Research Article

Research Article

Controlling Airborne Infection During COVID-19

Ehab Nader Tuffaha*

Mechanical Engineering Department; Hashemite University, Amman, Jordan

Ehab Nader Tuffaha, Mechanical Engineering Department; Hashemite University, Amman, Jordan.

Received Date: November 22, 2022; Published Date: December 13, 2022

Abstract

During the pandemic, nearly every industry faced new challenges and discovered new opportunities. The HVAC industry is no exception. This article aims to find proper solution to mitigate and try to eliminate the airborne infection risk during pandemic such COVID-19. In this article am suggesting using heat recovery wheel with the air handling units which are serving Emergency department & public waiting area, despite the normal conditions which are under the traditional rules and standards of HVAC codes in healthcare facilities allowing to return airborne with fresh supply air.

Keywords:HVAC; Ashrae; Pandemic; WHO; Heat wheel

Introduction

During COVID-19 and up to November -2022 a total of 14,122 deaths in Jordan been reported to WHO, the most seriously in this number that many of those cases are infected on hospitals which is driving us to think more seriously by focuses on the airborne infection risk of COVID-19 in nursing units in inpatient building ,furthermore in my country (Jordan) we had been on unexpected effect - it has made people wary of visiting hospitals over fears of contracting the disease, a consequence of this fear among people, could put fur ther stress on the already strained healthcare system in the country [1], so the infection control in the hospitals is a vital focus area [2,3]. Basically, the first trajectory of any patient is the emergency department, that’s why I will focus on this department in term of HVAC. To discuss point of view based on the below table as a sample of ASHRAE Standard 170 Design parameters for clean rooms, Table 1 page 9.2 ASHRAE Handbook—HVAC (Table 1).

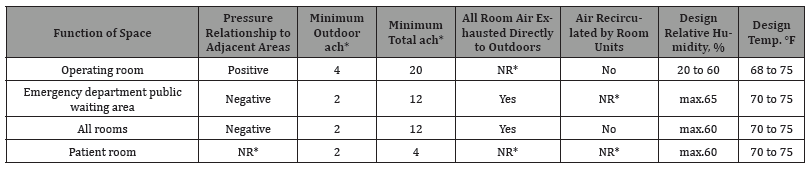

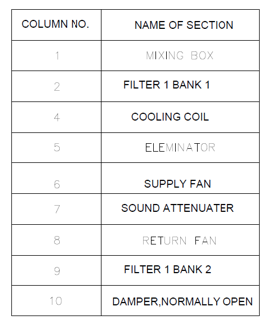

Table 1:Sample of ASHRAE Standard 170 Design Parameters [6].

For Emergency department public waiting area its clearly ASHRAE is asking for fresh air of 2 air change per hour with mini mum total of 12 ACH, however the point here is the table parameters showing no requirements for Air Recirculated by Room Units ,based on this allowance all designers are returning the airborne to AHU mixing box which will be mixed with outdoor fresh air passing to cooling coil throwing the treated air again and again to the same department [4]. Such air treatment in normal conditions might be accepted but definitely it’s not in pandemic conditions ,however as the latest updated guidance by [5] - Centers for Disease Control - about how COVID spreads emphasizes that the virus can be spread through the air via “very fine droplets and aerosolized particles” from an infected person who is more than 6 feet away, so even the air handlers are equipped with portable high-efficiency particulate air filters (“HEPA”) like MERV 14 , or even air purifiers can help clean the air in areas where lots of people tend to congregate but still in pandemic no chance to venture [5].

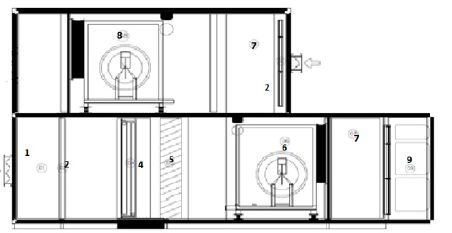

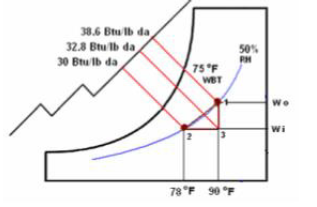

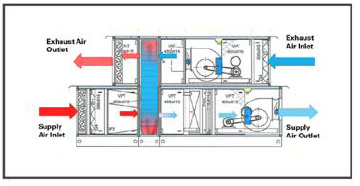

On the other hand, the main point is to avoid airborne return during the pandemic conditions, so let see the normal conditions then suggest the way of modification, the below it’s a double deck hygienic air handler unit using for emergency department waiting public area in one of larger hospitals in Uganda under name of ISHU in the capital (Kampala city) (Figures 1&2).

Figure 1:

Figure 2:Air handling unit sectional parts illustration by Authur.

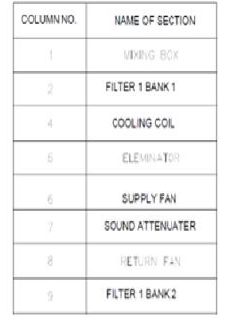

Therefore, the designer suggest to have motorized damper in the mixing box which is mix the outdoor fresh air and the return airborne , aiming to say is in the normal conditions as per ASHRAE 170 there is no obligation to mix both air streams neither to exhaust the return, but in case of pandemic conditions such control is required, so if we have a motorized damper in the mixing box which will be normally open in normal conditions and shut off in pandemic outbreak to stop the mixing and exhaust the return out of the AHU ,please see the below proposed modification by designer (designer proposal, 2022) (Figures 3&4).

Figure 3:

Figure 4:Modified Air handling unit sectional parts illustration by Authur.

Methods

Might somebody will ask what’s the affecting of such modification in the cooling coil size capacity, however this is a valid question, therefore let take a case study and apply the air thermodynamics theories to get a conclusion whether such suggestion doable or not. The below parameters are a valid case in one of the biggest hospitals in Africa, so we have one air handler unite covering emergency department with area of 1600 square meters, after analytical design information’s to get the below details:

Outside air flow rate as per ASHRAE 170 @ 2 ACH and the emergency department has an area of 1600 square meters @ 2.75 m height, so OA= 1600 *2.75*2*0.277 so almost 2440 l/s as fresh Air requirements. The space load sensible and latent load based on heat load calculations obtained based on civil parameters available in the design stage are sensible load 60.8 kw with latent load of 30 kw. Since ASHRAE 170 asking for 12 ACH as a total air supply for emergency department, then for emergency department has an area of 1600 square meters @ 2.75 m height, then SA= 1600 *2.75*12*0.277 so almost 14626 l/s as total supply Air requirements.

Return air flow rate = supply air flow rate – outside fresh air

flow rate =14626 -2440 = 12180 l/s. So, in order to have the total

cooling load need to get the below (a & b) details:

a) Space loads (sensible and latent) = [Q roof + Q walls + Q

windows + Q people + Q lights + Q appliances] (It does not include

ventilation load). --------- [This is also called Room Total Load].

b) Total loads = Space Loads + Ventilation Load-------- [This

is also called Gross Total Load].

Total space loads = 60.8+30 = 90.8 kw

For ventilation load:

So analyzing tow options, the first is the normal way of mixing outside fresh air with return air (i.e. airborne return from emergency and public waiting area waiting) and the second option which designer suggesting to use the motorized damper to stop the mixing and exhaust the return airborne then to study the affecting on the cooling coil capacity whether doable or not.

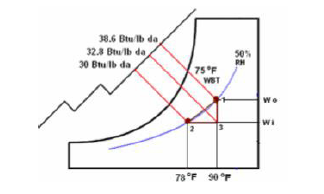

Option 1:(Mixing airborne with outside fresh air -Normal conditions) (Figure 5).

Figure 5:ASHRAE Psychrometric Chart app 2009.

Sensible Heat

Q Sensible = 60 * CFM * ρ * CP * ΔT

Q Sensible = 60 hr/min * CFM (ft³/min) * (0.075) Ibm/ft³ *

(0.24) Btu/Ibm-°F * ΔT (°F)

Q Sensible = 1.08 * CFM * ΔT

ρ = Air density (0.075 Ibm/ft3)

Cp = Specific heat of air (0.24 Btu/Ib F)

Recommended ventilation is 14626 l/s (this will ensure conservative

analysis), therefore,

CFM (Air flow rate) = 30,990 ft³/min

Now

Q Sensible = 1.08 * CFM * ΔT

ΔT = Indoor minus Outdoor temperature difference (To - T i)

since both streams are mixed so we have To = 90 °F, Ti = 78 °F, Tmix =

80 °F based on percentage mixing of air steams (2440 /14626 =17

%) & (12180/14626 = 83%) so we have (90 *17 %) + (78 * 83%)

=T mix = 80 °F

Therefore

Q Sensible = 1.08 * 30,990 * (80- 78)

Q Sensible = 33,469 Btu/hr almost 10 kw

Latent Heat

Q Latent = 4840 * CFM * ΔW

Where:

ΔW = Humidity ratio of indoor air minus humidity ratio of

outdoor air, (Wo - Wi) in lbm water/ lbm dry air however here we

have new mixing properties of W mix @ T mix = 80 °F

From Psychometric chart:

Indoor - For 78° F dry bulb temperature (DBT) at 50% Relative Humidity:Wi = 0.0102 Ibm water/Ibm dry air

Outdoor - For 90 ° F dry bulb temperature (DBT) at 50% Relative Humidity:

Wo = 0.0152 Ibm water/Ibm dry air, however W mix @ 80 °F is =0.0112 Ibm water/Ibm

ΔW = (Wmix - Wi) = 0.0112 - 0.0102 = 0.001 Ibm water/Ibm dry air

Therefore

Q Latent = 4840 * 30,990 * 0.001 =150,000 Btu/hr almost 44 kw

Gross Total Load = (space loads 60.8+30) +Fresh air sensible and latent (10+44) = 145 kw so cooling coil capacity of 42 tons.

Option 2 :(Total outside fresh air without mixing -Emergency conditions at pandemic outbreak) (Figure 6).

Sensible Heat

Q Sensible = 60 * CFM * ρ * CP * ΔT

Q Sensible = 60 hr/min * CFM (ft³/min) * (0.075) Ibm/ft³ *

(0.24) Btu/Ibm-°F * ΔT (°F)

Q Sensible = 1.08 * CFM * ΔT

ρ = Air density (0.075 Ibm/ft3)

Cp = Specific heat of air (0.24 Btu/Ib F)

Recommended ventilation is 14626 l/s (this will ensure conservative

analysis), therefore,

CFM (Air flow rate) = 30,990 ft³/min

Q Sensible = 1.08 * CFM * ΔT

ΔT = Indoor minus Outdoor temperature difference (To - Ti)

since both streams are mixed so we have To = 90 °F, Ti = 78 °F

Therefore

Q Sensible = 1.08 * 30,990 * (90- 78)

Q Sensible = 401,603 Btu/hr almost 118 kw

Latent Heat

Q Latent = 4840 * CFM * ΔW

Where:

ΔW = Humidity ratio of indoor air minus humidity ratio of

outdoor air, (Wo - Wi) in lbm water/ lbm dry air.

From Psychometric chart:

Indoor - For 78° F dry bulb temperature (DBT) at 50% Relative

Humidity:

W i = 0.0102 Ibm water/Ibm dry air

Outdoor - For 90 ° F dry bulb temperature (DBT) at 50% Relative

Humidity:

Wo = 0.0152 Ibm water/Ibm dry air

ΔW = (Wmix - Wi) = 0.0152 - 0.0102 = 0.005 Ibm water/Ibm

dry air

Therefore

Q Latent = 4840 * 30,990 * 0.005 =749,958 Btu/hr almost 220

kw

Gross Total Load = (space loads 60.8+30) +Fresh air sensible

and latent (118+220) = 429 kw so cooling coil capacity of 122 ton.

Let wrap both options by one conclusion:

If use the second option of motorized damper in emergency

case and still using the same cooling coil of first option then,

Q Sensible = 1.08 * CFM * ΔT

33,469 Btu/her =1.08 x 30,990 cfm x (90- Ti)

Ti =90-1=89 °F

That’s mean such cooling coil super under size will not be suitable for such application, moreover the larger size of the second option will drive to move away from both methodology by finding another way compromising by healthy requirements with economical side.

Result

Based on the previous analytical information’s we discover the big difference in term of tonnage capacities between mixing the return airborne with fresh supply air methodology versus the totally fresh supply air using motorized damper , however such large difference should not stop us to use another efficient way which can reduce the energy consumption and reduce the cooling coil size furthermore the most important is to stop mixing the return airborne with fresh supply air in emergency and public waiting area. The below figure self-explanatory of heat recovery wheel idea, the most important is such method is eliminating the return of airborne and extracting the energy of the return air (Figure 7).

Figure 6:ASHRAE Psychrometric Chart app 2009.

Figure 7:Heat wheel recovery unit illustration by Author.

Discussion

The below are several points advantages to have such methodology

in hospitals:

1. In general terms it is a type of energy recovery heat exchanger

between two streams of air.

2. Buildings use mechanical ventilation to supply fresh air and

extract contaminated air from buildings.

3. The fresh air must be either heated or cooled to acceptable

temperature and relative humidity. The heating or cooling of

fresh air consumes significant energy and on the other hand

already conditioned air is being exhausted out.

4. Heat Recovery wheel rotates between the air streams and

transfers energy between fresh air and exhaust air. Hence

precool or preheat the fresh air hence reducing the cooling or

heating energy (Figure 7).

Therefore, based on the above ASHRAE guidance for heat recovery system which where the two air streams are not close enough then it generally delivers a maximum efficiency of around 35% to 50% which is still better option instead of having a large cooling coil with adding motorized damper suggestion neither mixing of return airborne with fresh supply air.

Conclusion

COVID-19 virus can spread in poorly ventilated and/or crowded indoor settings, where people tend to spend longer periods of time such emergency department public waiting areas, This is because aerosols can remain suspended in the air or travel farther than conversational distance, this is often called long-range aerosol or long-range airborne transmission, that why we have to stop mixing return airborne with fresh supply air inside the air handling units. Also, the utilizing of motorized dampers Inside the fresh air handler units is totally wastage of energy and wastage of money consequently hence the cooling coil will be larger than the normal minimum of 60%. The concept of heat recovery wheel more efficient healthy wise and more economically.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Who (2022) Coronavirus disease 2019 COVID-19. World Health Organization.

- NHS (2021a) (HTM 03-01) Specialised ventilation for healthcare buildings.

- NHS (2021b) National Standards of Healthcare Cleanliness 2021.

- Ashrae (2022) Ventilation of Health Care Facilities. Standing Standard Project Committee 170.

- CDC (2022) Updated COVID-19 guidance for health care personnel. The Centers for Disease Control and Prevention.

- Standard, Ashrae (2013) Ventilation of Health Care Facilities. 170.

-

Ehab Nader Tuffaha*. Controlling Airborne Infection During COVID-19. Glob J Eng Sci. 10(4): 2022. GJES.MS.ID.000741.

-

Hvac, Ashrae, Pandemic, Who, Heat wheel

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.