Case Report

Case Report

Development of a Non-Toxic CubeSat Propulsion System using Water as an Inert Propulsion Storage Medium (PSM)

Gregory E Ogden*

Chemical & Environmental Engineering, University of Arizona, USA 1133 E James E Rogers Way, Room 105E, Tucson, Arizona, 85721, USA

Chemical & Environmental Engineering, University of Arizona, USA 1133 E James E Rogers Way, Room 105E, Tucson, Arizona, 85721, USA

Received Date:October 13, 2025; Published Date:October 24, 2025

Abstract

The increasing number and complexity of CubeSat missions have created a need for on-board propulsion capability for orbital control. These propulsion systems provide guidance navigation and attitude control (GNAC). While several propulsion processes exist, most have characteristics that make them sub-optimal for CubeSat applications such as fuel toxicity, large size and weight, fuel volatility, low specific thrust or needing pressurized propellant tanks. Mitigating these risks increases mission costs, which is contrary to the fundamental CubeSat concept-providing lowcost access to space. An alternate CubeSat propulsion system is proposed that is based using inert water as the propellant storage medium (PSM). Once in orbit, the water is electrolyzed, generating hydrogen and oxygen for thrust generation. A 0.2N CubeSat thruster design can produce a V exceeding 2700 m/s more than sufficient for GNAC requirements.

Keywords:CubeSats; Non-toxic Propellants; Electrolysis; Propulsion Storage Medium

Abbreviations 1U: Base size of CubeSat module representing a 10cm cube; Al: Aluminum; Ar: Argon; COTS: Commercial-off-the-Shelf; GNAC: Guidance, Navigation and Attitude Control; H2: Elemental Hydrogen; I: Iodine; Isp: Specific Impulse, the ratio of thrust produced per amount of propellant, has units of Seconds; Kr: Krypton; N: Unit of Force; Ni: Nickel; NTO: Nitrogen Tetroxide; O: Elemental Oxygen; psig: Gauge Pressure; PSM: Propellant Storage Medium; SO2: Sulfur Dioxide; Xe: Xenon; ΔV: Change in Velocity, represents impulse needed to change a satellite’s orbit; : Thrust, a force produced by expellant propellant from a nozzle that pushes a satellite forward.

Introduction

Deployment of CubeSats have increased exponentially over the past decade. Currently nearly three quarters of these deployments have communications-focused missions. As CubeSat utilization increases, the need for divert and attitude control capabilities also increases requiring the addition of propulsion systems in the micro satellite platform. Propellant technologies used in conventional satellites and the heavy-launch vehicles used to transport the CubeSats into orbit often use toxic propellants, have high-power demands or do not produce sufficient thrust for orbital maneuvering. This paper proposes an alternate propulsion technology that uses water as an inert propulsion storage medium (PSM) that is electrolyzed once the CubeSat is in orbit into hydrogen and oxygen which can be used for divert and attitude control. Use of a PSM propulsion system can greatly reduce costs and risks related to CubeSat fabrication, transportation to the launch site and launch.

Case Presentation

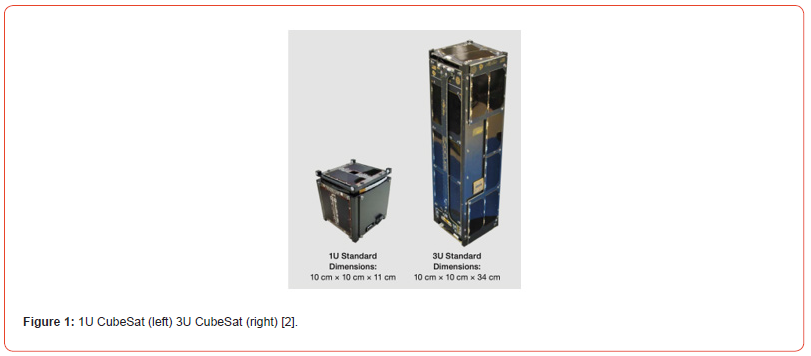

CubeSats, first launched in 2003, were the brainchild of professors Jordi Puig-Suari and Bob Twiggs. In 1999, these professors envisioned CubeSats as a low-cost means of accessing space with fast development windows enabling space-based research for graduate research [1]. CubeSat configurations are based on a 10-centimeter cube. This base module is referred to as a 1U CubeSat. The modular CubeSat platform has greatly reduced fabrication and development costs and significantly increased access to space using affordable spacecrafts. The modular configuration also allows for more diverse and complex missions through combining multiple modules. Examples of 1 U and 3 U CubeSats are depicted in Figure 1. Due to their standardized aspects, companies can mass produce components and offer commercial off-the-shelf (COTS) parts. This allows CubeSat design to be less costly and very customizable [2]. A concise summary of the history of CubeSats can be found at Microsat Blitz [1].

CubeSats are classified as nanosatellites based on size and weight constraints. Their modular formfactor and the availability of low-cost, flight certified COTS components have created explosive growth in the CubeSat market. There were over 2800 CubeSat launches in 2023 a mere 20 years after the first CubeSat launch [3]. The increased interest in CubeSats has also dramatically changed hardware architectures and approach to space applications. In the mid 2010’s, approximately 50% of CubeSat missions focused on remote sensing. However, within the past 10 years, the use of CubeSat constellations such as those operated by Starlink and OneWeb for communications applications has skyrocketed. Communications applications currently account for over 75% of current nanosatellite missions [3].

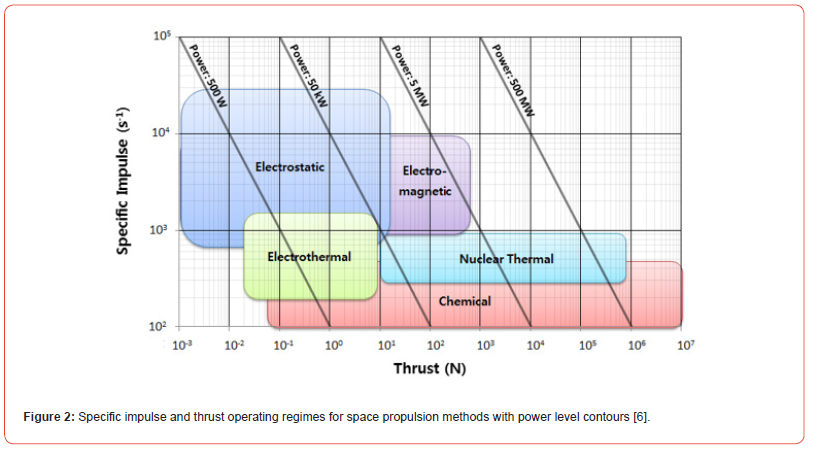

As CubeSat missions have shifted to longer and more complex missions, the need for CubeSat propulsion technologies has increased to maintain orbit, increase attitude as well as provide navigation control [4]. Propulsion systems serve a myriad of purposes in spacecraft including LEO maneuverability. Propulsion systems can also help extend the lifetime of satellites and facilitate induced or natural orbit decay caused by the atmosphere near the end of a mission. Common propulsion technologies including chemical, cold gas, electrospray, and vacuum arc thrusters have been launched in the CubeSat platform [5]. A concise summary of CubeSat propulsion technologies can be found in “An Overview of Cube-Satellite Propulsion Technologies and Trends” by Tumalla and Dutta [5]. Each propulsion technology comes with benefits and risks in terms of performance, reliability and mission risk reduction. Propulsion technologies are typically compared via two major performance characteristics: thrust (n) and specific impulse (Isp). Thrust is produced by expelling propellant at high velocities as well as the exhaust pressure at the rocket’s nozzle. Increasing mass flow, system pressure or exhaust temperatures (i.e. hot combustion byproducts) increases thrust. The specific impulse depends on thrust generated and propellant mass flow rate. As shown in Figure 2, electric propulsion technologies can produce very high specific impulse, but at very low thrust, whereas chemical propulsion systems can achieve high thrust but at relatively low Isp.

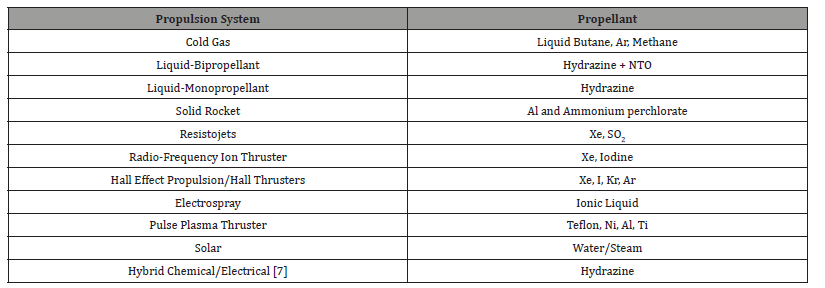

As noted in Tumalla and Dutta’s review, propulsion systems utilized in CubeSats are classified as micro-propulsion units given their relatively low thrust ranging from nano- to micro-Newtons. The major CubeSat thruster categories are electric and non-electric, depending on their reliance on the CubeSat power bus. Electric Systems requiring on-board power include resistojets, electrospray, ion and Hall thrusters, and pulsed plasma systems. Cold gas, liquid and solid propellant systems are classified as non-electric as they only require on board power to initiate/terminate thrust. Common CubeSat propulsion systems and propellants are presented in Table 1.

Table 1:Examples of micro propulsion systems and their propellants.

Table Abbreviations: Al: Aluminum; Ar: Argon; I: Iodine; Kr: Krypton; Ni: Nickel; NTO: Nitrogen Tetroxide; SO2: Sulfur Dioxide

Cold gas systems are reliable but require high pressure tanks increasing satellite weight and costs. Electronic propulsion including Hall Thrusters and ‘electrospray’ systems require volatile metal propellants such as sodium which can off-gas and coat control valves during the standby/wait period between final satellite assembly and mission launch impacting overall performance. Chemical propulsion technologies include both bipropellant and monopropellant systems. Bipropellant systems include a fuel and an oxidizer that react in a combustion chamber to produce hot gases that are subsequently expelled through a converging-diverging nozzle to produce thrust. In monopropellant propulsion, the propellant contains both fuel and oxidizer in a stable formulation that typically reacts with a catalyst to produce the high-temperature reaction products used to produce thrust.

While electric change practical to effective technologies can produce extremely high Isp’s, they are not practical for maneuvering in low-earth orbit that can require regular attitude control operations to maintain desired orbits and to avoid other satellites or space debris. Thus, practical CubeSat navigation systems include cold-gas or chemical propulsion technologies. Hydrazine has been commonly used for decades in satellite applications and was used in the Space Shuttle positioning thrusters. A major drawback for using hydrazine, especially in low-cost CubeSat applications, is its extreme toxicity. In reality, use of any chemical mono- or bi-propellant system significantly increases risks of hazardous or toxic leaks during launch in the event of failure. Chemical propellants by their nature are reactive with varying degrees of stability, which makes them ideal for controlled propulsion applications, but can have a negative impact on the environment or to human health in the event of an accidental release.

There have been 14 major launch failures over the past decade including three missions each from SpaceX and Rocket Lab, two missions from both AstroLab and Firefly. The remaining failures were attributed to individual company launches from Blue Origin, LandSpace, i-Space and Virgin Orbit [8-20]. These accidents resulted in loss/ destruction of payloads and likely release of propellants from both the launch vehicle and payload.

Discussion

Given the number of launch failures over the past decade and their resulting negative impacts on the environment, it is important to develop inert propulsion technologies for CubeSats. Cold-gas systems are an option, however, ss previously mentioned, their use can be limited due to weight constraints in CubeSat applications. An alternative approach is to create a propulsion system that includes an inert propellant storage medium (PSM) that can be subsequently converted into a reactive fuel/oxidizer combination suitable for high-thrust applications after the CuberSat enters near earth orbit. In this scenario, CubeSats would be filled with the PSM at the CubeSat manufacturing site, then transported to the launch integration facility where the CubeSat(s) are mated into the launch rocket. Such a design is a major advancement compared to conventional propellants like Hydrazine whose handling and transportation requirements prevent them from being transported ‘full’, rather they need to be fueled at the launch site. Should a launch vehicle failure result in CubeSat destruction, there would be basically no adverse impact due to release of the PSM due to its inert characteristics.

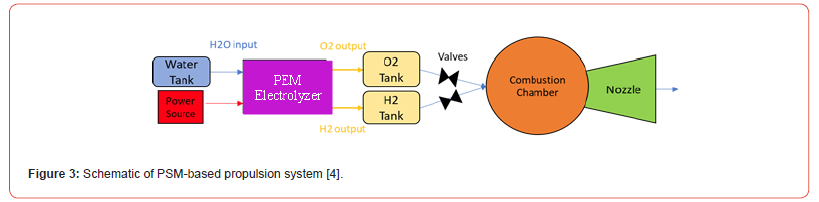

Research is ongoing to develop a CubeSat propulsion system using water as the PSM. Once a water-fueled CubeSat enters orbit, solar panels would be deployed to power a COTS electrolyzer where the water is converted into hydrogen and oxygen. This is an ideal combustion propellant combination that can produce extremely high thrust. A electrolyzer-based PSM propulsion system is depicted in Figure 3 below.

Simple, low-cost electrolyzers readily available to the academic community include those made by H-Tec (h-tec-education.com). Figure 4 depicts a H-Tec rebuildable electrolyzer (model E206) which has been pressure-tested to over 4 atmospheres.

Given the capability of operating at pressure, the hydrogen and oxygen product gases can be ‘self-pressurized’ and stored at 60 psig prior to combustion initiation. At this pressure, and at an oxidizer to fuel ratio of 8 a hydrogen-oxygen thruster can produce a theoretical vacuum Isp of 351s using an optimized diverging nozzle [21]. At this Isp, a 0.2N thruster can achieve a ΔV of 2714 m/s. ΔV relates thrust to total vehicle mass and represents the impulse needed to the change orbit of a satellite.

With the exponential rise in deployment of CubeSats and other micro-satellite platforms, and their expanding mission demands in low earth orbit, novel, non-toxic propulsion technologies are needed to reduce risks and costs associated with satellite fabrication, transportation and launch. Using water as a propellant storage medium achieves these outcomes while providing high thrust maneuverability in low earth orbit while embracing the low-cost paradigm of CubeSats.

Acknowledgement

The author gratefully acknowledges Alyza Khan, Dayannara Munoz, Julia English and Jake Egan for their research contributions for this effort. Support for this work was provided by NASA MUREP, Grant No. 80NSSC19M0197.

Conflicts of Interest

There are no Conflicts of Interest related to the research and findings presented in this paper.

References

- Staff Writers, “History of the CubeSat”, MICROSAT BLITZ, Betheda MD (SPX), Aug 23, 2016.

- California Polytechnic State University, San Luis Obispo CubeSat Systems Engineer Lab, NASA Launch Services Program “CubeSats101: Basic Concepts and Processes for First-Time CubeSat Developers.” NASA CubeSat Launch Initiative, Oct. 2017.

- (n.d.). Smallsats by the Numbers 2024. BryceTech.

- Alyza Muzaffar-Khan, Dayannara Munoz and Gregory E. Ogden. "Design and Testing of PEM hydrolysis system for producing Hydrogen and Oxygen propellants for CubeSat Applications," AIAA 2021-4185. ASCEND 2021. November 2021.

- Tummala AR, Dutta A (2017) An Overview of Cube-Satellite Propulsion Technologies and Trends. Aerospace 4(4): 58.

- Ebersohn, Frans & Raja, Laxminarayan & Shebalin, John (2013) Resistive Magnetohydrodynamic Study of Magnetic Field Effects on Plasma Plumes. 44th AIAA Plasmadynamics and Lasers Conference. 10.2514/6.2013-2759, United States.

- Agile Space Industries (n.d.), Agile Space is creating chemical-electric dual-mode propulsion systems — Agile Space Industries.

- NASA, Public Summary: NASA IRT SpaceX CRS-7 Final.

- Malik, Tariq (1 September 2016) Launchpad Explosion Destroys SpaceX Falcon 9 Rocket, Satellite in Florida. SPACE.com. Retrieved 7 May 2021.

- “First Private Chinese Attempt to Send Rocket into Space Fails.” The Guardian, 28 Oct. 2018.

- Rocket Lab Identifies Faulty Electrical Connector as Cause of Launch Failure.” Spaceflight Now, 31 July 2020.

- Foust, Jeff, March 3, 2023.

- “Two BlackSky Satellites Lost on Rocket Lab Launch Failure.” Spaceflight Now, 15 May 2021.

- "Firefly's Alpha rocket explodes on inaugural test launch". Spaceflight Now. 3 September 2021. Archived from the original on 21 February 2022. Retrieved 3 September 2021.

- “FAA Closes Blue Origin Mishap Investigation.” Federal Aviation Administration, 27 Sept. 2023.

- “AAIB Statement: LauncherOne Launch Failure.” UK Government, 12 Jan. 2023.

- “Radar Imaging Satellite Lost as Rocket Lab Electron Rocket Suffers Launch Failure.” Spaceflight Now, 19 Sept. 2023.

- “SpaceX Falcon 9 Suffers Rare Failure in Space, Imperiling Starlink Mission.” Reuters, 12 July 2024.

- “Launch Rocket by Chinese Private Firm i-Space Fails.” Reuters, 11 July 2024.

- “Firefly Aerospace Launches from Texas under FAA Oversight.” Austin American-Statesman, 2024.

- Khan, Alyza Muzaffar. “Design and Testing of Polymer Electrolyte Membrane (PEM) Electrolysis System for Hydrogen and Oxygen Production for Propellants in CubeSat Applications.” ProQuest Dissertations & Theses, 2022. Print.

-

Gregory E Ogden*. Development of a Non-Toxic CubeSat Propulsion System using Water as an Inert Propulsion Storage Medium (PSM). Glob J Eng Sci. 12(3): 2025. GJES.MS.ID.000787.

-

Propulsion storage medium, CubeSat fabrication, Nanosatellite missions, Electrospray, Chemical propulsion technologies, Space, Rocket Lab, Hydrogen and oxygen, Satellite fabrication

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.