Mini Review

Mini Review

Engineered Nanocomposites for Critical Thermal Management Needs – Opportunities and Challenges

Li Cao1*, Buta Singh2, Mohammed J. Meziani3* and Ya-Ping Sun2*

1Department of Chemical and Materials Engineering, University of Dayton, Dayton, OH 45469, USA

2Department of Chemistry, Clemson University, Clemson, SC 29634, USA

3Department of Natural Sciences, Northwest Missouri State University, Maryville, MO 64468, USA

Li Cao, Department of Chemical and Materials Engineering, University of Dayton, Dayton, OH 45469, USA. Mohammed J. Meziani, Department of Natural Sciences, Northwest Missouri State University, Maryville, MO 64468, USA. Ya-Ping Sun, Department of Chemistry, Clemson University, Clemson, SC 29634, USA.

Received Date:August 28, 2025; Published Date:September 10, 2025

Abstract

Hexagonal boron nitride (h-BN) and graphite are isoelectronic, so are their nanosheets, and they are both highly thermally conductive. However, h-BN derived nanosheets (BNNs) are electronically insulating, thus ideally suited for polymeric nanocomposites of high thermal conductivity but no electrical conductivity for a variety of critical thermal management needs. Highlighted here are advances in the development of polymer/BNNs composites and devices, excellent opportunities for further improvements, and also technical and other challenges, especially with the growing applications of 3D printing techniques.

Mini Review

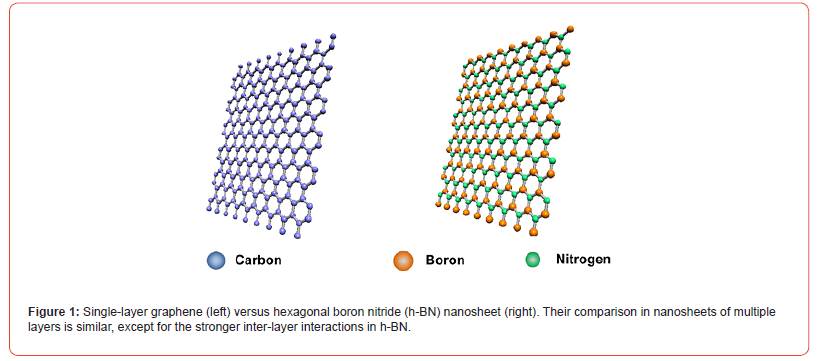

In the era of rapid advancement in transformative technologies, including especially artificial intelligence (AI), big data, advanced semiconductor chips, and the growing popularity of electric vehicles (EVs), there are enormous demands for and consumptions of energies, which are accompanied by the heat generation as a troubling or even in some cases prohibitive byproduct. Thus, in equally high demand are enabling thermal management (TM) technologies for the effective heat transport and dissipation, which are dependent on materials of high thermal conductivity (TC), including metals such as aluminum and copper and some carbon-based materials. For example, various combinations of aluminum and graphite are used for cooling the batteries in many EVs. However, graphite and even aluminum could become fuels at high temperatures, and their high electrical conductivity (EC) might disqualify their uses as thermal interface materials (TIMs) in chips and other devices. In this regard, isoelectronic with graphite and also of a similar layered structure is hexagonal boron nitride (h-BN), nicknamed white graphite, whose decoupled thermal and electric transport properties (high TC but no EC) are uniquely suited for TM applications. Indeed, h-BN nanosheets (BNNs, Figure 1) and their polymeric composites are being actively investigated, with some major advances already achieved [1-25].

Few-layer BNNs are mostly produced from the exfoliation of h-BN, for which the vigorous sonication of h-BN in isopropanol (IPA) as a preferred solvent has been popular [24-26]. Further improvements in the exfoliation efficiency and in the quality of the resulting BNNs, characterized by their larger aspect ratios and smooth surfaces, could be achieved by adding aqueous ammonia to IPA for the sonication [25, 27]. However, the inter-layer force is significantly stronger in h-BN than in graphite, making the exfoliation of h-BN more difficult and the resulting BNNs not as well defined nanosheets as their carbon counterparts. Beyond the commonly employed vigorous sonication, other processing tools and/ or conditions might be explored for the right level of shear forces to produce BNNs of better qualities and in higher yields.

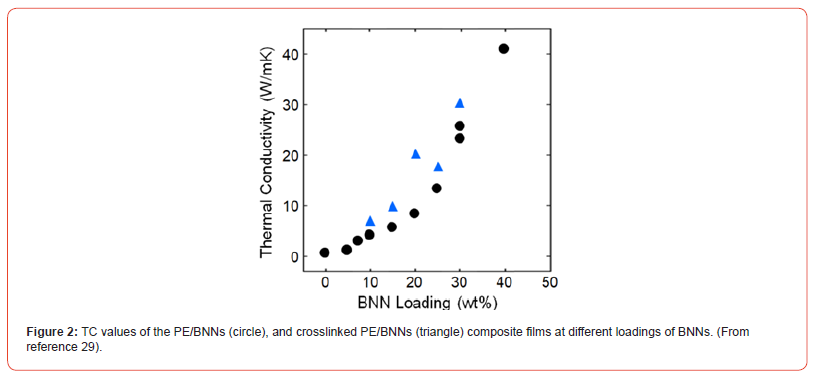

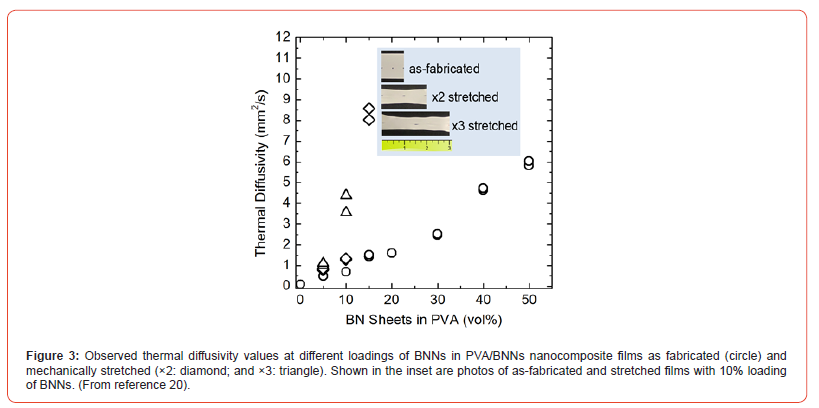

BNNs as planar nanofillers are anisotropic in thermal transport, with much higher in-plane TC than cross-plane TC. Therefore, more popular have been their uses in polymeric nanocomposite films designed for high in-plane TCs. Wet casting has been a convenient method for the fabrication of polymer/BNNs composite films, in which the filler BNNs are driven to align in the film plane, thus the observed high in-plane TC values [20, 28, 29]. For example, the dispersion of BNNs into polyethylene (PE) for PE/BNNs composite films resulted in monotonically increasing in-plane TCs with higher BNNs loadings (Figure 2) [29]. The crosslinking in the composite films could apparently enhance the TC performance significantly (Figure 2) [29]. A more effective strategy for further in-plane alignment of BNNs in composite films, such as those of poly (vinyl alcohol) (PVA) as the matrix polymer, is to apply the needed shear force with mechanical stretching of the films, resulting in substantially higher in-plane TCs (Figure 3) [20, 30]. As might be expected, the enlarged in-plane TCs associated with the more effective in-plane alignment of BNNs in the composite films are at the expenses of cross-plane TCs in the same films, generally with the cross-plane/ in-plane TC ratios lowered to less than 10%, which could serve as an indicator of how well the filler BNNs in composite films are inplane aligned. Among other shear force induced alignment methods for polymer/BNNs composite films of enhanced in-plane TCs is mechanical extrusion of the films [14, 31].

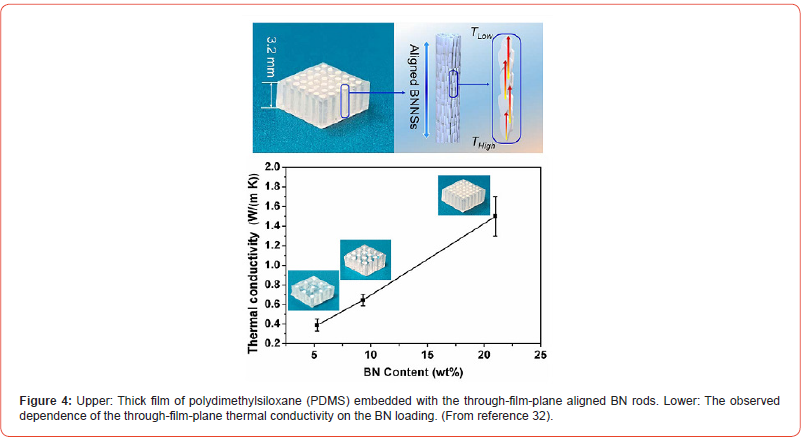

3D printing has emerged to represent an effective and versatile fabrication method for nanocomposites and related devices. Naturally it has been employed for the preparation of polymer/BNNs composite films for in-plane thermal transport purposes. Some of the more popular printing methods are limited to or more suitable for composite films of relatively low loadings of BNNs, offering advantages over simple wet casting in terms of more versatile and controllable fabrications, though in terms of in-plane TC performances the potential for major improvements seems limited. There are also other printing methods capable of preparing films with high loadings of BNNs, somewhat analogous to a more controlled extrusion method. Nevertheless, 3D printing should in principle be majorly advantageous for the fabrication of composite films and structures in which the filler BNNs are cross-plane aligned for high cross-plane thermal transport [32-35], because such composite configurations are pretty much beyond the capability of conventional wet casting. Illustrated in Figure 4 is a representative 3D printing fabrication of films (3.2 mm in thickness) in which the filler BNNs are cross-plane aligned in the embedded rod structures, with the observed TCs increasing linearly with loadings of BNNs (Figure 4) [32]. However, the TC of only 1.5 W/mK at >20 wt/% loading of BNNs leaves a lot of room for improvements.

In fact, the need for major performance improvements represents

a general challenge for 3D printing of polymer/BNNs composites

designed for TM applications. For such a challenge, specifically

developed and implemented printing strategies and protocols

are in demand for addressing the critical issues associated with the

challenge. The aimed improvements include:

(i) To make the printed structures more dense via reducing

voids and porosity and enhancing the interfacial bonding between

the polymer matrix and filler BNNs. For example, the

voids and structural discontinuities could be minimized by improving

the filler dispersion, optimizing the viscosity of feedstocks,

adjusting various printing parameters (layer height,

hatching space, printing speed, temperature, etc.), and applying

suitable post-processing techniques such as annealing or infiltration

to densify the printed parts.

(ii) To push for the uniform dispersion of BNNs within the

polymer matrix during the feedstock preparation and the subsequent

printing process. Strategies for the uniform dispersion

include the use of BNNs that are surface functionalized with

molecules fully compatible with the matrix polymer, the selection

of suitable solvents or dispersing agents, and the energetic

shear mixing.

(iii) To reduce and minimize the anisotropy and discontinuities

arising from the layer-by-layer deposition in the printing.

(iv) To reach high filler loading, for which the associated high

viscosity in the feedstock might impede the homogeneous flow

and deposition during printing, thereby reducing processability

and uniformity. Several mitigation strategies could be applied

by balancing the filler content with rheological properties

(leveraging non-Newtonian shear-thinning flow behavior in

the fabrication process), using hybrid filler systems, adjusting

printing temperature, and adding dispersing agents or rheology

modifiers to maintain processability while preserving the

desired mechanical or functional properties.

(v) To enable the fabrication of the composites in special form

factors, especially ultra-thin films in which BNNs are cross-filmplane

aligned for thermal transport needs in some high-end

electronic devices, as most commercially available systems are

not designed for such fine structures that require high precision.

Nevertheless, there are promising developments in the

relevant research field that are applicable to the printing of the

ultra-thin films, including strategies for the precise control over

deposition methods, the vat photopolymerization process with

two-photon excitation, micro-extrusion, inkjet printing, and

electrohydrodynamic printing.

In summary and conclusion, polymer/BNNs composites in various form factors engineered for high in-plane or cross-plane TCs but electrically insulating have shown great promises. Further rapid and broad developments of these materials and their derived devices for much improved performances, driven by the critical thermal management needs in some of the most exciting current and emerging technologies, may be envisaged.

Acknowledgement

Institutional supports of L.C. by University of Dayton and M.J.M. by Northwest Missouri State University are gratefully acknowledged.

Conflicts of Interest

No Conflict of Interest.

References

- Meziani M J, Song W L, Wang P, Lu F, Hou Z, et al. (2015) Boron nitride nanomaterials for thermal management applications. ChemPhysChem 16(7): 1339-1346.

- Pakdel A, Bando Y, Golberg D (2014) Nano boron nitride flatland. Chem Soc Rev 43(3): 934-959.

- Meng W, Huang Y, Fu Y Q, Wang Z, Zhi C, et al. (2014) Polymer composites of boron nitride nanotubes and nanosheets. J Mater Chem C 2(47): 10049-10061.

- Luo W, Wang Y, Hitz E, Lin Y, Yang B, et al. (2017) Solution processed boron nitride nanosheets: synthesis, assemblies and emerging applications. Adv Funct Mater 27(31): 1701450.

- Yu C, Zhang J, Tian W, Fan X, Yao Y, et al. (2018) Polymer composites based on hexagonal boron nitride and their application in thermally conductive composites. RSC Adv 8(39): 21948-21967.

- Guerra V, Wan C, McNally T (2019) Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Progress in Materials Science 100: 170-186.

- Aparna A, Sethulekshmi A S, Jayan J S, Saritha A, Joseph K, et al. (2021) Recent advances in boron nitride based hybrid polymer nanocomposites. Macromol Mater Eng 306(11): 2100429.

- Roy S, Zhang X, Puthirath A B, Meiyazhagan A, Bhattacharyya S, et al. (2021) Structure, properties and applications of two-dimensional hexagonal boron nitride. Adv Mater 33(44): e2101589.

- Meziani M J, Sheriff K, Parajuli P, Priego P, Bhattacharya S, et al. (2022) Advances in studies of boron nitride nanosheets and nanocomposites for thermal transport and related applications. ChemPhysChem 23(1): e202100645.

- Khan A, Puttegowda M, Jagadeesh P, Marwani H M, Asiri A M, et al. (2022) Review on nitride compounds and its polymer composites: a multifunctional material. J Mater Res Technol 18: 2175-2193.

- Wu M, Zhou Y, Zhang H, Liao W (2022) 2D boron nitride nanosheets for smart thermal management and advanced dielectrics. Adv Mater Interfaces 9(25): 2200610.

- Mazumder M R H, Mathews L D, Mateti S, Salim N V, Parameswaranpillai J, et al. (2022) Boron nitride-based polymer nanocomposites for heat dissipation and thermal management applications. Applied Materials Today 29: 101672.

- An L, Yu Y, Cai Q, Mateti S, Li L H, et al. (2023) Hexagonal boron nitride nanosheets: preparation, heat transport property and application as thermally conductive fillers. Progress in Materials Science 138: 101154.

- Singh B, Han J, Meziani M J, Cao L, Yerra S, et al. (2024) Polymeric nanocomposites of boron nitride nanosheets for enhanced directional or isotropic thermal transport performance. Nanomaterials 14(15): 1259.

- Jiang H, Cai Q, Mateti S, Bhattacharjee A, Yu Y, et al. (2024) Recent research advances in hexagonal boron nitride/polymer nanocomposites with isotropic thermal conductivity. Advanced Nanocomposites 1(1): 144-156.

- Li M, Han S, Dan C, Wu T, You F, et al. (2025) Boron nitride–polymer composites with high thermal conductivity: preparation, functionalization strategy and innovative structural regulation. Small 21(20): 2412447.

- Zhi C, Bando Y, Tang C, Kuwahara H, Golberg D, et al. (2009) Large-scale fabrication of boron nitride nanosheets and their utilization in polymeric composites with improved thermal and mechanical properties. Adv Mater 21(28): 2889-2893.

- Sato K, Horibe H, Shirai T, Hotta Y, Nakano H, et al. (2010) Thermally conductive composite films of hexagonal boron nitride and polyimide with affinity-enhanced interfaces. J Mater Chem 20(14): 2749-2752.

- Zhi C, Xu Y, Bando Y, Golberg D (2011) Highly thermo-conductive fluid with boron nitride nanofillers. ACS Nano 5(8): 6571-6577.

- Song W L, Wang P, Cao L, Anderson A, Meziani M J, et al. (2012) Polymer/boron nitride nanocomposite materials for superior thermal transport performance. Angew Chem Int Ed 51(26): 6498-6501.

- Tanimoto M, Yamagata T, Miyata K, Ando S (2013) Anisotropic thermal diffusivity of hexagonal boron nitride-filled polyimide films: effects of filler particle size, aggregation, orientation, and polymer chain rigidity. ACS Appl Mater Interfaces 5(10): 4374-4382.

- Huang X, Zhi C, Jiang P, Golberg D, Bando Y, et al. (2013) Polyhedral oligosilsesquioxane-modified boron nitride nanotube-based epoxy nanocomposites: an ideal dielectric material with high thermal conductivity. Adv Funct Mater 23(14): 1824-1831.

- Tsai M H, Tseng I H, Chiang J C, Li J J (2014) Flexible polyimide films hybrid with functionalized boron nitride and graphene oxide simultaneously to improve thermal conduction and dimensional stability. ACS Appl Mater Interfaces 6(11): 8639-8645.

- Tao H, Zhang Y, Gao Y, Sun Z, Yan C, et al. (2017) Scalable exfoliation and dispersion of two-dimensional materials-an update. Phys Chem Chem Phys 19(2): 921-960.

- Wang Z, Meziani M J, Patel A K, Priego P, Wirth K, et al. (2019) Boron nitride nanosheets from different preparations and correlations with their material properties. Ind Eng Chem Res 58(40): 18644-18653.

- Coleman J N, Lotya M, O’Neill A, Bergin S D, King P J, et al. (2011) Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 331(6017): 568-571.

- Cao L, Emami S, Lafdi K (2014) Large-scale exfoliation of hexagonal boron nitride nanosheets in liquid phase. Mater Express 4(2): 165-171.

- Wang T, Wang M, Fu L, Duan Z, Chen Y, et al. (2018) Enhanced thermal conductivity of polyimide composites with boron nitride nanosheets. Sci Rep 8(1): 1557.

- Wang Z, Priego P, Meziani M J, Wirth K, Bhattacharya S, et al. (2020) Dispersion of high-quality boron nitride nanosheets in polyethylene for nanocomposites of superior thermal transport properties. Nanoscale Adv 2(6): 2507-2513.

- Tu H, Xie K, Lin X, Zhang R, Chen F, et al. (2021) Superior strength and highly thermoconductive cellulose/boron nitride film by stretch-induced alignment. J Mater Chem A 9(16): 10304-10315.

- Chen Y, Gao Z, Hoo S A, Tipnis V, Wang R, et al. (2024) Sequential dual alignments introduce synergistic effect on hexagonal boron nitride platelets for superior thermal performance. Adv Mater 36(25): 2314097.

- Liang Z, Pei Y, Chen C, Jiang B, Yao Y, et al. (2019) General, vertical, three-dimensional printing of two-dimensional materials with multiscale alignment. ACS Nano 13(11): 12653-12661.

- Gao J, Hao M, Wang Y, Kong X, Yang B, et al. (2022) 3D printing boron nitride nanosheets filled thermoplastic polyurethane composites with enhanced mechanical and thermal conductive properties. Additive Manufacturing 56: 102897.

- Gorur M C, Doganay D, Durukan M B, Cicek M O, Kalay Y E, et al. (2023) 3D printing of hexagonal boron nitride nanosheets/polylactic acid nanocomposites for thermal management of electronic devices. Composites Part B: Engineering 265: 110955.

- Bagatella S, Guida L, Scagnetti G, Gariboldi E, Salina M, et al. (2025) Tailoring thermal conductivity and printability in boron nitride/epoxy nano- and micro-composites for material extrusion 3D printing. Polymer 317: 127899.

-

Li Cao*, Buta Singh, Mohammed J. Meziani* and Ya-Ping Sun*. Engineered Nanocomposites for Critical Thermal Management Needs – Opportunities and Challenges. Glob J Eng Sci. 12(2): 2025. GJES.MS.ID.000783.

-

3D printing techniques, Transformative technologies, Thermal transport, Electrohydrodynamic printing, Materials, Micro-extrusion, Hybrid filler systems, TM applications, Electric vehicles

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.