Review Article

Review Article

Biomass Derived Nanocarbon for Supercapacitor Fabrication

B Raghavendra Babu and Anil Kumar Sarma*

Electrochemical Process Division; Sardar Swaran Singh National Institute of Bioenergy; Kapurthala; Punjab

Anil Kumar Sarma; Electrochemical Process Division; Sardar Swaran Singh National Institute of Bioenergy; Kapurthala; Punjab; India.

Received Date:May 06, 2025; Published Date:May 22, 2025

Abstract

Biomass-derived nanocarbon (BNC) holds immense potential; particularly for energy storage devices such as supercapacitors and batteries; where it serves as an electrode material to enhance performance. This mini: article discusses the preparation methods of biomass-derived nanocarbon and examines emerging materials like carbon nanotubes and graphene nanosheets obtained sustainably from biomass. The application of biomass-derived nanocarbon (BNC) in supercapacitor electrode design is explored; highlighting improvements in performance metrics such as energy density; power density; and cyclic stability. Relevant articles are analyzed to assess the enhanced performance of supercapacitors employing BNCs..

Keywords:Biomass; nanocarbon; Supercapacitors; Electric double layer capacitors

Abbreviations: BNC: Biomass derived Nanocarbons; EDLC: Electric double layer capacitors; 0D: Zero dimensional; 1D: One dimension; 2D: Twodimension; 3D: Three Dimension; CNs: Carbon Nanostructures; BAC: Biomass derived Activated carbons; CVD: Chemical Vapor Deposition; SWCNTs: Single walled Carbon nanotubes; MWCNTs: Multiwalled Carbon Nanotubes; CD: Carbon dots; PECVD: Plasma-Enhanced Chemical Vapor Deposition; TMOs-Transition Metal Oxides; TMCs: Transition Metal Chalcogenides; CV: Cyclic Voltammetry ; GCD-Galvanostatic Charge-Discharge Studies; EISElectrochemical Impedance Spectroscopy

Introduction

Biomass; a carbon-rich; sustainable; and renewable resource; is a biogenic mixture of organic and inorganic matter primarily produced through photosynthesis in terrestrial and aquatic vegetation; animal digestion; and anthropogenic processing of organic materials such as wood; plants; manure; and household waste*1+. It serves as a key precursor for producing green carbon nanomaterials (solid component); value-added chemicals; and biofuels (liquid and gaseous components) from non-edible residues like paddy straw; corn cobs; wheat stalks; oilseeds and manure. Biomass is classified into two main categories: lignocellulosic and non-lignocellulosic; based on their origins and chemical structures*2+. Lignocellulosic biomass; primarily derived as waste from the wood and crop industries and rich in hemicellulose (15%– 40%); cellulose (25%–50%); and lignin (10%–40%); is regarded as a highly promising renewable resource for producing carbon materials and fuels in an environmentally friendly manner*3+*4+. Depending on the type of feedstock and conversion process; all biomass forms viz.; solid; liquid; and gaseous can be utilized to. Value-added materials; such as nanocarbon; have garnered significant global attention due to their derivation from biomass. In recent decades; several new processing technologies have been developed to synthesize nanocarbon from biomass at minimal cost; with reduced ecological hazards; thereby facilitating the transition from a linear economy to a circular economy [1-5].

Synthesis of Nanocarbon from Biomass

Nanocarbon refers to forms of carbon nanostructures whose dimensions are in the nanometer range. It has a graphitic structure with a regular arrangement of carbon atoms and is highly crystalline in nature*5+. Nanocarbon is classified into four categories based on dimensionality: 0D (e.g.; quantum dots; fullerenes); 1D (e.g.; nanorods; carbon nanotubes); 2D (e.g.; graphene; nanosheets); and 3D (e.g.; hierarchical mesoporous assemblies; metal-organic frame works) *6+. It exhibits diverse properties such as mechanical strength; surface area; and hydrophobicity; which vary according to each respective dimension. There are several routes of nanocarbon synthesis from different biomass precursors. Biomass-derived carbon involves three key processes: pyrolysis; carbonization; and graphitization. Pyrolysis is the process of converting feedstocks into biochar through heating in an inert atmosphere/ partially inert atmosphere*7+. The resulting biochar typically contains a lower percentage of carbon and includes inorganic mixtures. Carbonization involves heating biochar at higher temperatures to create a hierarchical carbon structure with a carbon content exceeding 95%. This process results in a material with a high surface area and significant porosity; making it particularly suitable for electrodes; especially supercapacitor electrodes*8+. Graphitization is the process of heating carbonaceous material at elevated temperatures in an inert atmosphere. It is the most crucial and complex step; where the amorphous carbon structure transforms into a crystalline graphitic structure*9+. This method is instrumental in altering the electrical and mechanical properties of biomass-derived carbon for specific applications [6-10].

a) Solid Biomass derived nanocarbon

Zero dimensional (0D) nanostructures like carbon dots (CDs) can be prepared from biochar using methods such as hydrothermal and microwave-assisted carbonization processes. Recently; techniques like ultrasonication and chemical oxidation have also been employed to produce carbon dots*10+. These carbon dots are utilized in energy storage applications such as supercapacitors; owing to their excellent electrochemical properties and luminescent characteristics; as well as in biomedical fields like drug delivery systems and imaging. 1D carbon nanotubes (CNTs) are tube-like structures formed by wrapping layers of graphene; which are nanometric in size. CNTs are classified into two types: single-walled carbon nanotubes (SWCNTs; <2 nm) and multi-walled carbon nanotubes (MWCNTs; >2 nm); based on the number of graphene layers wound together*11+. They exhibit high mechanical strength; a large specific surface area; and excellent conductivity; making them suitable for energy storage applications; especially in supercapacitors. CNTs can be synthesized using cellulose-rich solid biomass precursors like wood; grass; or crop residues through pyrolysis followed by chemical vapor deposition (CVD) [11-17]. Pyrolysis is used to produce biochar; and the CVD process; in the presence of a catalyst; facilitates CNT formation. For most solid biomass; thermochemical conversion via pyrolysis is the initial step in forming biochar. 2D nanostructures such as graphene nanosheets are prepared using activation methods. These methods are categorized into physical and chemical activation; based on the fuel and gas source. Physical activation involves heating biochar in the presence of steam or carbon monoxide; while chemical activation uses agents like KOH or ZnCl₂ in an inert atmosphere (e.g.; nitrogen or argon gas)*12+. These preparation techniques produce graphene with strong adsorption properties and high electrical conductivity; making them ideal for supercapacitor electrodes. 3D mesoporous hierarchical carbon is synthesized using methods such as direct carbonization; metal cross-linking agents; self-assembly; dual activation strategies (a combination of physical and chemical activation); soil-templated synthesis; and one-pot synthesis. This material features a high degree of mesoporous; which allows it to store ions effectively; enhancing the energy density of supercapacitors*13+.

b) Liquid Biomass derived Nanocarbon

Liquid biomass is produced through various processes such as the transesterification of vegetable oils or animal fats to create biodiesel; fermentation of carbohydrates to produce ethanol; or pyrolysis of biomass to generate bio-oil. Bio-oil is a complex liquid containing a wide range of aromatic compounds; including oxygenated molecules (such as acids; ketones; and furans); hydrocarbons; and water*14+. It has a significant carbon content with an abundant amount of oxygen which facilitates to prepare the Nanocarbon. Bio-oil is primarily derived from the decomposition of cellulose; [18-25] hemicellulose; and lignin during the pyrolysis process. CDs can be prepared using a hydrothermal method; where bio-oil is mixed with water and subjected to high temperatures maintained at a constant pressure. Carbon Nanotubes (CNTs) are synthesized through chemical vapored position (CVD) upon specific catalyst surface; which yields high-purity CNTs due to the direct conversion of liquid biomass into gaseous carbon-rich species that are deposited onto a substrate or biochar derived from solid biomass [15]. The catalyst can be later removed with dilute nitric acid treatment. 2D graphene is produced using several techniques; including chemical vapor deposition; hydrothermal carbonization; and laser-induced graphene synthesis; which offer cost efficiency and high product yield [16]. Nanocarbon derived from liquid biomass provides advantages over solid biomass in terms of both quantity and quality.

c) Biomass gas derived Nanocarbon

Biomass gas consists of syngas and biogas; both produced from organic matter through different processes such as gasification and anaerobic digestion. Syngas; primarily composed of carbon monoxide and hydrogen; is created by the gasification of biomass at high temperatures with limited oxygen. In contrast; biogas is produced by the anaerobic decomposition of biomass and is primarily composed of methane and carbon dioxide [17]. Carbon nanotubes (CNTs) can be synthesized using syngas through catalytic chemical vapor deposition (CVD); where carbon monoxide decomposes over a metal catalyst substrate [18]. Metal catalysts such as Fe; Ni; and Co are commonly used; as they significantly influence the morphology and growth of the CNTs. CNTs can also be produced from biogas; though this involves a more complex process [17]. First; the biogas undergoes an upgrading process to maximize its methane content with the help of catalysts. The upgraded biogas is then fed into a reactor in the presence of different catalysts to facilitate CNTs formation [26-30]. However; these methods generally incur high production costs due to the expensive catalysts and result in only minimal yields. 2D graphene can be synthesized from biogas using the Plasma-Enhanced Chemical Vapor Deposition (PECVD) process*19+. PECVD utilizes plasma that creates energy pulse and reacts with enriched methane biogas to dissociate the methane into reactive carbon species and deposited on the metal substrate. The main drawback is that catalytic efficiency is low and it tends to reduce the yield of the product*20+. The synthesis preparation employed using biomass to prepare the different dimension of nanostructures is given in Table 1.

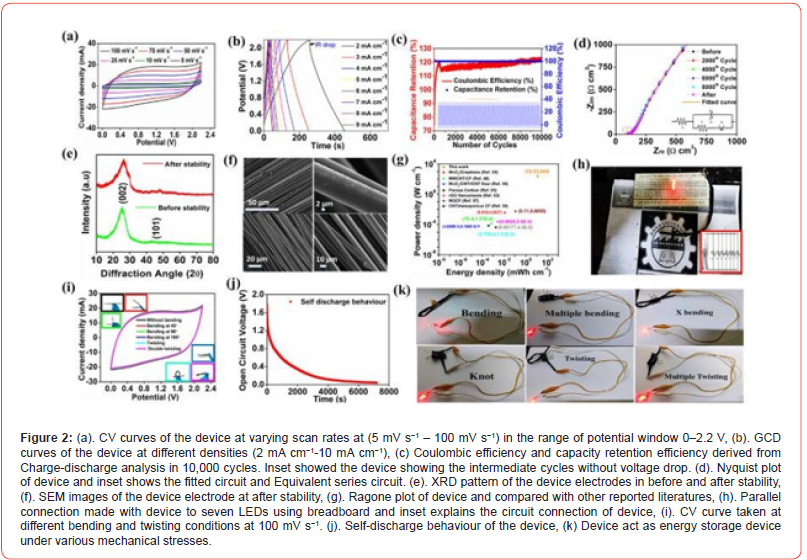

Table 1:Synthesis routes and preparation methods of biomass-derived nanostructures with varying dimensionalities (0D, 1D, 2D, and 3D).

Application of nanocarbon for supercapacitor electrodes

Supercapacitors are electrochemical energy storage devices known for their high-power density; exceptional cyclic stability; and long lifespan*26+. They are categorized into three types based on the electrode materials used: electrochemical double-layer capacitors (EDLCs); pseudo capacitors; and hybrid supercapacitors*27+. EDLCs employ carbon-based materials as electrodes; where charge storage occurs through an adsorption: desorption mechanism; with ions confined to the carbon surface. These electrodes are designed with a porous structure that provides a high surface area; enabling ultra-fast charging; high power density; and virtually infinite cycles without degradation*28+. Biomass-derived carbon; synthesized through chemical activation using activating agents; creates pores and functional groups on its surface; enhancing wettability and ion adsorption for efficient charge storage. Pseudo capacitors store charge through faradaic redox reactions; offering higher energy density and specific capacitance [31-35]. They utilize transition metal oxides (TMOs); conducting polymers; and transition metal chalcogenides (TMCs) as electrode materials; but their primary limitation is lower cyclic stability*29+. Hybrid supercapacitors combine carbon materials with metal oxides to achieve a synergistic effect; improving performance and stability. The integration of carbon materials reinforces the structure; preventing metal oxide degradation and ensuring longer operational life *30+.

Properties of nanocarbon obtained from biomass

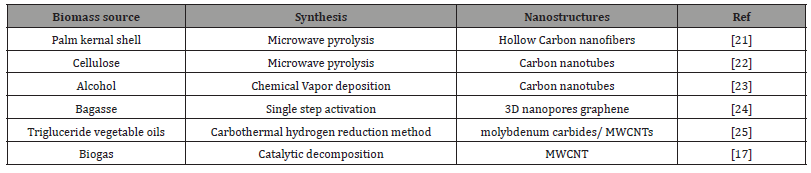

Biomass-derived nanocarbon (BNC) based materials; characterized by their graphitic crystalline structure and high degree of crystallinity; are excellent electrical conductors that enhance the electronic properties of supercapacitors. They also exhibit high porosity; facilitating ion transport pathways and improving electrolyte conductivity. The presence of functional groups on BNC materials increases wettability and reduces charge transfer resistance between the electrolyte and electrodes*31+. Additionally; these materials are highly suitable for heteroatom doping; further boosting energy density. Beyond performance; they offer thermal and chemical stability; making them ideal for advanced supercapacitor fabrication*32+. Recent studies highlight the potential of these nanocarbon derived from biomass as supercapacitor electrodes as depicted in Figure 1.

Reported capacitance and CV curves

Electrochemical studies are primary tools used to optimize the performance of supercapacitor electrodes. In general; these studies are conducted using either three-electrode or twoelectrode configurations*33+. The three-electrode system includes a working electrode; a reference electrode; and a counter electrode. The working electrode consists of the prepared material being studied. The reference electrode supports the working electrode by creating a constant potential across the two electrodes; thereby generating a potential difference. The counter electrode provides the current flow generated by the working electrode; completing the circuit*34+. Preliminary electrochemical studies include cyclic voltammetry (CV); galvanostatic charge: discharge (GCD); and electrochemical impedance spectroscopy (EIS) [36-40]. Cyclic voltammetry is used to determine the potential of the material at which the current response is at its maximum within a fixed potential range. GCD studies help to understand the charging and discharging times relative to the potential obtained from CV curves. EIS evaluates the resistance between the electrodes and the electrolyte in the supercapacitor; offering insights into ion transport; contact resistance; and solution resistance of the material*35+.

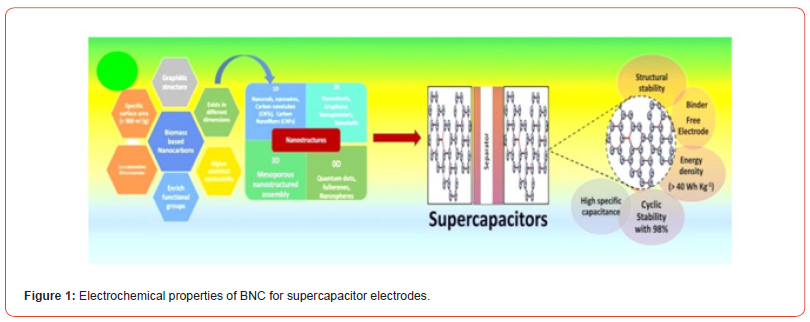

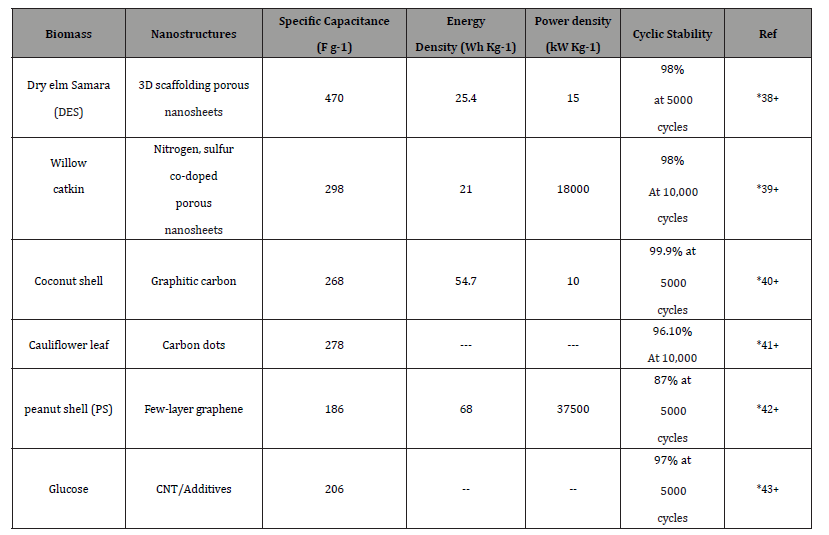

To assess the material’s stability and the longevity of the electrodes; cyclic stability analysis is conducted to compute the capacitance retention and coulombic efficiency. Additionally; the Ragone plot; an essential analysis; is used to determine the energy density and power density of the material. Finally; to evaluate the charge contribution of the electrodes in terms of both capacitive and surface charge storage; quantitative and qualitative methods are applied; based on the peak current of the CV curves*36+. Figure 2 demonstrates the comprehensive electrochemical and mechanical performance of the device. Cyclic voltammetry (CV) and galvanostatic charge: discharge (GCD) tests confirm excellent stability; rate capability; and non-faradaic charge storage behaviors; with 119% capacitance [41-43] retention over 10;000 cycles. Nyquist plots and XRD patterns reveal consistent conductivity and structural integrity; while SEM images confirm the fibbers’ durability. The device also exhibits outstanding flexibility and low self-discharge; effectively powering LEDs under mechanical deformation; highlighting its potential for flexible energy storage applications *37+. The electrochemical performance of the BNC derived nanostructures employing in supercapacitors electrodes and compare the feedstock source; energy density; power density and cyclic stability values are summarized in Table 2.

Table 2:Electrochemical performance of BNC nanostructures

Conclusion

Biomass-derived nanocarbon (BNC) presents a sustainable and efficient alternative for supercapacitor applications due to its unique properties; structural advantages attributed. Due to the graphitic crystalline structure; high specific surface area; enhanced electrical conductivity; and versatile dimensional nanostructures; combined with functional group fortification and heteroatom doping; shows significantly enhance charge storage and transfer capabilities. The rigidity of BNC allows for its use as a binder-free electrode; offering exceptional mechanical and chemical stability. It achieves a high specific capacitance exceeding 400 F g⁻¹; remarkable cyclic stability of 98%; and an energy density surpassing 40 Wh kg⁻¹; underscoring its potential for high-performance energy storage as per the recently reported literature. These features highlight BNC as a promising material for advancing supercapacitor technology; bridging the gap between sustainability and efficiency for energy storage solutions.

Acknowledgements

The authors acknowledge SSS-NIBE; Kapurthala for financial support and platform of works.

Conflict of Interest

There is no conflict of interest to declare for publication of this work.

References

- Y Li, LW Zhou, RZ Wang (2017) Urban biomass and methods of estimating municipal biomass resources, Renew Sustain Energy Rev 80: 1017-1030.

- F Rosillo-Calle (2016) A review of biomass energy - shortcomings and J Chem Technol Biotechnol 91(7): 1933-1945.

- Y Li, B Xing, Y Ding, X Han, S Wang (2020) A critical review of the production and advanced utilization of biochar via selective pyrolysis of lignocellulosic biomass. Bioresour Technol 312: 123614.

- DO Hall (1991) Biomass energy Energy 19: 711-737.

- Shenbagalakshmi, R Singh, N Prakash, G Raghu Babu, A Yasmine Begum, et al. (2023) Nanotechnology on Energy Storage, Mater Sustain Energy Storage Nanoscale 385-

- MA Munawar, AH Khoja, SR Naqvi, MT Mehran, M Hassan, et al. (2021) Challenges and opportunities in biomass ash management and its utilization in novel Renew Sustain Energy Rev 150.

- AK Kurchania (2012) Biomass energy, Biomass Convers Interface Biotechnol Chem Mater Sci 9783642284 91-122.

- JA Sanguesa, V Torres-Sanz, P Garrido, FJ Martinez, JM Marquez-Barja (2021) A review on electric vehicles: Technologies and challenges. Smart Cities 4: 372-404.

- H Marsh, AP Warburton (1970) Catalysis of graphitisation, J Appl 20(4): 133-142.

- Kumar R, Singh RK, Singh DP (2016) Natural and waste hydrocarbon precursors for the synthesis of carbon based nanomaterials: Graphene and CNTs. Renew Sustain Energy Rev 58: 976-1006.

- Zhai Y, Dou Y, Zhao D, Fulvio PF, Mayes RT, et al. (2011) Carbon Materials for Chemical Capacitive Energy Storage. Adv Mater. 23(42): 4828-4850.

- Lee SM, Lee SH, Roh JS (2021) Analysis of Activation Process of Carbon Black Based on Structural Parameters Obtained by XRD Crystals 11(2): 153.

- Huang Y, Peng L, Liu Y, Zhao G, Chen JY, et al. (2016) Biobased Nano Porous Active Carbon Fibers for High- Performance Supercapacitors, ACS Appl Mater Interfaces. 8(24): 15205-15215.

- G Kabir, BH Hameed (2017) Recent progress on catalytic pyrolysis of lignocellulosic biomass to high-grade bio-oil and bio-chemicals. Renew Sustain Energy Rev 70.

- X Wang, X Lu, B Liu, D Chen, Y Tong, et al. (2014) Flexible energy-storage devices: Design consideration and recent progress. Adv Mater 26(28): 4763-4782.

- B Huang, Y Liu, Z Xie (2017) Biomass derived 2D carbons via a hydrothermal carbonization method as efficient bifunctional ORR/HER electrocatalysts. J Mater Chem A 5(45): 23481-23488.

- Yan Q, Yu F, Chu IW, A Lawrence (2015) Direct Conversion Biogas to Multiwall Carbon Nanotubes and Syngas over Starch Derived Ni@C Nanoparticles. Microsc Microanal 21: 1829-1830.

- Xu X, Zhou J, Nagaraju DH, Jiang L, Marinov VR, et al. (2015) Flexible, highly graphitized carbon aerogels based on bacterial cellulose/lignin: Catalyst-free synthesis and its application in energy storage Adv Funct Mater 25: 3193-3202.

- Wang XD, Vinodgopal K, Dai GP, Wang XD, Vinodgopal K, et al. (2019) Synthesis of Carbon Nanotubes by Catalytic Chemical Vapor Deposition. Perspect Carbon Nanotub.

- He D, Jiang Y, Lv H, Pan M, Mu S (2013) Nitrogen-doped reduced graphene oxide supports for noble metal catalysts with greatly enhanced activity and stability. Appl Catal B Environ 379-388.

- Omoriyekomwan JE, Tahmasebi A, J Zhang, Yu J (2017) Formation of hollow carbon nanofibers on bio-char during microwave pyrolysis of palm kernel shell. Energy Convers Manag 148: 583-592.

- Omoriyekomwan JE, Tahmasebi A, Zhang J, Yu J (2019) Mechanistic study on direct synthesis of carbon nanotubes from cellulose by means of microwave Energy Convers Manag 192(5582): 88-99.

- Maruyama S, Kojima R, Miyauchi Y, Chiashi S, Kohno M (2002) Low-temperature synthesis of high-purity single-walled carbon nanotubes from alcohol. Chem Phys Lett 360: 229-234.

- Mahmoudian L, Rashidi A, Dehghani H, Rahighi R (2016) Single-step scalable synthesis of three-dimensional highly porous graphene with favorable methane adsorption. Chem Eng J 304.

- J Han, J Duan, P Chen, H Lou, X Zheng, et al. (2011) Chemistry, undefined 2011, Nanostructured molybdenum carbides supported on carbon nanotubes as efficient catalysts for one-step hydrodeoxygenation and isomerization of vegetable oils. Pubs Rsc Org.

- Y Wang, Z Shi, Y Huang, Y Ma, C Wang, et al. (2009) Chen, Supercapacitor devices based on graphene J Phys Chem C 113(30).

- L Yu, GZ Chen (2020) Supercapatteries as High-Performance Electrochemical Energy Storage Devices, Electrochem Energy Rev. 3(2).

- Y Wang, Z Shi, Y Huang, Y Ma, C Wang, et al. (2009) Supercapacitor devices based on graphene J Phys Chem C 113(30).

- A Venkataraman (2015) Pseudocapacitors for Energy Pseudocapacitors for Energy Storage 1-81.

- H Chen, E Bao, H Sun, X Ren, X Han, et al. (2024) Sonochemical synthesis of CoNi layered double hydroxide as a cathode material for assembling high performance hybrid supercapacitor. J Colloid Interface Sci 664: 117-127.

- P Manasa, S Sambasivam, F Ran (2022) Recent progress on biomass waste derived activated carbon electrode materials for supercapacitors applications—A review. J Energy Storage 54(13): 105290.

- X Huang, (2009) Fabrication and properties of carbon Materials (Basel) 2(4): 2369-2403.

- H Chen, D Liu, Z Shen, B Bao, S Zhao, et al. (2015) Functional Biomass Carbons with Hierarchical Porous Structure for Supercapacitor Electrode Materials. Electrochim Acta 180.

- N Choudhary, C Li, J Moore, N Nagaiah, L Zhai, et al. (2017) Asymmetric Supercapacitor Electrodes and Devices. Adv Mater 29(21).

- G Muungani, MN Pillay, WE van Zyl (2023) The mineral manaksite, KNaMnSi4O10, as a supercapattery- type electrochemical energy storage material. RSC Adv 13(38): 26732-26743.

- BR Babu, M Arivanandhan, R Jayavel (2023) Fabrication of coin cell supercapattery device using morphology-controlled nickel cobaltite nanostructures as active J Energy Storage 74: 109227.

- B Raghavendra Babu, R Sasikumar, M Arivanandhan, R Jayavel (2025) Functionalised carbon fiber based flexible symmetric supercapacitors with wider potential window for sustainable energy storage applications. J Power Sources 625:

- C Chen, D Yu, G Zhao, B Du, W Tang, et al. (2016) Three-dimensional scaffolding framework of porous carbon nanosheets derived from plant wastes for high-performance supercapacitors. Nano Energy 27.

- Y Li, G Wang, T Wei, Z Fan, P Yan (2016) Nitrogen and sulfur co-doped porous carbon nanosheets derived from willow catkin for supercapacitors. Nano Energy 19: 165-175.

- L Sun, C Tian, M Li, X Meng, L Wang, et al. (2013) From coconut shell to porous graphene- like nanosheets for high-power supercapacitors. J Mater Chem A 1(21): 6462-6470.

- VC Hoang, LH Nguyen, VG Gomes (2019) High efficiency supercapacitor derived from biomass based carbon dots and reduced graphene oxide composite. J Electroanal Chem 832: 87-96.

- T Purkait, G Singh, M Singh, D Kumar, RS Dey (2017) Large area few-layer graphene with scalable preparation from waste biomass for high-performance Sci Rep 7(1): 15239.

- N Rey-Raap, M Enterría, cio Martins, MR Fernando Pereira, L Figueiredo (2019) Influence of Multiwalled Carbon Nanotubes as Additives in Biomass-Derived Carbons for Supercapacitor Applications. ACS Appl Mater Interfaces 11(6): 6066-6077.

-

B Raghavendra Babu and Anil Kumar Sarma*. Biomass Derived Nanocarbon for Supercapacitor Fabrication. Insi in Chem & Biochem. 3(2): 2025. ICBC. MS.ID.000559.

-

Biochemical, Nutritional Value, Balanites, Aegyptiaca, Laloub, Seed Oil, Biochemistry, protein, Physicochemical, chloroform, benzene, diethyl.

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.