Review Article

Review Article

Characterization of Marine Composites: A Comprehensive Review of Marine Materials in Shipbuilding, Their Mechanical Behaviors and Degradation Mechanisms

Yifei PENG1,2,3, Jean-Marie NIANGA1,2,3 and Zefeng WANG2,3*

1University of Lille, Villeneuve-d’Ascq, France

2Huzhou University, Huzhou, China

3ASIR, Institute - Association of intelligent systems and robotics, Paris, France

Zefeng WANG, Department of Information Engineering, Huzhou University, China.

Received Date:April 07, 2025; Published Date:April 23, 2025

Abstract

As substitutes for metals, composite materials are experiencing an upward trend in their applications of shipbuilding and offshore construction. Through the perspective of the shipbuilding materials evolution, composites offer better options than metallic materials and timber in terms of mechanical properties, resistance to aging in marine environments, and special-purpose needs. Focus on metallic materials and reinforcement fibers of composites for structural materials in the ship and boat building, comparative studies are conducted in order to characterize marine composites, especially for their mechanical properties and degradation mechanisms. Composite materials with glass fibers, aramid fibers and carbon fibers as reinforcement materials provide respectively economy, fire and impact resistance, and lightweight characteristics while taking into account excellent mechanical strength in shipbuilding applications. Basalt fibers similar to glass fibers have great potential for applications, while natural fibers are a prospect for solving the problem of composite recycling, and environmental protection. In marine environments, composite structures also face the risk of physical and chemical aging, and even the mechanical aging of the reinforcement fibers, leading to overall structural failure. Corrosion of metals and aging of polymer matrix composites in the marine environment, as well as influences of environmental factors are discussed. Recent developments in marine applications of composites and related research are presented.

Keywords:Composite materials; Reinforcement fibers; Metallic materials; Shipbuilding; Mechanical properties; Aging; Corrosion

Introduction

Metals have been used for major structural parts in the shipbuilding industry for over 160 years, since the first iron-hulled warship “HMS Warrior” launched in 1860 [1]. Ever since, steel and aluminum alloys have become the two most commonly used structural materials in marine industries due to their excellent mechanical properties, workability, and cost-effectiveness [2]. However, with the development of composite materials, there has been a significant transformation in the materials used for the manufacture of marine structures, primarily in fishing boats, pleasure and sporting boats, commercial vessels, naval ships, submersibles, and offshore platforms [2]. Aging resistance, longer service life, and lower maintenance costs are fundamental characteristics of composite materials in the marine environment. In the ship and boat building industry, glass fiber reinforced polymers (GFRP) have virtually dominated the market for small vessel construction due to their reliable mechanical properties and low costs. Aramid fiber reinforced polymers (AFRP) stand out for military level requirements due to their high mechanical properties, impact resistance and fire resistance capabilities. Carbon fiber reinforced polymers (CFRP), on the other hand, have become one of the top choices for building high-performance vessels, thanks to their outstanding mechanical properties and low density. Furthermore, composite materials can meet specific requirements for special uses, such as electrical insulation, non-magnetism, and electromagnetic wave transparency. The history of using composite materials in shipbuilding spans just over 70 years, with the first use of GFRP in the construction of small vessels around 1950 [3-6]. Composite materials have been developed since and able to meet the construction needs of small, medium vessels, superstructures of large vessels. They have also gradually been employed in the construction of internal ship structures and equipment, becoming the preferred choice for enhancing performance, cost-effectiveness, and reducing energy consumption as an alternative to metallic materials. The use of composite materials in the manufacture of marine structures presents an inevitable trend.

Despite possessing better durability and aging performance, the fatigue behavior of composites in marine environments, mechanisms that lead from aging to eventual failure are still an important challenge for composite research and development. Especially due to the complexity of composite applications, the combination of different matrices and reinforcement fibers, the material structure, the contact and joining with metallic materials. This article presents the evolutionary history of structural materials used in shipbuilding and conducts a comparative study between metallic materials and composite materials in marine structures applications from multiple perspectives. Visual data demonstrates the mechanical characteristics of composite materials in marine applications. The effects of marine environmental factors in corrosion and aging are discussed. A comparative study between metallic materials and composite materials on their degradation in seawater, as well as fatigue and failure behaviors are conducted. The latest developments of composite materials in relevant marine applications have also been introduced, providing a reference for researchers in this field.

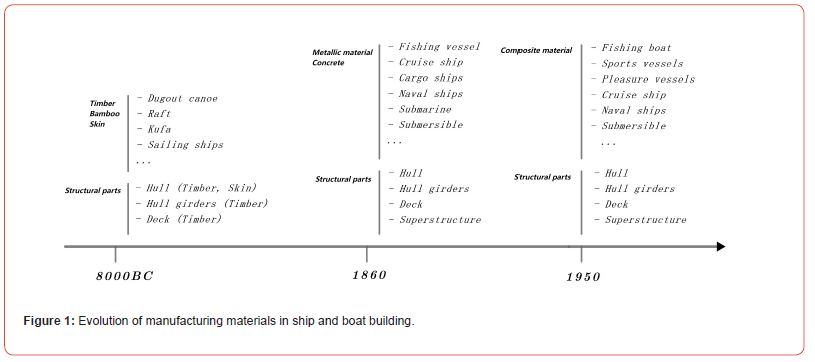

Evolution of Manufacturing Materials in the Ship and Boat Building

In the early era of water transportation, the main criteria for selecting construction materials were buoyancy and accessibility. Without a doubt, timber becomes an excellent option, and it provides strength support. Since the choice of material is to a certain extent determined by the region, bamboo and skin products are also used for water transportation, such as the raft and Kufa. Into the modern times, the extensive use of metallic materials has benefited from the development of industrial capabilities, superior mechanical properties have become an important indicator, stiffness and strength means more tonnage. The emergence of composites, a kind of material that incorporates mechanical properties with the advantage of light weight, has made them leap forward as an alternative option to metallic materials. The proportion of composites used on a vessel determines its high performance. Figure 1 below succinctly illustrates the evolution of shipbuilding materials over time and their application to structural components.

Following this evolution line, the following sections mainly describe timber, metallic materials and composites as structural materials in shipbuilding.

Timber

Timber is the most traditional shipbuilding material with a long history of human use, they possessed good buoyancy, they are readily available, easily shaped and processed. It wasn’t until the 19th century that timber was largely replaced by metallic materials for shipbuilding. The dugout canoe is the earliest means of water transportation, with the “Pesse canoe” discovered as the oldest known watercraft, constructed from a single Scots pine during the early Mesolithic period around 8000 BC [7]. The wooden raft, characterized by its absence of a hull structure, also has a long history as a watercraft. With the development of shipbuilding technology and advancements in timber processing, sailing ships became the mainstream water transportation for maritime trade, long-distance ocean exploration, and warfare. Sailing ships evolved from ancient times to the 19th century, spreading across the world and giving rise to various types of sailboats on each continent and in different periods. Famous sailing ship types include ancient Mediterranean civilizations’ Galley and Trireme, European sailing ships from the Middle Ages to the 19th century such as Longship, Cog, Caravel, Carrack, Galleon, Cromster, Galleasse, and Clipper, as well as Chinese sailing ships, the Junk and Chinese treasure ship [8-10]. Sailing ships varied in displacement, ranging from tens of tons to several thousand tons. The Ship of the Line, HMS Victory (launched in 1765), had a calculated displacement exceeding 3,000 tons [11,12].

Metallic Material

Advancements in metallurgical techniques led to mass production and widespread use of metallic materials in shipbuilding. Following iron, steel was quickly employed for ship hull construction. The “Redoutable” (launched in 1876) was the first cruiser constructed primarily using steel, although the “HMS Iris” (launched in 1877) was the first all-steel made warship [13,14].

The primary consideration for using metallic materials in shipbuilding is their advantages of high strength, toughness, and stiffness. In the shipbuilding industry, steel and aluminum alloys are the most commonly used structural materials, while other common options include titanium and its alloys, copper alloys, cast iron, and so on. Modern large ship construction employs block construction techniques, where prefabricated modular sections are closed together through welding processes. The advancement of welding technology has enabled the construction of larger ships with greater dimensions and tonnage. This has given rise to supersized maritime giants like the TI-class supertanker, which exceeds 350 meters in length and has a Deadweight Tonnage (DWT) exceeding 400 000 tons.

Steel: In addition to excellent mechanical properties, steel also has good ductility and is easy to shape and process. It benefits from abundant iron ore reserves for steelmaking; mature industrial metallurgical processes capable of large-scale production at a low cost. Furthermore, steel is easily alloyed, offering a wide range of steel products possessing different performance specifications to meet the construction requirements of various types of vessels. These advantages have led to the widespread use of steel in the shipbuilding industry.

Stainless Steel: For the sake of corrosion resistance, stainless steel contains a high level of chromium, typically not less than 10.5%, the dissolved chromium in stainless steel can form a passive layer of chromium-rich oxide on the surface, providing corrosion resistance capability [15]. Simultaneously, the major alloying addition of nickel can enhance the general corrosion resistance of stainless steel (especially in acidic environments when the proportion is up to 8%), which also promotes the formation of austenite, exhibiting superior welding and working characteristics while enhancing mechanical properties.

Aluminum Alloy: Aluminum alloys are, after steel, the second most widely used structural materials in shipbuilding. They have relatively high specific modules (modulus-to-density ratio) and specific strength (strength-to-density ratio). Their main advantages include being lightweight, corrosion-resistant, good workability, non-magnetic (or weakly magnetic), and easy to produce.

Other Metallic Materials: Titanium and its alloys have high specific modules and specific strength, excellent fatigue properties, outstanding corrosion resistance, and are non-magnetic. However, titanium is an expensive metal, thus the use of titanium alloys typically requires a distinct technical advantage. Titanium alloys are considered suitable for constructing the hulls of deep-diving submarines.

Copper alloys are traditional marine materials, primarily chosen for their corrosion resistance and fouling-resistant properties. Copper-nickel alloys were once considered suitable as structural materials for hull construction [16]. They have good fatigue properties, and they are easy to produce and shape, and they can be welded to steel. However, copper alloys are relatively expensive, have lower strength, density greater than that of steel (around 8.5- 8.9 g/cm³). They are noble materials compared to other structural materials, for instance, copper-nickel alloys can corrode steel in a marine environment.

Reinforcement Fibers of Composite Materials

The application of composite materials in shipbuilding benefited from the commercialization of reinforcement fibers. Industrial production of glass fiber first began in the United States in the 1930s. With the launch of the first GFRP (Glass Fiber-Reinforced Plastics, also called Glass Fiber Reinforced Polymer) ship, people began to recognize the lightweight and corrosion-resistant characteristics of composite materials. GFRP, as a structural material, has already captured over 90% of the production market for small vessels. Composite materials are complex in composition and structure, for example, laminated composites are suitable for the construction of hulls for small vessels, while sandwichstructured composites represent a better choice in the case of larger sizes. Therefore, the discussion is thus primarily based on the category of reinforcing fibers, as they are the main component that determines a composite’s mechanical properties. In addition to glass fibers, other reinforcement fibers used in shipbuilding as structural materials are mainly aramid fibers and carbon fibers. In recent research, basalt fibers have also been extensively studied for their applications in the maritime field [17-22]. And facing the environmental issues of degradation and recycling of composites, natural fibers are also being investigated for the construction of boat hulls.

Glass Fiber: Glass fiber is used in the shipbuilding industry due to its cost-effectiveness, high strength, humidity and chemical resistance. The term “glass” represents a rather large family of materials. Glass refers to amorphous bodies obtained by supercooling a melting composition, resulting in a gradual increase in viscosity until it becomes mechanically solid. In its massive form, glass is characterized by very high fragility and is sensitive to cracking. However, when produced in the form of fibers with small diameters, it loses these characteristics and then exhibits convincing mechanical properties.

Aramid Fiber: Aramid fibers are advantageous for shipbuilding due to their high specific strength (tensile resistance), stiffness, impact resistance, vibration absorption, chemical resistance, and flame resistance. Aramid fibers are organic synthetic fibers, and the term “aramid” refers to wholly aromatic polyamides. A more understandable definition provided by the U.S. Federal Trade Commission states that aramid fibers are manufactured fibers in which the fiber-forming substance is a long-chain synthetic polyamide in which at least 85% of the amide linkages (the amide bonds -CO-NH-) are attached directly to two aromatic rings [23]. When it comes to aramid fibers, many may immediately think of the famous product “Kevlar”, which was commercialized by the DuPont Company in 1972, and Kevlar is a type of para-aramid fiber. Marketcommercialized aramid fiber products can generally be categorized into meta-aramid fibers, para-aramid fibers, and aramid copolymer fibers. Commercial brands of meta-aramid fibers include Nomex (DuPont), Teijinconex (Teijin), Newstar (Yantai Tayho); the brands Kevlar (DuPont), Twaron (Teijin), Taparan (Yantai Tayho) are paraaramid fibers; and Technora (Teijin) is an aramid copolymer fiber. Meta-aramid fibers like Nomex are known for their outstanding heat resistance, flame-retardant properties, chemical resistance, and electrical insulation capabilities, which also have good textile properties. Para-aramid fibers like Kevlar, on the other hand, excel in mechanical properties, impact resistance, and cut resistance while maintaining heat and chemical resistance. Kevlar is commonly used in ballistic protection equipment. Aramid copolymer fibers like Technora offer high strength and modulus, good heat and chemical resistance, as well as good fatigue resistance, low creep, and lower moisture regain.

Carbon Fiber: As a high-performance fiber, carbon fiber is used in shipbuilding due to its high strength (tensile and compressive), high stiffness, low density, humidity resistance, and excellent chemical resistance. In reality, carbon fiber products come in a wide range of strength and stiffness levels, categorized into different grades. Carbon fiber can be defined as a fiber primarily composed of carbon atoms, with a carbon content greater than 92%. Based on this, when the carbon content reaches 99%, we can distinguish it as graphite fiber, there isn’t a specific definition, and some criteria except for carbon content include factors such as heat treatment temperature (greater than 1700 ℃), elastic modulus (greater than 50 Msi, units of million pounds per square inch, approximately 344.74 GPa), 3D ordering of atoms, or high degrees of preferred orientation [24,25].

It wasn’t until 1960 when Roger Bacon first experimentally produced graphite whiskers and demonstrated their high performance, with an extremely high tensile strength of about 20 GPa and a modulus of at least 700 GPa, that the development and commercialization of high-performance carbon fibers began [26]. The types and uses of carbon fiber products are diverse, and the focus here is on carbon fibers related to mechanical properties. Carbon fibers exhibit unique dynamic performance characteristics. Due to the anisotropy of the graphite crystal’s structure that makes up carbon fibers, achieving very high strength and modulus simultaneously is not possible, which has resulted in a wide range of mechanical properties in carbon fiber products. The crystallographic structure of a perfect single crystal of graphite is composed of many sheetlike layers of carbon atoms stacked on top of each other. In the plane of the sheets, carbon atoms are connected by very strong covalent bonds, as the covalent bonding between sp2 hybridized carbon is the strongest covalent bond in nature. Therefore, the crystal exhibits extremely high theoretical tensile modulus of elasticity and ultimate tensile strength in the direction parallel to these planes, on the order of 146 Msi (1000 GPa) and 15 Msi (100 GPa), respectively. In contrast, the sheet-like layers of carbon atoms are connected by weaker Van der Waals bonds between them, and the theoretical tensile modulus of elasticity in the direction perpendicular to the sheet planes is only 5 Msi (35 GPa).

In shipbuilding applications, carbon fibers are well suited for lightweight, high-strength, vibration-absorbing, and fatigueresistant requirements of water racing sports, making them popular choices for constructing canoes, kayaks, sailboats, powerboats, and performance crafts. Additionally, their high strength and chemical resistance make them an excellent alternative to metallic materials for building large vessels. While they are more expensive, using carbon fibers for yachts can showcase a symbol of luxury. When used as structural components in large vessels, carbon fibers are typically combined with other fibers like glass fibers to optimize performance while controlling costs. They can also be used in constructing superstructures, propellers, and other critical components. However, it’s essential to consider carbon fiber’s lower impact resistance in these applications.

Basalt Fiber: While not yet widely used in the shipbuilding industry, the reason for mentioning basalt fiber here is its superior mechanical properties compared to glass fiber and its significantly lower cost compared to carbon fiber. It is considered a highly promising high-performance fiber as a potentially strategic material. Basalt fiber is produced from basalt rocks, a type of volcanic rock, and it possesses characteristics such as high strength, good modulus, fatigue resistance, chemical resistance, and flame resistance [27]. Reports suggest that the performance of fiber produced from basalt rocks may vary depending on the region.

Natural Fiber: With the extensive use of composites, their disposal and recycling face significant environmental challenges. Degradation of composites usually takes a long time, and their complex composition and structure make recycling difficult. Facing this problem, the natural fiber reinforced composites that are biodegradable have become a hotspot for research. In shipbuilding, flax fiber and bamboo fiber are reinforcement materials that can provide sufficient strength, and they have been successfully used in the manufacture of hulls, decks, and structural parts of small vessels [28,29].

Investigations on Mechanical Properties of Metallic Materials - Composites as Structural Materials

Mechanical Properties of Metallic Material for Shipbuilding

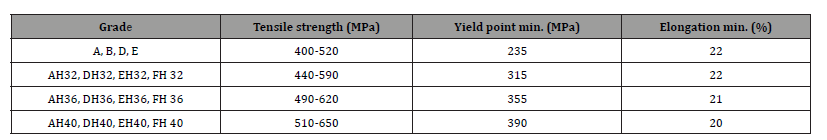

Steel and Stainless Steels: The Young’s modulus of steel is primarily a property of its matrix crystal structure. Therefore, an ultra-high steel will have substantially the same Young’s modulus as an ordinary mild steel [30]. Steel ensures stiffness while, through adjusting carbon content and alloying elements, it offers a broader range of strength options, providing choices for vessels of different sizes and types. For ship hull construction, the American Bureau of Shipping (ABS) Rules for Materials clearly define the elemental composition and mechanical performance requirements for Ordinary-strength Hull Structural Steel, Higher-strength Hull Structural Steel, and Extra High Strength Steel. Ordinary-strength Hull Structural Steel is typically categorized into four grades: A, B, D, and E. It possesses a Tensile Strength ranging from 400 to 520 MPa, with a minimum Yield Point of 235 MPa and a minimum elongation of 22%. Higher-strength Hull Structural Steel has four designated grades based on increasing notch toughness: AH, DH, EH, and FH. Each grade is further categorized and denoted with 32, 36, and 40 according to the level of yield strength, with units in kgf/ mm2 (1 kgf/mm2 = 9.81 MPa). Extra High Strength Steel designates four different alphabetic indicators of AQ, DQ, EQ, and FQ based on the Charpy V-notch impact test temperature. Each grade is further categorized into levels of yield strength, including 43, 47, 51, 56, 63, 70, 91, and 98, with units in kgf/mm2 (except for levels 91 and 98 for FQ grades) [31,32]. Table 1 shows the mechanical properties of different grades of steel. Extra High Strength Steel, such as the AQ98 grade, can achieve a Tensile Strength of up to 1150 MPa, with a Yield Strength of 960 MPa.

Table 1:Tensile property requirements for Ordinary-strength and Higher-strength Hull Structural Steel (thickness up to 150 mm).

However, steel also has distinct drawbacks. Firstly, steel is relatively heavy, and the density of steel typically falls in the range of 7.7 - 8.1 g/cm³. Secondly, steel requires corrosion prevention measures, often through coatings, and extensive maintenance. Furthermore, it’s worth noting that the steel structure has a lower fatigue limit at welded seam and can be brittle, potentially leading to sudden and rapid fractures. Other factors to consider such as steel’s magnetism, which renders it unsuitable for specialized vessels like mine countermeasures vessels.

Stainless steels used in shipbuilding include austenitic stainless steels such as 304, 304L, 316, 316L, 316LN, 317, 317L, 317LN, 321, and 347; ferritic-austenitic duplex stainless steel such as S31803/2205, S31803/2507. Among these, all grades of 316 and 317 stainless steel incorporate the element molybdenum (Mo), which increases resistance to both local forms of corrosion (such as pitting and crevice corrosion) and general corrosion. And in comparison, to austenitic stainless steels, duplex stainless steels have higher strength, improved corrosion resistance, a lower risk of hydrogen cracking, and greater resistance to solidification cracking [15,31,33]. Due to its higher cost, the use of stainless steel in shipbuilding requires consideration of economic factors. Additionally, it’s important to note that the strength of stainless steel, especially the yield strength, may be lower than that of regular steel. And stainless steel is not entirely non-magnetic, as its magnetic properties are determined by its crystal structure (martensitic, ferritic), heat treatment, and processing techniques.

Aluminum Alloys: The density of aluminum alloys falls within the range of 2.6-2.8 g/cm³. When compared to steel, for a simple structure without cyclic load, the use of aluminum alloys can result in a weight saving of approximately 65% [16]. Commonly used grades of aluminum alloys as structural materials in shipbuilding include 5059, 5083, 5086, 5383, 5454, 5456, 6061, and others. The corrosion resistance of aluminum alloys comes from the oxide protective layer formed on their surface. However, aluminum alloys in a marine environment should avoid coupling with noble metals (such as copper) and steel to prevent electrolytic corrosion, so that marine-grade aluminum alloys need the ability to resist intergranular and exfoliation forms of corrosion when in direct contact with seawater or marine environmental conditions. Aluminum alloys have lower strength and stiffness compared to steel. For instance, the Ultimate Tensile Strength of 5083-H321 (“- H” indicates “Strain-hardened”) ranges from 305-385 MPa, with a minimum Yield Strength (2% offset) of 215 MPa [31,34]. Other limiting factors for their use include higher cost, poor fatigue properties, and the fire risk associated with their lower melting point..

Mechanical Properties of Reinforcement Fibers for Shipbuilding

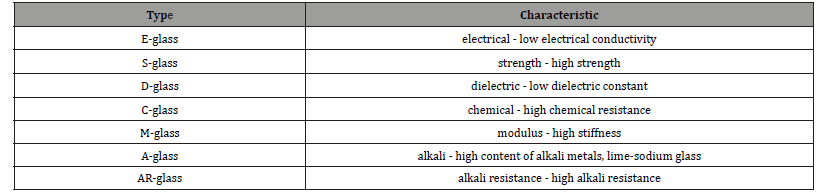

Table 2:Glass fiber types and their special characteristics.

Note: Other glass fibers often discussed in the literature include R-glass, Te-glass, Silica/Quartz fiber, ECR-glass.

Glass Fiber: Glass fiber products vary widely, and many of them use letter designations to imply special properties, for example, the “E” in E-glass stands for electrical. In general, glass fibers can be categorized into two major classes: general-purpose fibers and special-purpose fibers. General-purpose glass fibers, such as E-glass, dominate over 90% of the glass fiber market. The remaining glass fibers are developed for specific purposes. For instance, S-glass is specifically designed for aerospace applications, the “S” stands for strength. Table 2 shows common glass fibers and their special characteristics.

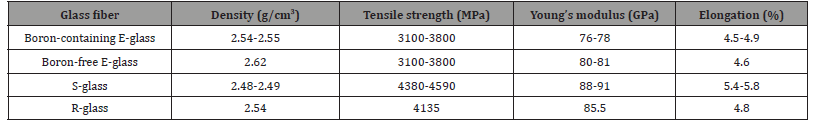

Just like their name suggests, E-glass shows low electrical conductivity. It is the most economical type of glass fiber and the most widespread in civilian applications. The tensile strength of E-glass is 3100-3800 MPa (measured in the form of filaments), making it widely used as reinforced fibers where both strength and high electrical resistivity are required. E-glass is classified into boron-containing glass fiber and boron-free glass fiber based on the production area. Their chemical composition differs, but the mechanical properties of these two types of E-glass are almost identical. The Young’s modulus of boron-free glass fiber (80-81 GPa) is slightly higher than that of boron-containing glass fiber (76- 78 GPa), compared to which, it has a slightly higher density (2.62 g/cm³ compared to 2.55 g/cm³). However, the main difference lies in its acid resistance, which is more than seven times higher than that of boron-containing glass fiber [35]. S-glass, R-Glass, and Teglass are high-strength glass fibers with higher mechanical strength and modulus compared to E-glass. They typically exhibit 10 to 15% higher strength at room temperature, and they have also improved fatigue resistance [35]. These high-strength glass fibers are commonly used in structural applications, and their value also lies in the ability to withstand higher in-use temperatures than E-glass. Many types of glass fibers are developed from S-glass, such as the HS4 brand from Sinoma, T glass from Nittobo, and S-2 glass from Aiken. S-glass fibers exhibit a strength of 4500-4800 MPa at room temperature, with a Young’s modulus of 86-87 GPa. The modulus of R-glass is equivalent to that of S-glass, but the elongation percentage or strain to failure is lower, at approximately 85% of S-glass. S-2 glass is a variant of S-glass with nearly identical chemical composition but different coatings which are used in ballistic and military applications. Up to this point, E-glass, S-glass, and R-glass are the most suitable glass fibers for structural components in the shipbuilding industry. Table 3 shows the mechanical properties of some glass fibers.

Table 3:Glass fibers and their mechanical properties.

Aramid Fiber: When it comes to applications, Nomex can replace toxic asbestos as a core material for ship hull sandwich structures to reduce weight and increase structural strength and stiffness. Para-Aramid fibers such as Kevlar have higher strength and stiffness compared to E-glass fibers and can be considered for building structural components such as ship hulls and decks. However, it’s important to note that Kevlar is more expensive than E-glass fibers, it also presents processing challenges as it is difficult to cut and does not wet out well with polyester and vinyl ester resin. It performs better with epoxy resin to fully utilize its mechanical properties.

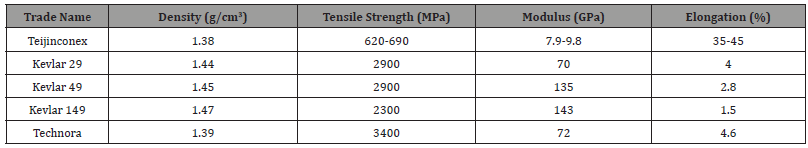

Additionally, para-aramid is sensitive to UV light, which can lead to oxidation and a reduction in strength, coating protection is thus necessary. Therefore, it’s common to consider using Kevlar in combination with other reinforcing fibers such as glass fibers or carbon fibers to create hybrid composites. However, Kevlar does provide impact protection for vessels, it is used in military vessels in areas where ballistic protection is required, and Kevlar is also used in racing boats for the absorption of vibrations. Table 4 shows the mechanical properties of some aramid fibers.

Table 4:Mechanical properties of some popular aramid fibers.

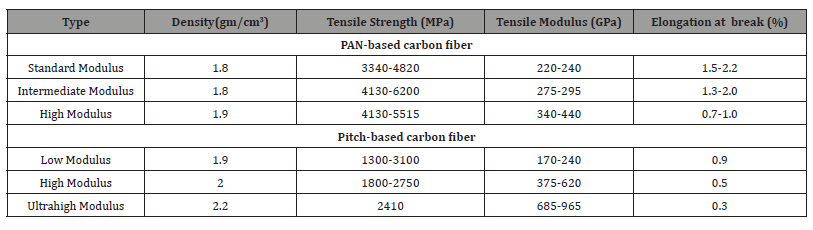

Carbon Fiber: The mechanical properties of carbon fibers also depend on the type of precursor and the processing conditions (temperatures, fiber tension, and the presence of flaws or defects). The precursors primarily include acrylic precursors (PAN, polyacrylonitrile), Pitch precursors (isotropic pitch, mesophase pitch), and Cellulosic precursors (rayons). Based on the exhibited mechanical properties, carbon fibers can be categorized into the following types: Low modulus (referred to as standard modulus in some literature), Intermediate modulus (IM), High modulus (HM), Ultrahigh modulus (UHM), and High tenacity (HT, referring to tensile strength). Due to variations in the mechanical properties of carbon fiber products produced from different precursors, it is generally observed that pitch-based carbon fibers have lower strength compared to PAN-based carbon fibers, but they can achieve higher moduli (the ultrahigh modulus grade). The mechanical properties of different grades of carbon fiber are presented in Table 5.

Table 5:Mechanical properties of common PAN-based and Pitch-based carbon fibers.

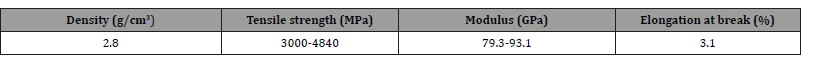

Basalt Fibers: Basalt fiber has a slightly higher density than glass fiber, which falls within an acceptable range. In shipbuilding, basalt fiber can be used as a structural material to replace E-glass fiber, partially replace carbon fiber, or be combined with other fibers to optimize performance [27,36,37]. Research [18] has indicated that basalt fiber can replace S-2 glass fiber in shipbuilding applications. Table 6 shows some mechanical properties of continuous basalt fiber.

Table 6:Mechanical properties of continuous basalt fiber..

Marine Environment

Understanding the marine environment is important for ship material selection, structural design, anti-corrosion and anti-aging protection. The composition of seawater, seawater properties, sea loads and other factors are all important considerations affecting the corrosion and aging of materials. Figure 2 shows the general marine environment.

Seawater Properties

The density of seawater affects the draft of the ship. The density range of seawater is from 1.02200 to 1.030000 g/cm3 [38]. The density of seawater depends on salinity, temperature and pressure. Therefore, the density of seawater in the vertical direction also changes.

As depth increases, the primary factor to concern is the increase in pressure. Pressure is usually described in reference to atmospheric pressure at sea level (1 atm = 101325 Pa). It is generally considered that for every 10 meters of increase in depth, the pressure will increase by 1 bar (1 bar = 100000 Pa).

The sea surface temperature comes from the heat of solar radiation. Low-latitude areas receive more solar radiation than high-latitude areas. Typically, global climate zones are categorized by latitude from high to low, that is, from the poles to the equator, and include polar climates, temperate and continental climates, dry climates, and tropical climates. Polar climate zones are located in the polar regions of the earth, with temperatures below 10°C in the warmest months and as low as −2°C or lower in colder months; the temperate and continental climate zones usually have temperatures ranging between 10°C and 18°C; dry climates are commonly used to describe climates with significant temperature fluctuations in desert areas; the tropical climate zones extend from the equator to north and south about 15° to 25° latitude, with average temperatures around 18°C or above, and can reach up to 35°C. In the vertical direction, solar radiation heat is evenly distributed in the water layer to a depth of approximately 100 meters. Below this depth and extending to around 1000 meters, the temperature sharply decreases, stabilizing between 4°C and 0°C below the depth of 1000 meters [39].

The description of salinity varies according to different measurement techniques. Knudsen salinities measured by titration-based techniques are expressed in units of grams of dissolved salts per kilogram of water (‰) or parts per thousand (PPT); the measurement results based on electrical conductivity will be expressed by adding the suffix PSU (practical salinity unit). The three measurement values are basically equivalent. The salinity of seawater varies between 32 and 37, with an average of 35. In the vertical direction, salinity also varies, with different areas experiencing either a decrease or increase in salinity with increasing depth, ultimately converging to around 35.

The conductivity of the solution determines the rate of electrochemical reactions, that is, the corrosion of metallic materials in the ocean. Various salts in seawater exist in the form of ions, such as NaCl, which dissociates into Na+ and Cl- ions and migrates under the action of an electric field. The conductivity of seawater, which is measured as siemens/meter, depends on temperature, salinity, and pressure changes caused by depth. The conductivity increases with increasing salt concentration and temperature. The electrical conductivity range of the global sea surface is 0.0999–6.45 S/m.

The ocean and atmosphere exchange gases through the air−sea interface to maintain the gas balance. The main dissolved gases in the ocean include nitrogen, oxygen, carbon dioxide, and a small number of rare gases. Carbon dioxide exists in a dissociative state in seawater and can react with H2O to form carbonic acid (H2CO3), HCO3–, CO32- and H+ ions, which will affect the pH value in the area. The proportions of dissolved oxygen and carbon dioxide in surface oceans are approximately 36% and 15% respectively. Ions are present in the ocean, constituting the electrolyte for electrochemical reactions, which mainly include chloride (Cl-), sodium (Na+), sulfate (SO42-), magnesium (Mg2+), calcium (Ca2+), and potassium (K+). Ions such as nitrate (NO3-), Cl-, Ca2+ and ammonium (NH4+) playimportant roles in the marine environment.

Other factors that can be considered include: the pH value of seawater, which is usually 8 (slightly alkaline); the oxidation reduction potential (ORP) of seawater, which is related to the corrosion of metal; and the Kinematic viscosity of seawater, which affects ship dynamics, it is 1.19×10-6 m2/s (15℃ , 1 atm) and 1.05×10-6 m2/s (20℃, 1 atm).

Sea Loads

Marine structures constantly experience a complex and combined loading environment, with inevitable environmental loads mainly coming from wind, waves, and ocean currents. Ocean environmental loads, such as wave loads, are the primary factors leading to structural fatigue and failure.

For marine structures, the impact of wind loads is primarily on the stability and overturning issues, which are specifically manifested in the effects of drag and lift forces induced by the wind, leading to overturning moments that influence the stability of both floating and fixed structures [40]. However, when performing load calculations on marine structures, wind loads are often considered a secondary factor because the average static forces and moments caused by wind are only fractions of the total loads [41].

Waves, generated by the interaction of wind with the free water surface, are the most significant and dangerous environmental load that marine structures face. Intense waves can impose high loads on structures or result in significant displacements. Waves bring not only static loads but also dynamic loads that can accelerate structural fatigue [42]. Of course, when analyzing waves loads, it is also necessary to consider wave impacts and the effects of green water loading. The size of waves depends on factors such as wind velocity, the duration of which wind blows in the same direction, the fetch (extent of the surface over which the wind is blowing), and the water depth [39]. Waves are generated when the wind creates ripples on the water surface, and as the wind continues, these ripples grow into waves, gradually increasing until the wave slope in deep water exceeds 1:7, causing the waves to break and preventing further energy absorption [39]. Fully developed waves can surpass the wind speed and propagate over long distances without losing energy.

Ocean currents are continuous, horizontal, and routed movements of seawater caused by a variety of factors. The static load imposed on marine structures by ocean currents is mainly hydrodynamic drag, especially for large marine structures, frictional drag is a necessary factor to consider [43]. The dynamic loads, on the other hand, can impact the fatigue behavior of structures [42].

Corrosion and Degradation of Materials

All marine structures are attacked by seawater, marine organisms and environmental loads, which are in physical, chemical and mechanical nature. The corrosion of metallic materials and the aging of polymer matrix composites (PMCs) in the marine environment are different phenomena and are the main reasons for the safety risks of structures.

Metals Corrosion with Seawater

Corrosion of metallic materials, according to the standard “ISO 8044: 2020“, is physicochemical interaction, which is often of electrochemical nature, between a metallic material and its environment that results in changes in the properties of the material, potentially leading to significant impairment of the function of the system to which they belong [44]. The presence of metallic materials in seawater creates the conditions for electrochemical reactions: seawater serves as an electrolyte, providing ionic compounds as well as anionic and cationic solutes, thus facilitating the formation of an electric current; heterogeneity in metallic materials or the seawater environment results in the existence of potential differences both between the metallic materials and the electrolyte and within the interior of the metallic materials, forming anodes and cathodes; the short-circuiting of each pair of half-cells on the material surface leads to the formation of numerous galvanic cells and initiates electrochemical reactions. Taking steel as an example, the first step of the anodic reactions is the generation of ferrous ions and the release of electrons from iron elements, followed by various degrees of oxidation, resulting in the formation of thick corrosion products on the material surface after years. Relatively, the most common cathodic reduction reactions in seawater are the oxygen reduction reaction and hydrogen evolution reaction, where dissolved oxygen and H+ ions in seawater gain electrons to produce OH- ions and hydrogen gas.

In fact, the corrosion mechanism of steel in the marine environment is very complex. It is not the goal here to explain the electrochemical reaction of metallic materials corroding in seawater, but to introduce different corrosion modes in the marine environment and the impact of environmental factors in the corrosion reactions.

The marine environment encompasses physical, chemical, and mechanical elements that can lead to corrosion of metallic materials. The corrosion phenomenon is complex and comprehensive. In different areas and depending on the material’s condition, one or multiple corrosion modes may be observed. Among them, one mode may dominate, leading to the eventual failure of the structure. First of all, it can be affirmed that erosion and abrasion phenomena can be involved in the corrosion process. They target the passive layer and protective coatings of the material, gradually wearing them away. This continual damage exposes the metallic materials to the environment, leading to subsequent corrosion. Then, various corrosion modes can be observed on ships and offshore constructions, and they are mainly in electrochemical nature, including general corrosion, galvanic corrosion, crevice corrosion, pitting corrosion, intergranular corrosion and selective leaching. When corrosion occurs, environmental loads become one of the driving forces leading to structural failure. The material is subjected to external loads or pre-existing stress that have not been eliminated, allowing corrosion cracks to propagate and leading to stress corrosion cracking. For metallic materials, hydrogen embrittlement is also a specific and highly complex factor leading to failure. This is primarily due to the infiltration of hydrogen into the material during processing or corrosion in the environment, resulting in a decrease in mechanical properties and a reduction in the fracture threshold. In the following discussion, the focus is on the electrochemical reaction nature corrosion modes.

The characteristic of general corrosion is that the corrosion process occurs uniformly over the entire surface of the metallic materials, with a generally consistent electrochemical reaction rate, and alternating between anodic and cathodic areas. If the corrosion products are soluble, it will directly result in a reduction of material thickness and loss of mass. But if they are insoluble, they will uniformly deposit on the material surface. Galvanic corrosion occurs due to the direct contact with an electrolyte between metals or alloys with different electrode potentials, forming a short circuit. The more active metal usually acts as the anode and is preferentially corroded, while the corrosion of the cathodic metal is reduced. This situation is more common in duplex or multiphase alloys, as well as structures composed of different metallic materials. It’s important to note that electrode potential is not an absolute factor in determining an anode. For example, titanium is highly corrosion-resistant in seawater but is more prone to polarization. When coupled with a more reactive metal like steel, titanium often acts as the anode, corroding and protecting the steel. For some electrode potential data on specific metallic materials, one can refer to galvanic series tables in documents [42,45]. Crevice corrosion typically occurs in stagnant solutions, in enclosed spaces where liquids are difficult to flow and cannot be renewed, such as holes, cracks, or gaps between jointing components, especially in areas covered by deposits or sludge. Pitting corrosion is a localized corrosion phenomenon that occurs on the surface of metallic materials, resulting in the formation of tiny holes. This type of attack is highly localized but can quickly damage the material, and it typically occurs on materials protected by a passive layer, such as stainless steel, aluminum alloys, and so on. Intergranular corrosion refers to the phenomenon where corrosion occurs along the grain boundaries of a metallic material and erodes inward. This is primarily due to the heterogeneity existing between grains and grain boundaries, and factors inducing intergranular corrosion can arise during welding and heat treatment processes. Intergranular corrosion can compromise the bonding between grains, reducing the mechanical properties of the material, posing a threat to the overall structural integrity. Additionally, the occurrence of this corrosion is challenging to detect based on the surface condition of the material. Finally, selective leaching refers to the phenomenon where a specific element in an alloy or a phase of a multi-phase alloy is preferentially corroded and dissolved under environmental conditions. The dezincification of brass alloys is a well-known example of this.

Sabot, Compère, and Mémet summarized the main corrosion modes of carbon steel, stainless steel, and aluminum alloys in the marine environment, along with corresponding protective measures [45]. In the marine environment, corrosion of carbon steel may include general corrosion and crevice corrosion. In addition to typical electrochemical corrosion, there are also microbiologically influenced corrosion (aerobic bacteria), erosioncorrosion, and hydrogen embrittlement of ultra-high strength steel. Stainless steel is susceptible to crevice corrosion and pitting corrosion. Aluminum alloys need to be alert to the risks of galvanic corrosion, intergranular corrosion and pitting corrosion caused by heavy metals.

The marine environmental factors influencing the corrosion rate of metallic materials mainly include salinity, dissolved oxygen, temperature, marine organisms, seawater flow rates, etc. The overall variation in pH values of seawater is minimal, so it is not a direct factor affecting the corrosion of metallic materials.

Within the range of seawater salinity levels, corrosion rates are directly proportional to salinity. The impact of salinity on the corrosion process is primarily manifested in two aspects: the electrical conductivity of seawater and the degradation of the passive film on the surface of metallic materials. First, the electrical conductivity of seawater is directly related to salinity, reducing the difficulty of galvanic corrosion. Secondly, since the dissolved salts in seawater are mainly composed of chloride, higher concentrations of Cl- ions will harm the passive film on the surface of metallic materials, such as stainless steel and aluminum alloys, causing localized damage and triggering pitting corrosion.

Dissolved oxygen in seawater is also one of the main driving forces for corrosion, as most cathodic reactions require the presence of oxygen. Taking steel as an example, its corrosion rate is directly proportional to the concentration of oxygen.

Generally speaking, higher temperatures accelerate the occurrence of corrosion, although they may cause a partial release of dissolved oxygen. In more enclosed environments, such as during crevice corrosion, this effect becomes more obvious, resulting in an increased corrosion rate until the oxygen is all consumed. Data on the effect of increasing temperature on corrosion rates under different conditions can be found in document [46].

Usually, marine organisms will quickly gather on the surface of unprotected materials and form a biofilm. Initially, a thin film of organic matter covers the material surface within a few hours, providing a habitat for marine microorganisms such as bacteria, fungi, or microalgae, gradually forming a microbial biofilm. Subsequently, larger marine organisms, primarily barnacles and other invertebrates that attach to hard surfaces, also cover the material surface. This increases the load on the structure, changes stress conditions, increases resistance to heat exchange, and simultaneously reduces fluid flow over the material surface, constituting factors that influence corrosion behavior. What is more noteworthy are microorganisms, especially sulfate-reducing bacteria (SRB) [47], a type of anaerobic heterotrophic bacteria that use sulfate in the environment to perform anaerobic respiration, undergo reduction reactions, and ultimately produces hydrogen sulfide (H2S). The impact of SRB on corrosion behavior mainly depends on the H2S product. On the one hand, it can destroy the passive film on the metal surface, causing local damage or pitting corrosion. On the other hand, it can directly undergo chemical reactions with some metals, promoting corrosion. Additionally, the involvement of SRB and similar microorganisms is generally believed to accelerate the corrosion rate [42].

The movement of seawater relative to the structure is more violent, that is, with higher velocity, the corrosion rate accelerates. Generally, low to medium flow velocities have a minor impact on the corrosion rate, while high-velocity seawater is more prone to promote corrosion rates [48,49]. This is attributed not only to the greater impact of high-speed water flow on structures but also to the substantial influx of dissolved oxygen.

Aging of Polymer Matrix Composites in Marine Environment

Composite ships have advantages over metal ships in terms of service life, maintenance, and repair cycles. Excluding specialpurpose vessels such as racing boats, the average lifespan of PMC boats is around 30 years or even longer which underscores the durability and aging performance of the materials [50-53]. However, this does not imply absolute safety for composite materials working in the marine environment over the long term. Unlike metals that dissolve through electrochemical reactions, the “aging” process of PMCs is referred to that material undergoes slow, irreversible changes in their initial performance over prolonged exposure to the working environment and ultimately lead to structural fractures. Such changes which lead to safety risks in the work of the structure are about the decrease in the mechanical performance of the material. Through the analysis of laboratory test data from some composite boats that have been in service for over a decade, it has been concluded that the Young’s modulus and tensile, flexural, and compressive strengths of these boats have decreased by up to 20%, 20%, 30%, and 35%, respectively, after years of concluded conditions [50,54].

The aging process of PMCs is multi-level, involving changes from the matrix to the matrix-fiber interface, and further to the fibers. The attack is caused by the complex interplay of physical, chemical and mechanical degradations that the material undergoes. The degradation is related to the inherent properties of the material as well as its working environment. It should be noted that the interaction of these three degradation mechanisms is not always detrimental to the material’s usage [55].

From the perspective of a fracture mechanism, the basic components of a composite laminate include the matrix, fibers, and the matrix-fiber interface, and in many cases, the degradation of the matrix in a PMC is the key factor leading to a decline in overall material performance. A laminate’s mechanical performance mainly depends on the health of the reinforcing fibers, therefore, good adhesion between matrix and fibers is crucial to the integrity of the material’s mechanical properties. In the degradation process of PMCs, the attack first started from the matrix and slowly developed to the matrix-fiber interface, resulting in debonding between the matrix and reinforcing fibers and endangering the health of the reinforcing fibers, then the degradation of fibers begins, the mechanical performances of the material are decreasing. This is why reinforcing fibers undergo a “sizing” process, applying the coating compound to form a protective film and improve aging performance.

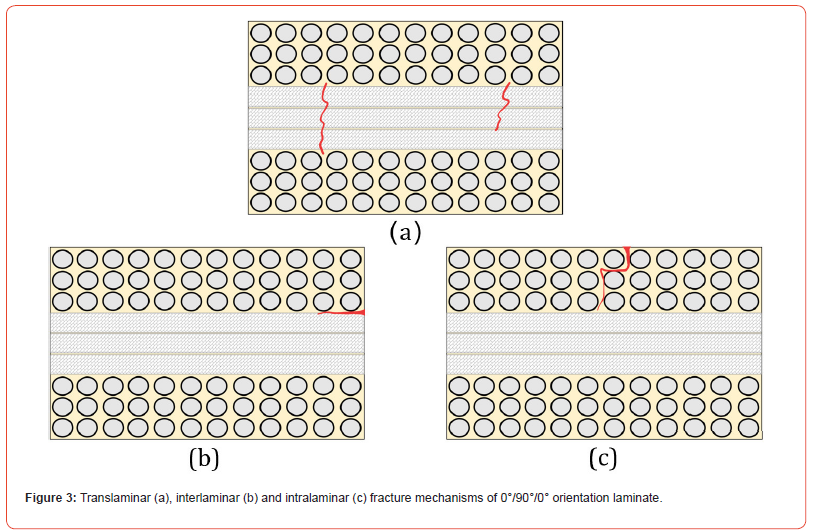

In fact, due to the production process, composite materials always contain defects, such as voids, air pores, and inclusions, which can induce a cracking or accelerating growth. The three main fracture mechanisms of a composite laminate include interlaminar, intralaminar and translaminar cracks (Figure 3). Interlaminar failure, more commonly known as delamination, refers to the damage to the ply interface based on the plain, resulting in progressive separation between piles of a laminated composite. Since plies are bonded by the polymer matrix which has weaker strength and toughness, so ply interfaces are the most susceptible to damage, thus the delamination represents the most critical failure for composite laminates. Intralaminar matrix crack can be categorized based on their development direction into longitudinal intralaminar matrix crack and transverse intralaminar matrix crack. The former propagates along the direction of the reinforcing fibers, while the latter develops in the thoroughthickness direction. Even in multi-axial laminates, cracks occurring in different directions may bridge together, eventually extend through the entire thickness. The first two types of cracks are associated with matrix damage, while translaminar cracks are related to the reinforcing fibers and is typically caused by tensile or compressive loads leading to fiber fractures. It should be noted that intralaminar cracks and delamination may interact with each other, and under specific working conditions, one may serve as a trigger for the other. In some cases, fiber/matrix debonding and fiber pullout may occur, where the degradation of reinforcing fibers leads to fractures, causing a decrease in mechanical properties and impacting the overall material performance [56,57].

Based on the understanding of composite fracture mechanisms, the physical, chemical and mechanical degradation of PMCs indicate the aging processes that occur in the matrix, interfaces and fibers. For the polymer matrix, physical aging refers to the changes in material properties caused by environmental factors as the polymer approaches thermodynamic equilibrium in the glassy state (below the Glass Transition Temperature, Tg). This type of change typically does not involve the breakage of chemical bonds within molecules or the formation of new chemical substances. It is reversible upon returning to initial conditions and usually results in alterations in the polymer’s free volume, enthalpy, and entropy [55]. The impact of physical aging on the mechanical properties of the material is macroscopically measured. Chemical aging of the polymer matrix involves a series of degradation processes primarily driven by environmental factors. It encompasses structural changes in the polymer, mainly through cross-linking or chain scission in the polymer molecular chain or network [55]. This process is irreversible and typically includes thermal aging, oxidation, and hydrolysis reactions in the polymer. Mechanical aging refers to measurable performance changes resulting from longterm exposure to loads in the working environment. The process is irreversible and typically results in a reduction in the mechanical properties, which will eventually lead to failure of the structure after experiencing the aforementioned fracture mechanisms.

In marine environments, factors affecting the aging of PMCs primarily include temperature, moisture absorption, ultraviolet (UV) radiation, environmental loads, marine organisms, etc. These effects lead to the degradation of a PMC’s individual components through complex and interrelated processes.

The physical aging of the polymer matrix induced by temperature primarily involves changes in the material’s free volume, resulting in alterations in properties. The temperature range of seawater is between 0–35°C, which is below the glass transition temperature (Tg) range of most typical marine resins, approximately between 80–100°C. Even with variations in Tg by manufacturers’ different formulations, such as the measured Tg data of epoxy, polyester and phenolic resins in research [58-61], the impact is generally negligible. Below the temperature Tg, polymers exhibit a rigid glassy state. Due to the high specific heat capacity of seawater and the relatively small day-night temperature difference in the same marine area, the impact on the volume of the polymer matrix can be neglected. However, it’s essential to consider the effects of prolonged exposure to temperature variations caused by solar radiation and in areas with large temperature differences. Additionally, extended exposure to low-temperature marine environments can also lead to embrittlement of the polymer matrix, posing a potential risk.

Moisture absorption is one of the primary causes of PMCs degradation in the marine environment, often resulting in measurable decreases in mechanical properties. Due to the chemical properties and molecular structure of the polymer matrix, hydrophilic groups tend to form intermolecular hydrogen bonds with water molecules, polymer molecules may have great spacing between them, or the presence of defects such as pores and cracks, allowing water molecules to be absorbed into the material and diffuse within its internal structure [62]. For the overall permeation of composite materials, in addition to water molecules diffusing through the matrix and filling material defects, when reaching the matrix-fiber interface, infiltration into the fibers can occur through capillary action [63]. Furthermore, composite moisture absorption property is also influenced by additives used in the production process, such as the curing agent, with water-resistant curing agents typically chosen for marine applications. Moisture absorption behavior of composite materials can generally be described and predicted using Fick’s law [64], which is applicable to most industrial laminated composite materials, while more complex mathematical models also exist to describe the overall process of moisture diffusion [65,66]. The aging of the polymer matrix induced by moisture absorption is both physical and chemical: it leads to changes in free volume, causing swelling, as the diffusion enlarge, the polymer matrix may undergo plasticization, resulting in irreversible damage, including the breakdown of the fiber-matrix interface and the development of microcracks due to internal stress accumulation; it can also lead to hydrolysis, causing the polymer chain breakage, the generation of small molecules, and the disruption of molecular networks, causing a decrease in crosslink density and mean molecular mass between links [63]. Moisture absorption of the polymer matrix has a significant impact on its properties, leading to changes in factors such as the coefficient of thermal expansion (CTE), glass transition temperature (Tg), modulus, and viscoelastic behavior [62,67]. In some experimental studies focusing on the aging of PMCs in seawater condition: there is a report of toughening and embrittlement occurring in epoxy resin causing by moisture absorption [68]; glass and carbon fibers reinforced composites with polyester and vinyl ester matrix resins experienced a 20-40% decrease in flexural strength after a 2-year seawater aging experiment [69]; moisture absorption of sisal fiberreinforced polypropylene composite research showed a reduction in overall tensile properties due to attacks on the matrix-fiber interface [70]; moisture penetrating to the core-facing interface of sandwich composites caused moisture absorption of core material and led to an increase in the fracture toughness of the foam core, but accelerated the propagation of interfacial cracks [71]. When moisture reaches the fibers, it also poses a certain risk to different types of reinforcing fibers. Many reports indicate a decrease in the mechanical properties of natural fibers, glass fibers, carbon fibers, aramid fibers, and some of their hybrid fibers composites after moisture absorption [72-77].

On the open and unobstructed sea surface, ships and offshore constructions are exposed to long-term solar radiation, and ultraviolet radiation is one of the factors that cause the degradation of PMCs. The polymer matrix will undergo photodegradation after absorbing UV radiation, where polymer molecules generate free radicals in the presence of photons. These free radicals will undergo oxidation reactions, resulting in a chain scission of the polymer molecules and damage of the molecular structure, thus a reduction in molecular weight and mechanical properties [78,79]. UV radiation may also cause changes in material color or make the material brittle which leads to the occurrence of microcracks in the matrix. Photodegradation also occurs in natural fibers, with lignin being a primary component involved in fiber degradation. Studies have reported the impact of lignin’s participation in photodegradation on various composite materials and evaluated the changes in mechanical properties. Lignin can accelerate the photodegradation of materials as observed in the case of HDPE (High-Density Polyethylene), or it can serve as a UV-blocking component in some cases, enhancing the material’s stability against photodegradation [80-83].

Environmental loads mainly come from the loads carried by ships, as well as the loads from waves, wind, and special weather conditions. These loads become predominant after physical or chemical aging mechanisms alter the material properties, ultimately leading to structural failure. Experimental studies have indicated a significant reduction in the performance of flexural strength of glass fiber composites with different matrices subjected to seawater aging under external bending loads, particularly in the case of phenolic resin-based composite [84]. Similar seawater aging experiments involving different load conditions have demonstrated the impact of loading on mechanical properties and crack propagation [85-87].

PMCs are also subject to the influence of marine organisms. Marine borers, principally pholadidae, which are produced from wood or wood components in composite materials, have been reported to attack most polymers, but these damages are usually minor [10,52]. Another type of marine organism-related harm arises from the additional mechanical loads introduced by macro-organisms attached to the material surface, hindering fluid performance and heat exchange performance.

Recent Developments in Marine Composite Applications and Research

In relevant research, Rubino and al. presented the state of the art regarding the application of fiber-reinforced composite materials in the marine structures. They analyzed the mechanical and anti-aging advantages of using composite materials based on different case studies [88]. Palomba and al. introduced recent marine applications of sandwich structure composites and provided descriptions and recommendations for the static bending response, fatigue bending behavior, and impact properties of the materials in design [89]. Luong and al. studied the compressive properties of closed-cell PVC (Polyvinyl Chloride) core material of sandwich composite, the results showed that the mechanical properties depend on the foam density and are strain rate-sensitive, with the compressive strength and modulus increasing with the foam density [90]. Kathavate and al. proposed a modeling approach for the mechanical behavior of marine composites under high pressure and verified it experimentally [91].

Addressing the challenges of non-biodegradability and difficulty in recycling associated with thermosetting polymer-based synthetic fiber composites, biodegradable natural fibers are being developed for the application. Yang reported on the prospects of using hybrid composites formed by cellulose fiber and reinforcing fibers in the marine environment [92]. Fragassa presented a case of producing a yacht deck hatch using renewable and biodegradable natural-organic fibers reinforced composites [93].

In pursuit of better mechanical performance, hybrid composites, and metal matrix composites offer options for marine applications. Fiore and al. introduced marine applications of glass–basalt/ epoxy hybrid composite and evaluated the influence of uniaxial basalt fabric layers on mechanical performance [94]. Dinesh and al. conducted water absorption and mechanical tests on hybrid composite materials reinforced with Kevlar (K29), eggshell, and coir fiber, noting improvements in tensile strength and lightweight properties [95]. Raheem and Subbaya also conducted similar experiments, showing improved performance of hybrid composite materials [96].

Elanchezhian reviewed the metallic matrix composite of titanium alloy with Kevlar and carbon fiber, highlighting their low density, high strength, impact resistance, corrosion resistance, weldability, and processability, making it suitable for marine applications [97]. Vijayakumar and al. researched the fabrication, characterization, microstructural, mechanical, and tribological properties of aluminum alloy-based composite A5083/Fly ash/SiC for marine applications [98].

Facing the ongoing development of marine composite materials, Shenoi and al. pointed out five technical challenges: load transfer mechanisms, safety, life cycle assessment, concurrent engineering and structural health monitoring [99].

Beura and al. studied the effects of salinity and strain rate in the marine environment for glass fiber-reinforced polymeric composites [100]. Afshar and al. studied the aging of carbon fiber/ vinyl ester (CFVE) composites in the marine environment, observing changes in their flexural properties over time [101]. Kumar and Ahmed investigated the mechanical performance decrease of foam core sandwich composites due to aging in seawater [102]. Jesthi and Nayak conducted experiments to compare the changes in the mechanical properties of glass and carbon fiber hybrid composites with different inter-ply rearrangements after undergoing seawater aging [103].

Davies and Verbouwe conducted aging experiments on basalt/ epoxy composite in seawater, comparing the mechanical properties with glass fiber composites under the same conditions [104]. The aging performance of the two materials was similar, but basalt/ epoxy composite could potentially be improved through structural optimization.

Post and al. reviewed the experimental research and modeling of fiber-reinforced polymer composites subjected to variable amplitude fatigue and compared the predictive ability of some models for spectrum loading using experimental fatigue data, thus providing suggestive help for the analysis of the fatigue behavior of structures subjected to wave loads [105].

Conclusion

Composite materials possess excellent lightweight and mechanical properties in the ship and boat building. Although steel and aluminum alloys are still the main materials occupying the shipbuilding market, the application of glass fiber, carbon fiber, and aramid fiber reinforced composites in shipbuilding has become quite mature. Even more, research indicates that basalt fiber possesses great potential as an alternative to glass fiber and carbon fiber. And facing the environmental issues caused by composite waste, biodegradable natural fibers offer a viable option. The comparative study between metallic materials and composite materials has identified the mechanical performance advantage of composite materials in marine applications.

Different from material dissolution due to corrosion of metallic materials in the marine environment, the failure of polymer matrix composites lies in the risk of mechanical degradation of the reinforcement fibers. Metallic materials face complex electrochemical corrosion processes, influenced by environmental factors such as salinity, oxygen levels, and temperature. However, for PMCs, aging and mechanical performance decline were attributed to physical, chemical, and mechanical degradation processes. Factors such as moisture absorption, UV radiation, temperature fluctuations, and environmental loads were identified as primary contributors to the matrix and fiber deterioration. The interaction between these factors and inherent material properties underscores the need for optimized composite formulations and protective strategies.

PMCs used in marine environments face significant risks due to aging, leading to declines in mechanical performance and potential structural failure. The risks are amplified by environmental challenges like prolonged exposure to seawater, solar radiation, and biofouling, making PMCs vulnerable to crack propagation, delamination, and loss of strength and flexibility. In addition to continuing the development of composite formulations, protective coatings, hybrid composites, inspections and material repair technologies are the directions to aim to reduce the risk of structural failure and extend the service life.

Composites are not fully up and rising for marine applications, hybrid composites and metal matrix composites are researched for more superior mechanical performance. Compared with metallic materials, the workability and cost-effectiveness of composite materials are still no match, making it challenging to apply them in the construction of large vessel structures. The expensive cost of high-performance fibers, the production processes and cost considerations for large composite structures, quality control, assembly, jointing issues, and environmental concerns related to the use of materials (recycling and degradation) are all factors that restrict their development.

Acknowledgement

This work was supported by the Zhejiang-French Digital Monitoring Lab for Aquatic Resources and Environment, Department of Science and Technology of Zhejiang Province, and the Huzhou Key Laboratory of Waters Robotics Technology (2022- 3), Huzhou Science and Technology Bureau.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Davies W (2011) HMS Warrior Ironclad Frigate 1860.

- Surís Regueiro JC, Garza Gil, Varela Lafuente MM (2013) Marine economy: A proposal for its definition in the European Union. Marine Policy 42: 111-124.

- Bai Y, Jin WL (2016) Chapter 2 Marine Composite Materials and Structure. Y Bai, WL Jin, Marine Structural Design 19-37 Butterworth-Heinemann.

- Casari P (2008) Applications marines des matériaux composites. Techniques Ingé

- Mouritz AP, Gellert E, Burchill P, Challis K (2001) Review of advanced composite structures for naval ships and submarines. Composite Structures 53(1): 21–42.

- Selvaraju, S, Ilaiyavel, S (2011) Journal of Applications of composites in marine industry Engineering Research and Studies 2(2): 89-91.

- Usluer HB (2022) General Overview of Ships. In Smart Ships 19-36.

- E Keble Chatterton (1909) Sailing Ships and Their Story.

- Culver H B (2012) The book of old ships From Egyptian galleys to clipper ships. Courier Corporation.

- Anderson, R Anderson RC (2003) A short history of the sailing ship. Courier Corporation.

- Eastland J, Ballantyne I (2011) HMS Victory First Rate 1765. Pen and Sword.

- Turnock SR (2006) Application of simulation technology to the performance evaluation of HMS Victory as an exemplar of the ships at the battle of Trafalgar.

- Jordan J, Caresse P (2019) French Armoured Cruisers 1887-1932 Seaforth Publishing.

- Richard NT, Campbell P (2013) The Meyer’s Boatyard Vessel Part 1 The Historical Significance of M-Class Gunboats. Bermud J Archaeol Marit Hist (20): 90-106.

- Kuroda T, Ikeuchi K, Kitagawa Y (2005) MICROSTRUCTURE CONTROL FOR JOINING ADVANCED STAINLESS STEEL. Novel Materials Processing by Advanced Electromagnetic Energy Sources PP: 419-422.

- Chalmers DW (1988) The properties and uses of marine structural materials. Marine Structures 1(1):47-70.

- Osei Bonsu A, Liang W, Mensah C, Yang B (2022) Assessing the mechanical behavior of glass and basalt reinforced vinyl ester composite under artificial seawater environment. Structures (38): 961-978.

- Zhang W, Tang WY, Pu C, Zhang SK (2010) Ultimate strength analysis of ship hulls of continuous basalt fiber composite materials. Advanced Materials Research (150):736-740.

- Li Z, Ma J, Ma H, Xu X (2018) Properties and Applications of Basalt Fiber and Its Composites. IOP Conference Series Earth and Environmental Science 186(2): 012052.

- Shi J, Wang X, Wu Z, Zhu Z (2017) Fatigue behavior of basalt fiber reinforced polymer tendons under a marine environment. Construction and Building Materials (137): 46-54.

- Wang X, Wu G, Wu Z, Dong Z, Xie Q (2014) Evaluation of prestressed basalt fiber and hybrid fiber reinforced polymer tendons under marine environment. Materials Design (64): 721-728.

- Bonsu AO, Mensah C, Liang W, Yang B, Ma Y (2022) Mechanical Degradation and Failure Analysis of Different Glass Basalt Hybrid Composite Configuration in Simulated Marine Condition. Polymers 14(17): 3480.

- MÖ Seydibeyoğlu, AK Mohanty, M Misra (2017) Fiber Technology for Fiber-Reinforced Composites. PP Woodhead Publishing 153-167.

- Campbell FC (2004) Chapter 2 Fibers and Reinforcements the String That Provides the Strength. Manufacturing Processes for Advanced Composites Elsevier Science 39-62.

- Riggs DM, Shuford RJ, Lewis RW (1982) Graphite Fibers and Composites. In G Lubin Handbook of Composites 196-271.

- Bacon R (1960) Growth structure and properties of graphite whiskers. Journal of Applied Physics 31(2): 283-290.

- Acar V, Cakir F, Alyamaç E, Seydibeyoğlu MÖ (2017) Basalt fibers. MÖ Seydibeyoğlu, AK Mohanty, M Misr (Eds.), Fiber Technology for FiberReinforced Composites 169-185 Woodhead Publishing.

- El Hawary O, Boccarusso L, Ansell MP, Durante M, Pinto F (2023) An Overview of Natural Fiber Composites for Marine Applications. Journal of Marine Science and Engineering 11(5): 1076.

- Corradi S, Isidori T, Corradi M, Soleri F, L Olivari (2009) Composite boat hulls with bamboo natural fibres. International Journal of Materials and Product Technology 363: 73-89.

- Reuben RL (2012) Materials in marine technology. Springer Science Business Media.

- American Bureau of Shipping (2023) Rules for Materials and Welding (Part 2) American Bureau of Shipping.

- Misra SC (2016) Design principles of ships and marine structures. CRC Press.

- Gunn RN (1997) Welding metallurgy In Duplex Stainless Steels pp 110-132 Woodhead Publishing.

- Goodwin F, Guruswamy S, Kainer KU, Kammer C, Knabl, et al. (2005) Metals. W Martienssen H Warlimont (Eds.), Springer Handbook of Condensed Matter and Materials Data p. 161-430.

- Wallenberger FT, Watson JC, Li, H (2001) Glass fibers Composites 27-34.

- Govind V, Kumar JS, Shyam Venkataraman V, Elanchezhain C, Vijayaramanath B (2014) CNT REINFORCED BASALT FIBER BASED SHIP HULLS. International Journal of Research in Engineering and Technology.

- Kim MT, Rhee KY, Jung I, Park SJ, Hui D (2014) Influence of seawater absorption on the vibration damping characteristics and fracture behaviors of basalt/CNT/epoxy multiscale composites. Composites Part B Engineering (63): 61-66.

- Molland AF (2008) Chapter 1-The Marine Environment. In The Maritime Engineering Reference Book PP. 3-42 Butterworth-Heinemann.

- Misra SC (2015) Design principles of ships and marine structures. CRC Press.

- Van Walree F, Willemsen E (1988) Wind loads on offshore structures. BOSS’88 1413-1428.

- Bai Y, Jin WL (2016) Wind Loads for Offshore Structures. Marine Structural Design PP: 95-118.

- Reuben RL (2012) Materials in marine technology. Springer Science Business Media.

- Isaacson M (2011) Wave and current forces on fixed offshore structures. Canadian Journal of Civil Engineering 15(6): 937-947.

- ISO 8044:2020 (2020) Corrosion of metals and alloys-Vocabulary.

- BÉRANGER G, MAZILLE H (2002) Corrosion des métaux et alliages Mécanismes et phénomènes Lavoisier

- Revie RW (2008) Corrosion and corrosion control an introduction to corrosion science and engineering. John Wile Sons.

- Stipaničev M, Turcu F, Esnault L, Schweitzer EW, Kilian, et al. (2013) Corrosion behavior of carbon steel in presence of sulfate-reducing bacteria in seawater environment. Electrochimica Acta (113): 390-406.

- Bhandari J, Khan F, Abbassi R, Garaniya V, Ojeda R (2015) Modelling of Pitting Corrosion in Marine and Offshore Steel Structures-A Technical Review Journal of Loss Prevention in the Process Industries pp. 39-62

- Guedes Soares, C Garbatov, Y Zayed, A (2011) Effect of environmental factors on steel plate corrosion under marine immersion conditions. Corrosion Engineering Science and Technology (46): 524-541.

- Davies P, Choqueuse D (2008) Ageing of composites in marine vessels. In R Martin Ageing of Composites pp. 326-353.

- Frej HBH, Léger R, Perrin D, Ienny P, Gérard P, et al. (2021) Recovery and reuse of carbon fibre and acrylic resin from thermoplastic composites used in marine application. Resources, Conservation and Recycling 173: 105705.

- Cucinotta F, Guglielmino E, Sfravara F (2017) Life cycle assessment in yacht industry: A case study of comparison between hand lay-up and vacuum infusion. Journal of Cleaner Production 142: 3822-3833.

- Le Duigou A, Davies P, Baley C (2009) Seawater ageing of flax/poly (lactic acid) biocomposites. Polymer Degradation and Stability 94: 1151-1162.

- Smith C S (1990) Design of marine structures in composite materials. Elsevier Science Publishers, London.

- Gates T (2008) 1—The physical and chemical ageing of polymeric composites. In R. Martin (Ed.), Ageing of Composites. Woodhead Publishing PP. 3-33.

- Oterkus E, Diyaroglu C, De Meo D, Allegri G (2015) 4—Fracture modes, damage tolerance and failure mitigation in marine composites. In J. Graham-Jones & J. Summerscales (Eds.), Marine Applications of Advanced Fibre-Reinforced Composites. Woodhead Publishing PP. 79-103.

- Laffan M J (2012) 5—Testing the toughness of polymer matrix composites. In P. Robinson, E. Greenhalgh, & S. Pinho (Eds.), Failure Mechanisms in Polymer Matrix Composites. Woodhead Publishing PP. 110-128.

- Carbas R J C, Marques E A S, da Silva L F M, Lopes A M (2014) Effect of Cure Temperature on the Glass Transition Temperature and Mechanical Properties of Epoxy Adhesives. The Journal of Adhesion 90: 104-119.

- Startsev O, Vapirov Yu M, Lebedev M P, Kychkin A K (2020) Comparison of Glass-Transition Temperatures for Epoxy Polymers Obtained by Methods of Thermal Analysis. Mechanics of Composite Materials, 56(2): 1-14.

- Yu X, Jia J, Xu S, Lao K U, Sanford M J, et al. (2018) Unraveling substituent effects on the glass transition temperatures of biorenewable polyesters. Nature Communications 9(1): 2880.