Review Article

Review Article

Durability of Sand Concrete Based on Marble Mineral Admixture in Sulfate Environment

Yasmina Biskri*, Ouided Dehas and Laidi Babouri

High School of Technological Education (ENSET)-Skikda, Algeria

Yasmina Biskri, High School of Technological Education (ENSET)-Skikda, Algeria.

Received Date:September 09, 2023; Published Date:October 18, 2023

Abstract

The durability of the concrete depends on the porosity of the microstructure, the latter conditions the degree of the reactions of the concrete with the aggressive agents.

The recovery of waste in the form of fibers and the recovery of local by-products in the form of mineral additions in the manufacture of a new range of sand concrete and the improvement of their properties, will lead to the search for a compromise between performance and cost in order to obtain a solid material with increased durability.

The main objective of this work is to study the evolution of the mechanical resistance and the microstructure of sand concretes based on mineral additions (marble filler) preserved in a medium rich in magnesium sulphate.

The first part of this study focuses on the effect of the mineral addition of marble filler as well as the content of PET fibers on the physiomechanical and microstructural properties of sand concretes.

The second part concerns the durability of sand concrete stored in an environment rich in magnesium sulphate.

The results obtained show that the physio-mechanical properties of sand concretes vary according to the incorporation of marble filler and PET fibers in these concretes.

The use of marble filler as a mineral admixture for sand concretes is beneficial to reduce porosity and improve the durability of sand concretes, especially in an environment with a high content of magnesium sulphate.

Keywords:Sand concrete; Marble; PET fiber; Sulphate attack; Mechanical strength; Microstructure

Introduction

Sand concrete, through its current design, its simplicity of manufacture and installation, its competitive cost price, its mechanical performance and its durability, constitutes a new advance for concrete construction and it offers advantages economic, technical, aesthetic and even ecological.

The diversification and improvement of the performance and durability of construction materials and their adaptation to the climate and environment of each region as well as the reduction to the maximum of the costs of carrying out the works are the most sought-after objectives in the building sector and public works [1].

Several parameters such as the Water / Cement ratio, the nature and dosage of cement and mineral additions, type and size of aggregates influence the quality of concrete, in particular mechanical strength and durability. These are still the most important factors for judging the quality of concrete.

Several research works have been carried out on sand concrete in order to reduce its drawbacks as much as possible and to improve its durability and mechanical performance by correcting the granular extent, choosing the type and dosage of fines of mineral addition or addition, addition of adjuvants [1-3].

To ensure the durability of cementitious materials, we need to focus not only on the formulation and manufacturing methods, but also on the environmental conditions. All external environments are considered aggressive to cement matrix [2].

External sulphate attacks covering all cementitious materials degradation phenomena in which aggressive agent is sulfate ion (SO42− )coming from the surrounding medium for example: seawater, soil rich in gypsum, underground water [4].

These attacks are associated with precipitation of secondary sulphate products, a significant expansion and physical chemical and mechanical deterioration (changes in transport properties of porosity, cracking, loss of strength and cohesion) [5].

The chemical attack of cementitious materials is mainly carried out on portlandite Ca(OH)2 contained in the cement paste. The attack of silicates and hydrated lime aluminate C-S-H and CAH is not negligible where there is formation of gypsum and secondary ettringite as well as thaumasite from the surface exposed to sulphate.

Several studies have been made to demonstrate the phenomenon of degradation of cementitious materials in sulphatic environments. Some research [6-8], shows that there are many parameters which affect this degradation, namely the type and the concentration of the etching solution as well as temperature. They demonstrated that the magnesium sulphate solution MgSO4 is more aggressive than the sodium sulphate solution Na2SO4 and the increase in temperature accelerates the attack of these sulphates.

In recent years, several researchers have studied the effects of different plastic wastes on the properties of concrete. Among the most commonly used plastic wastes for concrete reinforcement are polyethylene terephthalate (PET) bottle wastes [9-11], polyethylene (PE) bag wastes [12], polyvinyl alcohol (PVA) fibres [13] and polypropylene (PP) fiber wastes [14, 15]. These plastic wastes are likely to be used as fibrous material in the production of durable concrete to prevent micro-cracking and improve the durability of concrete [16-18].

This study deals with the valorization of plastic waste in the form of PET fibres which is available in huge quantities in our country replacing polypropylene fibres which are expensive fibres and the use of marble as filler. The influence of these fibres and marble filler on the physical-mechanical properties of sand concrete specimens preserved in an environment rich in magnesium sulphate was examined.

Materials and Method

Binders

The binders used were Portland cement CEM II 42.5/A as classified by the European Standard EN 197-1 [19] and a mineral admixture which is the white marble dust waste is collected from the Filfila quarry in Algeria (Figure 1). The crushed marble waste was prepared at the Geomaterials and Environment Materials laboratory of the University of Annaba. A ball mill with a capacity of 10 kg was used for grinding. The time of crushing was kept constant during the procedure. Table 1 describes the various chemical and physical-mechanical properties of cement and mineral admixture.

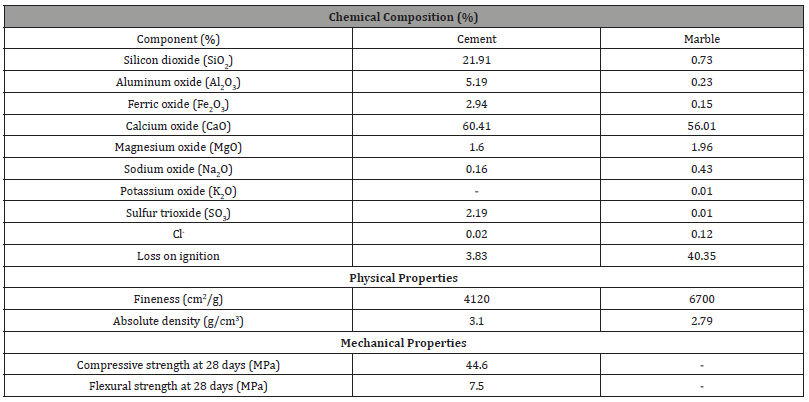

Table 1:Chemical and physical-mechanical properties of cement and mineral admixture.

Aggregates

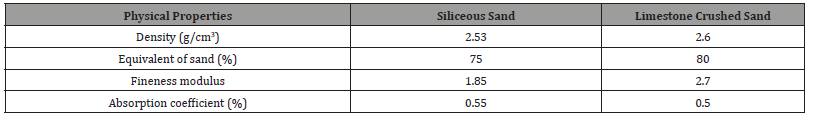

Two different size fractions of 0/2 mm fine siliceous sand and 1.25/5 mm limestone crushed sand of aggregates were used. Table 2 describes the physical properties.

Table 2:Physical properties of sand.

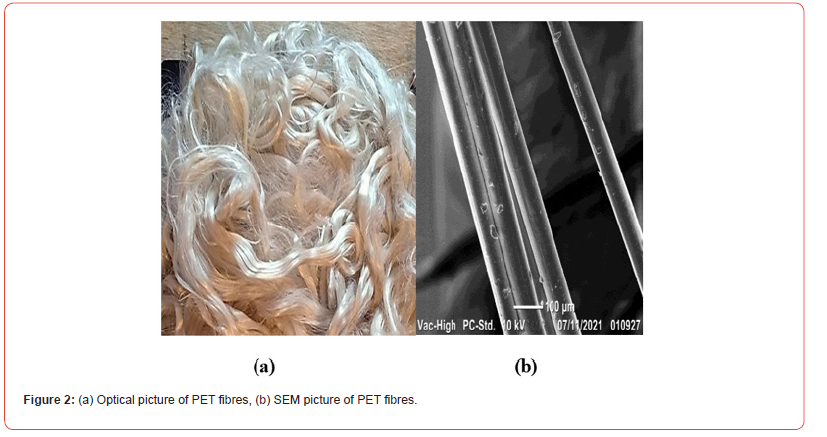

PET fibres

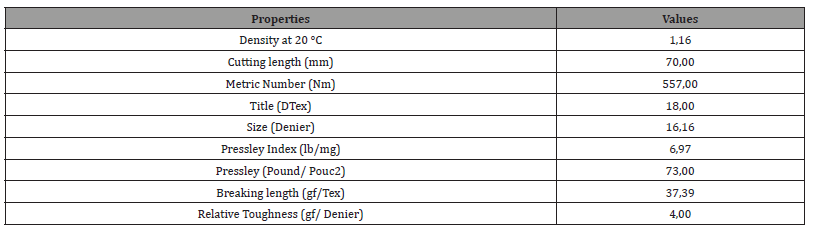

In our study we used PET fibres supplied by the company RET-PLAST, located in the region of Mezloug-Sétif (Algeria), which specializes in the recycling of post-consumer PET bottles in the form of polyester fibres (Figure 2).

The characterized PET fibre at the Mediterranean Wires (MediFil) company in Hammam Guergour (Bouga-Setif), gave us the physical and mechanical properties summarized in Table 3.

Table 3:Physical and mechanical properties of PET fibre.

Adjuvant

The adjuvant used is a highly water-reducing super-plasticizer marketed by the Algerian company Granitex under the name ‘MEDAPLAST SP 40 in liquid form with a color brown and a PH of 8,2, The density of this adjuvant is 1,20.

Sulfates

The solution of sulphate attack used is a magnesium sulfate solution (MgSO4.7H2O), concentration of 50 g/l.

Concrete mixtures

In our study, the formulation approach used is the one defined in the SABLOCRETE draft of the revised standard P 18-500 “sand concrete” set out in the book entitled “concretes of sand: characterizations and practice of use” [20].

Technical and experimental procedure

The experimental study was carried out on prismatic specimens of dimensions (4 × 4 × 16) cm3 according to the European standard EN 12390-1 [21]. The approach of this comparative study is to quantify over time the resistance to external sulphate attacks characterized by the physio-mechanical and microstructural degradation of sand concrete with marble as a mineral adjuvant, preserved in water and in a sulphate solution. of magnesium-water (MgSO4.7H2O) concentration of 50g/l according to standard NF P18- 837 [NF P18-837, 1993] with renewal of the solutions and control of the PH at saturated humidity HR= 100% and at a temperature of 20 ±2°C until the end of the various tests.

The evolution of mechanical strength with time is obtained by exploiting the flexural strength and compression on specimens produced according to European standards NF EN 12390-5 [22] and EN 12390- 3 [23].

The mass loss of the samples according to the three conservation methods is carried out on prismatic specimens of dimension (4 × 4 × 16) cm. Weighing is carried out using an electronic scale. The loss of mass is determined according to the following formula:

LM: Loss of mass in % M1: mass of the specimen after demolding in (g) M2: mass of the test piece at different times in (g)

Results and Discussion

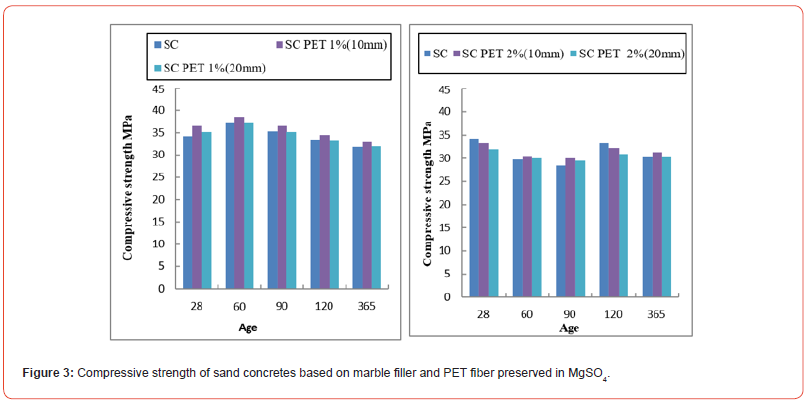

Compressive strength

The effect of the level of marble filler on the mechanical compressive strength of sand concretes preserved directly in a solution of magnesium sulphate MgSO4 is illustrated by Figure 3.

According to Figure 4, we observe that the compressive strength shows a slight drop in strength after 28 days for the control sand and fiber concretes. At 60 days, a gain in compressive strength was recorded by increasing the compressive strength to 28 days. This gain in resistance is probable with the addition of 10% marble filler which can slightly improve this resistance. It is also noted that the compressive strengths are not affected by sulphate attack, this can be explained by the formation of brucite Mg(OH)2 on the outer layer of the specimens in the sulphate which can prevent the penetration of ions sulphate. After 90 days, there is a decrease in mechanical strength for all the sand concretes studied.

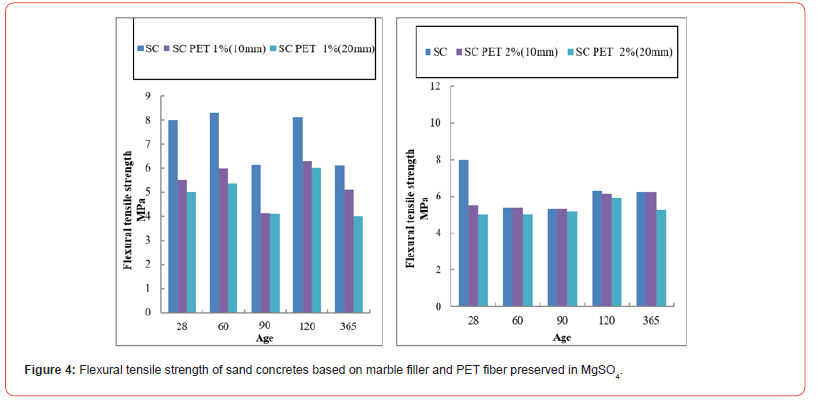

Flexural tensile strength

According to Figure 4, it can be seen that the tensile strength by bending is reduced compared to the 28-day strength of concrete with control sand and with fibres. At the age of 60 days, a gain in tensile strength of all types of concrete was recorded. This strength gain is likely due to the addition of 10% marble filler which may slightly improve this strength and by the formation of brucite Mg(OH)2 on the outer layer of the specimens exposed in the sulphate which may prevent the penetration of sulphate ions. After 90 days, there is a decrease in the mechanical resistance in tension by bending for all the sand concretes studied. For the control sand concrete, the drop in strength after one year of storage is around 12%. Adding PET fibers does not change the shape of the curve.

Mass variation

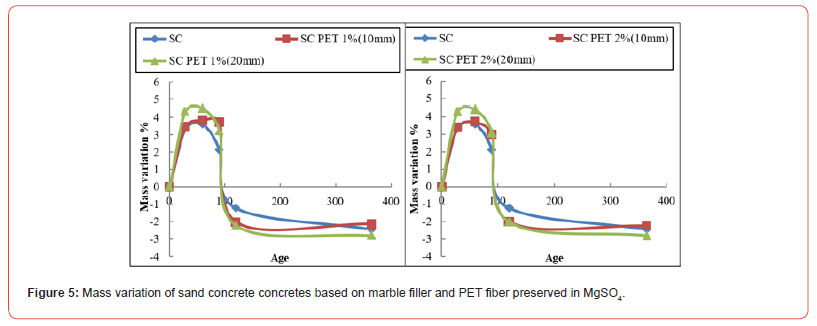

According to figure 5, it can be seen that all the concretes studied show the same mass variation patterns.

At the age of 28 days up to 90 days, a significant increase in mass is observed for all the control and fiber-reinforced sand concretes preserved directly in the sulphate solution after demolding.

This increase is obtained following the formation of brucite Mg(OH)2, ettringite and secondary gypsum which results from the reaction between portlandite Ca(OH)2 and MgSO4 in the presence of water. This reaction is accompanied by swelling followed by damage to the mortar samples.

After 90 days, there is a gradual decrease in mass with storage age. This mass loss is due to the leaching of portlandite Ca(OH)2.

Conclusion

The main conclusions of the study should be summarized in a short Conclusions section.

A drop in mechanical resistance was recorded for all the sand concrete studied preserved in a solution of magnesium sulphate MgSO4 for more than 90 days. This fall is mainly due to the formation of gypsum and secondary ettringite which causes expansion. This promotes the birth and growth of cracks followed by a drop in mechanical strength.

During the period up to 90 days, the mechanical resistances are slightly affected by the external sulphate attack. This is explained by the formation of a layer of brucite Mg(OH)2 on the external surfaces of specimens stored in sulphate solution which temporarily delays the effect of sulphate ions and allows the continuity of the hydration kinetics.

PET fibers have no effect on the variation of the mechanical resistance of sand concretes stored in an aggressive environment and PET fibers are not affected and do not undergo any degradation.

Acknowledgement

None.

Conflicts of Interest

No conflict of interest.

References

- FZ Melais (2016) Durabilité des bétons de sable fibres dans les Différents milieux agressifs effets de la nature des fines d’ajouts et fibres. Mémoire de doctorat, Université Badji mokhtar Annaba, Algérie.

- Achoura D, Redjel B, Jauberthie R (2009) Durability of sandcretes based blast furnace slag in sulphatic attack. 1st International Conference on Sustainable Built Environment Infrastructures in Developing Countries ENSET Oran (Algeria) 12-14: 7p.

- YasminaB, Mohamed B, Laidi B, Ouided D, RedjemB (2022) Valorization and recycling of packaging belts and post-consumer PET bottles in the manufacture of sand concrete 62: 225-239.

- Rozière E, Loukili A, El Hachem R, Grondin F (2009) Durability of concrete exposed to leaching and external sulphate attacks. Cement and Concrete Research 39(12): 1188-1198.

- Kelifa MR (2009) Effet de l’attaque sulfatique externe sur la durabilité des bétons autoplaçants. thèse de doctorat. Constantine University and University d'Orleans, 173p.

- Irassar EF (2009) Sulfate attack on cementitious materials containing limestone fillers - A review. Cement and Concrete Research 39(3): 241-254.

- Benosman AS, Mouli M, Taïbi H, Belbachir M, Senhadji Y, et al. (2009) Etude des matériaux composites mortier-polymère en milieux sulfatiques (Na2SO4, MgSO4). 1st International Conference on Sustainable Built Environement Infrastructures in Developing Countries ENSET, Oran, Algeria 12-14: 8p.

- Patsikas N, Katsiotis N, Pipilikaki P, Papageorgiou D, Chaniotakis E, et al. (2012) Durability of mortars of white cement against sulfate attack in elevated temperatures. Construction and Building Materials 36: 1082-1089.

- Kim SB, Yi NH, Kim HY, Kim JHJ, Song YC (2010) Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cement Concr Compos 32(3): 232-240.

- Foti D (2011) Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr Build Mater 25(4): 1906-1915.

- Bui NK, Satomi T, Takahashi H (2018) Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: an experimental study. Waste Manag 78: 79-93.

- Al-Hadithi AI, Hilal NN (2016) The possibility of enhancing some properties of self-compacting concrete by adding waste plastic fibers. J Build Eng 8: 20-28.

- Passuello A, Moriconi G, Shah SP (2009) Cracking behavior of concrete with shrinkage reducing admixtures and PVA fibers. Cement Concr Compos 31(10): 699-704.

- Mohammadhosseini H, Tahir MM (2018) Durability performance of concrete incorporating waste metalized plastic fibres and palm oil fuel ash. Constr Build Mater 180: 92-102.

- Mohammadhosseini H, Yatim JM (2017) Microstructure and residual properties of green concrete composites incorporating waste carpet fibers and palm oil fuel ash at elevated temperatures. J Clean Prod 144: 8-21.

- Marzouk O, Dheilly R, Queneudec M (2007) Valorization of Post-Consumer Waste Plastic in Cementitious Concrete Composites. Waste Management 27(2): 310-31.

- Bilal Zeb, Mohd Yunus Ishak (2017) The effect of high temperature on concrete containing fibers from recycled plastic bottles, A project report submitted in partial fulfilment of the requirements for the award of the degree of Master of Engineering (Structure), Universiti Teknologi Malaysia.

- Hossein M, Mahmood Md Tahir, Rayed Alyousef, Hisham Alabduljabbar, Mostafa Samadi (2019) Effect of elevated temperatures on properties of sustainable concrete composites incorporating waste metalized plastic fibres, SN Applied Sciences.

- EN 197-1 (2012) Composition, Specifications and Conformity Criteria for Common Cements, AFNOR, La Plaine Saint-Denis, France (in French). Cement - Part 1.

- Sablocrete (1994) Sablocrete, béton de sable: caractéristiques et pratiques d’utilisation », presses de l’école nationale des ponts et chaussées, France, 230p.

- NF EN12390-1 (2001) Essai pour béton durci, partie1: Forme, dimensions et autres exigences relatives aux éprouvettes et aux moules.

- NF EN12390-3 (2000) Essai pour béton durci, partie3: résistance à la compression sur éprouvette.

- NF EN12390-5 (2001) Essai pour béton durci, partie5: résistance à la flexion sur éprouvette.

-

Yasmina Biskri*, Ouided Dehas and Laidi Babouri. Durability of Sand Concrete Based on Marble Mineral Admixture in Sulfate Environment. Glob J Eng Sci. 11(3): 2023. GJES.MS.ID.000761.

-

Sand concrete, Marble, PET fiber, Sulphate attack, Mechanical strength, Microstructure

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.