Research Article

Research Article

Characterization of Morphological and Microstructural Properties of Bamboo Species for Composite Industry

Yalew Dessalegn1*, Balkeshwar Singh2 and Aart W van Vuure3

1Department of Mechanical Design & Manufacturing Engineering, Adama Science & Technology University, Ethiopia

2Professor, Department of Mechanical Design & Manufacturing Engineering, Adama Science & Technology University, Ethiopia

3KU Leuven, department Materials Engineering; Campus Groep T, Composite Materials Group, Andreas Vesaliusstraat 13, 3000 Leuven, Belgium.

Yalew Dessalegn, Research Scholar, Department of Mechanical Design & Manufacturing Engineering, Adama Science & Technology University, Adama City, Ethiopia.

Received Date: March 04, 2022; Published Date: March 28,2022

Abstract

More than 1 million hectares of bamboo plant is covered in Ethiopia, but it is used for home furniture and structural purposes. The aim of these studies characterize and evaluate bamboo species in Ethiopia whose morphological, thermal decomposition, crystalinity index and microstructure properties are a suitable for fibre composite application. From the three different regions of Ethiopia, bamboo culm harvested in 1, 2, and 3 years old which are collected 3 samples from each age. Morphology of the culms are improved with ages of 1-3 years old, but thermal and crystallinity properties are improved in one growing season. The vascular bundle structure of Injibara and Kombolcha bamboo is categorized in Type I, whereas Mekaneselam bamboo is categorized in type III.

The outer culm diameter of Injibara, Kombolcha, and Mekaneselam bamboo are 78–120 mm, 37–51mm, 47–54mm, Internodal lengths are 350–400 mm, 270 mm– 360mm, and 390 mm–430 mm, as well as, wall thickness are 9–11 mm, 10–15 mm, and 8–11mm, respectively. The average breast height diameter and wall thickness of Kombolcha bamboo is higher compared to Injibara, and Mekaneselam, whereas Internodal length of Mekaneselam is higher compared to Injibara, and Kombolcha. In Ethiopia, bamboo species have a similar range of thermal decomposition temperatures to each other and they have a similar range of thermal decomposition temperatures compared to in the literature. Moreover, the crystallinities index of Kombolcha and Mekaneselam bamboo fibre are 6% and 3% lower compared to Injibara respectively.

Keywords: Bamboo species; Crystallinity index; Microstructure; Morphology; Thermal properties

Introduction

Ethiopian bamboo species

Ethiopia is among the most endowed countries in bamboo resources in Africa [1]. The two indigenous bamboo species in the country are the African alpine bamboo (Arundinaria alpina) and a monotypic genus of lowland bamboo (Oxytenanthera abyssinica) [2]. Besides, twenty three different bamboo species under seven genera were introduced in Ethiopia since 2007. The seven genera of introduced bamboo species include Bambusa, Dendrocalamus, Gigantochloa, Guadua, Phyllostachys, Schizostachyum and Thyrsostachys. Seven species of 1st entries namely Denderocalamus asper, Dendrocalamus hamiltonii, Dendrocalamus giganteus, Dendrocalamus membranaceus, Bambussa vulgaris sub. Var. green, Bamusa vulgaris sub. var. vitata and bambusa balcooa have been tested for their adaptability and growth performance in different locations (Figure 1). The species could be used in wood working and furniture industries substituting wood, for pulp and paper production, as well as, for construction purposes. Additionally, further research on management and utilization especially on value addition and improving the socio-economic benefits of the bamboo to the local community is vital [3] (Figure 1).

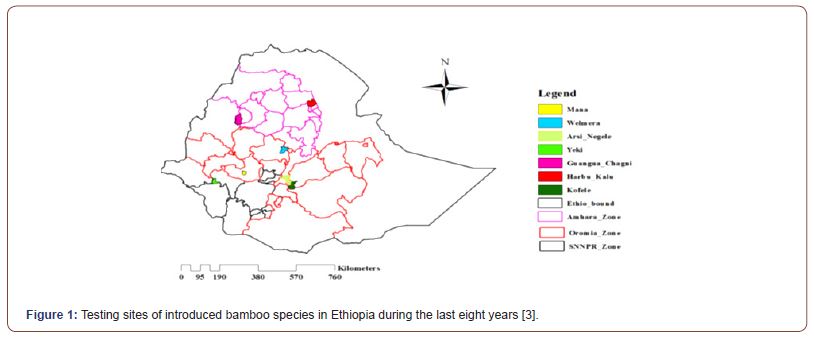

There are nearly 1500 different bamboo species found throughout the world, with the majority of them native to Asia, Africa, North, South, and Oceania. Bamboos are primarily found in warm tropical and subtropical climates [4]. Figure 2 represented that bamboo species have existed within the continent of America, Asia-Pacific, and Africa (I, II, and III regions, respectively). Bamboos were allocated in the region of tropical, subtropical, and template regions of the country, but it was covered globally with 1% of the entire global forest land [5]. Bamboo shoots are used as food for both humans and animals [6] (Figure 2).

Morphology of bamboo

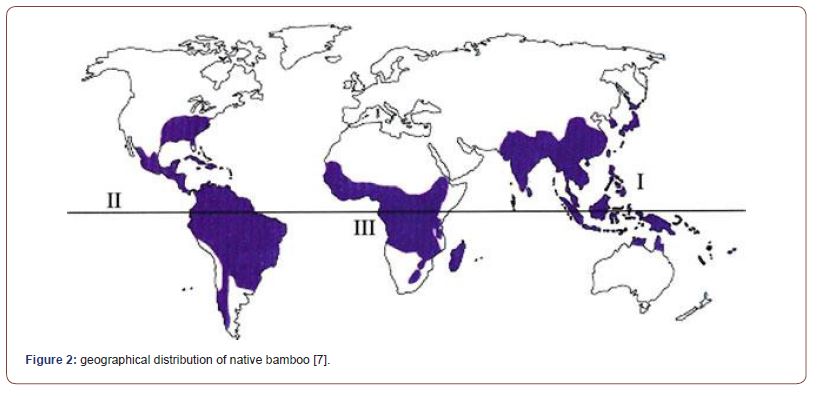

Bamboo has a distinct appearance. Figure 3(a) depicts a typical bamboo plant and its structure. Long segmented stems, known as culms, are visible above ground, along with branches and leaves near the plant’s crown [8]. Bamboo culm structures are depicted in Figure 3(b). The culm is made up of numerous joints called nodes that are connected by hollow internodes. At each node, diaphragms separate the hollow internodes. Long unidirectional (UD) fibers run across the culm walls of the internodes and terminate at the nodes. Fibres within the nodes are randomly oriented, as indicated in Figure 3(c), preventing the culms from bending and buckling out [9]. The UD fibres within the internodes reinforce the culm and provide it with greater mechanical property, allowing it to withstand harsh environmental conditions [5,10] (Figure 3).

Depending on the species and climatic conditions, bamboo culms come in various of sizes. Culm lengths vary greatly between species. Some species are grown as small as 0.5 m, while others can potentially achieve 30 m in height, with some even reaching 40 m [7,8,13]. As previously stated, bamboo culms are made up of many internodes separated by nodes. The length, diameter, and wall thickness of these internodes are varied along the culm [14].

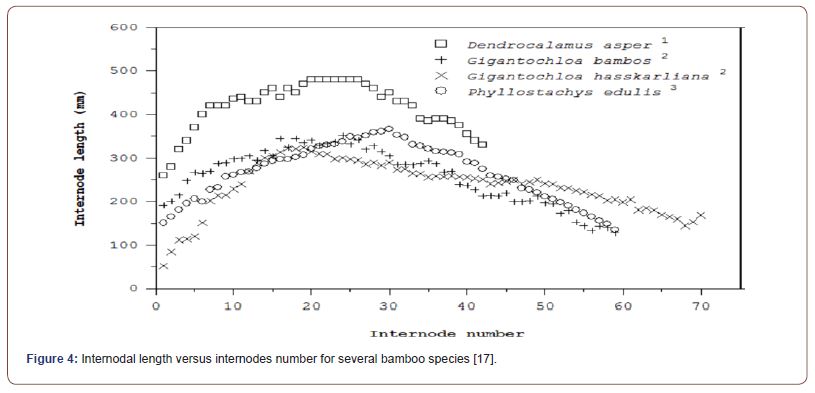

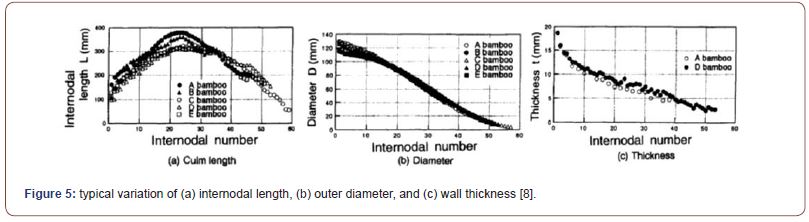

Figure 4 depicts the various Internodal length difference for various bamboo species. Some species exhibit a rapid increase of up to 4-5 cm per internodes, reaching their maximum length (40- 50 cm) between internodes number 15 and 25, and then rapidly decreasing Internodal length towards the culm’s top. Internodal lengths determine the maximum length of the fibres which used for composite application. The amount of fibres extraction are determined by the culm diameters and wall thickness. Figures 5(b) and 5(c) illustrate how outer diameter and wall thickness vary along the culm. In general, outer diameters and wall thickness decrease from bottom to top position. According to reported of [9,15], between internodes number 10 and 50, the outer diameter and wall thickness decrease by about 2.6 and 0.2 mm per internodes, respectively. The outer diameters have been characterized to range approximately 5 and 30 cm based on the species [8], [13]. When the proportion of wall thickness to culm diameter is calculated, the lowest values are located in the middle segment of the bamboo culm. This could be an architectural adaptation of bamboo to make it more resistant to strong winds [16] (Figure 4 & 5).

Description of anatomy

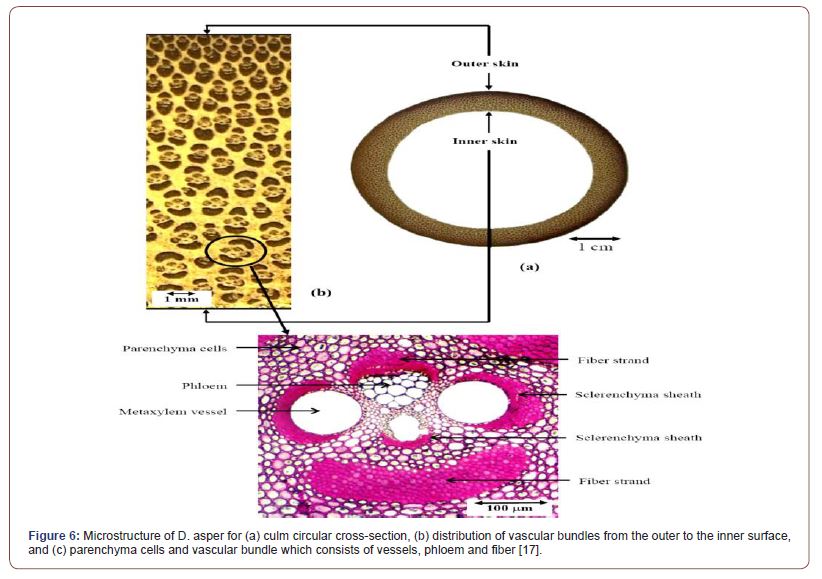

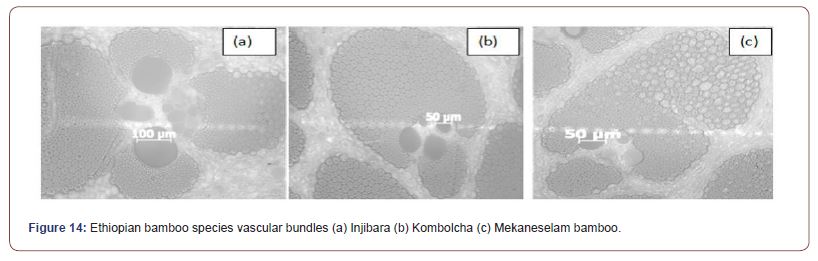

A typical cross section of a culm wall is shown in Figures 6(a), (b) and (c). The wall is composed of many vascular bundles, sclerenchyma (light grey), and parenchyma cells (grey). The ground tissue is made up of parenchyma, which is a filler material that helps to keep bamboo stable and flexible [11]. Epidermal cells are found on the culm’s outermost layer [5]. A typical vascular bundle and its constituents are depicted in Figure 6(c). Sclerenchyma cells surround vascular bundles (caps), which form the technical bamboo fibers [8], [11]. Figure 6(b) illustrates the inward decrease in the abundance of vascular bundles from the outside to the inside (at a constant height of the culm), the inner portion is mostly made up of parenchyma tissue.For most bamboo species, the total culm consist of approximately 50% parenchyma cells, 40% fibres and 10% vascular bundles by weight [11], [18]. The amount of parenchyma cells decreases towards the top, whilst the number of vascular bundles and fibres remains constant along the length of culm, therefore volume faction of the fibres varies with height [8]. The volume percentage of fibres in the top, bottom, and middle segments are 60%, 30%, and 25%, respectively. The average fibre volume fraction inside the culm wall is about 32% [18].

Bamboo culms can mature completely in just one growing season, with some species growing 36 m in only 6 months. Every year, new shoots appear, allowing for continuous production and harvesting. Bamboo, unlike woods, does not grow much in diameter after sprouting [8]. Bamboo culms exhibit aging processes, including significant lignifications of the fibers, that appear to begin in the late stages of culm elongation, which the fibre thickens during this time period. Their thickening is caused by the deposit of extra lamellae on the walls. As the fibres thicken, their density and strength increase [11], [19], [20]. During the early stages of shoot growth, parenchyma cells become lignified [21]. According to Itoh, [22] lignifications occurs in each internodes from top to bottom and from inside to outside of the culm, with the greater part of bamboo culm achieving full cell wall thickening within a year. Gritsch [19] found significant cell wall thickening in fibres up to one year old, but also (less significantly) thickening in fibres from one year to three years old. The amount of layers in the fibre cell walls increased from 2 to 5-6 during the first year of growth. The quantity of fibres with 7-8 layers had increased significantly after 3 years of maturation. Other research has also shown further fibre lignification at least up to 3 years [20-24].

Materials & Methods

Characterisation of bamboo species

Study area description

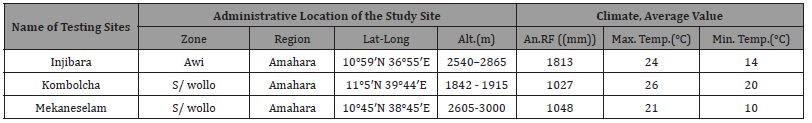

Geographic location and climatic conditions of the study sites is described in Table 1. Injibara region is high altitude in the sea level next to Mekaneselam region, but Kombolcha is low altitude and high maximum temperature (Table 1).

Table 1:Geographic location and climatic conditions of the study sites.

Bamboo culm harvesting

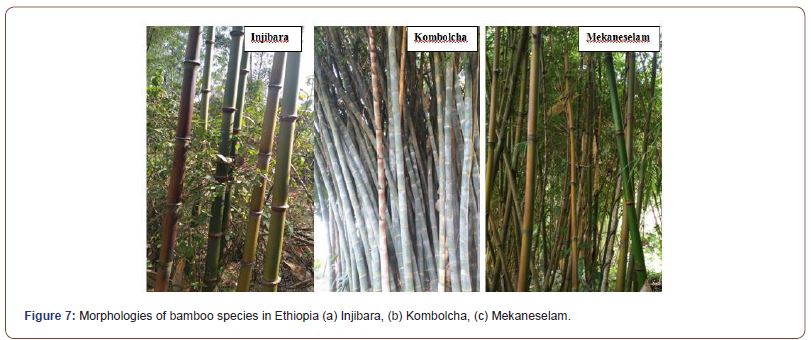

Injibara (Y. Alpina), Kombolcha (bambusa oldhamii), and Mekaneselam (Bambusa tulda) were harvested on the 11th of February, 2020. Three representatives of their bamboo culm were harvested in each age of one, two, and three years old. The ages were known by experienced field personnel using its color and sheath. The culm was later subdivided into three parts such as the bottom, middle, and top portions based on the criteria of internodes length greater than 25cm and outer diameter greater than 3cm. The microscopy image of bamboo species in Ethiopian are indicated in figure 7 (a), (b), and (c). As indicated in figure 7(a), Injibara (Y.Alpina) bamboo is a giant tropical and subtropical clumping and evergreen bamboo species native to Ethiopia. Culms are 15 - 30 m tall and 8-20 cm breast diameter with internode length of 40 – 50 cm. Kombolcha (Bambusa oldhamii) is presented in figure 7 (b), It is a large clumping bamboo that can reach a height of 20 m and a diameter of 10 cm in optimal conditions. Furthermore, Mekaneselam (Bambusa tulda) bamboo is represented in figure (7c). It is a vast clump-forming bamboo that is regarded as one of the most useful bamboo species in the world. It is an evergreen or deciduous bamboo with culms ranging in height from 6 to 20 m. The thin-walled culms are about 5 - 10 cm in diameter and culm internodes 36 - 70 cm long.

Age determination methods

The age was known by experienced field personnel using its culm color, bud break, branches, and sheath in the culm. Identifying the age using their color is possible with new and young culms, but becomes more difficult with older culms. One-year-old has a distinct sheen, which is common in green, yellow, and black bamboo varieties. Bamboo with green color are one year old. However, as the culms age, the color fades and becomes murky. Researcher has carefully observed the pattern of color changes of culms of a species in a specific environment or location. At best, observing the color of culms can provide hints as to whether young, mature, or old. The age determination of bamboo species in Ethiopian are characterized based on previous research [8].

Morphological characterization

Morphological measurements were done during the week of harvesting, before any major size reductions occurred, because of moisture loss. The length, wall thickness, and diameter were measured for each Internodes along the whole culm. The wall thickness was also measured at the middle of the Internodes. A calliper was used for the diameter and wall thickness measurements, whereas, tap rule are used for Internodal length measurement.

Gas pycnometer

Gas pycnometer measurements were performed to measure the density of the fibres, using a Quantachrome multipycnometer model MVP-D160-E with helium gas at a pressure of 1.5 bar as displacement medium. The fibres were dried in the oven prior to milling for 1 week at 60 °C. By milling the fibres with a centrifugal mill, type Retsch ZM100 (Gemini BV, Netherlands), all the particles became smaller than 250 μm. The fibre powder was dried in a vacuum oven for at least 5 hours at 30 °C before measuring. The evaluated density can be interpreted as the density of the bamboo fiber’s cell wall.

XRD characterization

A length of < 2 mm fibres were cut using scissor for hammer milling which was produced a fibre powder to a size smaller than < 250 μm. For the reflection (R) measurement a Bruker D8 Advance goniometer was used (Bragg-Brentano geometry), equipped with a copper Kα (λ = 0.154189 nm) X-ray source operating at 40 mA and 40 kV in line focus. Data was collected over an angular range of 5 – 60° 2θ using a Lync Eye-XE-T detector with a step size of 0.04° 2θ and a counting time of 0.1s per step. Data reduction was performed with the origin lab 2019 software. The total areas under the defined crystalline and amorphous components were used to calculate the degree of crystallinity (DOC). The empirical method proposed by Segal et al. [25] was used to evaluate the crystallinity using Eq. (1):

xCR = (I002-I am)/I002 Eq. (1)

where xCR is the sample crystallinity, I002 is the maximum intensity of the (002) lattice diffraction at 2θ degrees, representing both crystalline and amorphous materials, and IAM is the diffraction intensity at 2θ degrees, representing amorphous material only.

FTIR Characterization

The samples of bamboo powders were finely ground and oven-dried at 60 °C for 5 hrs. FTIR spectrum of the sample was determined using BRUKER OPUS 65. FTIR spectrometer for wave number ranged 4000–400 cm-1, resolution 4 cm-1, scan mode transmittance, and number of scans 32.

Thermogravimetric analysis (TGA)

TGA characterize weight loss or gain due to decomposition, oxidation or dehydratation, to evaluate the thermal stability and oxidative stability of a material at temperatures up to 500 °C. Usually the first derivative of the TGA curve (DTG) is also calculated to determine the points on the weight loss curve with the highest rate of change.

Thermogravimetric analysis (TGA) for technical fibres was carried out on a SDT Q600 T.A. Instruments, starting temperature of the room. The experiment carried out under inert atmosphere at a flow rate of 20mL/min and a heating rate of 5 °C/min. For the TGA measurements, the samples tested ranged in size from 5 to 12 mg. TGA/DTG curves for fibres in argon environments are used during thermal analysis.

Results and Discussion

Morphological Characterisation

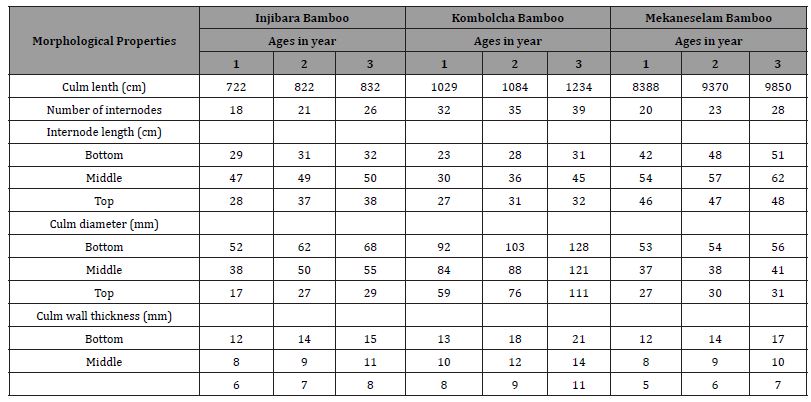

The measured size of culm size, number of internodes, outer diameter, internode length and wall thickness are presented in Table 3. The outer diameter, Internode length, and wall thickness of Injibara bamboo is 36-51 mm, 35-40 cm and 9-11 mm, respectively. 1 and 2 years old of Injibara bamboo has 29% and 10% lower diameter, moreover, 26% and 3% lower Internodal length compared to 3 years old bamboo respectively, whereas 2 years old bamboo has 24% higher diameter and Internodal length compared to 1-year-old bamboo. The outer diameter, Internode length, and wall thickness of Kombolcha bamboo is 78-120 mm, 27-36 cm and 10-15 mm, respectively. Kombolcha bamboo in 1 and 2 years old has 35% and 26% lower diameter, as well as, 25% and 11% lower Internodal length compared to 3 years old bamboo respectively, whereas 2 years old has 12% higher diameter and 13% higher Internodal length compared to 1-year-old.

The outer diameter, Internode length, and wall thickness of Mekaneselam bamboo is 39-43 mm, 47-54 cm and 8-11 mm, respectively. 1 and 2 years old of Mekaneselam bamboo has 9% and 5% lower diameter, moreover, 13% and 6% lower Internodal length compared to 3-years-old bamboo, respectively, whereas 2 years old bamboo has 5% higher outer diameter and 8% Internodal length compared to 1-year-old. Injibara and Mekaneselam bamboo is 58% and 64% lower outer diameter compared to Kombolcha bamboo, respectively, whereas Injibara bamboo has 16% higher than Mekaneselam. Moreover, Kombolcha and Injibara bamboo is 33% and 26% lower Internodal length compared to Mekaneselam bamboo, respectively, whereas Injibara bamboo has 10% higher than Kombolcha bamboo. Furthermore, Kombolcha bamboo has 26% higher wall thickness compared to Injibara, and Mekaneselam (Table 3).

Table 2:Table summary results of morphology of the culm in Ethiopia.

Table 3:coefficients of the linear fit for the linear region: (a) outer diameter (mm) = a*number of Internodes (N) + b, and (b) wall thickness (mm) = a*number of Internodes (N) + b.

The morphology of bamboo species in Ethiopia are presented in Table 3. Culm height (m), DBH (cm), and basal wall thickness (mm) of P. nigra Boryana (PNB) is 7.7±0.9, 3.8±0.1 and 7.2±0.8; P. aureosulcata Spectabilis (PAS) is 7.3±1.5, 3.9±0.2 and 7.3±2; P. vivax (PV) is 11.7±1.2, 7.4±0.8, and 10.7±1.9, and; P. vivax McClure Jiantonging (PVMJ) is 10.4±0.8, 6.2±0.3 and 10.8±0.4 respectively [26].

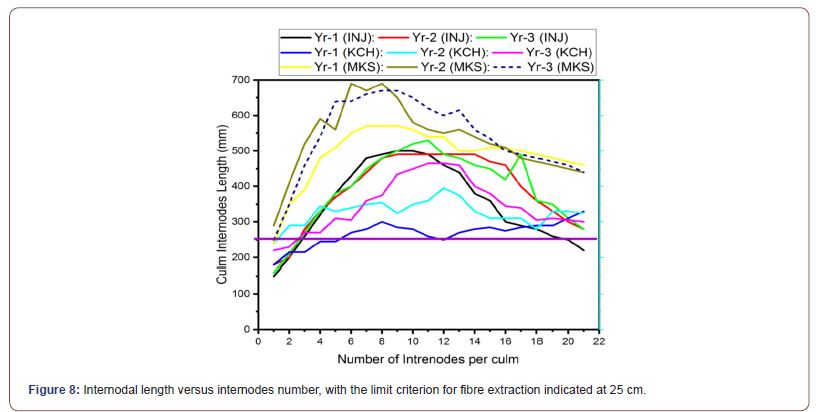

Injibara and Mekaneselam bamboo are higher culm height, DBH, and basal wall thickness compared to PNB and PAS, however, they are lower culm height, DBH, and basal wall thickness compared to PV and PVMJ. Whereas, Kombolcha bamboo is larger culm height, DBH, and basal wall thickness compared to PNB, PAS, PV, and PVMJ. Injibara and Mekaneselam bamboo are similar wall thickness, smaller outer diameter, and higher internodal length compared to G. angustifoliais. Whereas Kombolcha bamboo is higher average outer diameter, and wall thickness compared to G. angustifoliais, but it has a similar average Internodal length [12]. The internodal length of bamboo species in Ethiopia are illustrated in figure 8. The Internodal length of the culm increase when the number of internodes increase up to middle, then decreased from middle to top position. The Internodal length of Injibara and Mekaneselam bamboo are 100% satisfied the minimum requirement of internodes length for fibre extraction. The minimum Internodal length for fibre extraction settled above 25 cm Internodal length based on unidirectional continuous fibre composite production.

Culm of Mekaneselam is higher Internodal length compared to Injibara and Kombolcha, and culm of Injibara is a higher Internodal length compared to Kombolcha. 2 and 3 years old bamboo have similar internodal length, but their Internodal length is a higher than 1 year old (Figure 8).

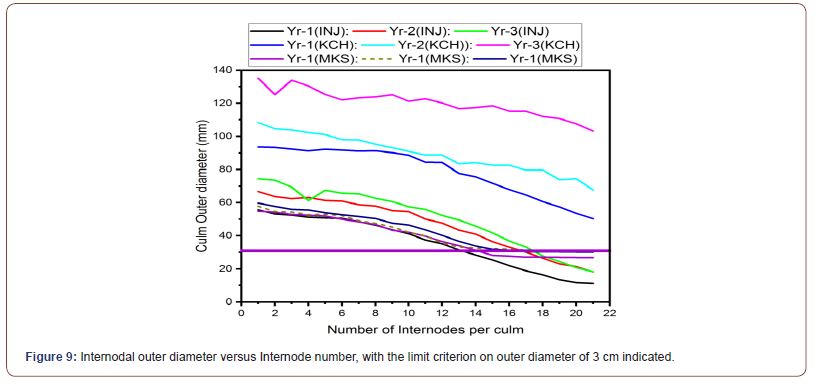

The outer diameter of bamboo in Ethiopia are indicated in the figure 9. The outer diameter of Bamboo is decreased when moved from bottom to top along the culm height. The culm outer diameter of Kombolcha is 100% satisfied the minimum requirement of outer diameter for fibre extraction. Mekaneselam has a similar outer diameter in all ages of years old and above 67% number of culm could satisfy the minimum criteria of 3cm culm outer diameter. Above 81% number of the culm of Injibara bamboo have satisfied the minimum requirement of outer diameter. The minimum outer diameter for fibre extraction is settled above 3 cm outer diameter on the required amount of fibre extraction. Kombolcha is the highest culm outer diameter compared to Injibara and Mekaneselam, as well as, Injibara is a higher outer diameter compared to Mekaneselam bamboo. 2 and 3 years old of Injibara bamboo have similar outer diameter, but their outer diameter are higher compared to 1 year old (Figure 9).

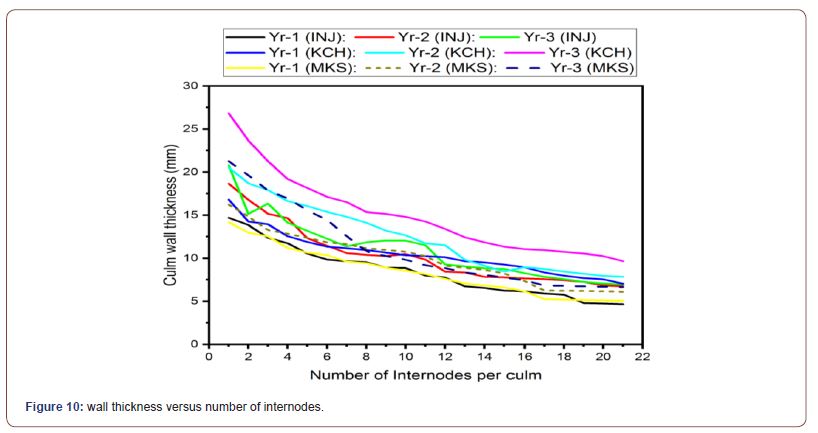

The wall thickness of bamboo culm in Ethiopia are indicated in figure 10. The wall thickness of bamboo species decreased when move from bottom to top. 3 years old of Kombolcha bamboo is higher wall thickness compared to 1 and 2 years old. Mekaneselam and Injibara bamboo have a similar wall thickness in all age, but Kombolcha has a higher wall thickness compared to Mekaneselam and Injibara (Figure 10).

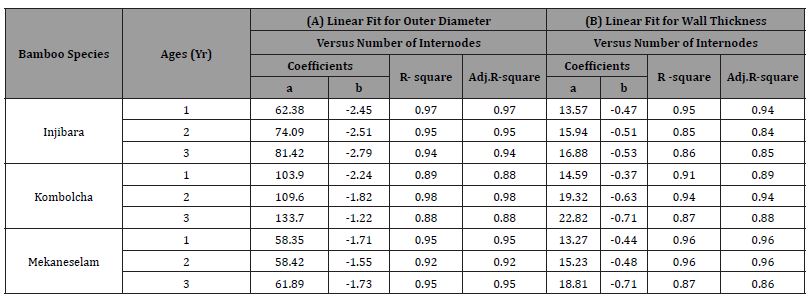

In generally, outer diameter, Internodal length, and wall thickness of bamboo species in Ethiopia are indicated in the figure (8–10). Mekaneselam has a higher Internodal length comaperd to Kombolcha and Injibara, however, it has a lower wall thickness and outer diameter compared to them. Kombolcha has a larger outer diameter compared to Injibara and Mekaneselam, but it has the lowest Internodal length compared to them. The morphology of bamboo culm in Ethiopia are fittest for fibre composite production since they are fulfilled the minimum requirement of culm Internodal length and outer diameter. Coefficient of the linear fit for outer diameter and wall thickness versus number of Internodes are presented in the Table 4. The slope of outer diameter and wall thickness are a negative relationship with the number of internodes. Injibara has a higher negative slope compared to Kombolcha and Mekaneselam, however, it has the lowest intercept value. Kombolcha has a higher intercept value both in outer diameter and wall thickness compared to Injibara and mekaneselam.

The R-square of the outer diameter for Injibara, Kombolcha and Mekaneselam bamboo are 94–97%, 88–98% and 92–95%, whereas R-square of wall thickness for Injibara, Kombolcha and Mekaneselam are 84–94%, 88–94% and 86–96% respectively. R-square of outer diameter has a good linear fit compared to wall thickness (Table 3).

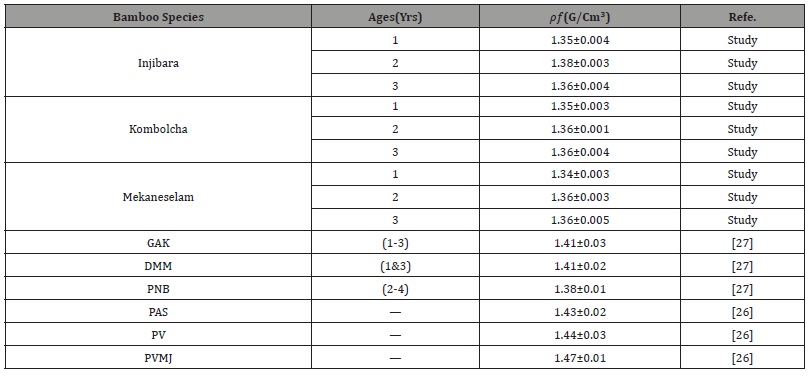

Density and areal fibre bundle fraction

The densities of the Ethiopian bamboo species fibre with the influence of the ages are indicated in Table 5. The range of the measured fibre densities (𝜌𝑓) for Injibara, Kombolcha and Mekaneselam bamboo are 1.35–1.38 g/cm³, 1.35–1.36 g/cm³, and 1.34–1.36 g/cm³ respectively. 1 year old bamboo fibres has low density compared to 2 and 3 years old. The difference between the three bamboo species is considered low (maximum 2 %) and the obtained values of the densities are comparable to PNB (1.38±0.01 g/cm³), lower than GAK (1.41±0.03 g/cm³) , DMM (1.41±0.02 g/ cm³), PAS (1.43±0.02 g/cm³), PV (1.44±0.03 g/cm³)and PVMJ (1.47±0.01 g/cm³) with densities investigated in literature [26], [27] (Table 4).

Table 4:Density of bamboo culm in Ethiopia.

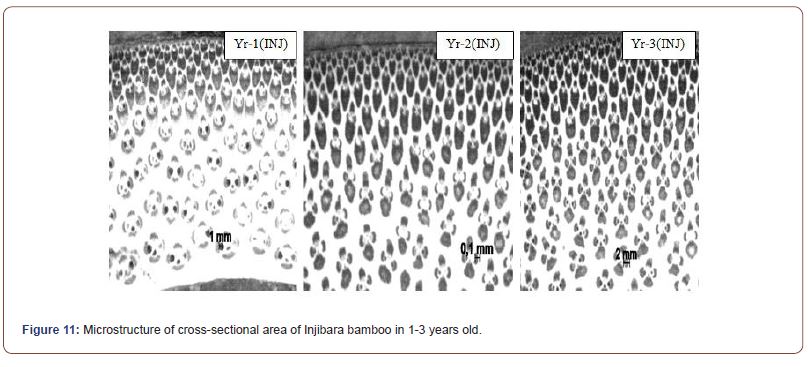

Microstructure characterization

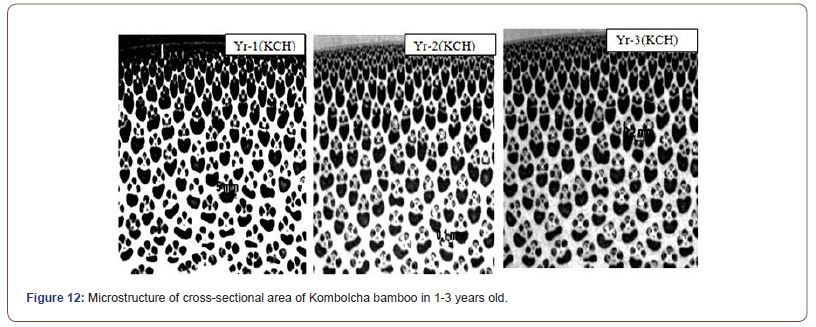

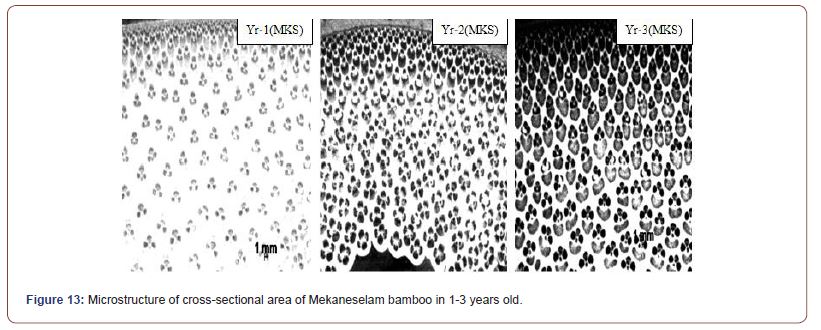

The optical microstructure of the Injibara, Kombolcha and Mekaneselam bamboo are indicated in Figure (11-13). Vascular bundles of the fibre is very dense on the outer and more sparse on the inner surface in all bamboo species. Injibara and Kombolcha bamboo have a similar vascular bundle structure. There are four basic types of vascular bundles by Liese et al. [11], the considered species can be assigned as follows: Injibara, and Kombolcha bamboo consist of vascular bundles of type I, whereas, Mekaneselam bamboo consists of vascular bundles of type III, see Figure (11-13). All the samples were prepared in the same methods, and no reason for this difference is known to the authors. Hence, it is assumed a similar preparation of characteristic of this species.

The influence of ages and bamboo species of the microstructure are indicated in figure (11-13). The bamboo species’ microstructure revealed that fiber strand has a lower contrast with the matrix. when the fibres are less mature, having larger lumen and resembling more the open structure of the parenchyma [27]. As the bamboo grows older, the microstructure image of the vascular bundle formed more dense regions to develop on the region (Figure 11-14).

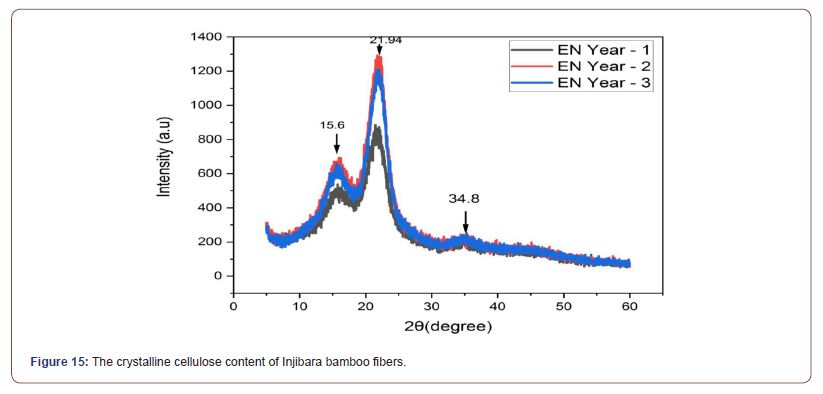

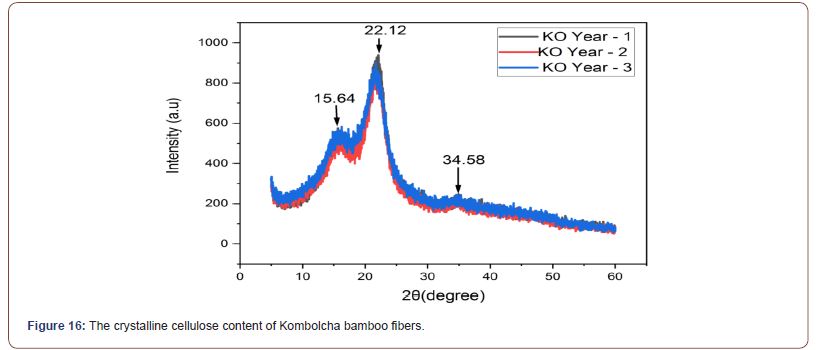

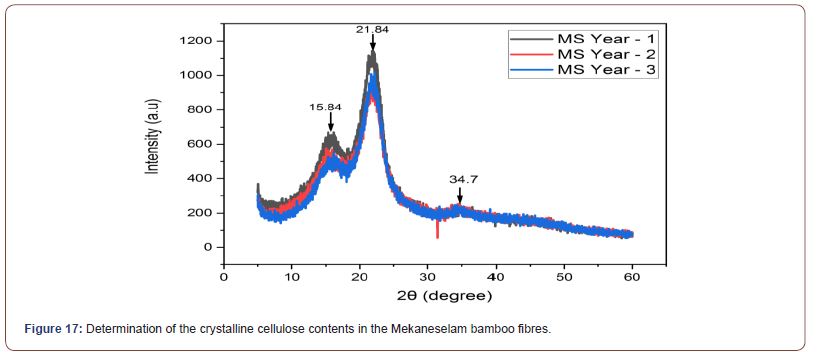

Characterization of crystallinity index

The influence of age on the percentage of the crystallinity and amorphous index are indicated in Table 6. Two years old bamboo of Injibara is a higher percentage of crystallinity index compared to 1 and 3 years old, but it’s record low percentage of crystallinity index in 1-year-old. The highest value of percentage of crystallinity index of Injibara is recoded 9% higher from the lowest. 1-year-old of Kombolcha and Mekaneselam bamboo are a higher percentage of crystallinity index compared to 2 and 3 years old, but they record a low percentage of crystallinity index of 2-year-old. The highest value of percentage of crystallinity index of Kombolcha and Mekaneselam are recoded 5% and 3% higher than from the lowest, respectively. Percentage of crystallinity index of Injibara bamboo record 6%, and 3% higher than Kombolcha and Mekaneselam, respectively. Whereas the Percentage of crystalline index of Mekaneselam bamboo record 3% higher than Kombolcha The highest to lowest value of percentage of crystalline index are Injibara, Kombolcha and Mekaneselam bamboo, respectively. Ethiopian bamboo species is higher percentage of Crystallinity index compared to Neosinocalamus affinis of (55%) [28] (Table 5).

Table 5:Crystallinity index measurement of bamboo species in Ethiopia.

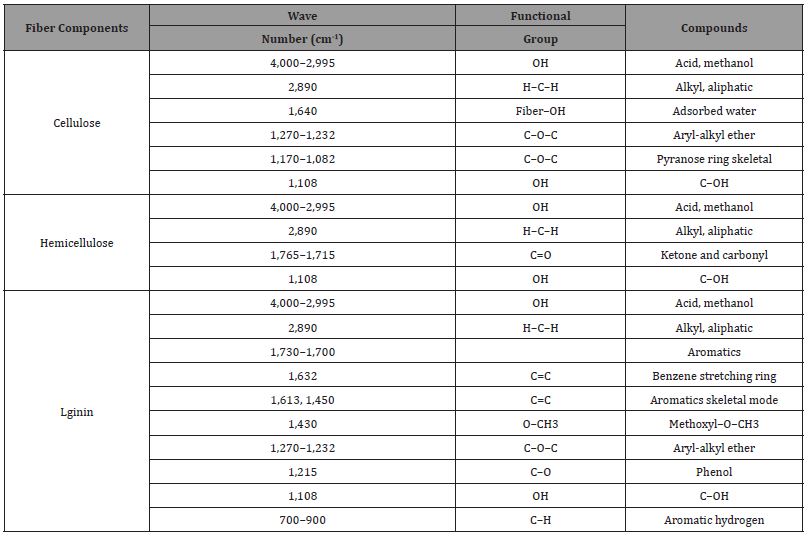

Table 6:Absorption bands for functional groups of cellulose, hemicelluloses, and lignin [29].

The influence of age on the crystallinity index of Injibara bamboo is presented in figure 15. Two years old of bamboo fibres has high intensity of transmission and crystallinity index compared to 1 and 3 years old, whereas 1-year-old of bamboo fibre is the lowest intensity of transmission and crystallinity index. The crystallinity and amorphous index of Injibara bamboo at 2θ is 21.94 and 15.6 respectively. However Injibara bamboo has some silicon content at 2θ of 34.8 (Figure 15).

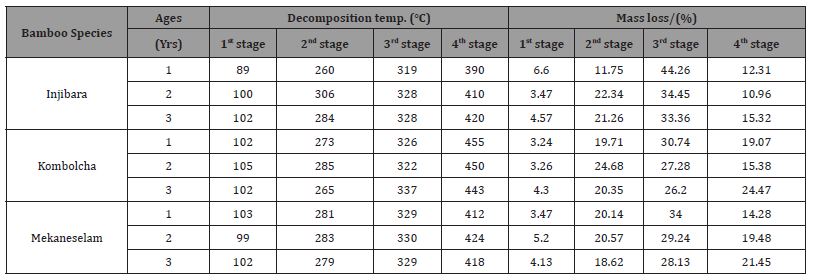

Table 7:Parameters obtained from TG/DTG curves of fibers at argon inert environment : temperature range of thermal degradation, and mass losses at 500°C.

The influence of age on the crystallinity index of Kombolcha bamboo fibre is presented in figure 16. One year old of bamboo fibres has high intensity of transmission and crystallinity index compared to 2 and 3 years old, whereas 2-year-old of bamboo fibre is the lowest intensity of transmission and crystallinity index. The crystallinity and amorphous index of Kombolcha bamboo at 2θ is 22.12 and 15.64 respectively. However Kombolcha bamboo fibre has some silicon content at 2θ of 34.58 (Figure 16).

The influence of age on the crystallinity index of Mekaneselam bamboo fibre is presented in figure 17. One year old of bamboo fibres has high intensity of transmission and crystallinity index compared to 2 and 3 years old that have a similar intensity of transmission and crystallinity index. The crystallinity and amorphous index of Mekaneselam bamboo at 2θ is 21.84 and 15.84 respectively. However Mekaneselam bamboo fibre has some silicon content at 2θ of 34.7 (Figure 17).

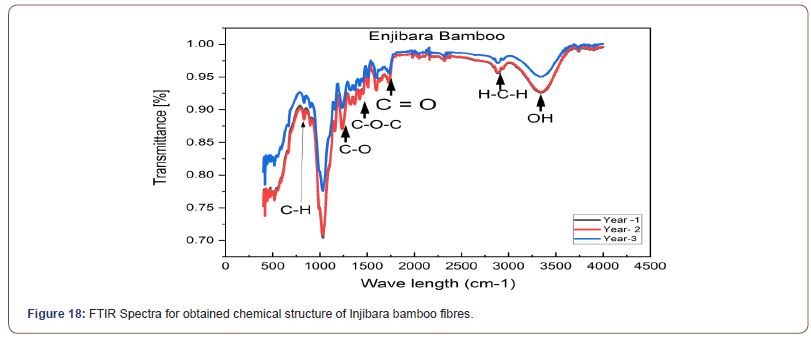

FTIR Characterization

The FTIR characterization of Ethiopian bamboo species on the effect of ages are presented in figure 18 and Table 7. The band coupled with the C–O ring of lignin at 1245–1268 cm–1 declines, and the band at 1740 cm–1 associated with carboxylic groups present in pectins and hemicellulose almost disappears. Other significant changes include the reduction of peaks between 3200 and 3600 cm–1, which correspond to the reduction of some hydroxyl groups associated with the vibration modes of chemical substances such as carbohydrates and fatty acids found in fibers. 3 years old has a high percentage of transmittance compared to 1 and 2 years old, whereas 1 and 2 years old are a similar percentage of transmittance. Chemical constituents such as cellulose, hemicelluloses, and lignin are found in different functional group of 1-3 years old in the Injibara bamboo species (Figure 18).

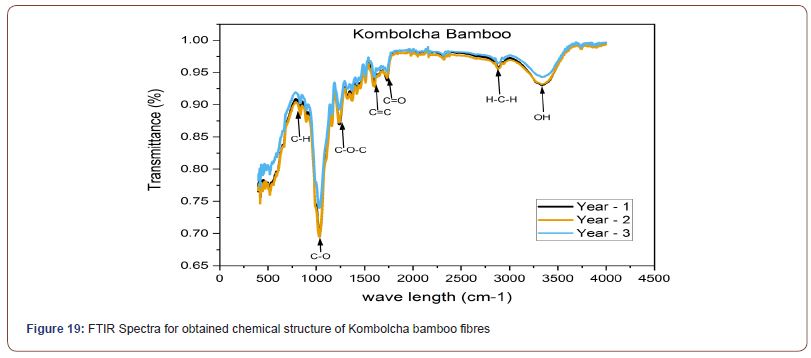

The influence of bamboo ages on the chemical structure are indicated in figure 19 and Table 7. Infrared spectroscopy using the Fourier Transform is performed. Bamboo fibers, cellulose, hemicelluloses, and lignin are among the samples examined. FTIR allows identify the chemical structure to characterize it. Each sample contains functional groups. 3 years old has a high percentage of transmittance compared to 1 and 2 years old, whereas percentage of transmittance 1 and 2 years old are a similar functional group. Chemical constituents such as cellulose, hemicelluloses, and lignin are found in different functional group 1-3 years old in Kombolcha (Figures 19).

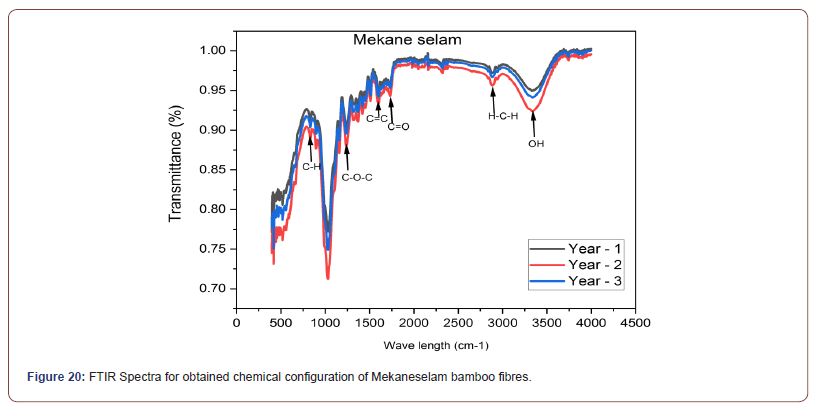

The influence of ages on the chemical configuration of Mekaneselam bamboo species are indicated in figure 20, and Table 7. One year old has a high percentage of transmittance compared to 2 and 3years old, whereas 2 years old is the smallest percentage of transmittance. Chemical constituents such as cellulose, hemicelluloses, and lignin are found in different functional group of 1-3 years old in Mekaneselam bamboo species (Figure 20 & Table 6).

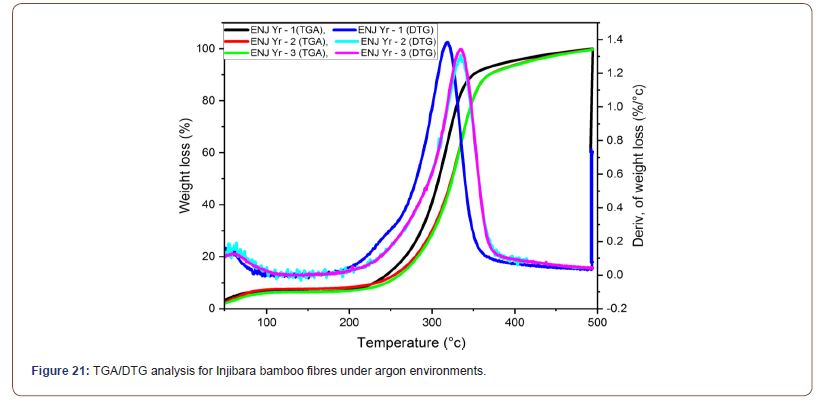

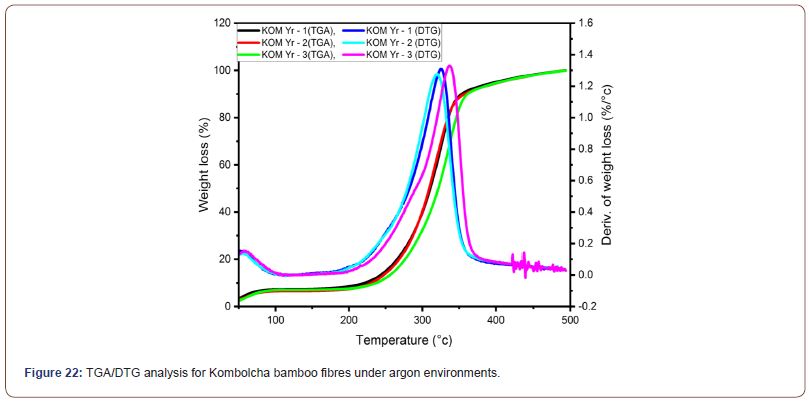

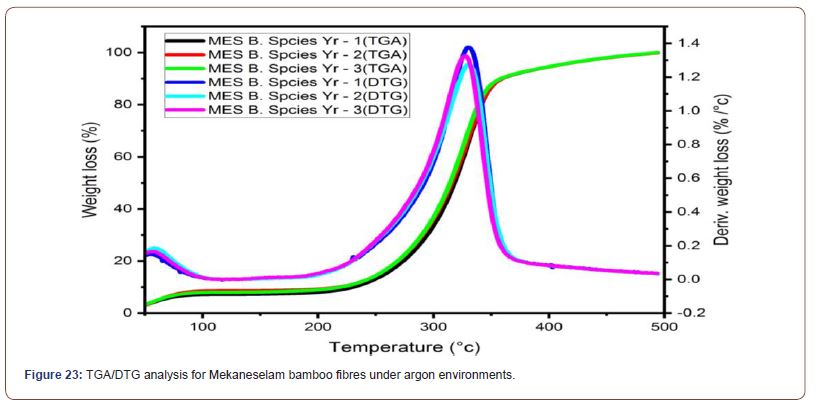

Thermogravimetric analysis of bamboo fibers

As indicated in Table 8, the thermogravimetric analyses (TG) and derivatives (DTG) curves under argon atmospheres for Ethiopian bamboo fibers. Temperatures less than 105ºC, all samples show a progressive loss of mass, which is associated with the release of water. In the DTG curves, the decomposition of lignocelluloses compounds (hemicelluloses, cellulose, and lignin) for all bamboo fibers confirmed only one distinct peak [30]. As presented in Table 8, the first stage, second stage, third stage, and fourth stage of thermal decomposition of fibres indicate the moisture release, hemicelluloses, cellulose, and lignin decomposition of temperature and percentage of mass loss of the fibres. 3 years old of Kombolcha bamboo has higher hemicelluloses, cellulose, and lignin decomposition temperature compared to 1 and 2 years old, which have a similar decomposition of temperature. Furthermore, 2 year old of Mekaneselam bamboo fibre has slightly higher hemicelluloses, cellulose, and lignin decomposition temperature compared to 1 and 3 year old which have a similar decomposition of temperature.

Mass losses of 3.47–6.6%, 3.24–4.3%, and 3.47–5.21% at temperatures ranging from 10 ºC to 105 ºC were observed in Ethiopian bamboo species of Injibara, Kombolcha and Mekaneselam respectively. The current moisture evaporation results in Ethiopian bamboo fibers are comparable to the values found in the literature in the range of 3 to 7% [31,32].

The hemicelluloses, cellulose, and ligin degradation temperature (°C ) of Injibara bamboo fibre is 260-306, 319-328, and 390-420, Kombolcha bamboo fibre is 265-285, 322-337, and 443-455, and Mekaneselam bamboo fibre is 279-283, 329-330, and 412-424 respectively.

Decomposition temperature of hemicelluloses for Injibara bamboo fibres is 7% and 8% higher compared to Kombolcha and Mekaneselam, respectively. Whereas decomposition temperature of cellulose for Kombolcha bamboo fibres is 3% and 2% higher compared to Injibara and Mekaneselam bamboo fibres, respectively.

In an inert environment, the degradation temperatures of hemicelluloses and celluloses for G. angostfilo was 288 °C and 340 °C, respectively, thus it is comparable to the current studies of Ethiopian bamboo fibres.

The decomposition temperature of natural fibres hemicelluloses are 234–297 °C [12]. The hemicelluloses are degraded at lower temperature compared to celluloses and lignin due to short molecular structure and low molecular weight [33]. Some changes in the physical properties of fibres at temperatures ranging from 100 to 297 °C can be observed by changes in either physical or chemical structures, such as depolymerization, hydrolysis, dehydration, decarboxylation, and recrystallization.Aside from that, the formation of free radicals has been observed [34]. In general, hemicelluloses and cellulose significantly contribute more to thermal degradation. Distinct peaks were realized in the literature, depending on the type of natural fiber treated [31] (Table 7).

As shown in figure 21, two years old of Injibara bamboo has lower hemicelluloses, cellulose, and lignin decomposition temperature compared to 1-year-old, whereas 2 and 3 years old have a similar decomposition of temperature. 2 and 3 years old are also noted that the maturity of the culm improved with thermal stability of the fiber, characterized by an increase in initial temperatures of degradation. There is an increase in the initial degradation temperature (291.0 and 284.0 ºC) of fibers that are 2 and 3 years old, respectively, when compared to natural fibers at temperature of (275 ºC). Similar results were found by Maheswari et al.,[35] who investigated the thermal properties of the tamarind fruit fibers (Figure 21).

As indicated in figure 22, three years old of Kombolcha bamboo fibres has higher hemicellulose, cellulose, and lignin decomposition temperature compared to 1 and 2 years old which have a similar decomposition of temperature. 1 and 2 years old are also noted that early stage improved with fibres thermal stability, which characterized by an increase in initial degradation temperatures. An increase in the initial degradation temperature (273.0 and 285.0 ºC) of 1 and 2 years old respectively, compared to natural fibers at temperature of 275 ºC. Similar results were observed by Maheswari et al.,[35] (Figure 22).

Furthermore the influence of ages on the thermal decomposition of bamboo fibres is presented in figure 23, two years old of Mekaneselam bamboo fibre has slightly higher hemicelluloses, cellulose, and lignin decomposition temperature compared to 1 and 3 year old which have a similar decomposition of temperature. Two year old is also noted that improved with fibres thermal stability, which characterized by an increase in initial temperatures of degradation. An increase in the initial degradation temperature (281.0 and 283.0 ºC) of 1 and 2 years old respectively, compared to natural fibers at temperature of 275 ºC. Similar results were observed by Maheswari et al., [35] (Figure 23).

Conclusion

All the morphological, microstructural, thermal, and crystallinity indexes of bamboo fibres were studied on the influence of ages and Ethiopian bamboo species, which have an influence on the culm morphological features. The morphological features have improved when the culm old, but breast height, diameter, and wall thickness reduce their sizes from bottom to top position, whereas Internodal length reaches its maximum in the middle of the culm, then decreases to the top of the culm along with its height. Kombolcha bamboo has a high breast height diameter and wall thickness compared to Injibara and Mekaneselam, but Mekaneselam bamboo culm has a larger internodal length compared to Injibara and Kombolcha. The morphological and microstructure behavior of the culm are very important for fibre composite application. The breast height diameter and wall thickness determine the quantities of fibre extraction, whereas the Internodal length is decisive for unidirectional continuous fibre composite production. Factors of the culm ages satisfied the minimum criteria requirement of the breast height diameter (3 cm) and the Internodal length (25 cm), as set by the author for composite application. The morphological features of bamboo species in Ethiopian are the best for fibre composite applications. Injibara and Kombolcha bamboo have different vascular bundle structures compared to Mekaneselam, but they have a similar vascular bundle structure to each other. The microstructure of the culm’s vascular bundles is influenced by age maturation. When the culm is old and young, the microstructure of the vascular bundles becomes more dense and sparse, respectively. The thermal and crystallinity index properties of the fibres improved after one season of growth. The moisture release, hemicelluloses, and cellulose decomposition temperature of Injibara bamboo is 89-102 ºC, 260-306 ºC, and 319- 328 ºC, Kombolcha bamboo fibre is 102-105 ºC, 265-285ºC, and 322-337ºC, and Mekaneselam bamboo fibres are 99-103 ºC, 279- 283 ºC, and 329-330 ºC, respectively. In Ethiopia, bamboo species have a similar range of thermal decomposition temperatures to each other and they have a similar range of thermal decomposition temperatures as found in the literature.

The crystallinity index of Injibara, Kombolcha, and Mekaneselam bamboo fibres is 63-69%, 62-65%, and 65-67%, respectively. The crystalline index of Kombolcha and Mekaneselam bamboo fibre are 6% and 3% lower compared to Injibara bamboo fibre, respectively. Bamboo species in Ethiopia have a high percentage of crystallinity index compared to other literature found.

Acknowledgement

The researchers would like to express their heartfelt gratitude to Dr. Alemayehu Wakjira, Dean of the School of Mechanical, Chemical, and Materials Engineering, and Mr. Mengistu Gelaw, Department of Mechanical Design and Manufacturing Engineering, for their valuable enthusiasm, motivation, and provision of relevant research facilities.

Funding

All prior investigations in preparation this study were funded by Minister of Science and Higher Education, Addis Ababa, Ethiopia.

Ethics

This article is original and contains unpublished material. The corresponding author confirms that all of the other authors have read and approved the manuscript and no ethical issues involved.

Conflict of Interest

No conflict of interest.

References

- Kassahun (2015) “REVIEW OF BAMBOO VALUE CHAIN IN ETHIOPIAwuro zone, P.O. Box 17, Dawuro, Southern Ethiopia,” Int J African Soc Cult Tradit 2(3): 52-67.

- Bekele-tesemma (1985) “Useful trees and shrubs of Ethiopia : Identification , Propagation and Management for 17 Agroclimatic Zones.”

- Y MAAZ Tadesse (2016) BAMBOO SPECIES Biological, Ecological and Management Aspects BAMBOO SPECIES.

- BN Kigomo, JF Kamiri (1985) “Observations on the Growth and Yield of Oxytenanthera Abyssinica (A. Rich) Munro in Plantation,” East African Agric For J 51(1): 22-29

- AK Ray, S K Das, S Mondal, P Ramachandrarao (2004) Microstructural characterization of bamboo. J Mater Sci 39(3): 1055-1060.

- Ensermu Kelbessa, Sebsebe Demissew (2014) Diversity of Vascular Plant Taxa of The Flora of Ethiopia and Eritrea. 13(1): 37-45.

- Wubalem Tadesse, Getachew Desalegn, Abraham (2012) “Forestry and Forest Products: technologies and Issues Ethiopian Institute of Agricultural Research, Addis Ababa, Ethiopia.,” For. For. Prod. Ethiop. Technol. Issues, p. 441, [Online]. Available: http://publication.eiar.gov.et:8080/xmlui/bitstream/handle/123456789/50/forestry

- RL Banik (2015) Bamboo The Plant and its Uses.

- Y Yu, H Wang, F Lu, G Tian, J Lin (2014) “Bamboo fibers for composite applications: A mechanical and morphological investigation.” J Mater Sci 49(6): 2559-2566.

- P Guznay (2004) “Guadua Angustifolia,” Palma Trop. S.A 3(61): 4, [Online]. Available:http://www.4shared.com/office/7cBG17R7/guadua_angustifolia_-_por_guzn.htm?locale=es.

- Walter Liese (1998) The anatomy of bamboo culm, International Network for Bamboo and Rattan.

- ETDELOS Ríos (2014) Polymer Composite Materials.

- E Trujillo, D Perremans, L Osorio, AW Van Vuure, J Ivens, et al. (2014) “Characterization of Unidirectional Discontinuous Bamboo Fibre / Epoxy Composites,”: 22-26.

- Abd Latif Mohmod, Ashaari Hj Amin, Jamaludin Kasim, Mohd Zin Jusuh (2016) “Effects of Anatomical Characteristics on the Physical and Mechanical Properties of Bambusa Blumeana: Forest Research Institute Malaysia Stable URL 6(2): 159-170.

- S Verheyden, I Verpoest, KU Leuven (2012) Microstructural Analysis and Mechanical Behaviour Of Bamboo Fibres: 24-28.

- F Wang, J Shao, LM Keer, L Li, J Zhang (2015) The effect of elementary fibre variability on bamboo fibre strength 75: 136-142.

- Chaowana (2013) “Bamboo : An Alternative Raw Material for Wood and Wood-Based Composites 2(2).

- SEE, SEE (2021) Plant growth and biomass distribution on Guadua angustifolia Kunth in relation to ageing in the Valle del Cauca - Colombia the Journal of the American Bamboo Society.

- D Division (2004) “Developmental Changes in Cell Wall Structure of Phloem Fibres of the Bamboo Dendrocalamus asper: 497-505.

- W Liese, G Weiner (1996) Ageing of bamboo culms. A review 30: 77-89.

- J Lin, X He, Y Hu, T Kuang, R Ceulemans (2002) “Lignification and lignin heterogeneity for various age classes of bamboo (Phyllostachys pubescens) stems Lignification and lignin heterogeneity for various age classes of bamboo (Phyllostachys pubescens) stems,”.

- AN Rao, G Dhanarajan, CB Sastry (1985) Recent Research on Bamboos Proceedings of the International Bamboo Workshop October 6-14.

- SP Pubescens (2007) Chemical Changes with Maturation Of The Bamboo Species Phy-Llostachks Pubescens,” 19(1).

- HN Hisham, S Othman, H Rokiah, MA Latif, S Ani, et al. (2006) Characterization of Bamboo Scortechinii at Different Ages Gigantochloa 18(4): 236-242.

- J Fu, L Fu, Q Zhang, W Gao (2015) Xylanase- and cellulose-aided bioprocessing of bamboo 605-611.

- Depuydt, Delphine EC (2018) Industrial Crops & Products European bamboo fi bres for composites applications, study on the seasonal in fl uence,” 133: 304-316.

- DEC Depuydt, N Sweygers, L Appels, J Ivens, AW Van Vuure (2019) “Bamboo fibres sourced from three global locations: A microstructural, mechanical and chemical composition study,”

- Y Nishiyama, P Langan, H Chanzy (2002) “Crystal Structure and Hydrogen-Bonding System in Cellulose I from Synchrotron X-ray and Neutron Fiber Diffraction,” 9074-9082.

- JI Mora (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers Extraction of cellulose and preparation of nanocellulose from sisal fibers.

- ACH Barreto, D S Rosa, FJN Maia, AEC Ju (2014) “Thermal and mechanical properties of biocomposites based on a cashew nut shell liquid matrix reinforced with bamboo fibers,”

- A Rachini, M Le Troedec, C Peyratout (2008) Comparison of the Thermal Degradation of Natural , Alkali-Treated and Silane-Treated Hemp Fibers Under Air and an Inert Atmosphere.

- Z Sebestyén, Z May, K Réczey, E Jakab (2013) “The effect of alkaline pretreatment on the thermal decomposition of hemp,” 1-12.

- IOPC Series, M Science (2020) “Changes in the density , specific gravity and dimensional stability of candlenut wood (Aleurites moluccanus (L.) Willd) from several variation temperatures with oil-heat treatment Changes in the density, specific gravity and dimensional stability of candlenut wood (Aleurites moluccanus (L) Willd) from several variation temperatures with oil-heat treatment.

- J Wei, H Liu, Y Chen, H Yu (2016) Functionalized Cellulosic Fibers through Periodate Oxidization of Bamboo Pulp.

- V Placet (2009) A Characterization of the thermo-mechanical behaviour of Hemp fibres intended for the manufacturing of high performance composites. Compos. Part A 40(8): 1111-1118.

-

Yalew Dessalegn, Balkeshwar Singh, Aart W van Vuure. Characterization of Morphological and Microstructural Properties of Bamboo Species for Composite Industry. Insi in Chem & Biochem. 2(2): 2022. ICBC. MS.ID.000532.

-

Crystallinity, Bambusa, Dendrocalamus, Gigantochloa, Guadua, Phyllostachys, Schizostachyum And Thyrsostachys, Environmental Conditions, Parenchyma Cells, Sclerenchyma, Sclerenchyma Cells.

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.