then higher substitutes, policy inconsistencies- mainly on tariffs, poor patron pride, put off in lead-time and reaction time, poor platform for Microeconomic performance and uncompetitive enterprise surroundings have brought about the decline of Operations in manufacturing corporations (Nigeria Gallery, 2012). The major hassle that this take a look at x-rayed is the nonstop downward fashion skilled in production enterprise considering that 2005 which have result to many businesses wounding up and this could be attributed to bad strategic deliver chain management which translates to high price of production and in flip high charge consistent with unit in their merchandise in comparison to that in their worldwide competitor (Alu, 2011). The industry is marred through low earnings margin due to excessive price burden.

The primary motivating pressure behind carrying out an enterprise is income. It affords the manner of measuring the development of the commercial enterprise and testing its pulses. An organization is required to earn enough earnings for its existence and enlargement. Thus, income making is the fundamental goal of each business; for this reason, profitability is the yardstick for measuring the performance of such firms. (Duck & Jerrish, F. R. J. 1964) Profit is indeed a magic eye that mirrors all the components of complete commercial enterprise operations. The larger the income, the more efficient and worthwhile a commercial enterprise is deemed to be. For personal enterprises, profits are the quilt of coverage; while for Government, they may be every now and then a result, every now and then a guide, occasionally a target and every now and then an instrument of national financial coverage. Profits to the management are the test of performance and a degree of manipulate; to the owners, a measure of well worth of their investments; to the creditors, the margin of safety; to the employees, a supply of fringe benefits; to the customers, a touch to call for for better pleasant and rate cuts; to an employer, a much less cumbersome supply of finance for increase and lifestyles; and in the end to the country, earnings are an index of monetary development (Dean,1992).

Statement of the Problem

Most manufacturing firms are unable to combine their deliver chain management operations efficaciously in any such way that it complements their sales and profitability and also, strive to create a Strategic Supply Chain machine so that it will create price and manage chance for their several clients from origination and processing, to logistics and distribution.

Over the past decades, strategic supplier partnership became visible to have very little importance to increase in earnings of a business enterprise. Therefore, the have a look at set out to investigate the contact of strategic supply chain management practices on profitability, its measures and how they raise profitability.

Research Questions

To guide the study, the following questions will be asked;

a) What role does effective strategic supplier partnership

contribute to company’s profitability?

b) How can postponement affect the profitability of a company?

c) How does the level and quality of information sharing affect

a company’s profitability?

d) What role does the effect of customer relationship play on

profitability?

Objectives of the Study

The general objective of the study is to examine the impact of strategic supply chain management practices as a tool to boost profitability.

Therefore, the specific objectives of the study are;

a) To examine the effect of strategic supplier partnership on

profitability of Manufacturing Companies in Plateau State

b) To examine the effect of customer relationship on profitability

of Manufacturing Companies in Plateau State

c) To determine postponement effect on profitability of

Manufacturing Companies in Plateau State.

d) To determine the level and quality of information sharing

effect on profitability of Manufacturing Companies in Plateau

State.

Research Hypothesis

H01: There is no significant effect of strategic supplier

partnership on profitability of Manufacturing Companies in Plateau

State.

H02: There is no significant effect of customer relationship on

profitability Manufacturing Companies in Plateau State.

H03: There is no significant effect of postponement on

profitability of Manufacturing Companies in Plateau State.

H04: There is no significant effect of level and quality of

information sharing on profitability of Manufacturing Companies

in Plateau State.

Significance of the Study

The locating of this study has in its context, contributes to; Policy Making, Practice, and Theoretical implications for the future of strategic supply chain management. In manufacturing industries particularly SWAN Paint Nigeria Limited due to the fact;

In its practice, the applicability of the suggestions will yield greatest result to the Paint Manufacturing enterprise underneath have a look at and others to. Studying the effect of Strategic Supply Chain Management at the profitability of the corporations in view may be useful to all groups who’re within the commercial enterprise of production and marketing. It is a version for production and advertising agencies, and therefore may be used in speculating the state of advertising and marketing and Supply chain control business in Nigeria.

In Policy Making, this take a look at, no question, shall inform and direct manufacturing groups and potential entrepreneurs in making diverse types of selections, which include financial selections on Supply chain control and advertising in standard. The large society might equally enjoy the pointers and findings supplied by way of this work. It might research that the economic and social justification of an corporation existence is focused on delivering cost and satisfaction to the client at a income, also, Government will be capable of setup regulations that will lead to powerful supply chain control in Nigeria as a tool to reinforce profitability.

In Theory, Business students as well as Academia will even learn from the opinions, findings, and guidelines, so that you can resource them in expertise the rudiments of impact of green deliver chain management device on profitability. Supply chain professionals and consultants may even advantage from this work, as it will decorate the sensible expertise of the major elements and components of supply chain control in our modern society. Researchers might also benefit from the observe, because it will enhance the theoretical knowledge of the researcher inside the area of supply chain, and contribute to the body of knowledge.

Literature Review

Concept of Supply Chain Management

Supply chain control is a broadly diagnosed and step by step developing multidisciplinary subject. Wide types of journals have advanced and contributed to the evolving foundation and practice of supply chain control continually over the last twenty (20) years [1]. “A deliver chain is defined as a gadget of three or extra entities (companies or individuals) directly concerned within the upstream and downstream flows of merchandise, offerings, finances, and/ or facts from a supply to a consumer” [2]. Mentzer, et al [2] Investigating the several definitions and processes to deliver chain control throughout history and stated that, it’s miles crucial to realize the implicit with those definitions is the fact that supply chains exists whether they’re managed or now not”. Firms that are going to achieve success already realize or have to quick realize that in nowadays fast paced and interconnected enterprise surroundings infused with mass globalization, a organization will not continue to exist in isolation but alternatively as a single entity of an integrated supply chain (Tan, Kannan, Handfield and Ghosh, 2009).

Researches’ have consistently mentioned that nowadays com mercial enterprise environment is not a reflection of organization versus corporation opposition however has advanced to that of supply chain as opposed to supply chain [3].

The Concept of Supply Chain Management Practices

Supply chain control practices have been described as a hard and fast of activities undertaken in an company to sell powerful control of its deliver chain [2]. Describing the brand-new evolution of supply chain control practices, which encompass dealer partnership, outsourcing and cycle time compression, non-stop system glide and statistics technology sharing [4]. Use shopping, great and consumer members of the family to represent supply chain control practices, of their empirical observe (Tan, Kannan, Handfield and Ghosh, 2009). Also encompass in their listing of supply chain management practices give attention to center skills, use of inter-organizational structures and removal of excess stock stages by means of suspending customization towards the give up of the supply chain [5].

Conceptual Framework of SCM Practices

Thus, the literature portrays deliver chain control exercise from a whole lot of special views with a common intention of ultimately improving organizational overall performance. In reviewing and consolidating the literature, 4 distinct dimensions, including strategic dealer partnership, customer dating, level and quality of information sharing, and postponement, are decided on for measuring deliver chain control exercise. The four constructs cowl upstream (strategic supplier partnership) and downstream (Customer dating) facets of a deliver chain, statistics float throughout a deliver chain (degree of information sharing and best of statistics sharing), and internal deliver chain technique (postponement). It should be pointed out that even though the above dimensions capture the main components of deliver chain control exercise, they cannot be considered complete. Other elements, along with geographical proximity, lean Capability, pass-useful groups; logistics integration, agreed vision and goals, and agreed supply chain leadership also are identified within the literature.

The gift have a look at, consequently, proposes supply chain control practices as a multi-dimensional concept. A more special discussion of those dimensions is supplied beneath.

Strategic Supplier Partnership

This is described because the long-term relationship among an enterprise and its providers. It is designed to leverage the strategic and operational competencies of individual collaborating organizations to assist them reap considerable ongoing blessings [6]. A strategic partnership emphasizes on direct long-time period affiliation and encourages mutual planning and problem-solving efforts [7]. Such strategic partnerships are entered into to sell shared blessings among the parties and ongoing participation in one or extra key strategic regions inclusive of generation, merchandise, and markets [8]. Strategic partnerships with providers enable companies to work greater successfully with a few essential providers who’re inclined to proportion responsibility for the fulfillment of the goods. Suppliers taking part early within the product-design method can provide greater value effective design selections, help pick the pleasant components and technologies, and assist in design assessment [6].

Customer Relationship

Customer dating accommodates the entire array of practices which might be employed for the reason of coping with customer court cases, building long-time period relationships with customers, and enhancing patron satisfaction (Wines, 2006). Considering client relationship management as an critical aspect of deliver chain management practices [6].

Level and Quality of Information Sharing

Both degree and best elements are critical for the practices of deliver chain management and had been dealt with as impartial constructs inside the beyond deliver chain control research. Level of statistics sharing refers to the volume to which crucial and proprietary records is communicated to 1 or extra supply chain companion [7]. Shared data can vary from strategic to tactical in nature and from information approximately logistics sports to general market and customer records [9].

Postponement

Is defined as the exercise of transferring ahead one or more operations or activities (making, sourcing and handing over) to a mile later factor inside the supply chain [10].

Two number one concerns in developing a postponement strategy

are:

a. Determining what number of steps to postpone, and

b. Determining which steps to put off (Beamon, 2005)

Management started to recognize the fee of postponement whilst the manufacturing philosophy modified from mass manufacturing to mass customization. Some researchers consider that postponement is particularly a pragmatic manner to transport closer to mass customization [11].

On a deliver chain degree, upstream postponement approach producers wait to order uncooked substances from suppliers until they receive the patron order, in contrast to downstream postponement that’s defined as delaying a few sorts of bodily exchange to the product after it leaves the primary production level [10]. Finally, shopping postponement is the exercise of suspending the incoming additives or uncooked cloth until call for is thought (Yang et al., 2004b). The above classification highlights the range in postponement practices, as well as the underlying complexity of the issues addressed with the aid of management, each on a organization and supply chain stage.

The Concept of Profitability

Although the idea of profitability is very commonplace within the educational literature, its general definition is the potential of a company or a enterprise unit to yield earnings. The idea of income refers back to the absolute quantum of earnings. It does now not communicate what the cause for earnings is, how it’s miles scattered and what the connection of 1 figure is with another. All those questions may be answered by using the concept of profitability.

The idea of profitability has four broad versions: (1) Social profitability, (2) Commercial or Accounting profitability, (3) Value- Added profitability and (4) Economic Value-Added profitability.

Social Profitability

From the society point of view, social profitability is a much higher measure of performance as compared to the alternative varieties of profitability. The measurement of social profitability is undertaken inside the framework of social fee-benefit analysis. In other phrases, whilst all the outputs and inputs are evaluated at their social possibility charges, and when all external consequences at the domestic economic system are given social valuation and protected inside the measure, we get a measure of internet social profitability.

Commercial or Accounting Profitability

In well-known phrases, the performance of a commercial enterprise is measured through the input-output evaluation. Commercial profitability is the conventional measure of the overall performance. By measuring the output as a percentage of the input and comparing it with the outcomes of other comparable firms or durations, the relative changes in its profitability can be measured.

Value Added Profitability

The extra of turnover plus earning from offerings over the fee of buy of products or offerings is called as cost-brought. It indicates the net cost or wealth created with the aid of the producer all through a given period. No corporation can live to tell the tale and develop if it fails to generate wealth. There are two methods of calculating cost-brought: (i) Subtractive approach, and (ii) Additive method.

Economic Value-Added Profitability

The previous couple of years have seen a growing realization of the importance of the shareholder fee advent inside the Indian Corporate Sector and capital markets. Two new principles, which have caught the flamboyant of each the monetary managers and the buyers of the capital marketplace players are: Economic Value Added (EVA) and Market Value Added (MVA). These new standards are being used together with conventional measures of price introduction including return on net worth and market/e book fee ratio. Some researches were performed and many corporates are publishing “Value Score-playing cards” primarily based on EVA and MVA of their annual reviews.

Theoretical Framework

A Theory is an idea, notion or a hard and fast of fundamental truths which might be used to explain a fact or a phenomenon and as a result, gives answers to a trouble The theories used to recognize this study are;

Resource-Based View (RBV) and Extensions

One of the relevant theoretical supports for the tremendous relation among supply chain management and profitability is the aid-based totally view (RBV) and its extensions, which was brought about by means of Wernerfelt and Rumelt (1984), as a foundation for the aggressive benefit of a organization lies mostly in the utility of a package of precious tangible or intangible sources at firm’s disposal. The useful resource-based totally view (RBV) considers that firms are heterogeneous and attain aggressive gain due to uncommon, precious, inimitable and now not substitutable resources and talents (Barney, 2001).

Systems Theory

Hegal von Barterlanfy developed this concept in 1956 to explain dynamic manner in records development. In supply chain control context machine theory brings collectively diverse components of a complicated deliver chain (this is the human, capital, statistics, materials and economic sources and so on.) to form a subsystem that is then a part of a bigger system of supply chains or community. The concept argues that for a holistic perspective machine principle ought to be employed to apprehend the inner and outside elements that shape an corporation’s supply chain performance. Systems concept treats an corporation as a device. A gadget may be both closed or open, but most strategies treat an business enterprise as an open system. An open gadget interacts with its environment by way of inputs, and outputs. In order to understand the theory, you have to first get a company information of a machine. A machine is any set of distinct components that have interaction to form a complicated complete.

Empirical Studies

The literature of deliver chain control become born on its sensible positive effect on company performance and its potential to increase earnings. Early research used to document anecdotal proof approximately corporations that had advert opted the deliver chain management approach and how this led to benefits for the company and other supply chain members (Handfield, 2002). Great part of this literature changed into descriptive, reporting practices of successful groups. The improvement of the supply chain control discipline changed into largely practitioner-led with idea following (Voss, Tsikriktsis, & Frohlich, 2002).

The study of Suhong, Bhanu, Nathan &Raod (2004). Their observe aimed at the effective deliver chain management (SCM) as a treasured manner of securing aggressive gain and improving organizational performances. Their research conceptualized and evolved five dimensions of supply chain control exercise (strategic supplier partnership, customer relation, degree of records sharing, best of information sharing and postponement) and tests the relationships among deliver chain management practice, competitive benefit and organizational performance. Structural equation modelling turned into used. From information accrued from 196 organizations the end result indicated that better stage of deliver chain management practice can cause more advantageous aggressive gain and progressed organizational overall performance.

According to Molahosseini [12] in his paintings Impact of supply chain integration at the overall performance of Bahman organization. Where deliver chain integration become extensively taken into consideration through both practitioners and researchers a essential contributor to supply chain performance. The key flows in such relationships are material and facts. In his paper, he investigated the integrations of both data and fabric flows between deliver chain companions and their impact on operational performance. Specifically, he tested the function of lengthy-term supplier dating because the driver of the combination. He used questionnaire for amassing records. The reliability of each element was extra than 0/70 via cronbach’s alpha. Using information from Bahman institution managers and staffs of logistics, IT, purchase and consumer services, he locates that information integration (information generation and information sharing) positively affect logistic integration and through this component it improves performance. He additionally verified that long time courting with suppliers not directly improves overall performance thru statistics and logistic integration.

The thesis of Charles, Daniel and Dorcas (2014), which become based on one production business enterprise in Ghana. Sought to observe supply chain control exercise and its impact at the performance of Kasapreko Company Limited (KCL). The objectives of the examine had been to look at deliver chain control (SCM) practice in Kasapreko Company Limited, verify the influence of SCM exercise on KCL overall performance, and to describe the trend in sale of Kasapreko Company Limited. A pattern length of two-hundred (200) out of the numerous customers of KCL turned into administered with questionnaires in the Greater Accra Region of Ghana. The researchers also interviewed key personnel of Kasapreko Company Limited the usage of a semi-structured interview manual. A descriptive analysis with the resource of SPSS was used to quantify the relationship among the software of deliver chain control exercise and the performance of Kasapreko Company Limited. The end result of the observe indicated that KCL is applying supply chain control exercise to its enterprise activities. The study additionally indicated that deliver chain management practice has considerably influence KCL business performance and was proof within the income overall performance of Kasapreko Company Limited through the years (2004-2010).

According to Ayman, Bader & Noor (2014) the purpose in their studies become to test the effect of deliver chain management practices on deliver chain overall performance in terms of deliver chain performance and supply chain effectiveness. A hierarchical regression become used to check the hypothesized relationships from information collected from 104 production agencies in Jordan. The end result suggests that 3 deliver chain management practices internal integration, dealer integration and records sharing however no longer and patron integration and postponement, appreciably and undoubtedly have an effect on supply chain efficiency performance.

According to Mutuerandu [13], the primary targets of his studies become to assess the extent of implementation of deliver chain management practices in Haco Industries Ltd, and to examine the connection among deliver chain control practices and organizational performance within the identical industries. To look at the relationship among deliver chain control practices and organizational performance, four key dimensions of deliver chain management practices (strategic provider partnership, client relationship, statistics sharing and schooling practices) had been used as independent variables, even as marketplace/business and operational performance variable had been used to degree the organizational overall performance. The observe found out that there’s a high degree of realistic implementation of supply chain control practices in Haco industries LTD in Kenya and that they all have a positive impact on business enterprise’s overall performance.

Research Gap

In the motive of my research in this subject matter, majority of papers reviewed on the subject are centered on variables like data accumulating, without carefully analyzing the effect and level of exceptional information sharing. John (2000) and others taken into consideration of their paintings taken into consideration that supply chain control practices can result in competitive gain there with the aid of boosting in trendy organizational performance. Also, maximum research is out of doors Africa as a whole in which their equipment of analysis isn’t like ours, and also 90 5 percentage (95%) of papers determined are of past due 1900s and early 2000s. Therefore, those shape an opening wherein this takes a look at handled. Looking at the topic, (strategic supply chain control practices) from a Nigerian perspective, the usage of a tool that suit our case and placing it in line with the advancement of age, The have a look at eventually will examine variables that are unnoticed and seen insignificant to reinforce profitability in unique and not normally organizational overall performance. Also serves as a base on which others can broaden theirs, in other words it is going an extended manner in developing street for more instructional studies.

Summary

As this chapter has highlighted, deliver chain control isn’t an in-residence characteristic. A deliver is more than simplistic set of links along linear path from raw substances extraction to cease consumer client use. Therefore, an organization should make deliver chain control a strategic priority to be able to boost profitability.

Research Methodology

Research Design

A research design is the general strategy or method selected to combine extraordinary components n a logical way to make sure the studies hassle turned into efficaciously addressed. There are numerous varieties of studies design but for the motive of this study, the descriptive research layout (survey design) may be used. This is due to the fact the facts collection turned into primarily based on communication with the consultant of the pattern length of the have a look at and also when a study is based totally on investigating the situation and relationships that exist, practices that be triumphant, notion and point of view or attitude which might be held, then, a survey layout have to be used. Population is a census of all factors or items of hobby that can be finite or endless (Asi ka,2006). The population size for this has a look at is a hundred employees which include administrative team of workers within the manufacturing business enterprise of Swan paint LTD of Jos South LGA in Plateau State.

Sample Size Determination

The sampling approach to be adopted is the Stratified opportunity

sampling approach because it shows a subset of the population

that shares at least one commonplace characteristics with real representation

of each chain, and without neglecting the population

with a low incidence relative compared to other stratum inside the

production of Paint. In determining the sample size, the Yamane’s

method could be followed.

n = N

──────────

1+N [e2]

Where: n= Sample Size

N=Population Size

e =level of accepted error

Substituting into the formula therefore:

100

n = ──────────

1+100(5%)2

= 100

────────

1+100(0.05)2

= 100

─────────

1+100(0.0025)

= 100

─────────

1+0.25

= 100

───────────

1.25

= 80 employees

Source of Data

The look at employed primary statistics to acquire its objectives. The tool used became developed and was acquired through the questionnaires. The examine incorporated this supply of information to beautify a stability between the studies commentary and available literature on the problem below consideration. This is usually believed to sell objectivity. The plan, shape and approach of investigation are conceived a good way to acquire answer to investigate problems. It guarantees that the desired information has been amassed and are accurate. However, the primary facts used inside the examine turned into received from the selected manufacturing agency (SWAN Paint LTD). The collecting of applicable records, using suitable instrument is the bedrock of any research. In this have a look at the approach that changed into hired on accumulating the requisite records questionnaire. A dependent questionnaire become followed which become closed ended. Multiple regression changed into adopted due to the fact multiple established variables are been use to test on impact of a single independent variable describing the relationship between the impartial variable and the structured variables as an instantly line. In studying the statistics that was accumulated thru questionnaires, the examine hired descriptive statistic. For descriptive statistic tables had been used in order to test the hypothesis of the look at checking out of the hypothesis became executed the use of more than one linear regression.

Method of Data Analysis

The regression model below was used to predict the profitability.

P =α + βSSP + βCR + βLQI + βPOS.

Where:

P =Profitability.

α = is the alpha level and is constant

βSSP = Strategic Supplier Partnership

βCR = Customer Relationship

βPOS = Postponement

βLQI = Level and Quality of Information sharing.

Presentation and Data Analysis

Descriptive Analysis

The genders of the respondents in percentage. Out of the total respondents (N=80), 60 respondents (75%) are male, while 20 respondents with (25%) are female. The level of educational qualification of the respondents in percentage. Out of the total respondents (N=80), 20 respondents (25%) have SSCE certificates, 40 respondents with (50%) are having Diploma or OND, while 20 respondents with (25%) have either B.sc /HND or M.sc. The years of experiences by respondents in percentage. Out of the total respondents (N=80), 20 respondents (25%) are within 1 – 5years, 20 respondents (25%) are within 6 – 10years, 40 respondents (50%) are within 11 and above. The positions and department by respondents in percentage. Out of the total respondents (N=80), 40 respondents (25%) work in the administrative department, while 60 respondents (75%) work in the production department.

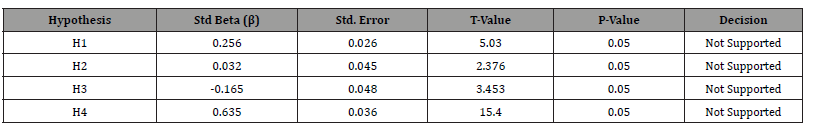

Test of Hypothesis

Hypothesis I: There is no significant effect of strategic supplier partnership on profitability of Swan Paint Nigeria LTD. This hypothesis is accepted based on SPSS output which shows that, there is a statistically significant relationship between of strategic supplier partnership on profitability. Based on the relationship between the construct which is positive (β=0.256: t=5.030 p<0.05). The relationship between the variables is strongly significant at p<0.05 with a relatively high beta value and t-value<5.030. it therefore indicates that the variable has a strong influence on profitability of Swan Paint Nigeria LTD. Therefore, the null hypothesis is rejected.

Table 1:Hypotheses Testing.

Source: Researcher’s Filed Survey, 2018.

Hypothesis II: There is no significant effect of customer relationship on profitability of Swan Paint Nigeria LTD. This hypothesis is accepted based on SPSS output which shows that, there is a statistically significant relationship between customer relationship on profitability. Based on the relationship between the construct which is positive (β=0.032: t=-2.376 p<0.05). The relationship between the variables is significant at p<0.005 with a relatively high beta value and t-value<2.37. Therefore, the relationship is supported while the null hypothesis is rejected. Therefore, it is indicated customer relationship on profitability of Swan Paint Nigeria LTD. Therefore, the null hypothesis is rejected.

Hypothesis III: There is no significant effect of postponement on profitability of Swan Paint Nigeria LTD. This hypothesis is accepted based on SPSS output which shows that, there is a statistically significant relationship between postponement and profitability. Based on the relationship between the construct which is positive (β=-0.165: t=3.453 p<0.05). The relationship between the variables is significant at p<0.05 with a relatively high beta value and t-value<3.45. Therefore, the relationship is supported while the null hypothesis is rejected. Therefore, it indicates that there is a strong significant effect of postponement on profitability of Swan Paint Nigeria LTD.

Hypothesis IV: There is no significant effect of level and quality of information sharing on profitability of Swan Paint Nigeria LTD. This hypothesis is accepted based on SPSS output. This shows that there is a statistically significant relationship between level and quality of information sharing on profitability. Based on the relationship between the construct which is positive (β=-0.635: t=15.400 p<0.05). The relationship between the variables is significant at p<0.05 with a relatively high beta value and t-value<15.40. Therefore, the relationship is supported while the null hypothesis is rejected. Therefore, it indicates that there is a significant effect of level and quality of information sharing on profitability of Swan Paint Nigeria LTD.

Discussion of Findings

The study discovered that supply chain control (SCM) as a treasured manner of securing competitive advantage and improving organizational performances, especially within the have a look at of Molahosseini [12] in his paintings Impact of deliver chain integration on the performance of Bahman organization. Where deliver chain integration changed into broadly considered by both practitioners and researchers a crucial contributor to supply chain performance. The key flows in such relationships are cloth and records. In his paper, he investigated the integrations of both facts and material flows between supply chain companions and their impact on operational overall performance. Specifically, he tested the role of long-term supplier dating as the driver of the combination. He used questionnaire for accumulating information, the study supported it and targeted on the recommendations, that corporations and their providers need to also form a synergy to boost profitability.

According to Lenny, koh& Mehmet (2007) have had a look at investigated courting among deliver chain management - associated organizational performance with special emphasis on small and medium size companies (SMEs). In evaluation both outsourcing and multi-suppliers and strategic collaboration and lean practice do now not have significant and direct effect on supply chain management – related organizational performance. According to Daniel and Jan [14] of them examine the impact of deliver chain records integration and logistics integration on firm performance. Supply chain integration entails both material and information integration. While the aspects of statistics generation and data sharing had been included in lots of studies, the logistics integration of the cloth waft among deliver chain companions has been in large part absent in empirical studies.

Ayman, Bader & Noor [15] the reason in their studies become to check the effect of deliver chain control practices on supply chain performance in terms of supply chain performance and deliver chain effectiveness. A hierarchical regression changed into used to test the hypothesized relationships from information amassed from 104 manufacturing businesses in Jordan. The end result suggests that 3 deliver chain control practices internal integration, provider integration and information sharing but no longer and customer integration and postponement, drastically and undoubtedly have an effect on supply chain performance performance.

Conclusion and Recommendations

Conclusions

In line with the findings of this have a look at, the subsequent conclusions are arrived at: Strategic dealer partnership has enormous nice impact on organizational performance. Effective sporting out of strategic supply partnership will cause boom in aggressive advantage for the employer in an effort to intend lead to profit. Customer Integration has great effect on organizational profit. That is the level of customer relationships effect at the organizational income substantially and consequently considered very essential to put in an awful lot effort by the organizational performance. Good level and first-rate of records sharing affects organizational performance substantially and definitely. Sufficient interest has to be region on stage and great of records sharing from the company, but not having superb effect to the profitability of SWAN Paint Nigeria limited. This takes a look at assesses the effect of strategic deliver chain management on employer’s profitability in SWAN Paint Nigeria LTD in Jos South, Plateau state. In attaining this, the observe considers four main practices of deliver chain control and measures their effect on profitability. The 4 practices of deliver chain management considered for the observe are strategic supplier partnership, consumer dating, postponement and the level and first-class of facts sharing. These 4 regions cowl all the aspect of deliver chain management practices that are the upstream, downstream and the inner practices. The take a look at adopts a questionnaire approach of statistics collection with a closed ended questionnaire administered to 60 operational staffs. Descriptive survey research design and makes use of purposive sampling approach in sampling the responses of 20 top manufacturing facility administrative workforce in SWAN Paint production in Jos South which makes a sample size of fifty (80) respondents. The instrument followed to achieve the applicable and required information used for the analysis is a five factor Likert scale dependent questionnaire which changed into subjected to each face and content material validities by means of relevant professionals. Descriptive records (mean and preferred deviation) have been used for the research questions at the same time as the hypotheses have been analyzed using multiple regression. The look at located that strategic supplies partnership, internal integration and patron integration have huge and nice effect on company’s profitability at the same time as postponement stage and best of statistics sharing, have poor and insignificant effect at the profitability SWAN Paint production in Jos South, Plateau state

Recommendations

In line with the conclusions arrived at in this observe, the subsequent

are consequently endorsed:

a. Improved strategic provider partnership will cause advanced

organizational earnings. Hence organizations need to

ensure they improve their strategic partnership with providers

through; Postponement practices should be practiced minimally

because it has a terrible even though insignificant effect on

profitability.

b. Strategic making plans for the destiny wherein both parties

need to be in the dating for the longer term. Getting suppliers

which have similar goals, but that doesn’t mean that they

won’t have a thought of their own.

c. Companies have to put in incredible effort on consumer

dating as it has high quality effect to profitability of the businesses.

Since patron loyalty improves sales thereby growing

profit margin. The stage and quality of information sharing in

businesses should be improved so as to enhance the overall

performance of such businesses. By giving in first-hand statistics

on difficulty surrounding their product and also seek for

information approximately their product from the market via

research.

Contribution to Knowledge

This research will make contributions in making regulations that will yield most excellent result to Paint Manufacturing Industry as well as useful resource in decision making. Also, from the assessment and recommendations of this work, commercial enterprise students and academias will learn extra approximately the simple rudiments of strategic supply chain control. The boundaries expected in this research are lack of openness at a part of respondents and thinking about the time frame to be had to paintings with, coupled with the truth that questionnaires had been allotted, quite a few times. The researcher indicates that different researchers embarking on projects referring to deliver chain management must first refer to comparable venture work like this, and additionally employ beneficial search engines at the internet. Also, similarly researchers must pin factor different variables like internal integration and logistics with the intention to educate producers on its impact and importance to organizational performance to be able to raise and create aggressive gain [16-85].

Acknowledgement

None.

Conflicts of Interest

None.

References

- Carinato MD (2001) Strategic management of issues of supply chain relationships and operations.

- Min S, Mentzer JT (2004) Developing and measuring supply chain concepts. Journal of Business Logistics 25 (1): 63-99.

- Lambert C, Pagh JD (2007) Supply chain management implementation issues and research opportunities.

- Donlon FJ (2005) Managerial role in strategic supply chain management. An inside view of manufacturing companies in Kenya.

- Alvarado UY, Kotzab H (2001) Supply Chain management: the integration of logistics in marketing. Industrial Marketing Management 32(2): 183-198.

- Tan KC, Lyman SB, wisner jd (2002) Supply Chain management: a strategic perspective. Internation Journal of operations and production management 22(6): 614-631.

- Gunasekaran A, Patel C, Tirtiroglu E (2001) Performance measures and metrics in a supply chain environment. International Journal of Operations and Production Management 21(1/2):71-87.

- Yoshino M, Rangan S (2005) Strategic alliances: an entrepreneurial approach to globalization. Boston, MA: Harvard Business School Press.

- Mentzer JT, Min S, Zacharia ZG (2000) The nature of inter firm partnering in supply chain management. Journal of Retailing, 76 (4): 549-568.

- Waller MA, Dabholkar PA, Gentry JJ (2000) Postponement, Product customization and market-oriented supply chain managment. Journal of Business Logistics 21(2): 133- 159.

- Feitzinger W, Lee L (2004) Effect of supply chain integration and market orientation.

- Molahosseini A (2013) Impact of supply chain integration on the performance of Bahman group: Interdisciplinary journal of contemporary research in business 5(1).

- Mutuerandu MN (2014) Impact of Supply Chain Management Practices on Organizational Performance: A Case Study of Haco Industries Limited Kenya. IOSR Journal of Business and Management (IOSR-JBM) e-ISSN: 2278-487X, p-ISSN: 2319-7668. 16(4).

- Daniel P, Jan O (2009) The effect of supply chain information integration and logistics integration on firm performance. Department of Management, Monash University, Australia.

- Ayman BA, Bader YO, Noor OA (2014) The Impact of Supply Chain Management Practices on Supply Chain Performance in Jordan: The Moderating Effect of Competitive Intensity.

- Anderson MG, Katz PB (2006) Strategic sourcing the international journal of logistics management. 9(1).

- Balsmeier PW, Voisin, W (2006) Supply chain management: a time-based strategy. Industrial management 38 (5): 24-27.

- Beamon BM (1998) Supply chain design and analysis: Models and methods. International Journal of production economics 55(3): 281-294.

- Barbara BF, Baofeng H, Xiande Zhao (2010) The impact of supply chain integration on performance: a contingency and configuration approach. Journal of Operations Management 28(1): 58-71.

- Barry D, Towill DR, Wadsley N (2004) Effects of trust mechanisms on Supply chain performance using multi agent simulation and analysis.

- Brown T (2000) Introduction to supply chain advisory services. In Texas

- Bullington KE, Bullington JE (2005) Strong supply chain relationship: learning from research on strong families.

- Carr AS, Person JN (1999) Strategically managed buyer’s seller relationships and performance outcomes. Journal of operations management 17(5): 497-519.

- Charles M, Daniel D, Dorcas O (1014) Assessment of supply chain management practice and it effect on the performance of Kasapreko Company Limited in Ghana: European Journal of Logistics Purchasing and Supply Chain Management 2(1): 1-16.

- Chen IJ, Paulraj A (2004) Towards a theory of supply chain management: the constructs and measurements. Journal of operations management 22(2): 119-150.

- Childhouse P, Towill DR (2003) Simplified material flow holds the key to supply chain integration. Omega 31(1): 17-27.

- Christopher M (2000) “The Agile Supply Chain”, Industrial Marketing Management 29(1): 37-44.

- Claycomb C, Droge C, Germain R (2009) The effect for just in time with customers on organizational design and performance. International journal of Logistics management 10 (1): 37-58.

- Cutler BD, Gross A (2002) Identifying antecedents of information exchange within supply chain: international journal of physical distribution and material management.

- Day GS (2000) Managing market relationships. Journal of the Academy of Marketing Science 28(1): 24-30.

- Ebrahim Karimi, Mahmoud Rafiee (2014) Analyzing the Impact of Supply Chain Management Practices on Organizational Performance through Competitive Priorities (Case Study: Iran Pumps Company).

- Feldmann M, Muller s (2003) An incentive scheme for true information providing in supply chain. Omega 31(2): 63-73.

- Fisher ML (1997) What is the right supply chain for your product. Harvard Business Review 75 (2): 105-116.

- Frohlich MT, Westbrook R (2001) Arcs of integration: an international study of supply chain strategies. Journal of Operations Management 19(2): 185-200.

- Fuller JB, O'Conor J, Rawlinson R (1993) Tailored Logistics: the next advantage. Harvard Business Review 71(3): 87-89.

- Jarrell JI (2009) Supply chain economics. World Trade 11(11): 58-61.

- Gavirneni N (2002) Value of information in capacitated supply chain management practice.

- Hines P (2001) Integrated materials management: the value chain redefined.

- Holmberg S (2000) A system perspective on supply chain measurement: international journal of logistics.

- John FP (2012) The impact of supply chain management business processes on competitive advantage and organizational performance. Department of Operational Sciences Graduate School of Engineering and Management Air Force Institute of Technology Air University.

- Johnson ME, Davis T (2008) Improving supply chain performance by using other fulfillment metrics. National Productivity Review 17(3): 3-16.

- Jones C (2008) Moving beyond ERP: Making the missing links. Logistics Focus 6(7): 2-7.

- Kulp B (2004) Supply chain coordination: how companies leverage information.

- Lambert C, Pagh JD (2007) Supply chain management implementation issues and research opportunities.

- Lalonde BJ (1998) Issues in supply chain costing: The international Journal of logistics management 5.

- Lee J, Kim Y (2009) Effect of partnership quality on IS outsourcing: conceptual framework and empirical validation. Journal of Management Information systems 15(4): 26-61.

- Lin F, Huang S, Lin S (2002) Effects of information sharing on supply chain performance in electronic commerce. IEEE Transactions on engineering management 49(3): 258-268.

- Matthew G Anderson, Paul B Katz (2006) strategy sourcing. the international journal of logistics management 9: PP. 1-13.

- Masaaki Kotabe, Xavier Martin, Hiroshi Domoto (2003) Gaining from vertical partnerships: knowledge transfer, relationship duration, and supplier performance improvement in the U.S and Japanese automotive industries.

- McGinnis MA, Vallopra RM (1999) Purchasing and supplier involvement in process improvement: a source of competitive advantages. Journal of Supply chain Managment 35(4): 42-50.

- Min S, Mentzer JT (2004) Developing and measuring supply chain concepts. Journal of Business Logistics 25 (1): 63-99.

- Metters P (1999) causes and remedies of bullwhip Effect in supply chain.

- Moberg CR, Cutler BD, Gross A, Speh TW (2002) identify antecedents exchange within supply chains. International Journal of Physical Distribution and Logistics management 32(9): 755-770.

- Monczka RM, Petersen kJ, Handfeild RB, Ragatz GL (2008) success factors in strategic supplier alliances: the buying company perspective. Decision Science 29(3): 5553-5577.

- Moran WT (1991) Research on discrete consumption markets can guide resource shifts, help increase profitability. Market News 14(23): 4.

- Movahedi B (2009) Supply chain management. A new challenge for researchers and managers in logistic.

- Naudo ML, Johanna AB (2011) The effect of problems of supply chain wide efficiency. Department of Business Management, school of Management, University of KwaZulu-Natal.

- Naylor JB, Naim MM, Berry D (1999) Legality: Integrating the lean and agile manufacturing paradigms in the total supply chain. International Journal of Production Economics 62(1,2): 107-118.

- Noble D (2007) Purchasing and supplier management as a future competitive edge. Logistics Focus 5(5): 23-27.

- Pagh JD, Cooper MC (2008) Supply chain postponement and speculation strategies: How to choose the right strategy. Journal of Logistics Management 19(2): 13-33.

- Porter ME (1985) Competitive Advantage: Creating and sustaining superior performance. New York: The Free Press.

- Power DJ, Sohal A, Rahman SU (2001) Critical Success factors in agile supply chain management an empirical study. International journal of Physical Distribution and Logistics Management 31(4): 247-265.

- Prasad S, Tata J (2000) Information investment in supply chain management. Logistics Information management 13 (1): 33-38.

- Pycraft (2000) operation. Management southern Africa edition. Pearson education south Africa.

- Ragatz GL, Handfield RB, Scannell TV (1997) Success factors for integrating suppliers into new product development. Journal of Product innovation management 14(3): 190-202.

- sheridan JH (1998) The Supply Chain paradox. Industry week 247(3): 20-29.

- Sahay BS (2003) Supply chain management for enhancing competitive potential.

- Shapiro J (2001) Beyond Suppy Chain Optimization to Enterprise Optimization Ascet 3.

- Shin H, Collier DA, Wilson DD (2000) Supply Chain management orientation and supplier/buyer performance. Journal of operations management 18(3): 317-333.

- Childerhouse P, Towill DR (2003) simplified material flow holds the key to supply chain integration. Omega 31(1): 17-27.

- Spekman RE, Kamauff JR, Myhr N (1998) An empirical investigation into supply chain management: a perspective on partnerships. Supply chain management, 3(2): 53-67.

- Stanely LI, Wisner JD (2001) Service quality along the supply chain: implications for purchasing. Journal of operations management 19(3): 287-306.

- Stein KE, Sweat A (1998) A model of factors influencing the supply chain performance.

- Stuart FI (2004) Supplier partnership: influencing factors and strategic benefits. International Journal of Purchasing and materials management 29(4): 22-28.

- Stuart FI (2007) supply chain Strategy: Organizational influence through supplier alliances. British academy of management 8(3): 223-236.

- Tan KC, Kannan VR, Handfield RB (2004) supply chain management: Supplier performance and firm performance. International Journal of Purchasing and materials management 34(3): 2-9.

- Tompkims J, Ang P (1999) Supply chain consortium: supply chain benchmarking and best practices.

- Tsai LM (2007) Frameworks of casino resorts supply chain.

- Van Hoek RI (2008) Measuring the Unmeasurable-measuring and improving performance in the supply chain. Supply chain managment 3(4): 187-192.

- Van Hoek RI, Voss B, Commandeur HR (1999) Restructuring European supply chainby implementing postponement strategies. Long Range Planning 32(5): 505- 518.

- Vereenke W, Muylee E (2206) Competitive advantage of a firm through supply chain responsiveness and supply chain management practices.

- Vonderembse MA, Tracey M (1999) The impact of supplier selection criteria and supplier involvement on manufacturing performance. Journal of Supply Chain Management 35(3): 33-39.

- Walton LW (2006) Partnership satisfaction: using the underlying dimensions of supply chain partnership to measure current and expected levels of satisfaction. Journal of Business Logistics 17 (2): 57-75.

- Wang L, Rivera J & Kempf G (2007) Dynamics in farm specific capabilities: the impact of capabilities on competitive advantage.

- Yamin S, Gunasekruan A, Mavondo FT (1999) Relationship between generic strategy, competitive advantage and firm performance: an empirical analysis. Tec novation 19 (8): 507-518.

-

Ruth Agwom Panle and Arinzechukwu Jude Okpara*. Strategic Supply Chain Management Impact on Profitability of Manufacturing Companies in Plateau State. (A Case Study of Swan Paint Nigeria Limited Jos South). Iris J of Eco & Buss Manag. 2(5): 2024. IJEBM.MS.ID.000547.

-

Supply chain management, Operations control, Logistics, Procurement, Information era, Strives, Sales, Product design, Finance, Facts generation, Profitability, Making, Practice, Theoretical, Paint manufacturing enterprise, Economic, Social justification

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.