Mini Review

Mini Review

Steel Structure of a Tunnel Dormitory for the Armed Forces Troops

Taher El-Bitar1* and Ahmed Shehata2

1Professor at Central Metallurgical R&D Institute (CMRDI), Egypt

2Civil & Structural Engineer, Research grant student, Egypt

Taher El-Bitar, Professor at Central Metallurgical R&D Institute (CMRDI), Egypt.

Received Date: September 08, 2020; Published Date: September 24, 2020

Abstract

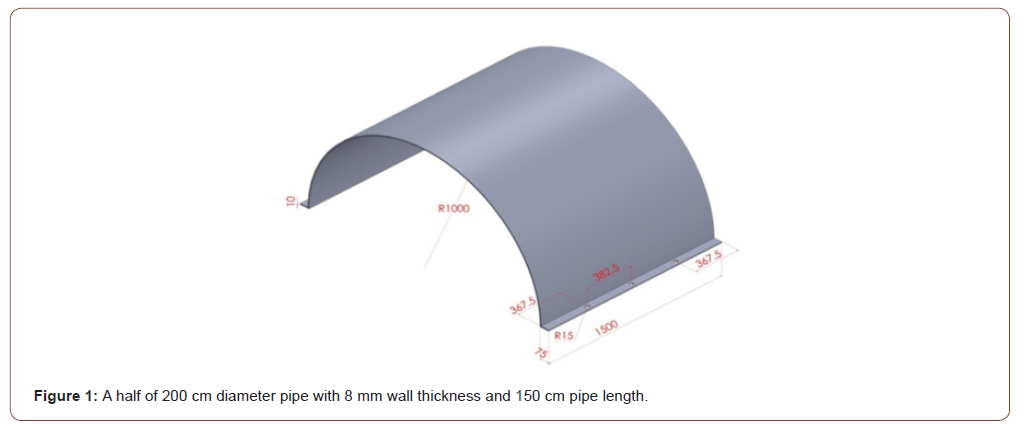

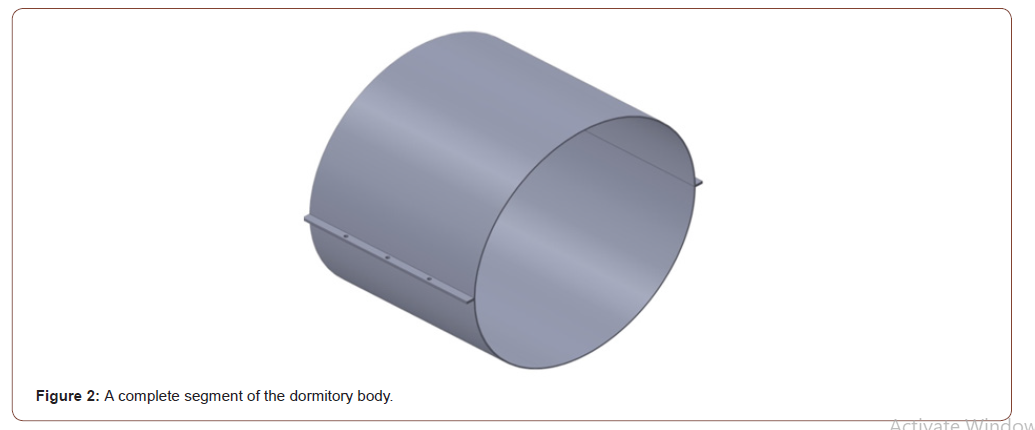

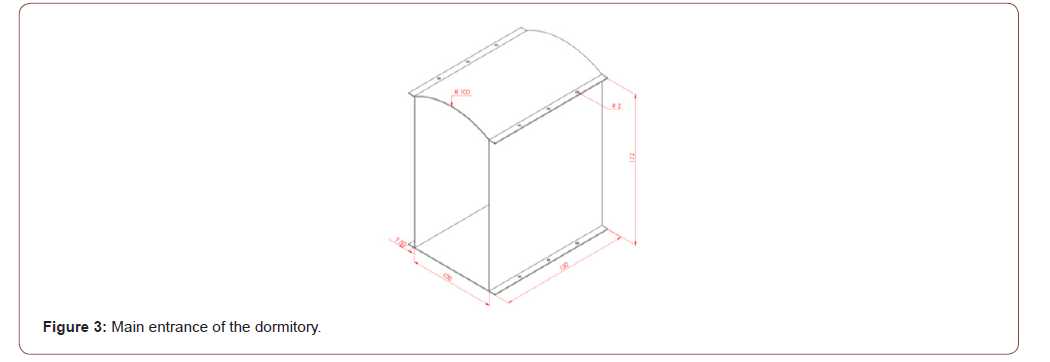

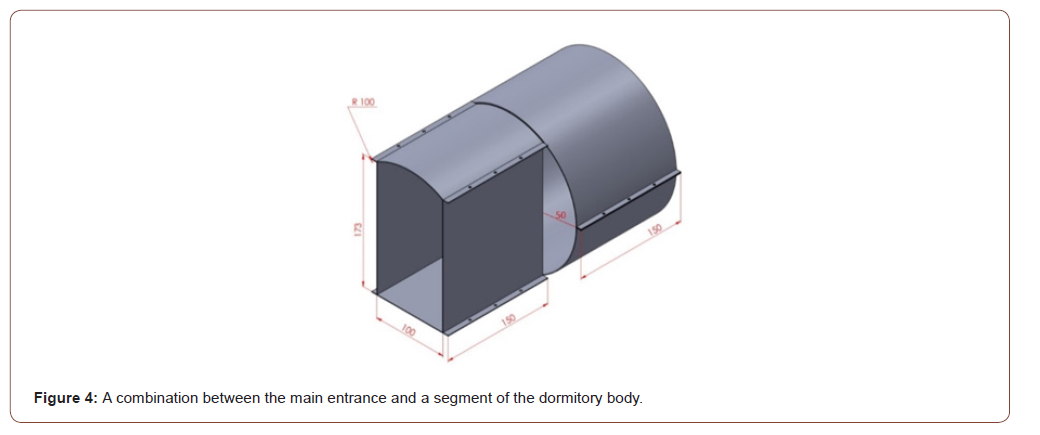

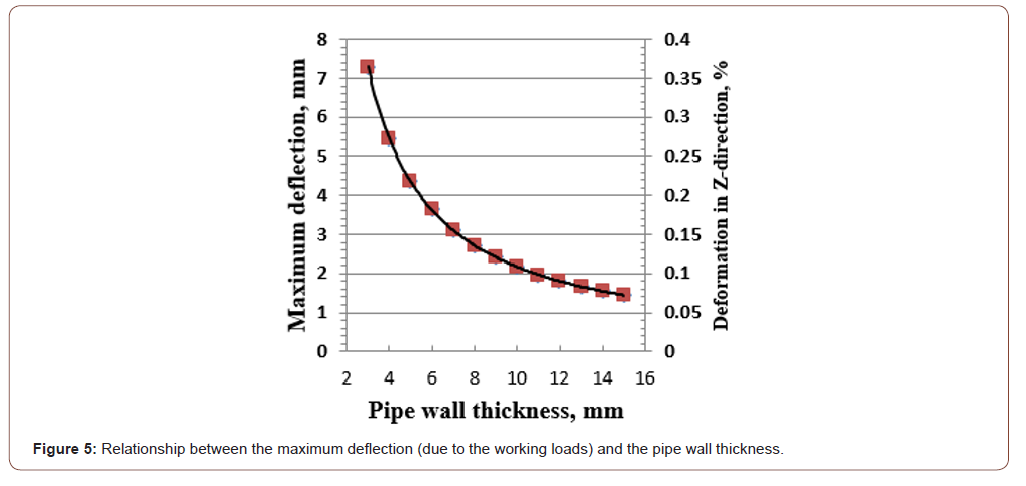

The current steel structure is used mainly as a dormitory for the armed forces troops, who are facing terrorist aggression. It is supposed that the structure of the dormitory can withstand 70 tons as a live load. Easy installation and dismantling for transportation are considered as essential requirements. The steel structure is processed of grade X42, with 8 mm thickness, according to the American Petroleum Institute specifications (API- 5L). The steel has a chemical composition comply with grade X42, as it contains (max.) 0.28 wt% C, 1.30 wt% Mn, 0.030 wt% P, and 0,030 wt% S. On the other hand, the steel sheets would possess mechanical properties as; 290 -496 MPa Yield stress, 414 -758 MPa Ultimate tensile strength, and 22% Elongation. The modulus of elasticity is considered as 20000 MPa. The main body of the dormitory steel structure consists of segments. Each segment consists of two halves of 200 cm diameter pipe with 8 mm wall thickness and 150 cm pipe length. The main body of the dormitory contains 2-3 segments. An additional subsidiary unit is usually constructed as a main entrance with vertical sides and arch roof. A Finite Element Analysis (FEA) was used through SAP 2000 software package as a tool for quick and precise physical simulation to apply the live and died loads and detecting any deflections, permanent deformations and moments about the X- and Y-directions in the steel structure of the tunnel dormitory. It is found that 8 mm wall thickness is the optimum, where the dormitory steel structure shows 2.72 mm maximum deflection under loading conditions, which represents 0.13 deformation% in the Z-direction. The moments are very low, as they reach to 0.023 and 0.066 t.m about the X- and Y-directions respectively.

Introduction

Fighting against terrorism is not a conventional battle. Conventional wars are controlled with well-known rules. On the other side, terrorism is deciding his own rules. Consequently, the troops should be ready for any unexpected movements of terrorists. At the same time, commanders are worry about the troops during the rest and/or battle periods. Secured troops dormitory is an essential element in the fighting system. The current work, is dealing with design of a tunnel dormitory steel structure for the armed forces troops. It is supposed that the steel structure of dormitory can with stand 70 tons as a live load. Easy installation, dismantling, and transportation are considered as essential requirements. The dormitory needs for previous preparations before installation as.

1. The main entrance door should be directed towards north-west direction for better natural ventilation.

2. A ground groove should be prepared with the following dimensions: 250 cm width, 250 cm depth, and 500 - 650 cm length (for 2-3 dormitory segments), in addition to 250 cm ramp.

3. The steel structure is processed of grade X42, with 8mm thickness, according to the American Petroleum Institute specifications (API-5L) [1]. The main body of the dormitory can contain 2-3 segments. Each segment consists of two halves of 200 cm diameter pipe with 8 mm wall thickness and 150 cm length. Fig. 1 shows a half of 200 cm diameter pipe with 8 mm wall thickness and 150 cm pipe length, while Fig. 2 represents a complete segment of the dormitory body. The dormitory is provided with a main entrance having vertical sides and arch roof as presented in Fig. 3, while Fig. 4 sketches a combination between the main entrance and a segment of the dormitory body (Figure 1 and 4).

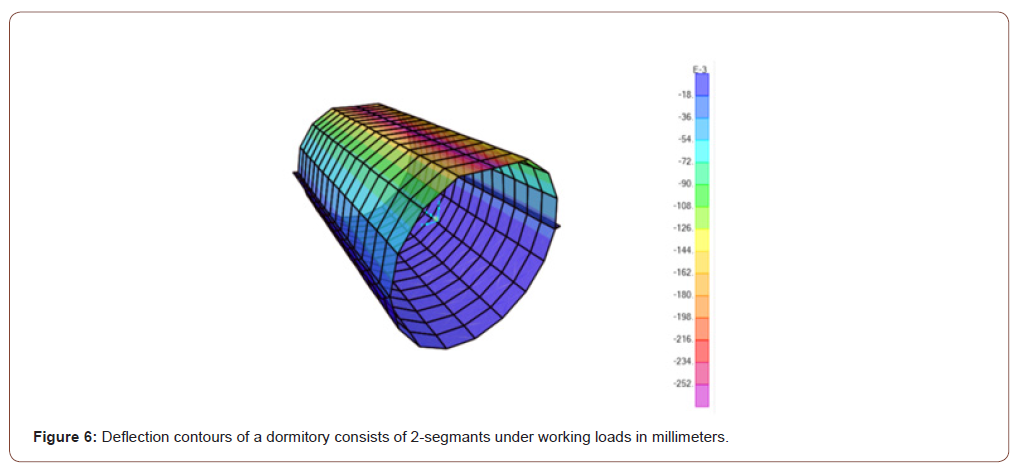

Structure Analysis

The steel structure analysis is done using the integrated software SAP2000 [2] as a finite element software package. It was decided that, the pipe section is modeled as a shell thin section which have bending stiffness therefore it resists a portion of the load through flexural deformation [2]. The Pipe section is loaded with its own weight, soil weight above the upper half of pipe and live load of 70 ton. Total working loads is considered as 75 ton distributed on 2-segments projected area. Upper half of pipe has only vertical degree of freedom while lower half is resting on soil so it has no degree of freedom. The modulus of elasticity is taken as 20000 MPa for the steel grade X42, as stated in a research gate [3]. Simulation trials were carried out for different pipe wall thickness. Fig. 5 represents a relationship between the maximum deflection (due to the working loads) and the pipe wall thickness. After the extensive investigation, a pipe wall thickness of 8mm is chosen as the optimum, where the steel structure shows 0.27 mm as a maximum deflection under loading conditions. Fig. 6 presents the deflection contours of a dormitory consists of 2-segmants under working loads in millimeters. Furthermore, the moments score very low values, as they reach to 0.013 and 0.33 t.m about the Xand Y-directions respectively (Figure 6, 5).

Conclusion

1. A dormitory steel structure for armed forces troops has been successfully designed.

2. 8 mm pipe wall thickness would be used as the optimum for processing the dormitory body.

3. Physical simulation by Finite Element Analysis shows that the maximum deflection under loading conditions would be 2.72 mm (0.13 deformation% in the Z-direction ). The moments score 0.023 and 0.066 t.m about the X- and Y-directions respectively

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- American Petroleum Institute (API) (2000) specifications 5L for line pipe. 42nd Edition January.

- SAP (2000) Integrated software for structural Analysis and design. Computers and Structure Inc California 1646N California Blvd Suit 6000 CA 94596 USA.

- Ameh ES (2017) Eigen value Buckling Computation and Impact on Pipeline Wall Thickness and Subsea Depth.

-

Taher El-Bitar, Ahmed Shehata. Steel Structure of a Tunnel Dormitory for the Armed Forces Troops. Cur Trends Civil & Struct Eng. 6(3): 2020. CTCSE.MS.ID.000639.

-

American petroleum institute specifications, Finite element analysis, Dormitory body, Steel structure analysis, Integrated software

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.